Submitted:

05 July 2023

Posted:

07 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

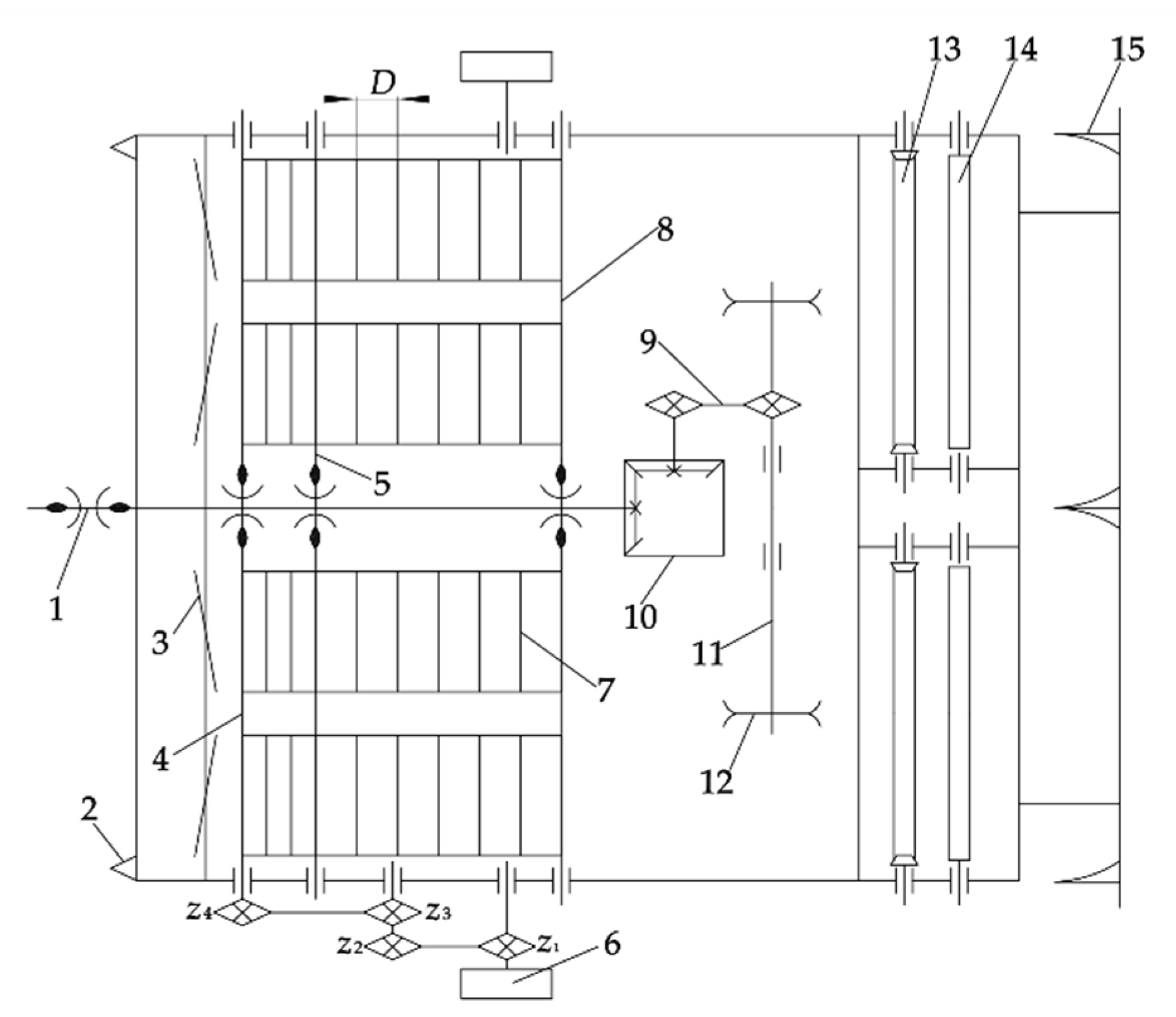

2. Structure and working principle of the machine

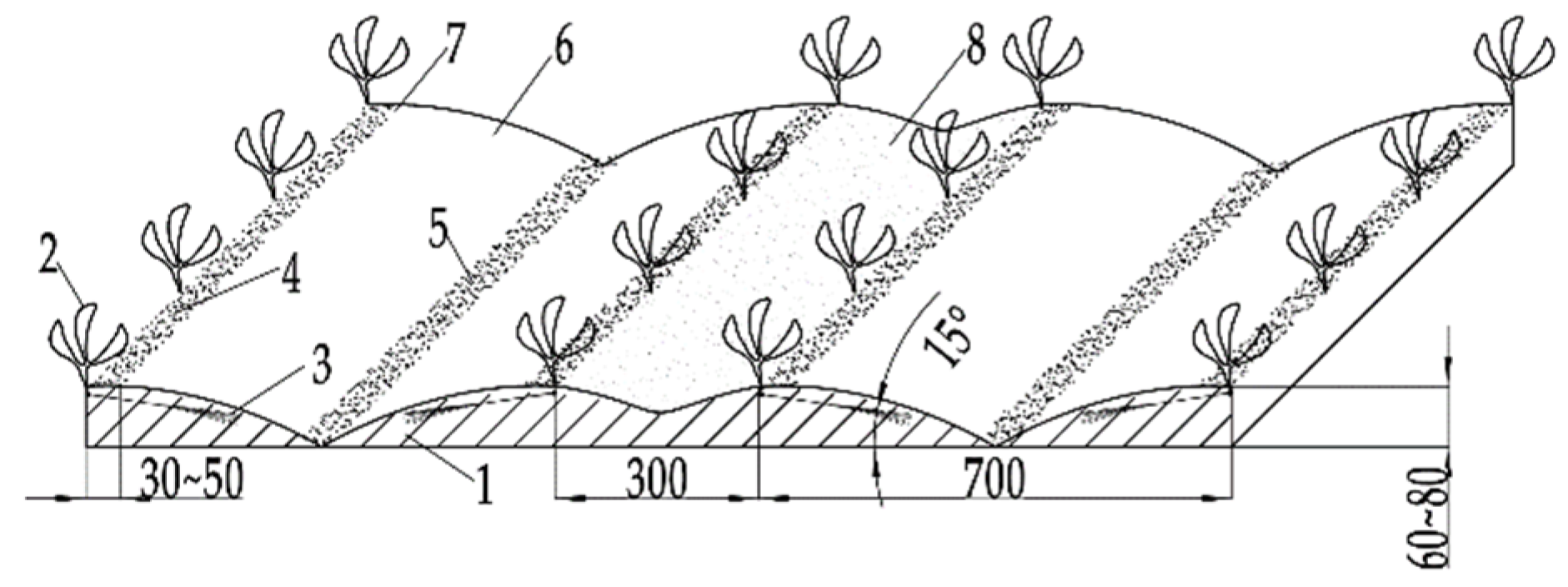

2.1. Agronomic requirements

2.2. Operation Procedure

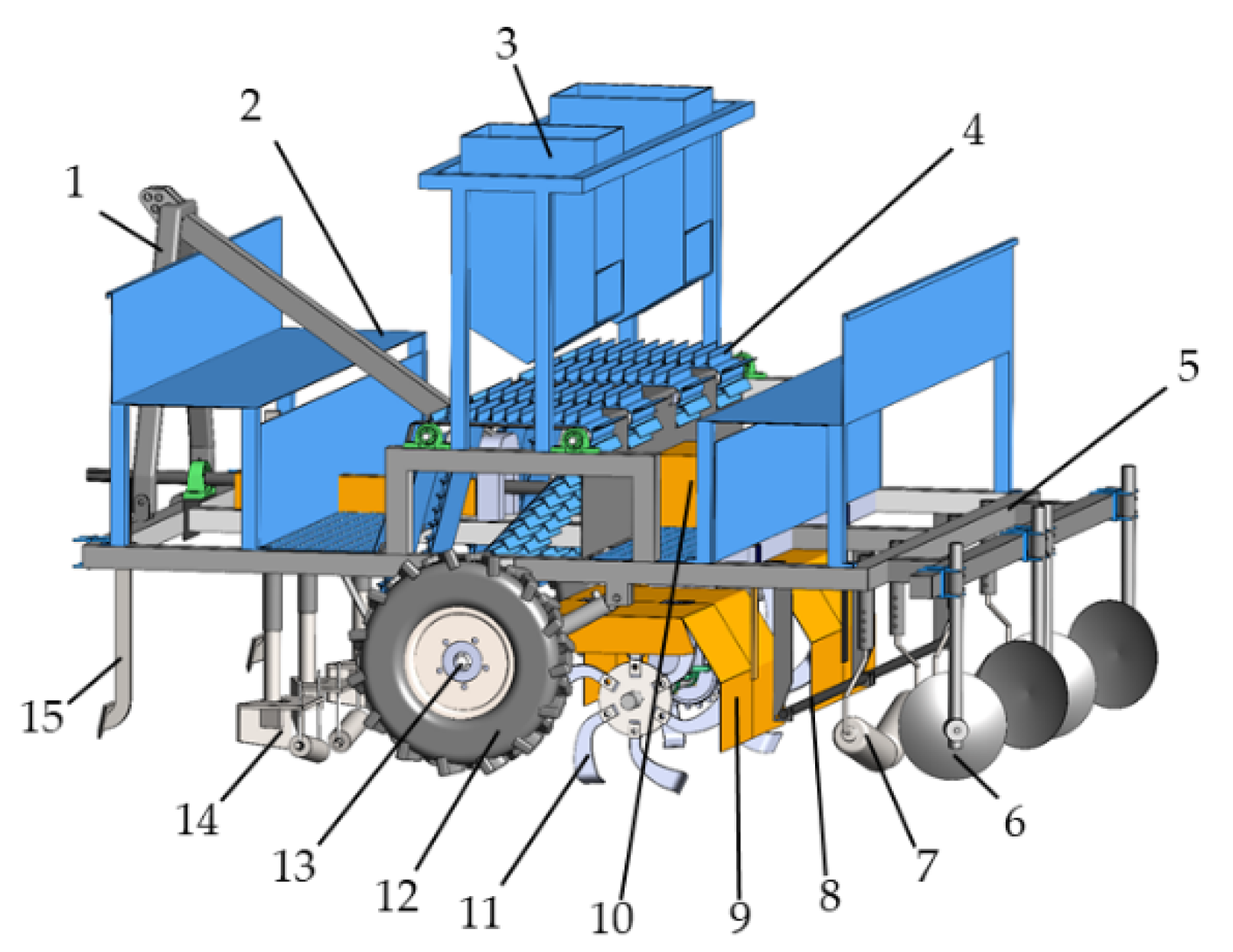

2.3. Structure and main technical parameters of the machine

2.4. Working principle

3. Design of main working parts

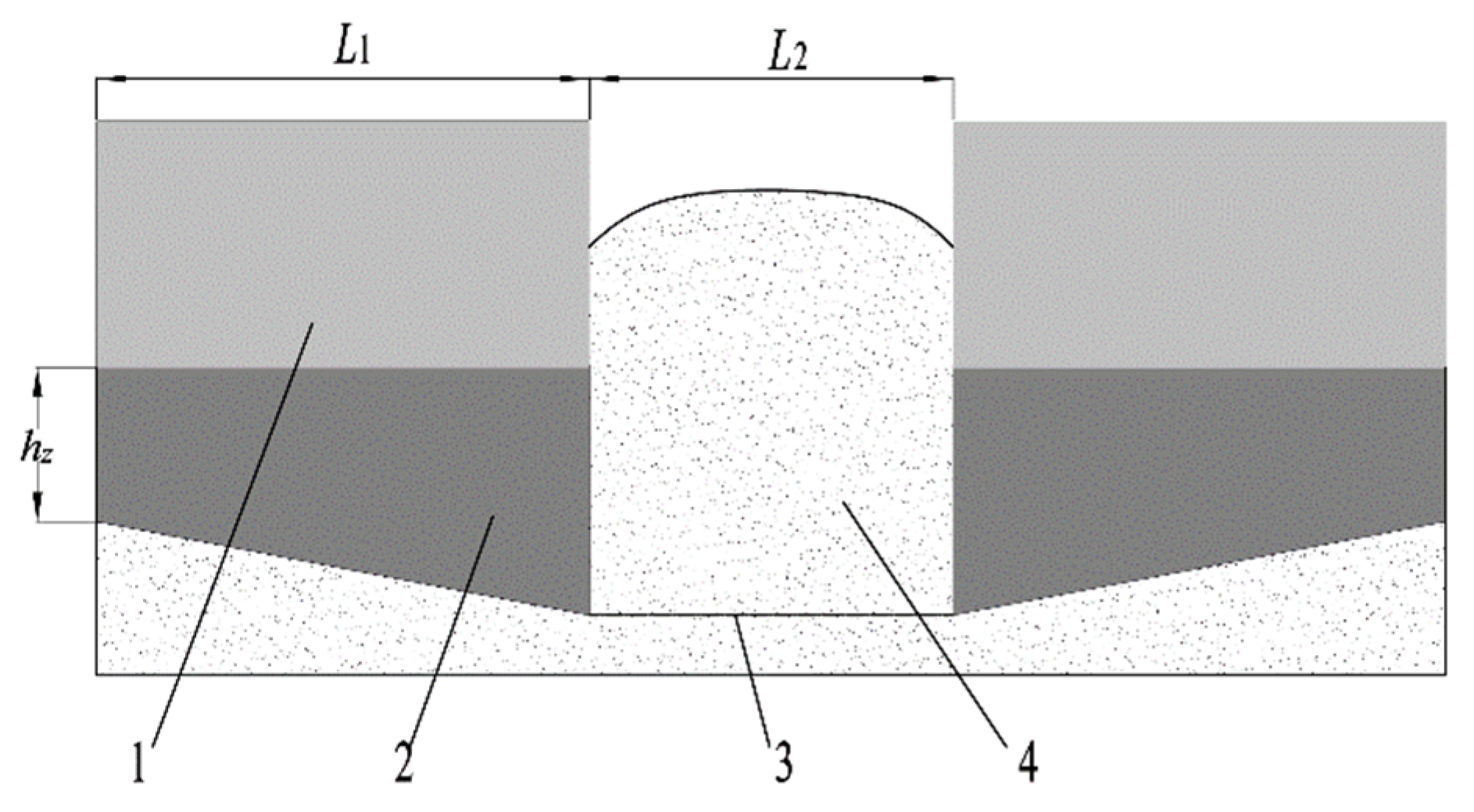

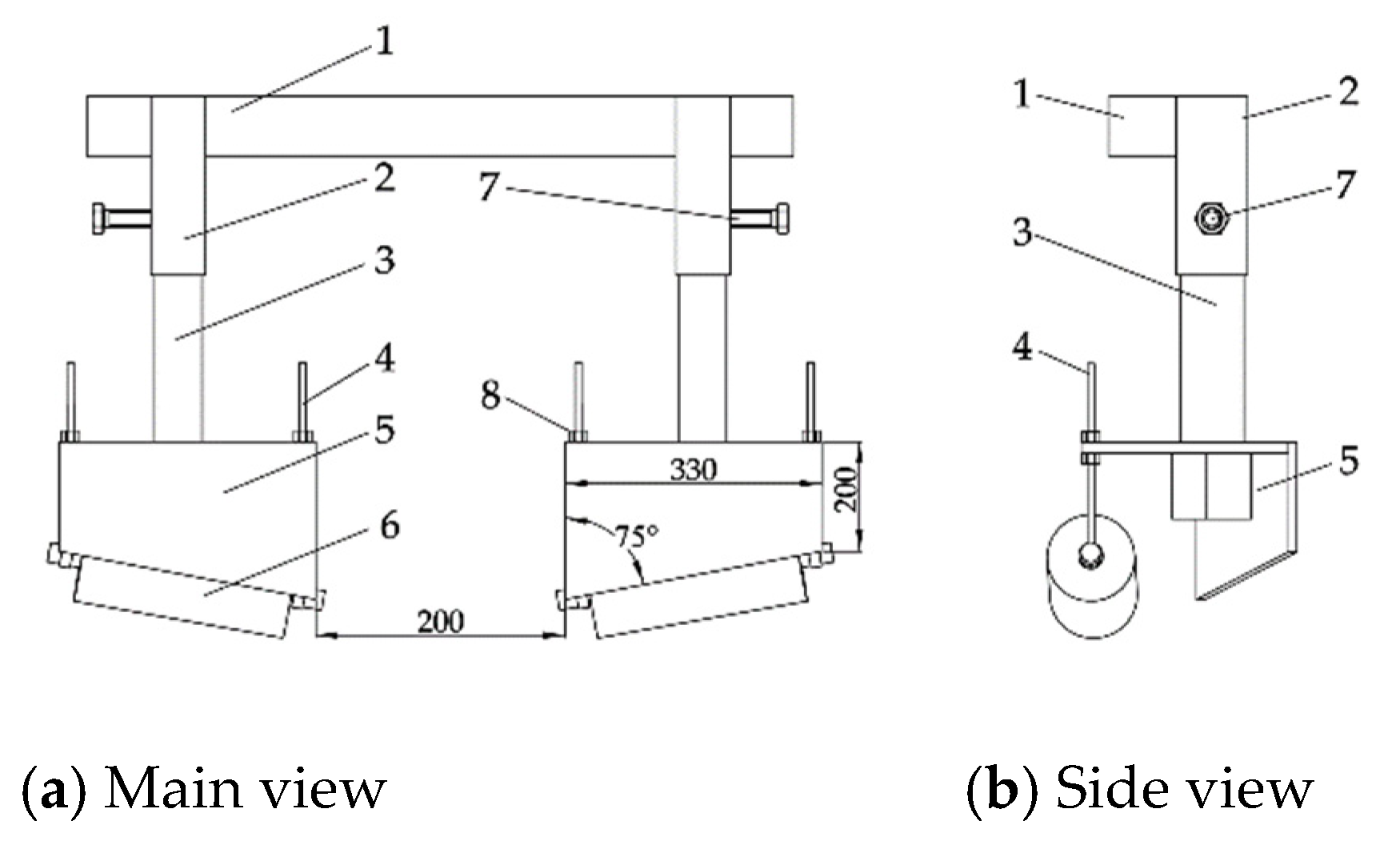

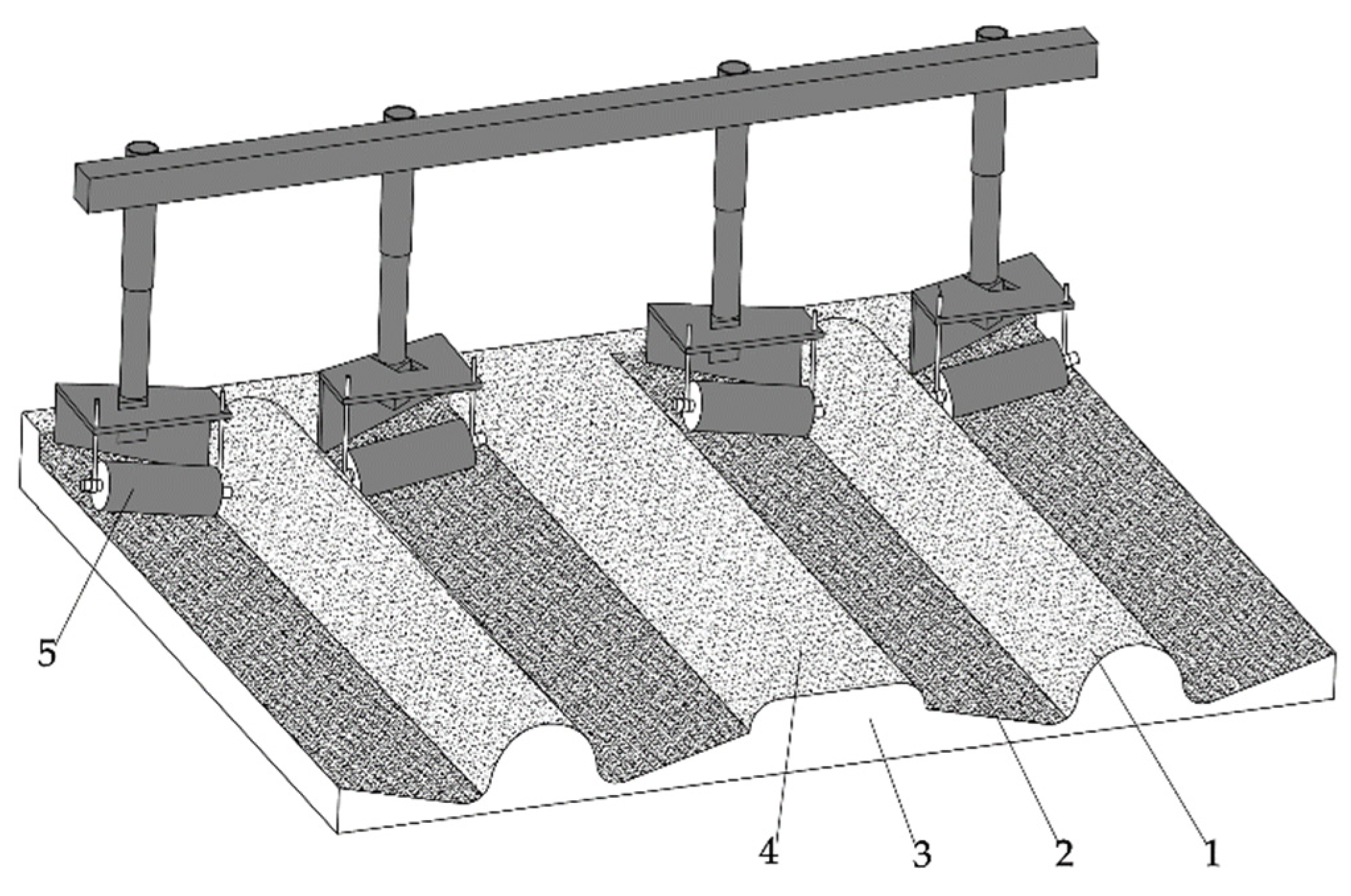

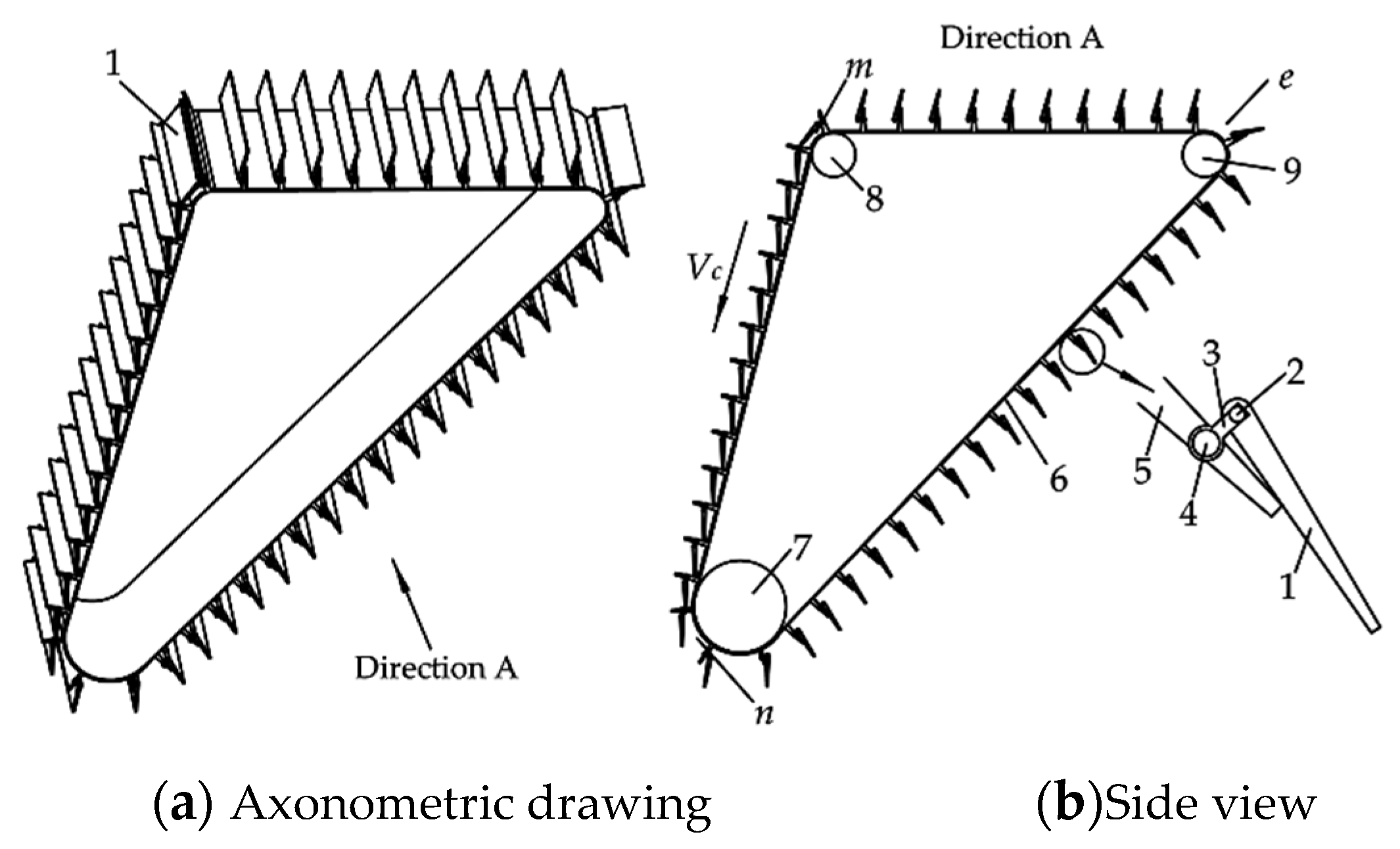

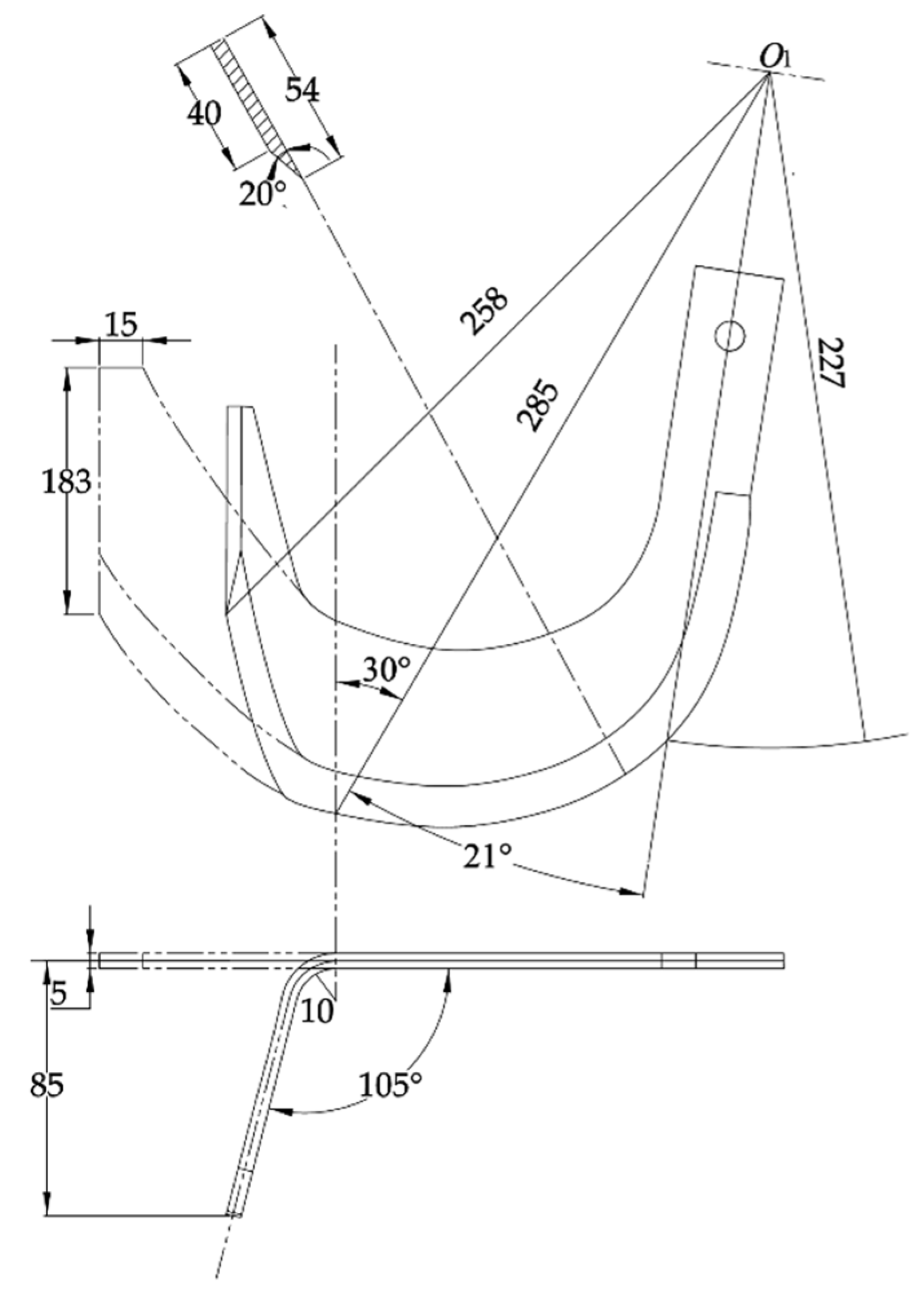

3.1. Seedbed preparation device

3.1.1. Structure and operation principle

3.1.2. Theoretical aggregate amount of soil

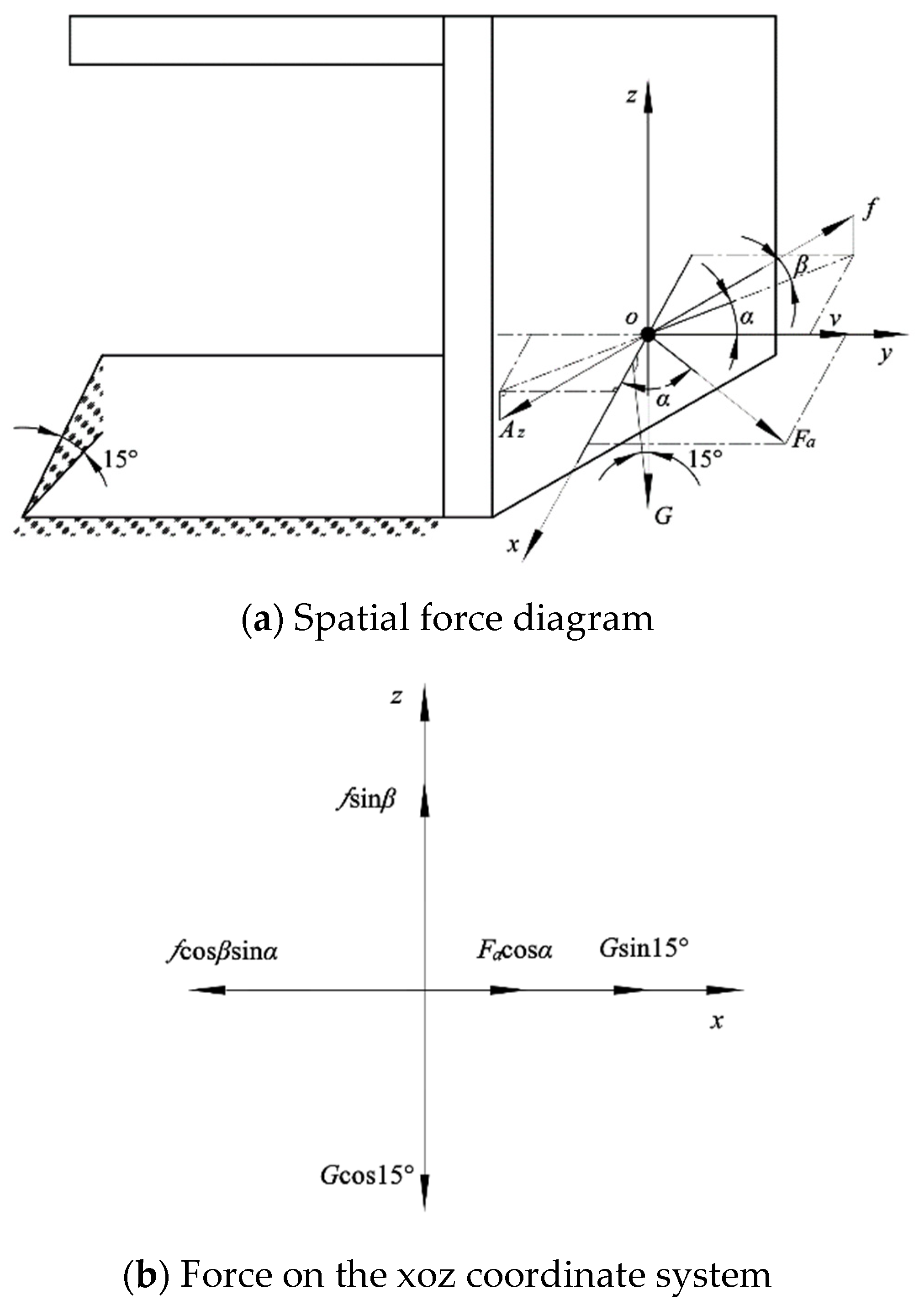

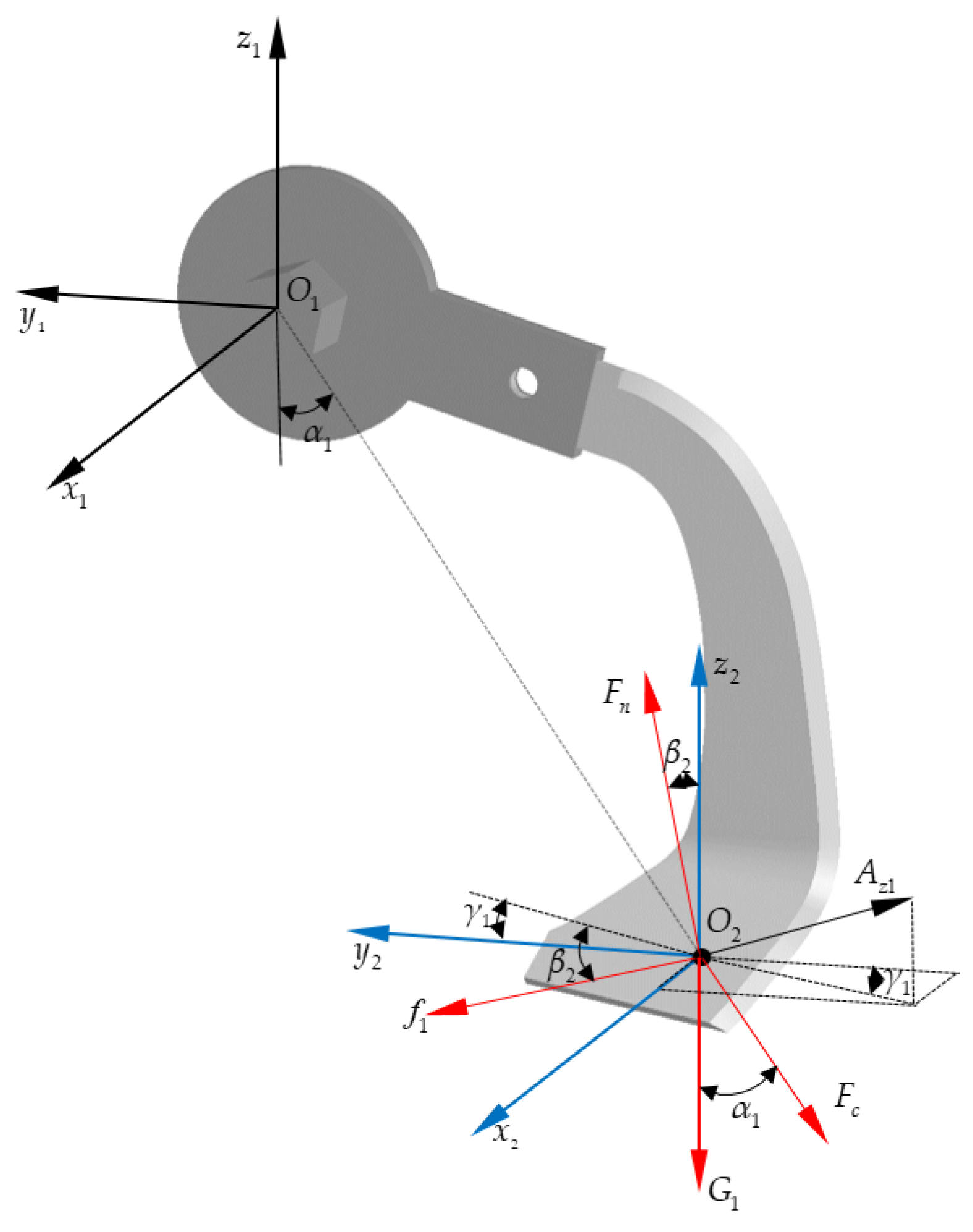

3.1.3. Mechanical analysis of shaper

3.2. Seedling casting device

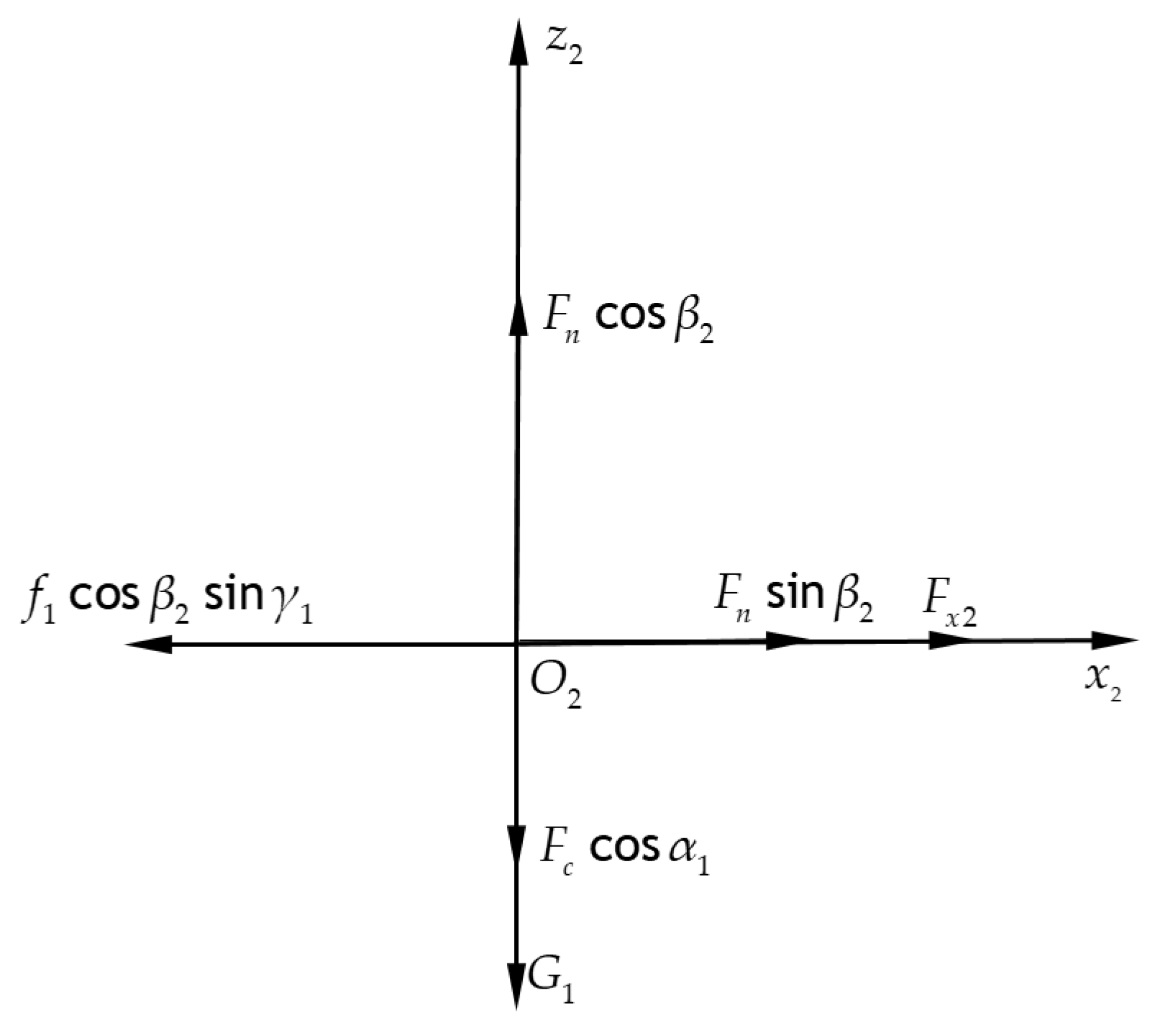

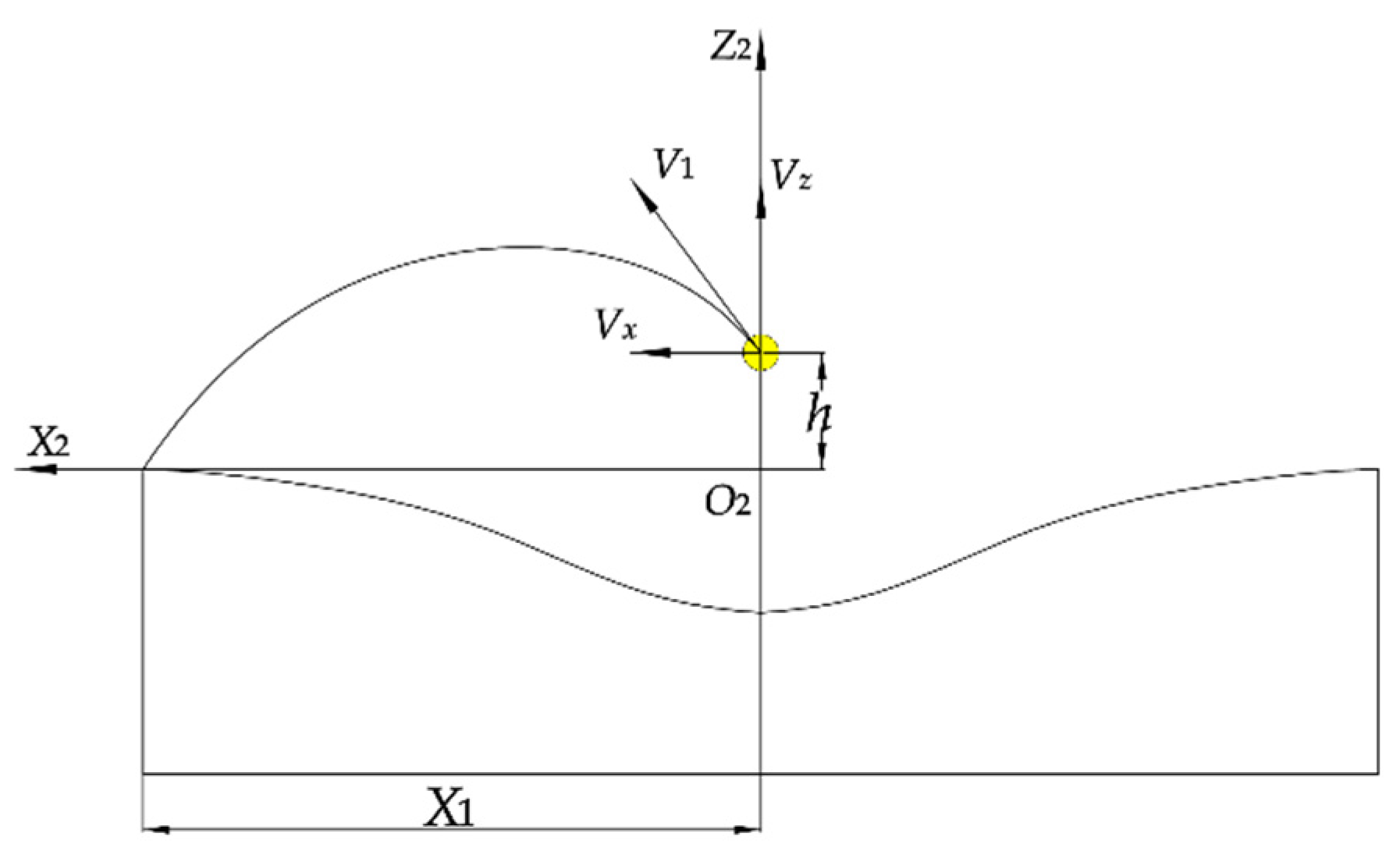

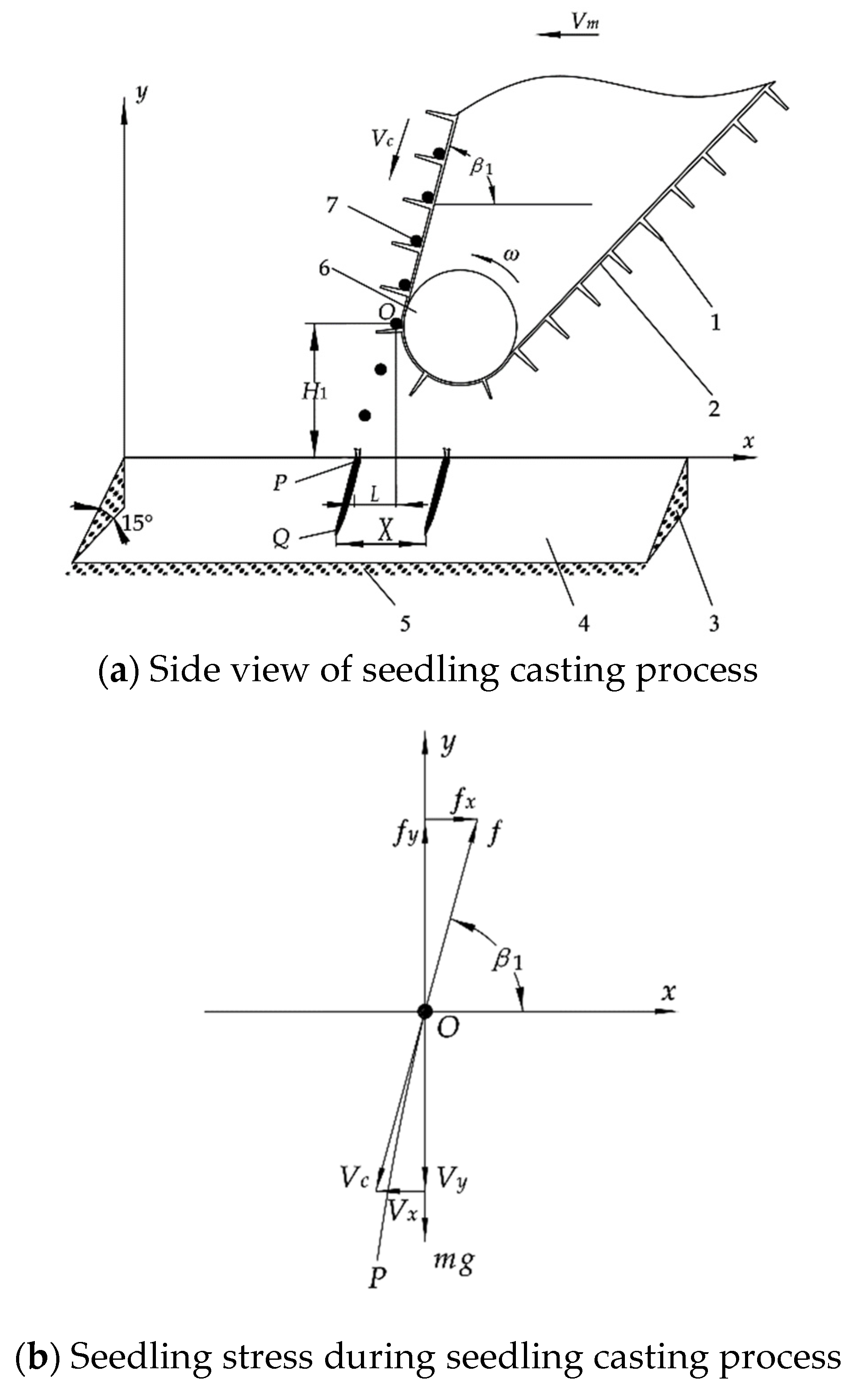

3.2.1. Analysis of seedling movement

3.2.2. Analysis of the collision process between seedlings and seedbed

3.3. Rotary tillage soil-covering device

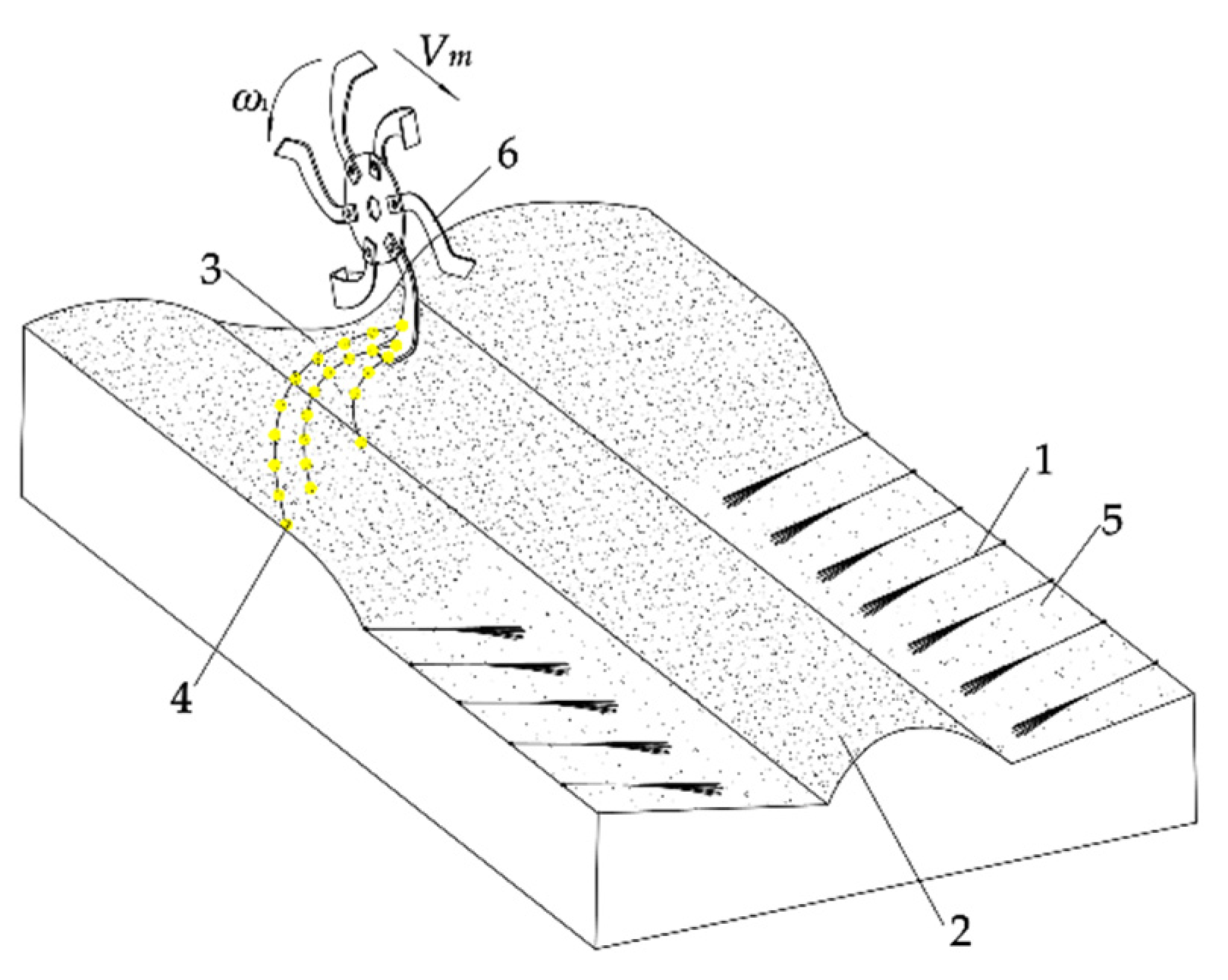

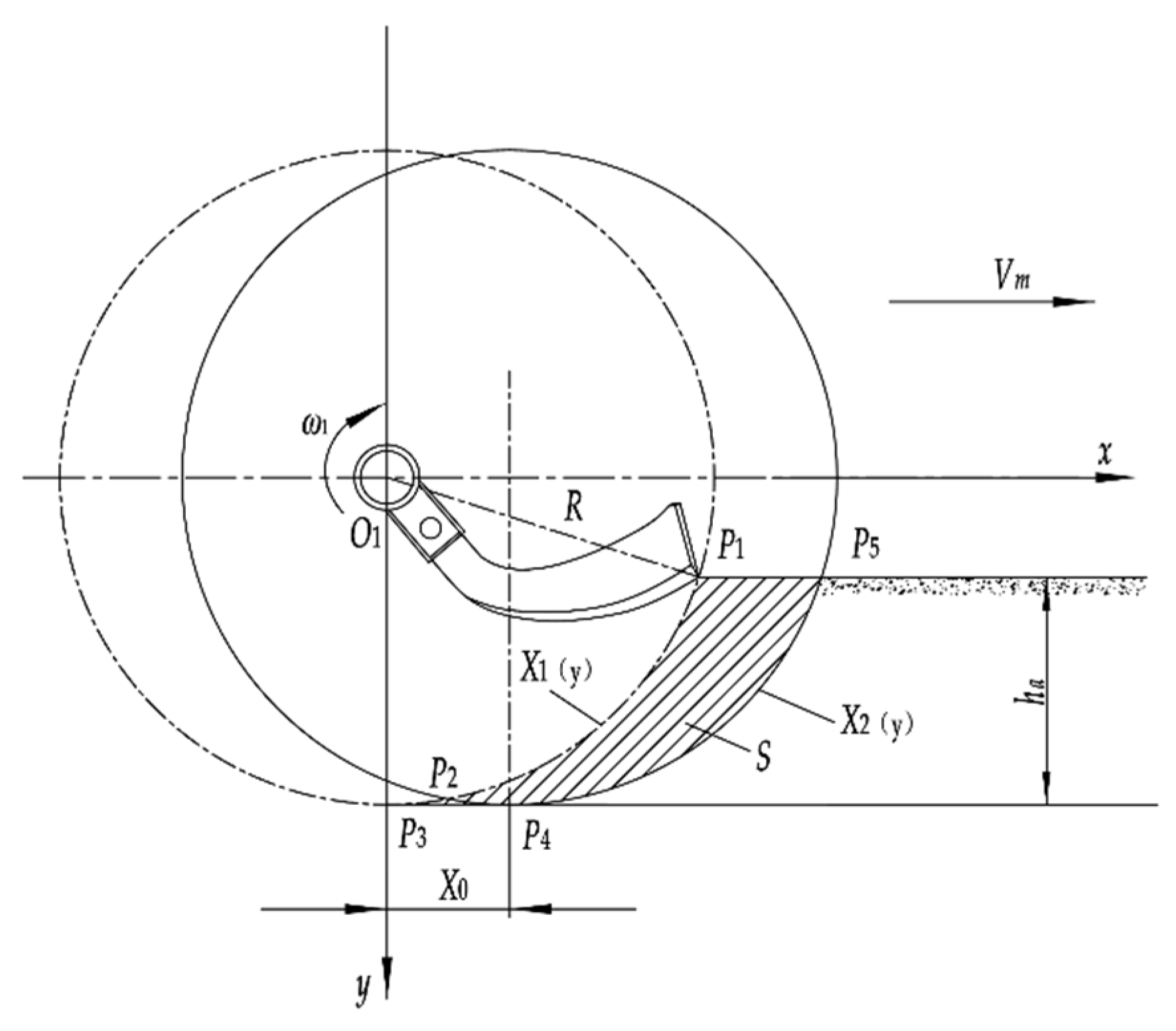

3.3.1. Analysis of soil-covering amount of rotary tillage knife

3.3.2. Analysis of axial soil-transporting performance of rotary tillage knife

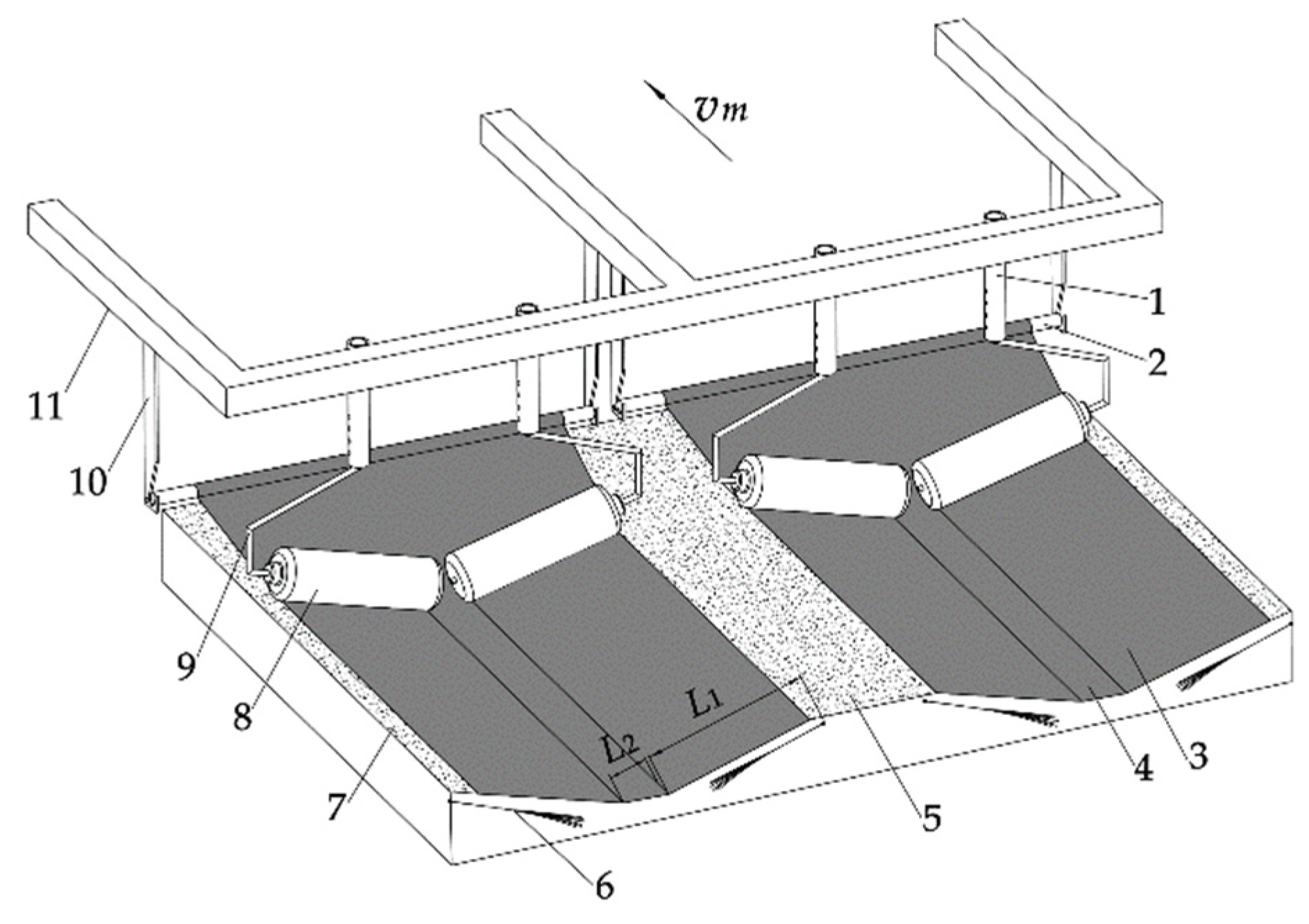

3.4. Film covering device

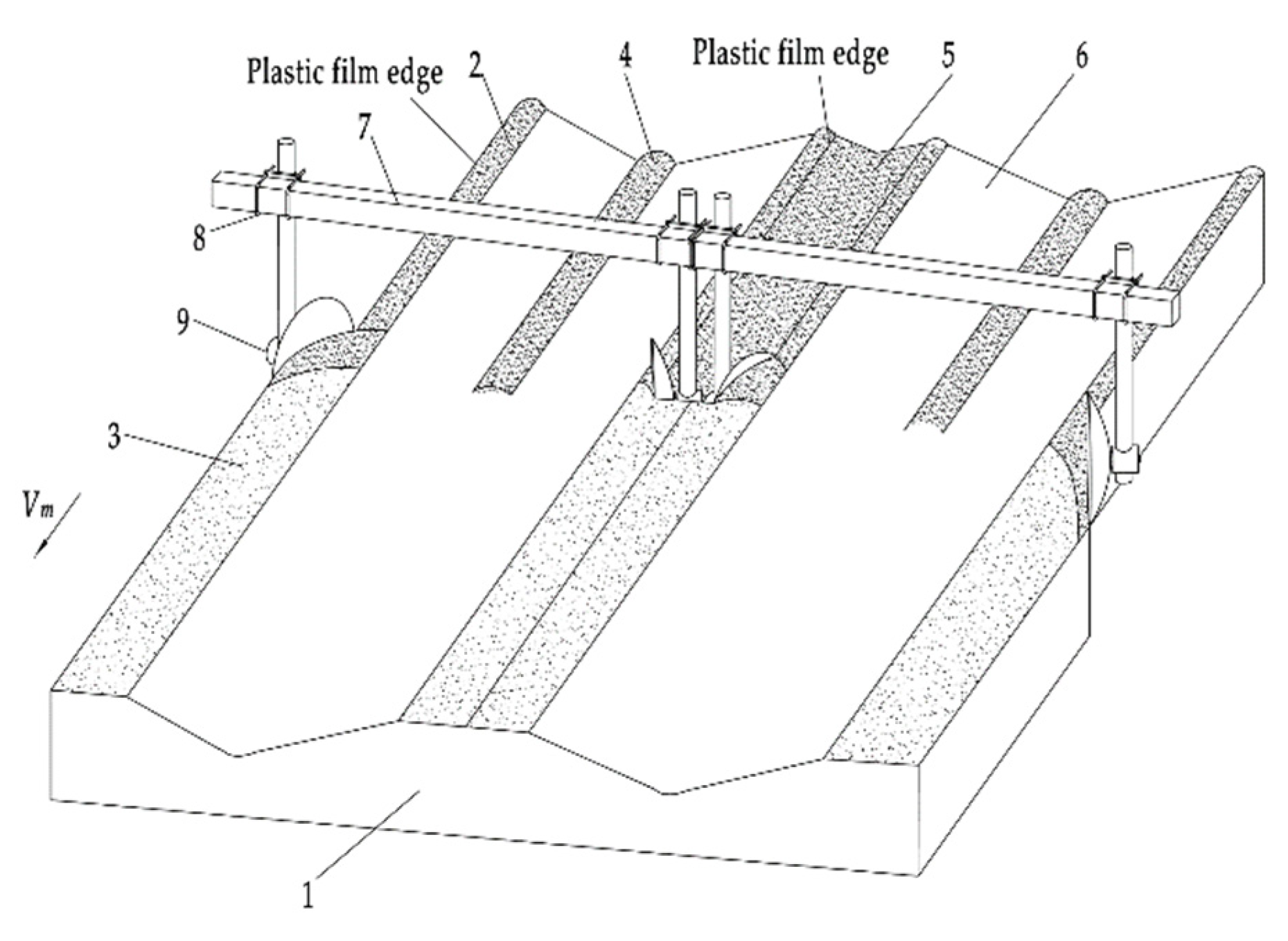

3.5. Seedling head burial and film edge soil-covering device

3.6. The transmission system

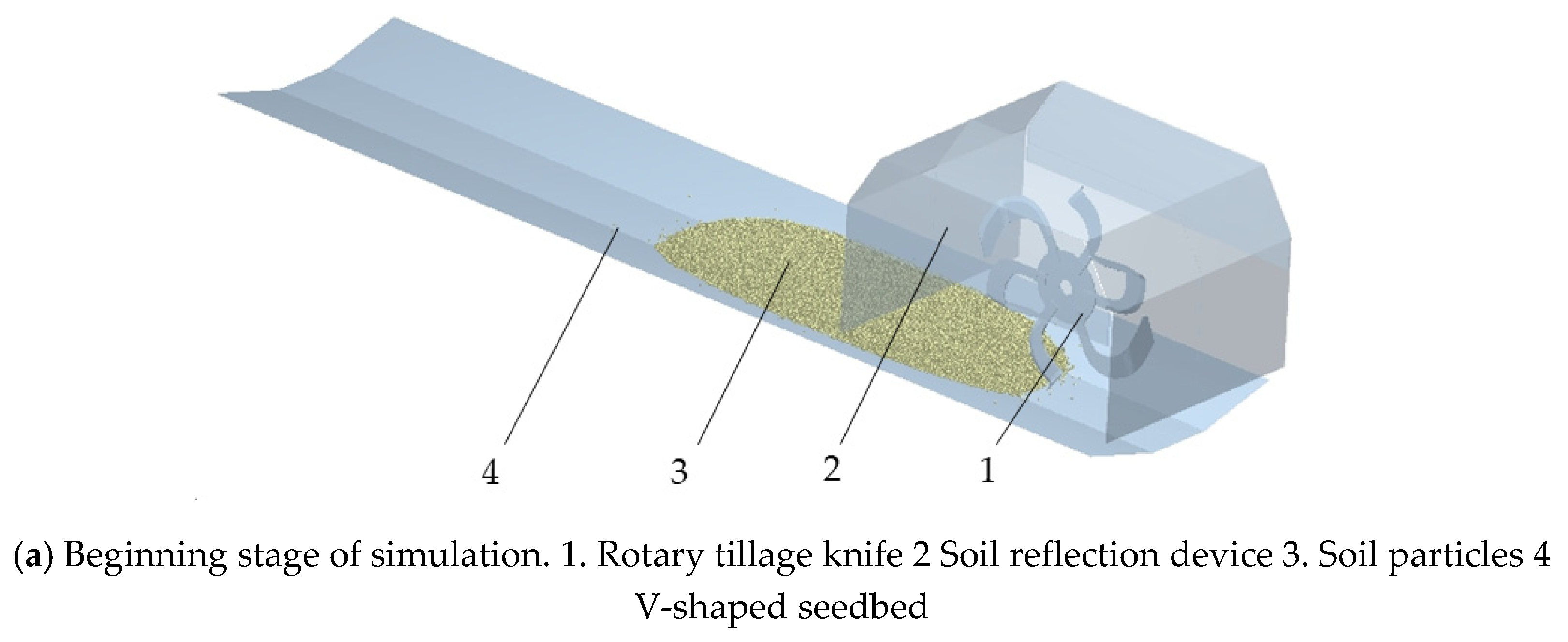

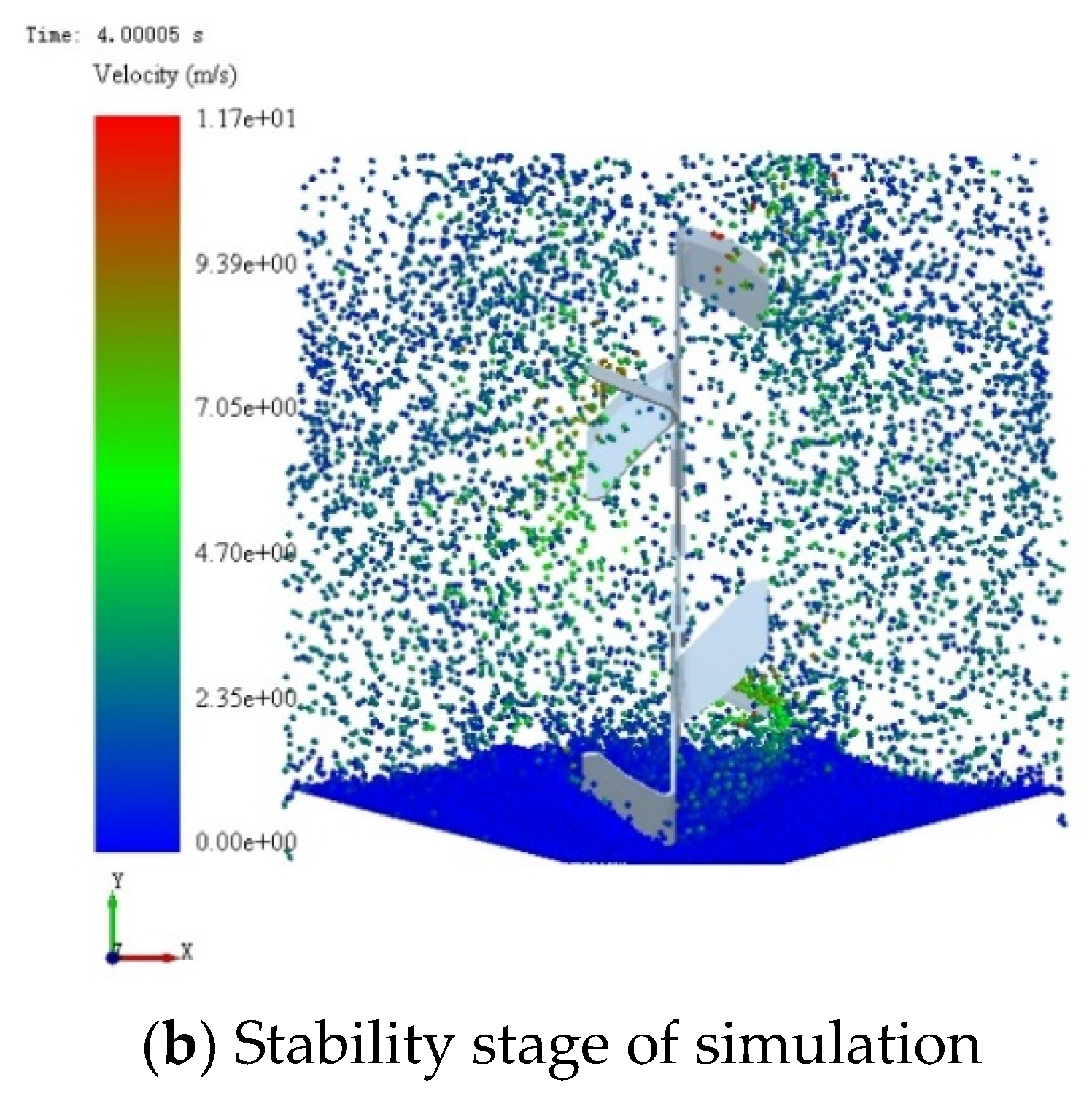

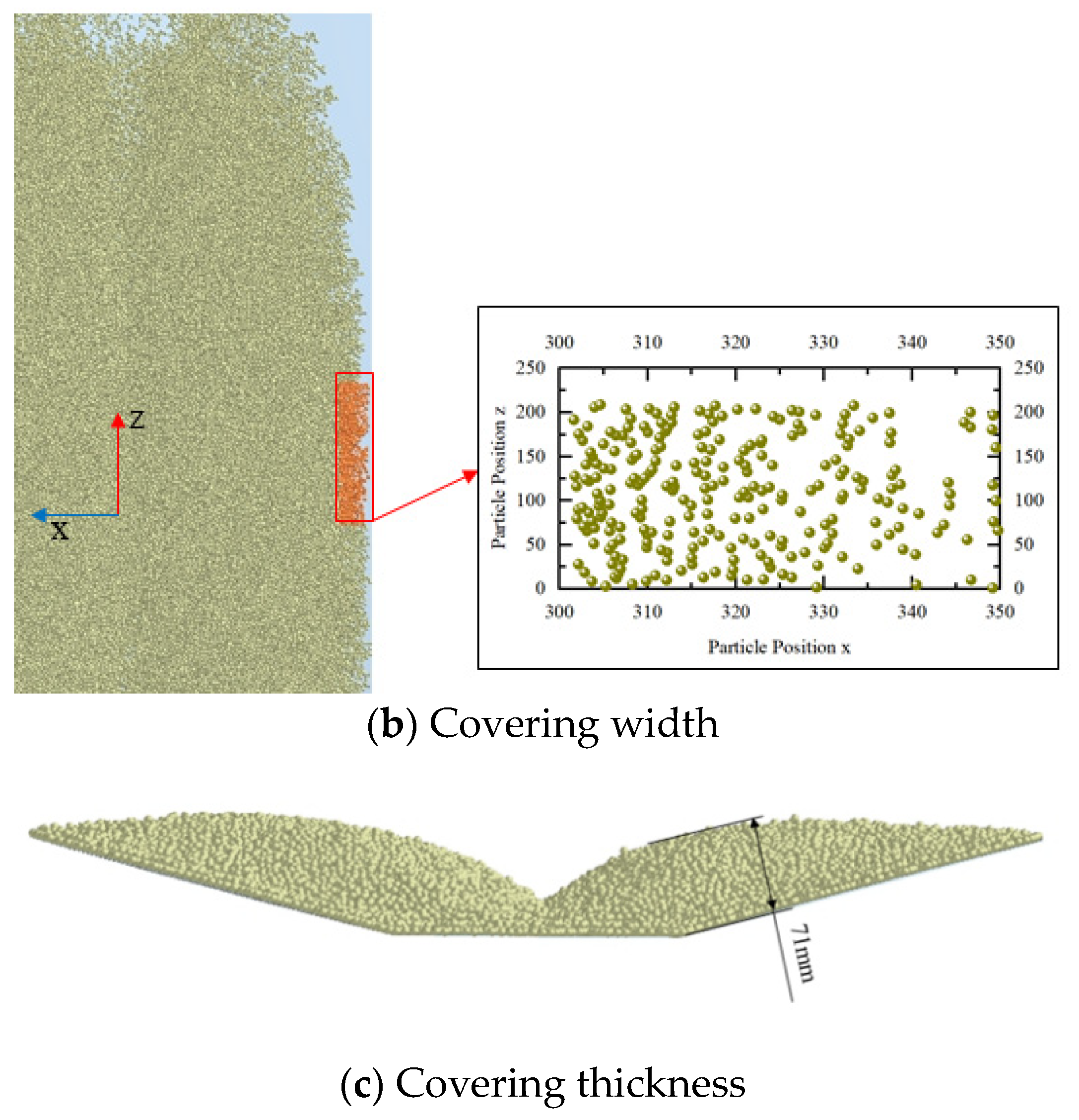

4. Simulation of rotary tillage covering operation process

4.1. Setting of simulation parameter

4.2. Simulation process and result analysis

5. Field experiment

5.1. Purpose and scheme design of the experiment

5.2. Accuracy of seedling spacing

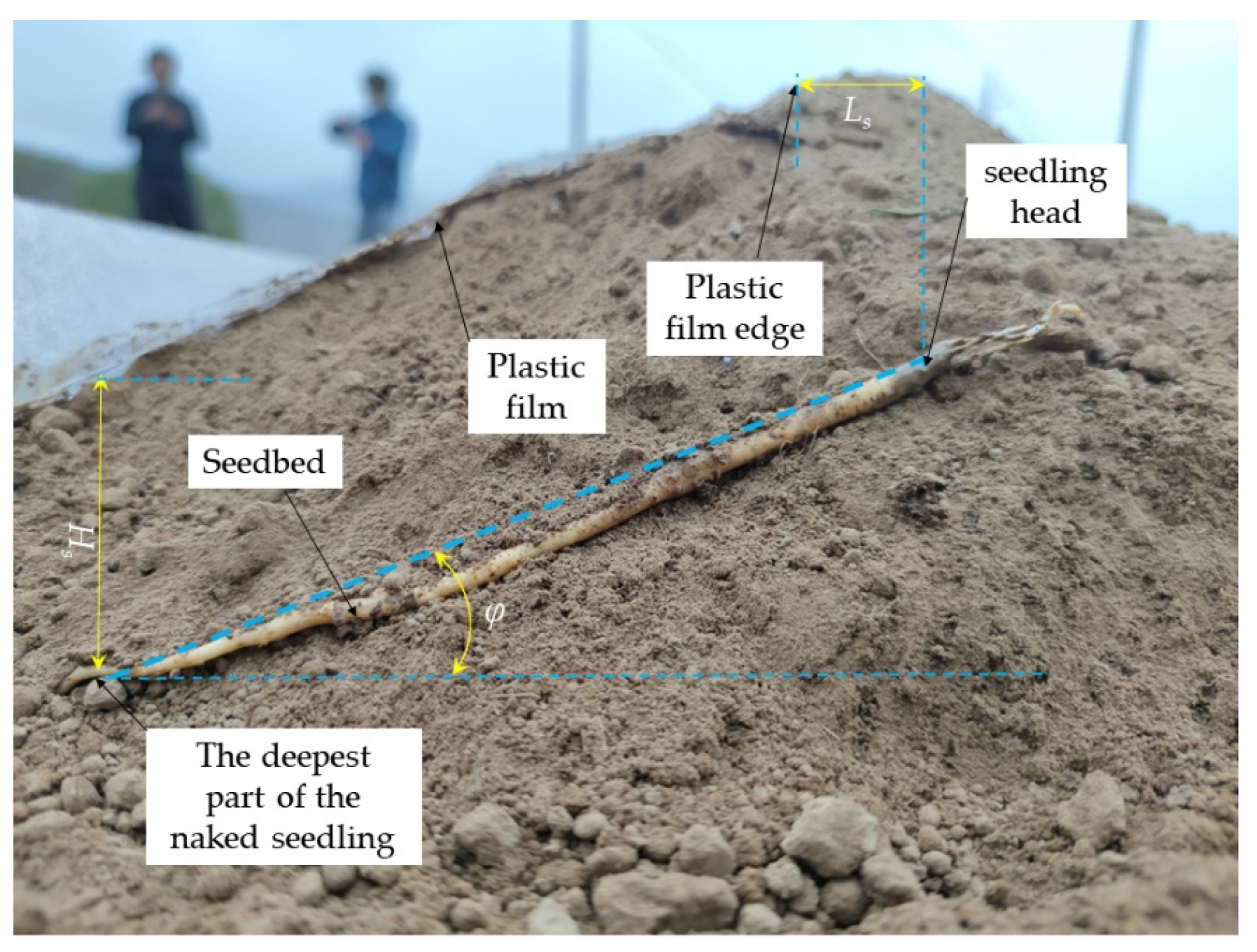

5.3. Qualified rate of planting depth, planting posture and film side outcrop

5.4. Discussion of test results

6. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang Huiling. Establishment of Codonopsis industrial technology innovation strategic alliance in Gansu Province [N]. Daily Ganws.com - Gansu Economic Daily,2018-10-23.

- Liu D, Gong Y, Zhang X, et al. EDEM Simulation Study on the Performance of a Mechanized Ditching Device for Codonopsis Planting[J]. Agriculture, 2022, 12(8): 1238. [CrossRef]

- Chang Yong. High-yield Cultivation Technology of Codonopsis in Tongwei County[J]. Journal of Gansu Agriculture, 2014 (16) : 68 + 70. https://doi.org/10.15979/j.cnki cn62-1104 / f 2014.16.093.

- Iqbal M Z, Islam M N, Chowdhury M, et al. Working Speed Analysis of the Gear-driven Dibbling Mechanism of a 2.6 kw Walking-type Automatic Pepper Transplanter[J]. Machines, 2021, 9(1): 6. [CrossRef]

- Han L, Mao H, Hu J, et al. Development of a Riding-type Fully Automatic Transplanter for Vegetable Plug Seedlings[J]. Spanish Journal of Agricultural Research, 2019, 17(3): e0205-e0205. [CrossRef]

- Jin X, Li D, Ma H, et al. Development of Single Row Automatic Transplanting Device for Potted Vegetable Seedlings[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(3): 67-75. [CrossRef]

- Yan W, Hu M, Li K, et al. Design and Experiment of Horizontal Transplanter for Sweet Potato Seedlings[J]. Agriculture, 2022, 12(5): 675. [CrossRef]

- Xu Gaowei, Liu Hongxin, FARMAN A C, Fang Huimin, Jian Shichun, He Tengfei. Design and Experiment of Tilting Transplanting Mechanism on Salvia Miltiorrhiza Film [J]. Journal of Agricultural Machinery,2019,50(02):78-89+101. [CrossRef]

- Wu Guangwei, An Xiaofei, Yan Bingxin, Li Liwei, He Yufan, Meng Zhijun. Design and Test Based on Pretreatment of Seedlings with Bare Sweet Potato Seedling Transplanting Machine [J/OL]. Journal of Agricultural Machinery: 1-13 [2022-10-25]. http://kns.cnki.net/kcms/detail/11.1964.S.2022081.html.

- Wang Xujian, Song Jiannong, Liu Cailing, Dong Xiangqian, Wang Jicheng, Zhang Chao. Design and Experiment of Liquorice Tilting Transplanting Ditcher [J]. Journal of Agricultural Machinery,2016,32(13):16-23.

- Na Mingjun, Teng Le, Zhou Kun, Wang Jinwu, Dong Xin, Zhou Maile. Optimization Design and Experiment of Planting Mechanism of Double Operation Machine for Pot seedling Transplanting in dryland [J]. Journal of Agricultural Machinery,2022,53(07):67-73.

- Liu D, Gong Y, Zhang X, et al. Design and Experiment of Dry-Farming Cantaloupe Transplanter under Water[J]. Agriculture, 2022, 12(6): 796. [CrossRef]

- Wang Jinwu, Tang Han, Wang Jinfeng, Lin Nannan, Huang Huinan, Zhao Yi. Design and Experiment of 1DSZ-350 Suspended Paddy Field Single-side Rotary Tillage Suppression and Construction Machine [J]. Journal of Agricultural Engineering,2017,33(01):25-37. [CrossRef]

- Niu Cong, Xu Liming, Duan Zhuangzhuang, Liu Xingxing, Ma Shuai, Yuan Quanchun, Wang Shuoshuo, Yuan Xunteng, Zeng Jian, Chen Chen. Development of Hedge Frame Type Grape Soil Removal and Cold-proof Cloth Recovery Machine in Winter [J]. Journal of Agricultural Engineering,2020,36(02):50-58.

- Ma Shuai, Xu Liming, Xing Jiejie, Yuan Quanchun, Yu Changchang, Duan Zhuangzhuang, Chen Chen, Zeng Jian. Development of Rotary Vane Removal Machine for Grape Vine Soil Burial [J]. Journal of Agricultural Engineering,2018,34(23):1-10.

- Yang Qizhi, He Mingsheng, Shi Lei, Shi Aiping, Zhao Xiaoqi. Study on Interaction between Wine-grape Scraper and Cold-proof Soil [J]. Journal of Agricultural Engineering, 2021,37(22):21-30.

- Hu Minjuan, Zhang Wenyi, Ji Yao, Qi Bing, Xia Qianqian, Li Kun. Influence of Hole Tray Seedling with Biodegradable Pot Transplanting on Pepper Growth Character [J]. Journal of Chinese Agricultural Mechanization, 2020, 41(09) : 57-62. [CrossRef]

- Hu Lianglong, Wang Bing, Wang Gongfu, Yu Zhaoyang, You Zhaoyan, Hu Zhichao, Wang Bokai, Gao Xuemei. Design and Experiment of 2ZGF-2 Compound Planting Machine for Sweet potato [J]. Journal of Agricultural Engineering,2016,32(10):8-16.

- Yuan Ting, Wang Dong, Wen Yongshuang, Zhu Sishuo, Chen Ying, Tan Yuzhi. Design and Experiment of Air-blown Vibration Compound Seedling Taking Mechanism of Vegetable Transplanter [J]. Journal of Chinese Agricultural Mechanization,2019,50(10):80-87.

- Fang Huimin, JI Changying, Farman Ali Chandio, Guo Jun, Zhang Qingyi, Chaudhry Arslan. Analysis of Soil Motion Behavior During Rotary Tillage Based on Discrete Element Method [J]. Journal of Agricultural Machinery,2016,47(03):22-28.

- Tan Haochao, XU Liming, Ma Shuai, Niu Cong, Yan Chenggong, Shen Congcong. Design and Test of Scraper Organic Fertilizer Strip Mixed with the Rotary Tillage Machinery of Fertilizer [J/OL]. Journal of Agricultural Machinery: 1-24 [2022-10-14]. http://kns.cnki.net/kcms/detail/11.1964.s.20220928.1749.0 08.html.

- Liao Qingxi, Du Wenbin, Zhang Qingsong, Lin Jianxin, Chen Zhiling, Zhang Jiqin. Design and Test of Cigar Tobacco Adjustable Seedbed Ridging Membrane Machine [J/OL]. Journal of Agricultural Machinery: 1-13 [2022-12-17]. http://kns.cnki.net/kcms/detail/11.1964.s.20221108.1209. .006.html.

- Sun Jingbin, Liu Qi, Luo Pengxin, Yang Fuzeng, Liu Zhijie, Wang Zheng. Study on Soil Erosion Law of Slope Contour Tilling by Tractor in Mountain [J]. Journal of Agricultural Machinery,2022,53(05):44-56.

- Chen Bin, Chen Xinhua, Chen Xiaobing, Zhu Jiping, Yu Qingxu, Liao Youyi, Liu Yan. Design and Test of Crawler Self-propelled Rotary Tillage Strawberry Ridging Fertilizer Compounding Machine [J]. Journal of Chinese Agricultural Mechanization,2022,43(01):55-60+85. [CrossRef]

- Zheng Kan, Li Yufei, Xia Junfang, Liu Guoyang, Cheng Jian, Kang Qixin. Design and Experiment of Axial Soil Levelling Cutter Roller with Gradual Spiral Lifting Angle for Furrow Rotiller [J]. Journal of Agricultural Machinery,2021,52(05):63-73.

- Sun Wei, Liu Xiaolong, Wang Hucun, Zhang Hua, Wu Jianmin, Yang Xiaoping, Wang Guanping. Design and Experiment of Double Crank Multi-bar Potato Film Punching Planter [J]. Journal of Agricultural Engineering,2018,34(08):34-42.

- Dai Fei, Xin Shanglong, Zhao Wuyun, Liu Fengjun, Xin Bingbang, Ma Mingsheng. Design and Experiment of Potato Sowing Machine with Full Film Surface Covering [J]. Journal of Agricultural Machinery,2017,48(03):76-83+56.

- Shao Chenghui, Kan Junwu, Tang Kehong. Research on Dynamic Parameters of Salt Pan Film Laying Machine Based on Dimension Analysis [J]. Journal of Agricultural Machinery,2003(01):121-123.

- Dai Fei, Song Xuefeng, Zhao Wuyun, Wei Wancheng, Zhang Fengwei, Ma Haijun. Design and Experiment of Micro-ridge Soil Covering Machine [J]. Journal of Agricultural Machinery,2020,51(03):97-105+129.

- Li Shangping, Pan Jiafeng, Zhong Jiaqin, Huang Zongxiao, Gan Fangfang. Design and Experiment of Ditch Cutter for Sugarcane Horizontal Planter Based on Effective Seed Dropping Space [J]. Journal of Agricultural Machinery,2022,53(07):162-170.

- Dai Fei, Zhang Shilin, Song Xuefeng, Zhao Wuyun, Ma Haijun, Zhang Fengwei. Design and Experiment of a Combined Plastic-film Mulching Machine on Double Ridges and Double Width [J]. Journal of Agricultural Machinery,2020,51(05):108-117.

- Sun Wei, Liu Xiaolong, Shi Linrong, Zhang Hua, Liu Quanwei, Wu Jianmin. Soil Covering Characteristics of Scraper Lift Belt Film Covering Device[J]. Journal of Mechanical Engineering,2016,52(07):38-45.

- Shi Linrong, Yang Xiaoping, Zhao Wuyun, Sun Wei, Li Rongbin, Sun Bugong. Design and Experiment of a Combined Potato Sowing Machine with Throwing and Lifting Interfilm Soil-covering [J]. Journal of Agricultural Machinery,2018,49(06):129-137.

| NO | Process | Picture | Requirements |

| 1 | Seedbed preparation |  |

The seedbed is tilted 10° to 20° |

| 2 | Setting seedlings |  |

The head of the seedlings is aligned and the spacing is 40~60mm |

| 3 | Covering the seedlings with soil (burying the seedlings) |  |

The thickness of covering soil is 40~80mm, and the soil should be scattered evenly |

| 4 | Mulching |  |

The distance between film edge and head of the seedling is 0~40mm |

| 5 | Coverig the membrane edge and seedlings with soil |  |

The amount of soil covering for a length of 1000mm should not be less than 1.5kg |

| Parameters | Numerical Values |

| Machine dimensions (length × width × height)/(mm × mm ×mm) |

2297×2107×1655 |

| Auxiliary power/kw | 44.1 |

| Overall quality/kg | 512 |

| Seedling placement method | Manual seedling placement |

| Seedling outcrop distance/mm | 0~40 |

| Plant spacing/mm | 44 |

| Productivity/(hm2·h-1) | 0.45~0.65 |

| Number of seeding rows | 4 |

| Angle of inclined planting/° | 15 |

| Covering thickness of seedlings/mm | 40~80 |

| Number of plastic films | 2 |

| The width of plastic film /mm | 620 |

| Suspension mode | Three-point suspension |

| Project | Parameters | Numerical value |

| Soil particles, V-shaped seedbeds |

Poisson’s | 0.4 |

| ratio shear modulus /Pa | 1.0×106 | |

| Density /(kg.m-3 ) | 1364 | |

|

Rotary tillage knife |

Poisson’s | 0.28 |

| ratio shear modulus /Pa | 3.5×1010 | |

| Density /(kg.m-3 ) | 7850 | |

| Soil particles - soil particles, seedbeds | Coefficient of recovery | 0.21 |

| Coefficient of static friction | 0.68 | |

| Coefficient of dynamic friction | 0.27 | |

| Soil Particles - Rotary tillage knife | Coefficient of recovery | 0.54 |

| Coefficient of static friction | 0.68 | |

| Coefficient of dynamic friction | 0.13 |

| Number | Forward speed (m/s) | Average seedling spacing /cm | Standard deviation/cm | Coefficient of variation /% |

|---|---|---|---|---|

| 1 | 0.10 | 4.54 | 0.40 | 0.09 |

| 2 | 0.10 | 4.57 | 0.41 | 0.09 |

| 3 | 0.10 | 4.56 | 0.31 | 0.07 |

| 4 | 0.15 | 4.85 | 0.88 | 0.18 |

| 5 | 0.15 | 4.91 | 0.86 | 0.17 |

| 6 | 0.15 | 4.84 | 1.02 | 0.21 |

| 7 | 0.20 | 4.90 | 1.73 | 0.35 |

| 8 | 0.20 | 4.80 | 2.16 | 0.45 |

| 9 | 0.20 | 4.65 | 1.89 | 0.41 |

| Number | Forward velocity (m/s) | Number of plants | Number of qualified plants for planting depth | Number of qualified plants for planting posture | Number of qualified plants on membrane side outcrop | Qualified rate of planting depth /% | Qualified rate of planting posture /% | Qualified rate of film side outcrop /% |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.1 | 40 | 38 | 36 | 36 | 95.00 | 90.00 | 90.00 |

| 2 | 0.1 | 40 | 38 | 39 | 38 | 95.00 | 97.50 | 95.00 |

| 3 | 0.1 | 40 | 39 | 38 | 38 | 97.50 | 95.00 | 95.00 |

| 4 | 0.15 | 40 | 37 | 37 | 36 | 92.50 | 92.50 | 90.00 |

| 5 | 0.15 | 40 | 38 | 35 | 35 | 95.00 | 87.50 | 87.50 |

| 6 | 0.15 | 40 | 36 | 35 | 35 | 90.00 | 87.50 | 87.50 |

| 7 | 0.2 | 40 | 36 | 35 | 32 | 90.00 | 87.50 | 80.00 |

| 8 | 0.2 | 40 | 36 | 34 | 35 | 90.00 | 85.00 | 87.50 |

| 9 | 0.2 | 40 | 37 | 32 | 34 | 92.50 | 80.00 | 85.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).