Submitted:

25 July 2023

Posted:

26 July 2023

You are already at the latest version

Abstract

Keywords:

Introduction

Materials and Methods

Timber preparation

Water-soluble flame retardant

Vacuum-pressure impregnation

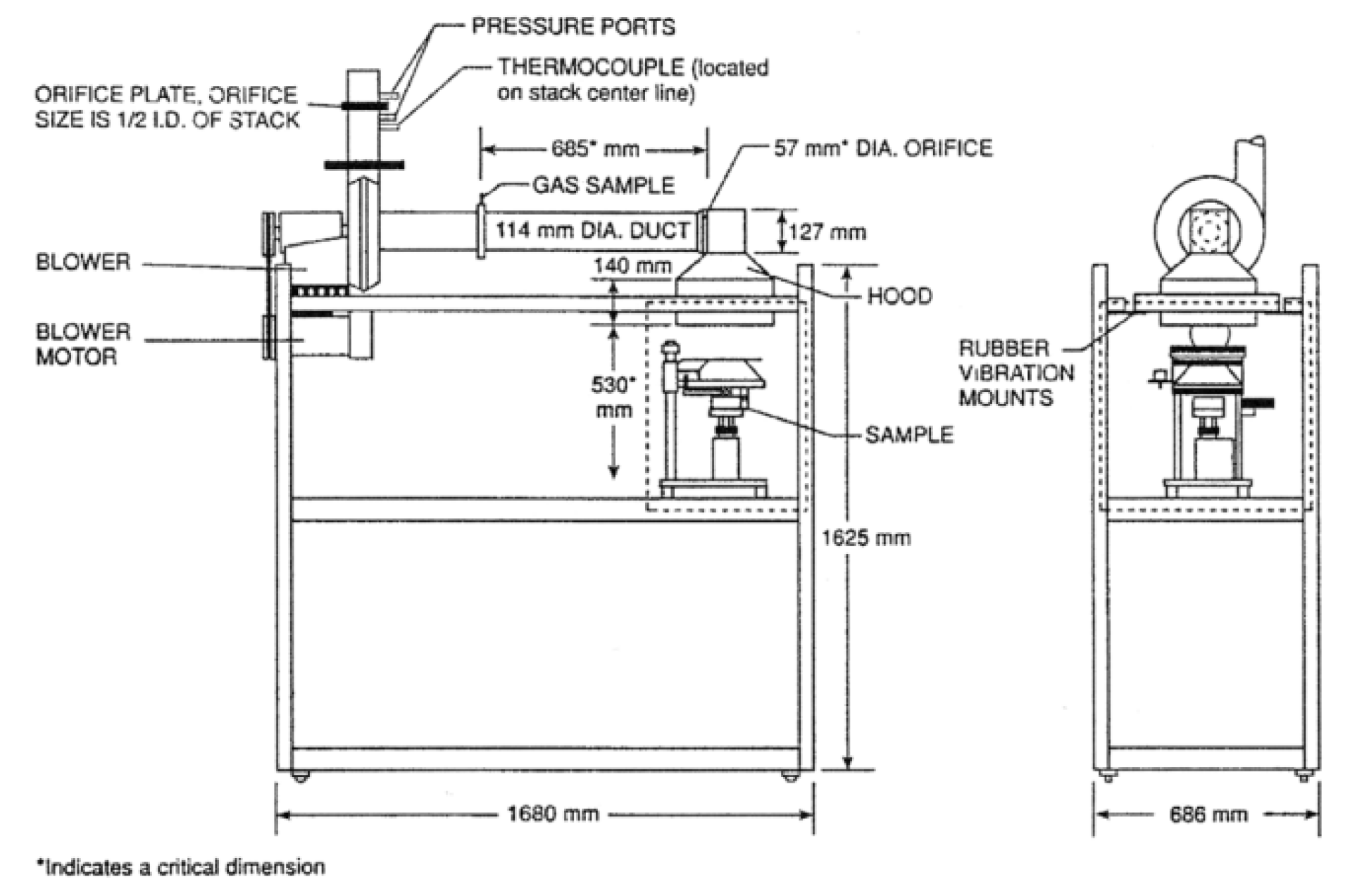

Cone calorimeter test

Results and Discussion

Visual inspection

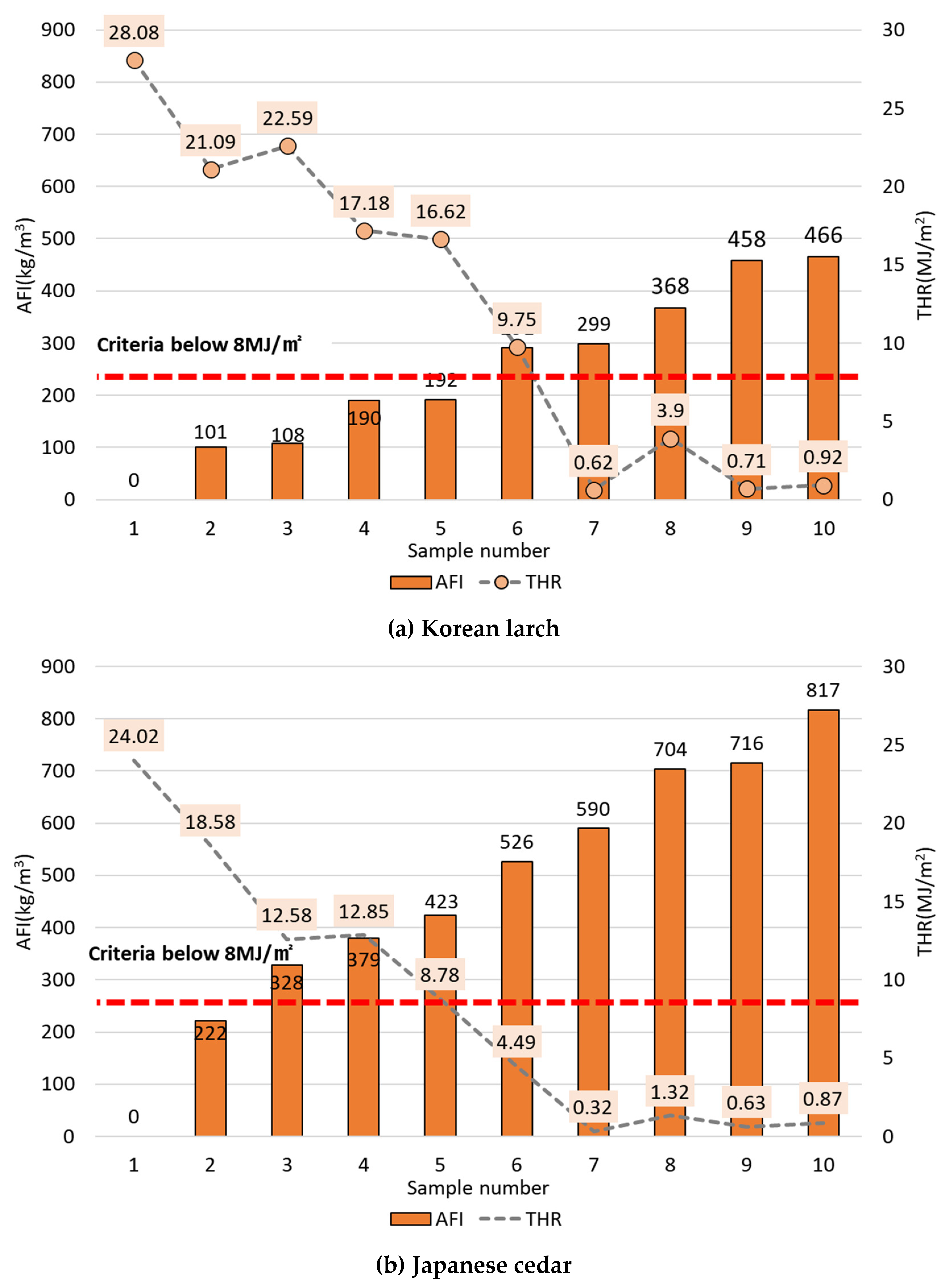

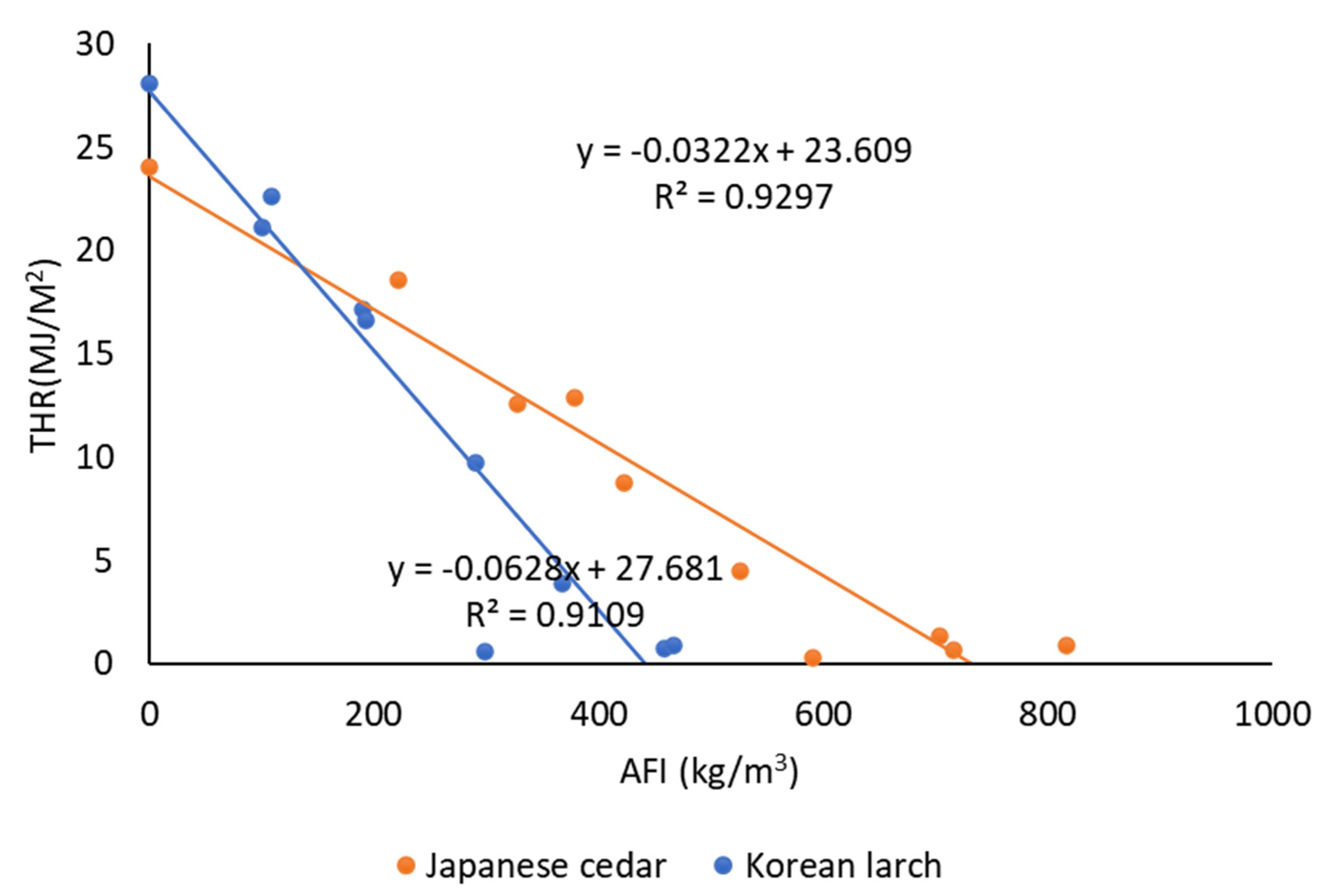

Comparison of AFI and THR

Conclusions

Author Contributions

Funding

Ethics approval and consent to participate

Consent for publication

Availability of data and materials

Acknowledgment

Competing Interest

Abbreviations

References

- Driga, A.M.; Drigas, A.S. Climate Change 101: How Everyday Activities Contribute to the Ever-Growing Issue. Int. J. Recent Contributions Eng. Sci. IT 2019, 7, 22–31. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, L.; Liu, J. Embodied carbon emissions of office building: a case study of China's 78 office buildings. Building and Environment 2016, 95, 365–371. [Google Scholar] [CrossRef]

- Chen, J.; Shen, L.; Song, X.; Shi, Q.; Li, S. An empirical study on the CO2 emissions in the Chinese construction industry. Journal of Cleaner production 2017, 168, 645–654. [Google Scholar] [CrossRef]

- Orsini, F.; Marrone, P. Approaches for a low-carbon production of building materials: A review. Journal of Cleaner Production 2019, 241, 118380. [Google Scholar] [CrossRef]

- Jang, E.-S. Use of Pine (Pinus densiflora) Pollen Cones as an Environmentally Friendly Sound-Absorbing Material. Journal of the Korean Wood Science and Technology 2022, 50, 186–192. [Google Scholar] [CrossRef]

- Jang, E.-S.; Kang, C.-W. () Investigation of the pore structure and sound-absorbing capability of the Chinese parasol tree (Firmiana simplex (L.) W. Wight) and Chinese tulip poplar (Liriodendron chinense) transverse sections as eco-friendly, porous, sound-absorbing materials. Journal of Porous Materials 2022, 29, 1791–1796. [Google Scholar] [CrossRef]

- Jang, E.-S. Investigation of sound absorption ability of Hinoki Cypress (Chamaecyparis obtusa) cubes. Journal of the Korean Wood Science and Technology 2022, 50, 365–374. [Google Scholar] [CrossRef]

- Farid, T.; Rafiq, M.I.; Ali, A.; Tang, W. Transforming wood as next-generation structural and functional materials for a sustainable future. EcoMat 2022, 4, e12154. [Google Scholar] [CrossRef]

- Fan, Z.; Sun, H.; Zhang, L.; Zhao, X.; Hu, Y. Lightweight, high-strength wood prepared by deep eutectic solvent treatment as a green structural material. ACS Sustainable Chemistry & Engineering 2022, 10, 9600–9611. [Google Scholar]

- Walter, A. France requires new public buildings to contain at least 50% wood. Availabe online: https://archinect.com/news/article/150183480/ (accessed on 23 June).

- Jang, E.-S. Experimental investigation of the sound absorption capability of wood pellets as an eco-friendly material. Journal of the Korean Wood Science and Technology 2022, 50, 126–133. [Google Scholar] [CrossRef]

- Sargent, R. Evaluating dimensional stability in solid wood: a review of current practice. Journal of Wood Science 2019, 65, 1–11. [Google Scholar] [CrossRef]

- Evans, P.D.; Matsunaga, H.; Preston, A.F.; Kewish, C.M. Wood protection for carbon sequestration—a review of existing approaches and future directions. Current Forestry Reports 2022, 8, 181–198. [Google Scholar] [CrossRef]

- Schultz, T.P.; Nicholas, D.D.; Preston, A.F. A brief review of the past, present and future of wood preservation. Pest Management Science: formerly Pesticide Science 2007, 63, 784–788. [Google Scholar] [CrossRef] [PubMed]

- Thybring, E.E. The decay resistance of modified wood influenced by moisture exclusion and swelling reduction. International Biodeterioration & Biodegradation 2013, 82, 87–95. [Google Scholar]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire science reviews 2013, 2, 1–19. [Google Scholar] [CrossRef]

- Popescu, C.M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire and Materials 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Mali, P.; Sonawane, N.; Patil, V.; Lokhande, G.; Mawale, R.; Pawar, N. Morphology of wood degradation and flame retardants wood coating technology: an overview. International Wood Products Journal 2022, 13, 21–40. [Google Scholar] [CrossRef]

- Ali, S.; Hussain, S.A.; Tohir, M.Z.M. Fire Test and Effects of Fire Retardant on the Natural Ability of Timber: A Review. Pertanika Journal of Science & Technology 2019, 27. [Google Scholar]

- Oh, S.; Park, H. Vacuum pressure treatment of water-soluble melamine resin impregnation for improvement of dimensional stability on softwoods. Journal of the Korean Wood Science and Technology 2015, 43, 327–333. [Google Scholar] [CrossRef]

- Jang, E.-S.; Kang, C.-W. Effects of Pressure and Temperature on Wood Impregnation–Focusing on Larch (Larix kaempferi) and Korean Pine (Pinus koraiensis). BioResources 2023, 18, 3208–3216. [Google Scholar] [CrossRef]

- Fukuta, S.; Nomura, M.; Kurisaki, H.; Okamura, H. Application of laser micro incisions in the fire-retardant treatment. European Journal of Wood and Wood Products 2022, 80, 255–258. [Google Scholar] [CrossRef]

- He, X.; Li, X.J.; Zhong, Z.; Mou, Q.; Yan, Y.; Chen, H.; Liu, L. Effectiveness of impregnation of ammonium polyphosphate fire retardant in poplar wood using microwave heating. Fire and materials 2016, 40, 818–825. [Google Scholar] [CrossRef]

- Kuai, B.; Wang, Z.; Gao, J.; Tong, J.; Zhan, T.; Zhang, Y.; Lu, J.; Cai, L. Development of densified wood with high strength and excellent dimensional stability by impregnating delignified poplar by sodium silicate. Construction and Building Materials 2022, 344, 128282. [Google Scholar] [CrossRef]

- Park, W.-H.; Cho, Y.; Kim, C.-Y.; Na, S.; Lee, D. Study on comparison and database for combustibility of various wood materials. Journal of the Korean Society of Hazard Mitigation 2018, 18, 207–214. [Google Scholar] [CrossRef]

- Jin, E.; Chung, Y.-J. Fire risk assessment of cypress wood coated with metal oxide and metal silicate flame retardant using cone calorimeter. Journal of fire sciences 2020, 38, 504–521. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Yang, T.; Wang, Z.; Xia, M.; Zhang, M.; Liu, D.; Yuan, G. Mineralizing wood with chitosan–silica to enhance the flame retardant and physical-mechanical properties. Journal of Sol-Gel Science and Technology 50, 1–13. [Google Scholar] [CrossRef]

- Hun, S. Flame resistance performance of architectural membranes using basalt woven fabric. Fire Science and Engineering 2016, 30, 35–42. [Google Scholar]

- Bong-Hoon, H.; Dong-Ho, S.; Young-Hee, K.; Se-Hong, M. A Study on the Fire Characterization of Foam block using Cone-calorimeter and FTIR. Fire Science and Engineering 2017, 31, 23–32. [Google Scholar]

- Seo, H.J.; Hwang, W.; Lee, M.C. Fire properties of Pinus densiflora utilizing fire-retardant chemicals based on borated and phosphorus (I)–combustion characteristics. BioResources 2017, 12, 5417–5427. [Google Scholar] [CrossRef]

- KSFISO5660-1; Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1: Heat release rate(cone calorimeter method) and smoke production rate (dynamic measurement). Korean Agency for Technology and Standards: Seoul, Korea, 2015.

- Park, S.-Y.; Kim, D.-H.; Im, H.-S. The experimental study for the combustion-property of sandwich panels using ISO 5660 cone calorimeter. Fire Science and Engineering 2006, 20, 33–41. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).