1. Introduction

Most of thermal energy that humanity encounters on a daily basis comes from the solar radiation. This fact is greatly exacerbated by the effects of global warming [

1]. The increase of heat flow in permafrost soils in the northern regions [

2] leads to the loss of their load-bearing capacity and, subsequently, the collapse of buildings and structures [

3]. There are problems in southern regions too: prolonged solar radiation exposure on water reservoirs leads to water evaporation increase [

4], which is most significant large area ones; long periods of drought reduce hydro power plant productivity [

5]; excessive growth of air and surface temperatures in buildings leads to a significant increase in energy consumption for space cooling having the lion’s share of the overall electricity demand growth [6-7].

These and other negative impacts of solar radiation on infrastructure have prompted the active development of solar-powered technologies to tackle the effects of the growing heat load [

8]. Installation of floatovoltaic plants [

9] on the reservoirs will not only reduce the intensity of evaporation due to shielding (with the efficiency equal to usual floating balls [

10]), but also provide energy to power the infrastructure surrounding the reservoirs [

11]. In agriculture, it is often necessary to create artificial shading (especially in arid regions) and for the same purpose, the use of agrivoltaics is promising [

12]. Installation of solar panels with a tracking system or translucent modules with wavelength selection on agricultural land allows not only to prevent direct sunlight on the plants, but also to meet the needs of the agricultural sector in electricity (e.g., solar irrigation [

13]).

There is also significant potential of solar panels and solar collectors integration into air conditioning and ventilation systems of buildings [

14]. This solution in many cases helps to fully cover the ever-increasing energy demand for the operation of these systems in a sustainable way. The main technological advantage of the considered systems lies precisely in the positive correlation of the solar irradiance and the need for cooling. This relation between energy production and consumption makes systems better balanced, and so, much cheaper.

In other words, the use of solar-powered cooling can significantly reduce the consequences of the main renewable energy disadvantage – intermittent output. This positive effect is particularly pronounced when the load explicitly follows the electricity generation (i.e., it is adaptive). A classic example of adaptive load is solar-powered water pumping [

13]. However, in order to fully achieve the potential of the adaptive load concept, the variability of load is required, that is reached by frequency control (i.e., inverter mode). And only in this case there will be a smooth mode of load (energy consumption by water pump or compressor) following the stochastic generation. Another approach to the design of standalone systems with a load following the generation in a wide output range is the principle of reducing the threshold power by using several low-power consumers (aggregates) instead of a single one [

15]. That is the aggregation method. Distribution of load by units at the design stage contributes to the reduction of installed capacity of renewable energy sources (RES) with maintaining the load operation and reducing the solar electricity cost. Combined, these approaches (frequency control and aggregation) allow the load to be treated as «variable» (i.e., allowing operation within a wide power range).

If the final consumer has a high level of energy consumption inertia, the problem of instability of RES generation is also relieved. For example, the previously mentioned soil thermal stabilisation system with a heat pump (HP). Storing energy in the form of cold in the ground (particularly with water/ice phase transition) is more efficient and cheaper than other ways (e.g., electrochemical). To be able to implement the principle presented, it is also necessary to have a frequency-controlled HP (inverter) compressor in order to utilize the maximum possible amount of solar energy. Thus, the period of low power generation (and, as a consequence, low cooling capacity) can be balanced out by the period when the generated power is higher than required

Using HP in thermal stabilisation systems, it is often worth using the aggregation method. The distribution of load over the aggregates ensures the optimum modes of their operation. If the output power is low, less powerful HP is operating above its threshold power. As the cooling load follows the generation, the output power is distributed over the aggregates in the optimal way to get the necessary amount of chill. It is important to note that the aggregation method does not affect the maximum power of the system determined by the sum of the maximum powers of all heat pumps in the system, which remains unchanged. Several aggregates also improve the system reliability, but increase its HP part of CAPEX and TCO.

As noted above, the excess energy can be stored not only by means of classic BES, but also in the form of cold in the ground (for thermal stabilisation systems). Another principle worth referring for off-grid systems is an impliсit storage [

16]. This approach contributes to the technological system simplification and its cost reduction by substituting the expensive BES with the excess nameplate capacity of RES. The latter is suggested to be implemented using a complementary source having a negative output correlation to the primary one (e.g., wind and solar) [

6].

This paper presents an analysis of the above mentioned design principles (aggregation; variable load following the generation) impact on the economic and technical efficiency of an off-grid power system for permafrost thermal stabilisation with solar-powered HP in northern Norway (70.310, 25.535). A comparison is carried out both for the initial purchase of equipment (CAPEX) and for the total cost of ownership (TCO) of power system with and without battery energy storage (BES). The study is based on the meteorological data analysis with a 1-hour temporal resolution. The results of this paper could be used in the design of stand-alone energy systems based on PV and Smart grids based on RES.

2. Materials and Methods

2.1. Model of the Power Supply System

The optimal configuration selection process of the off-grid power supply system requires a comprehensive operation analysis of individual components. Thus, it is necessary to simulate various configurations with different modes of HP operation in order to select the optimal solutions. The calculation is based on energy balance consideration of generation and load. The numerical model used is described in details in [

17]. The following describes the main additions to it.

2.1.1. Battery Energy Storage

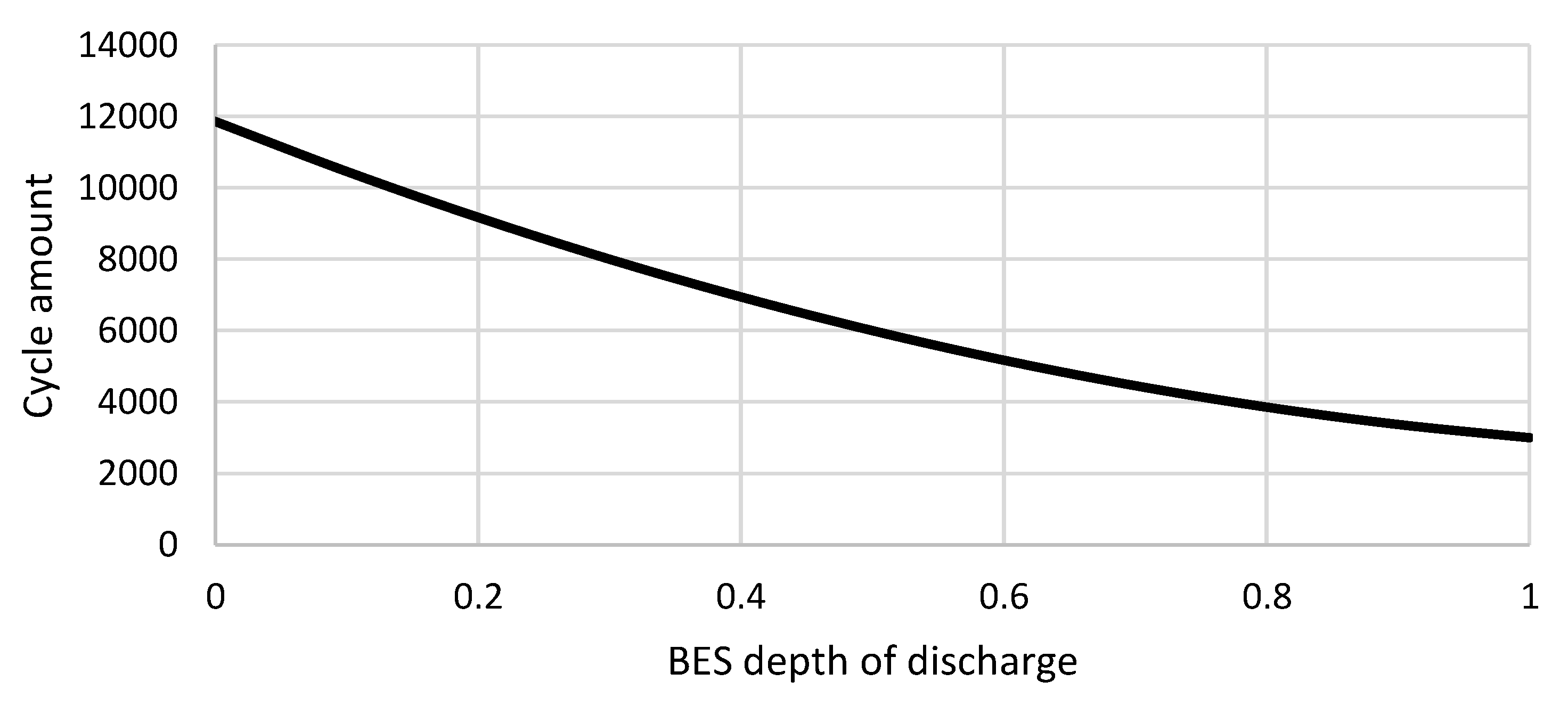

The lifetime of BES is determined by the amount of discharge cycles (LT). The dependence of LT on the BES State of Charge (SoC) can be given by the polynomial dependence:

where

—coefficients individual for different types of BES.

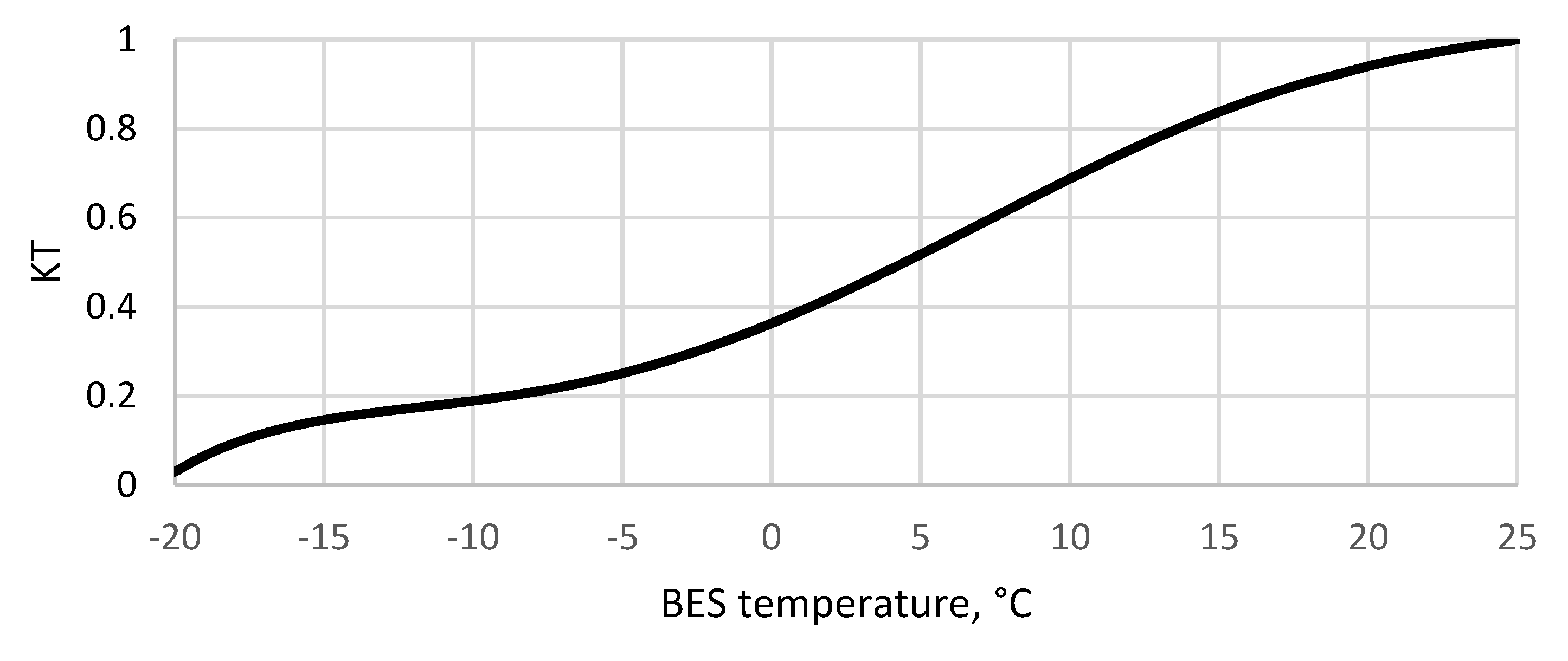

The service life of BES also largely depends on the operating temperature. A temperature correction can be taken into account in the form of a service life temperature coefficient (KT), which represents the degree of LT decrease:

where

—coefficients individual for different types of BES.

Accordingly, the service life part (ULT) that will be exhausted as a result of the discharge process:

2.1.2. Heat Pump

The main load is a compressor. This paper considers a start-stop (single frequency) and an inverter (in a certain frequency range) modes of compressor operation. The compressor rotor speed is controlled by changing the frequency of AC (f, Hz) within the range of f

min and f

max, the minimum and maximum limits, respectively. Those are determined by the type of the compressor, so continuous compressor operation beyond these frequencies can lead to its rapid failure. It is assumed that power consumed by the compressor is directly proportional to the frequency of AC. Therefore, HP actual power consumption (P

HP, W) relation to its rated electric power (P

HP_Rated, W) and frequency (f

Rated, Hz) is expressed as:

2.2. Weather Data

To simulate the operation of various standalone power system configurations, weather data with 1-hour temporal resolution of solar irradiance, air temperature, and wind speed are used. Such a high temporal resolution is necessary for a detailed behavior analysis of the off-grid system based on RES [

17] (it is impossible using monthly averaged data).

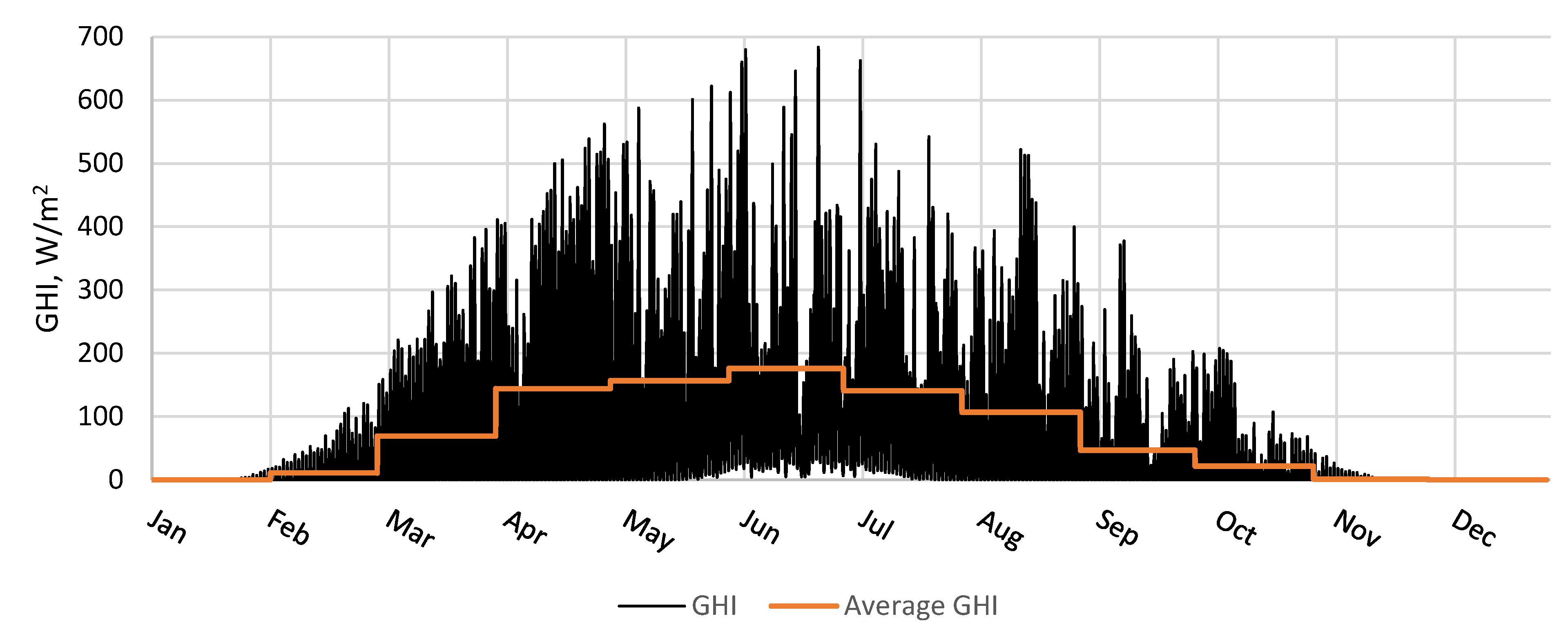

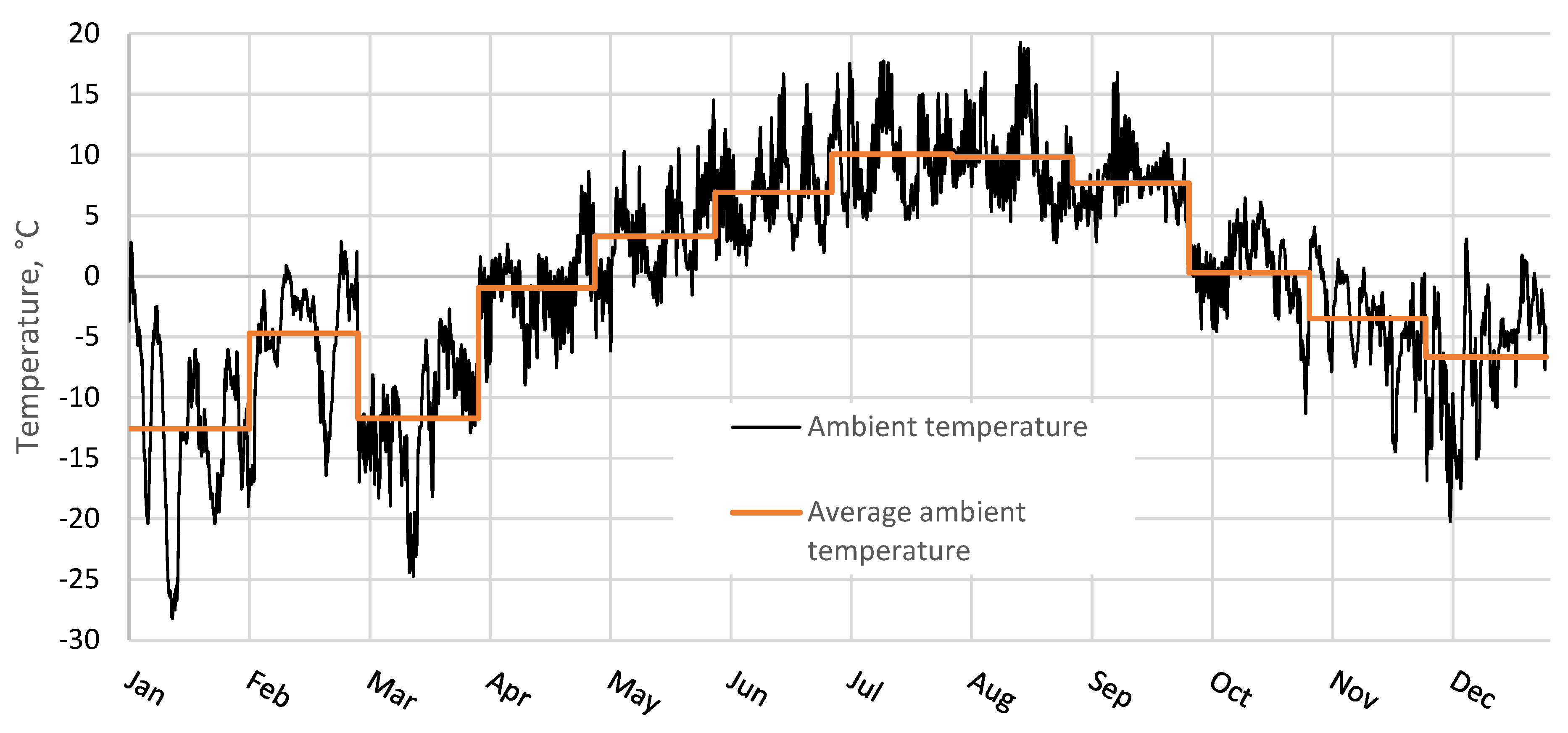

These data were sourced form Photovoltaic Geographic Information System (PVGIS) [

18], which provides high-quality data on solar radiation obtained from satellite images; ambient temperature and wind speed are based on climate reanalysis models. PVGIS provides data in the form of a typical meteorological year (TMY), representing a set of meteorological data of high temporal resolution, which are consistent with long-term mean annual values. The datasets used in calculations are shown in

Figure 1,

Figure 2 and

Figure 3; monthly averaged data are also presented for reference.

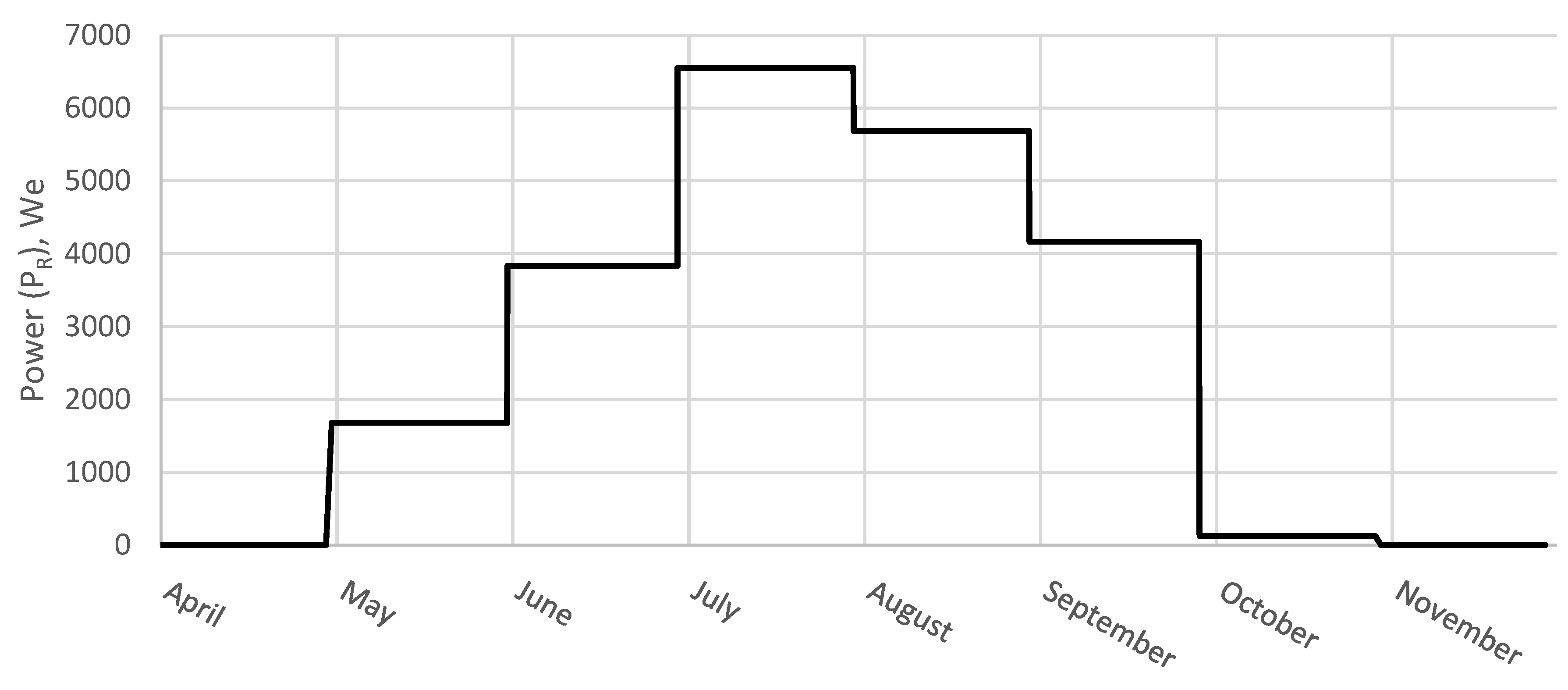

2.3. Load Analysis

Analysis of the soil thermal load and, accordingly, the required electric power of the HP is carried out on the methodology presented in [

19]. Operation of the thermal stabilisation system is assumed only in the presence of heat flow to the soil (when the ambient air temperature is above 0 °C, and solar radiation is considered to be reflected by the snow). Accordingly, the load calculation and, consequently, all further analysis of the system operation will be carried out for the period of May-October. The area of thermale stabilised soil is taken as 100 m

2. The distribution of HP electric power (P

R, W) demanded for thermal stabilisation is shown in

Figure 4.

Maximum heat load on the ground is in July. To avoid the penetration of heat into the soil during this time it is necessary to operate the HP compressor at a power of about 6.5 kWe. Consequently, the nominal power of the HP (PHP_Rated, We) should be sufficient to cover the corresponding annual demand for refrigeration capacity.

2.4. Considered Layouts and Loads

In this paper, the calculation is made for different power supply system layouts and operation modes. For convenience of description, the cases under consideration are numbered and presented in

Table 1:

In case of HP operating in «Start-Stop» mode, only nominal power is allowed. The inverter operation mode implies frequency control of the power consumption within the minimum power required to start the HP (limited by f

min) and the maximum permissible power (limited by f

max). The principle of aggregation is expressed in the use of several low-power HPs with a total nominal capacity equivalent to the single HP. Consideration of thermal stabilisation system operation with the possibility of energy storage in the soil (adaptive load mode) is expressed in the fact that HP tends to consume all available energy generated by PV regardless of the actual cooling demand. Non-adaptive mode of operation, on the contrary, is aimed primarily at the HP consumption of the minimum required power (according to the actual cooling demand;

Figure 4). However, in the calculation, when considering non-adaptive modes of operation, the fact of cold storage in the soil must still be taken into account. Hence, it is impossible to unambiguously consider the «Start-Stop» operation mode in both adaptive and non-adaptive modes with their subsequent comparison. Therefore, for the sake of correctness, the «Start-Stop» mode will be considered only under consideration of the adaptive load.

The set of parameters varied in the calculation is presented in

Table 2:

2.5. Calculation Algorithm

The Reliability of Power Supply (RPS) is the main characteristic of the stand-alone system performance. In this paper, to evaluate the cooling demand satisfaction, RPS can be represented as the ratio of energy consumed by HP (E

C, J) (during the season of the thermal stabilisation operation) to the total required electric energy (

Figure 4):

Accordingly, for each 1-hour time interval, the following calculations are performed:

The generated PV energy.

The amount of energy consumed by HP (EC’(t)=P C(t)Δt) (4), depending on the load mode, the amount of energy generated and energy stored in BES.

If there is a BES, the difference between the energy generated and the energy consumed. In this case, no more energy can be stored in BES than the maximum possible energy during the calculated time interval.

The energy capacity of BES and its SoC. The SoC restricts the maximum (minimum) allowable value (if the SoC together with the stored (consumed) energy is higher (lower) than the allowed SoC values at the previous calculation step).

Then EC can be calculated as the sum of EC’(t). Accordingly, it is possible to calculate RPS (5). Also, based on the analysis of SoC profile, the lifetime of BES can be estimated. This process is based on finding SoC (throughout the calculated time interval) to which it has been discharged - each process of BES discharging leads to a decrease in its lifetime by a certain amount (can be estimated by equations (1)–(3)).

The algorithm for selecting the optimal configuration of the power supply system is based on the «Brute Force» [

20]. Thus, for each possible configuration option (the main variable parameters of the system are presented in

Table 2), RPS and the configuration cost can be evaluated.

2.6. The Equipment

Information about the cost and the performance of HP (frequency range, rated electric power, service life, and price) used in the calculation is presented in

Table 3:

In case of aggregation (use of several HPs with the same rated power and total power equal to 6.5 kWe), the total cost of HP system significantly differs from the cost of a single equivalent power HP, since with the reduction of HP power, its cost changes disproportionately: 2 HPs–$4,800; 3 HPs–$6,000; 4 HPs–$8,000. Also the lifetime of a compressor is usually between 10,000 and 15,000. In single HP start-stop mode, we estimated 1382 motor-hours, so assumed 10 years lifetime. Aggregation has added ca. 340 h per unit (for 2-4 HPs). And load variability added another 623 h. On the one hand, these complications are reducing the compressor lifetime in years, but on the other hand, the continuous operation invertor mode and availability to provide better service to aggregates are improving operation conditions. So the reality, the compressor lifetime should be not affected so straight as it appears formally. Since this issue is out of this paper scope, we did not consider its influence on TCO.

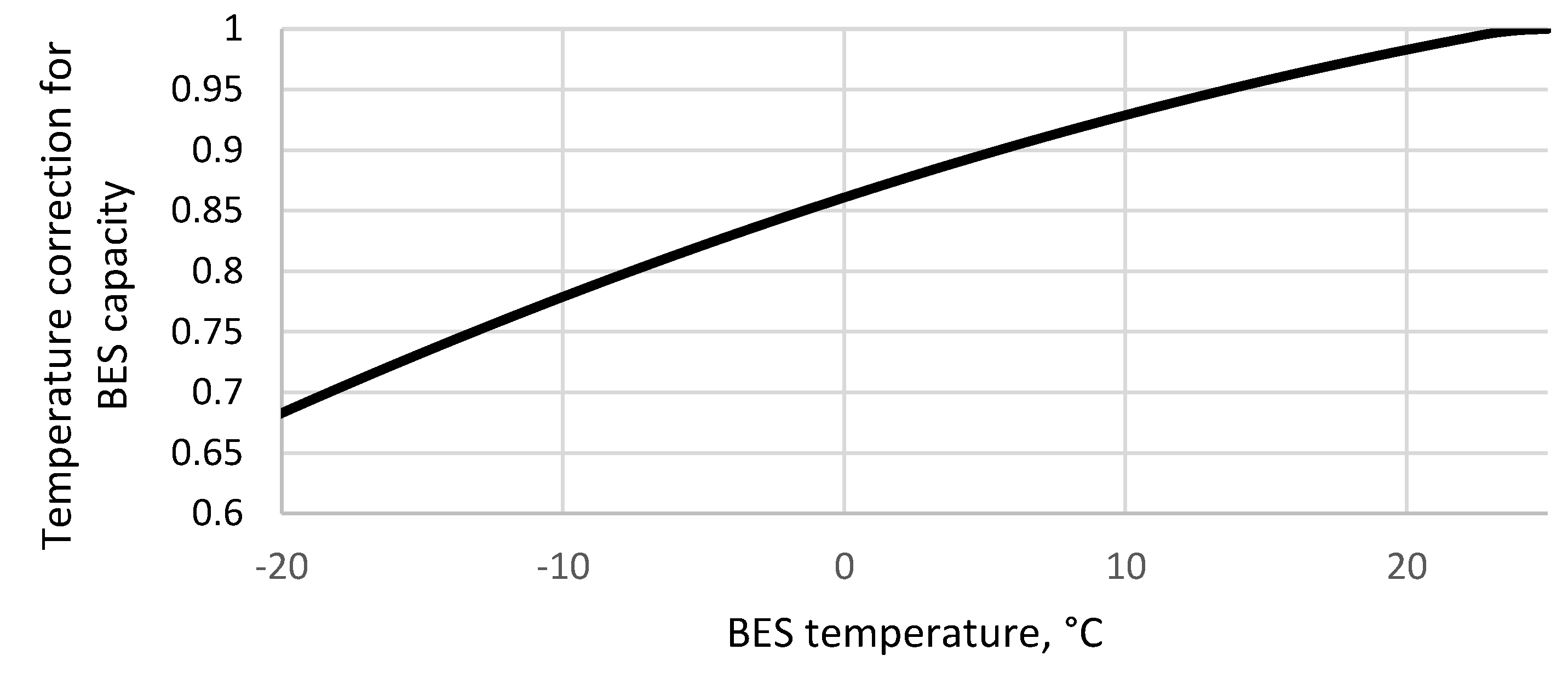

The use of lithium-titanate batteries (Li:LTO) is recommended for energy in cold climate. However, the performance characteristics (Wehler curve for the number of discharge cycles; direct dependence of service life on temperature) are not well known for those. Therefore, LiFePO

4 BES characteristics will be used in the calculation. Lithium batteries have a much longer life span (compared to the more usual AGM or GEL batteries) and also allow greater depths of discharge. Accordingly, they do not require frequent replacement. These facts contribute to the conclusion that lithium batteries are more cost-effective for standalone systems [

21], even in spite of their higher cost at initial purchase.

The minimum allowable SoC for LiFePO

4 is 20%. The information about the dependence of service life on the depth of discharge and the battery capacity dependence on temperature was taken from the «SunStonePower» manufacturer’s website and converted into dependencies convenient for analysis, whose polynomial coefficients (according to equations (1) and (2)) are presented in

Table 4 and

Table 5. The plots of temperature correction coefficients for capacity and lifetime of the BES and the plot for the estimation of the lifetime of the BES are shown in

Figure 5,

Figure 6 and

Figure 7, respectively. It is assumed that the cost of a battery depends linearly on the capacity.

Information about the cost and the main technical characteristics of the PV panels used in the calculation is presented in

Table 6. It is assumed that the cost of PV depends linearly on the installed power capacity. The efficiency of BOS is taken as η = 0.95.

Calculating TCO, we accounted initial CAPEX and additional cost of replaced equipment over time. We did not include any OPEX and discount rates. Both of those are highly variable for the specific project, and the former is also compensated by the negative annual growth rate of CAPEX for HP and BES to be replaced.

3. Results

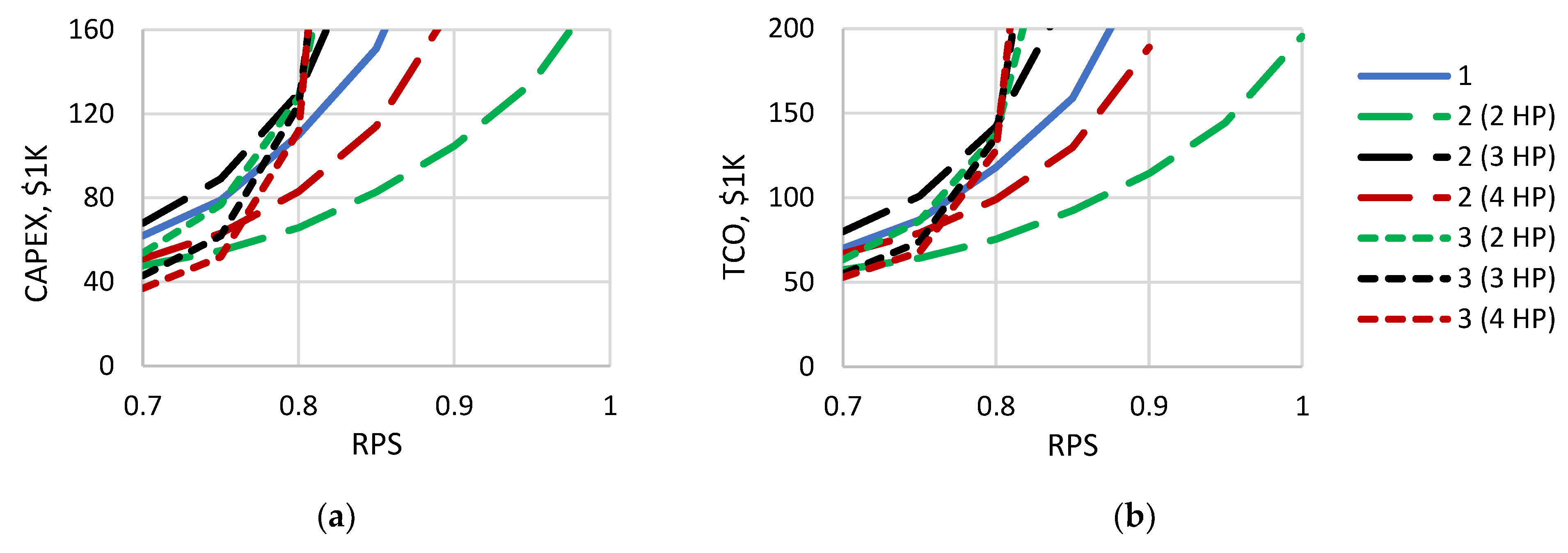

Thus, the operation of 30 different thermal stabilisation system options was simulated (for each aggregation one, the use of 2 to 4 HPs was considered). The total number of simulated systems (including variation in power system parameters) was about 292,000. For each thermal stabilisation system layout, the most efficient configurations (with RPS from 0.7 to 1, step 0.5) with minimum CAPEX and TCO were selected. The system life cycle is determined by the equipment having the maximum service life; that is, for the thermal stabilisation system, the TCO will be considered within 30 years. The calculation considered the effect on the TCO of the need to replace BES and HPs.

Figure 8 shows the areas comprising the most efficient and cost-effective configurations (both in terms of CAPEX (

a) and TCO (

b)): the «Classic» area includes system variants 1-6, and the «Adaptive» area includes system variants 7-14. Noteworthy, if thermal stabilisation requirements are not strict (RPS~0.7), there is not much difference in efficiency of the approaches: the best «Adaptive» configuration is cheaper than «Classic» only by 5% in terms of CAPEX. However, as the requirements for preventing heat penetration into the soil increase, the difference grows as well: at RPS=1, «Adaptive» is 28% cheaper than «Classic». When TCO is considered, the results are more pronounced: «Adaptive» is 27% cheaper when the requirements are not stringent, and 44% for the RPS=1.

According to CAPEX, the most efficient (RPS=1) and cheapest «Classic» configurations were the ones with BES and HPs working in «Start-Stop» mode, with light implementation of the aggregation (2 HPs). But in case of RPS=0.7 (using the classic approach) it is more preferable to use HPs with the possibility of frequency control and moderate aggregation (3 HPs). In case of using the adaptive load, in the same RPS ranges, in contrast, the cheapest configurations were options without BES and with aggregation (2 HPs). However, the best «Adaptive» configurations with RPS above 0.8 were the systems with BES.

Table 7 shows the main technical characteristics of the most economically and technically efficient configurations:

However, when comparing the configurations in terms of TCO, the most technically and economically efficient configurations in «Adaptive» mode are systems without BES (

Table 8), but with the application of the aggregation principle (2 HPs) and frequency control of HP operation. It was found that with the classic approach to load control, the most efficient configurations are those with BES. And as the requirements for the quality of thermal stabilisation increase, the ratio between the installed power capacity and the capacity of BES in optimal configurations also changes.

3.1.«. Classic» (Configurations Numbered 1-6)

This set of configurations is the least efficient.

Figure 9 shows the dependencies of CAPEX (a) and TCO (b) on the required RPS for systems without BES. In such systems, using the aggregation method could not always increase the efficiency of the system: as can be seen, using 3 or 4 HPs is not a viable solution in systems with «Start-Stop» control. Although deeper aggregation of the system reduces the minimum required starting energy, using 2 HPs with «Start-Stop» control leads to better results. This effect is observed due to the fact that the transition from 2 HPs to 3 HPs involves a change in the «steps» of the minimum power required to start the aggregates; at the same time, the difference between using 2 and 4 HPs is not so significant – the system with 4 HPs has the same power limits (besides two extra ones) as the system with 2 HPs.

The use of frequency control in HP operation is also significantly ineffective compared to the «Start-Stop» control. This is due to the fact that, focused on satisfying the electric power demand for thermal stabilisation at the given moment (

Figure 4), the «Start-Stop» system will somehow operate at a higher power than required, which will eventually lead to accumulation of cooling power in the soil. In frequency control mode, the HP power is more finely adjusted to the demand for cooling (without its excessive production). For the same reason, a system with 4 Start-Stop HPs loses to a system with 2 HPs due to the possibility of finer adjustment to the power consumption: there is a reduction in the production of excess cooling capacity and, accordingly, a reduction in the efficiency of the thermal stabilisation system as a whole.

All of the above features also apply to systems with BES (shown in

Figure 10a,b). However, the use of BES can significantly improve system efficiency and reduce cost: to achieve RPS=0.9, the CAPEX reduction is about 60%, and the TCO reduction is 38%.

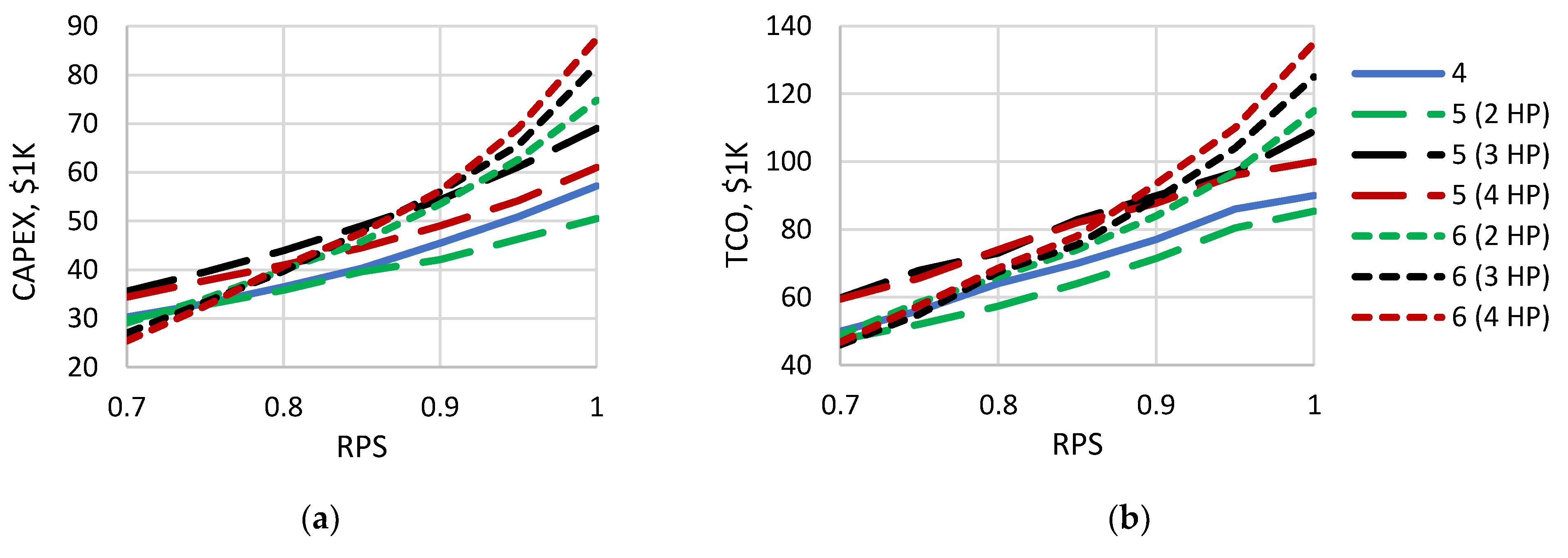

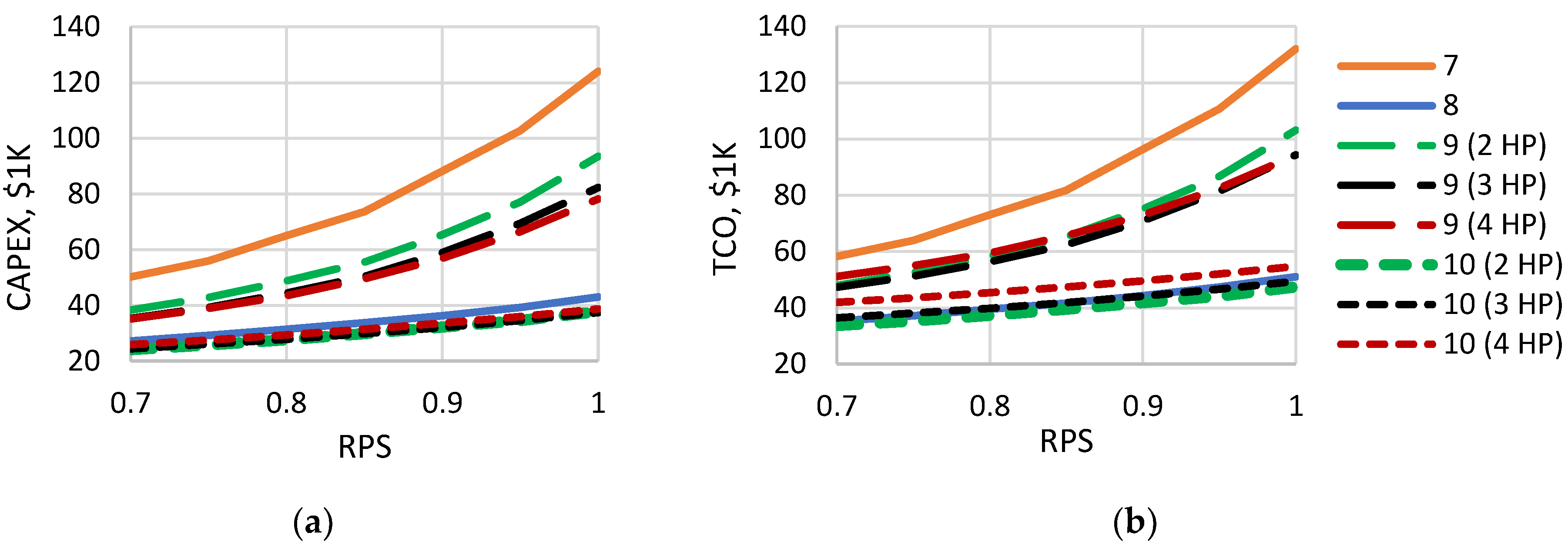

3.2.«. Adaptive» (Configurations Numbered 7-14)

Load adaptivity principle application (in the case of a thermal stabilisation system: using the soil as a thermal accumulator) significantly increases the overall efficiency of the system. For non-BES systems in case of «Start-Stop» operation, aggregation leads to a significant cost reduction (CAPEX—33%, TCO—31%) for systems capable of providing RPS=1 (

Figure 11). However, for frequency-controlled HPs, the economic effect of aggregation is not so significant. Moreover, the most optimal solution for these systems is to use 2 HPs: in

$20-40k range, the cost of HP has a significant impact on the entire thermal stabilisation system. It is worth noting that the result obtained is typical only for a certain ratio of equipment prices, when the increase in cost due to aggregation minimizes all the advantages of this approach. This fact is also observed when considering TCO of the most optimal non-BES systems: for the «Start-Stop» system, the best option is 3 HPs, and for the frequency-controlled HPs – with 2 HPs (the system with 4 HPs is less feasible solution by TCO than installing 1 HP).

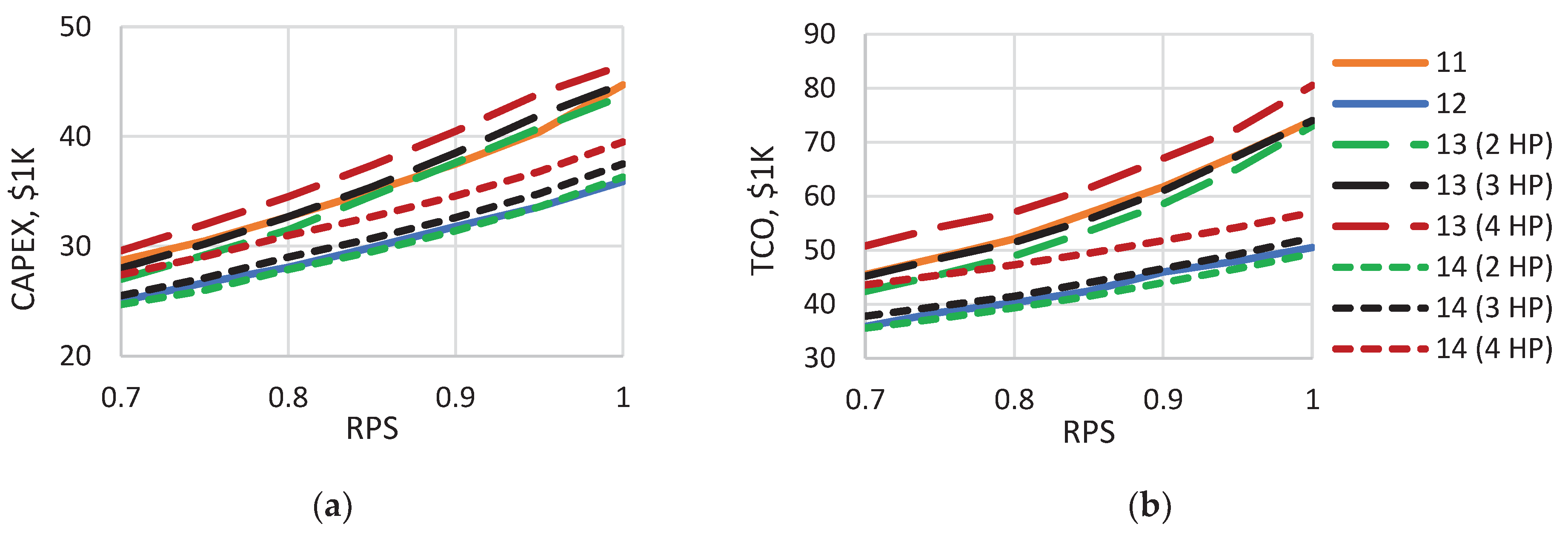

The introduction of BES into the system reduces the most efficient configurations costs of systems operating in «Start-Stop» mode. However, for inverter systems the influence of the BES is quite insignificant (

Figure 12). It is also noteworthy that in the case of BES, the effect of aggregation on system efficiency is minimized (especially for «Start-Stop»).

4. Discussion

The calculation results unambiguously show the advantages of the adaptive load principle once that is applicable. However, it is important to note that other optimal system configurations may be observed in other price conditions (it is also valid for «Classic» configurations, but less so). According to the results of this study, for «Adaptive» systems the use of BES is much less relevant than for classic systems: the accumulation of excess energy in the form of cold in the ground is certainly more benefitial (but only within the limits of the considered price conditions). For other HP applications than soil thermal stabilization, it means a special thermal storage is needed. This is also valid if the load has a power threshold: on the one hand, the presence of BES allows the system to gradually accumulate energy for further plant start-up, but on the other hand, the excess generating capacity will also allow to pass the threshold under unfavorable conditions for electricity generation (e.g., for PV, at low solar irradiance).

The aggregation method proved to be a rather effiicient way of increasing the thermal stabilisation system operating time (if applied to decrease the load power threshold), which significantly improved the soil freezing quality over the season. But nevertheless, this method may not always be economically justified either: often, the consumer devices unit cost grows nonlinearly as the unit power decreases. And thus, in case of a low-cost power supply system, in certain cost conditions it is economically inefficient to use deep aggregation (despite all the technical advantages of this method). This was found as a result of calculations for all configurations with BES and frequency-control.

As a result of calculations it was found that, for thermal stabilisation in northern Norway, the best configuration (in terms of TCO) of active thermal stabilisation system is a non-BES system. However, the use of small capacity BES in real thermal stabilisation systems can significantly increase HP operation reliability in cloudy weather conditions. Thus, in such systems it is recommended to install a small capacity BES, which will slightly increase the cost of the system (due to the possibility of reducing the PV installed capacity), but will significantly improve the system quality as a whole.

The results of the present study also correlate with the results of [

15], aimed on investigation of the effect of aggregation on the thermal stabilisation system performance in the same region (northern Norway). In non-BES systems with frequency-controlled HPs, the use of the aggregation method increases the system operating time during the warm season. However, there is no significant decrease in the optimal configurations costs.

A further promising area of thermal stabilisation system configuration development is the use of thermal storage in a compressed-liquid [

22] rather than an electrochemical storage device. So, for instance, the cost of energy removed from R32 refrigerant (when it is used as a «cold» accumulator) is 3 times lower than the cost of energy removed from BES. Storage in refrigerant will have an even greater impact on the TCO: in contrast to BES, the thermal accumulator has no limit in discharge cycles and therefore will not require replacement over the lifetime of the plant.

Another promising method of increasing the efficiency of the off-grid thermal stabilisation system is the use of an expander instead of a throttle system in HPs [

23]. Such a technological solution makes it possible to utilize energy (that would be lost in the throttle) in the expander at about 50% efficiency. In turn, this approach too expensive for grid-powered HP, will reduce the power demand of the thermal stabilisation system, allowing a reduction in the installed PV and BES capacity.

5. Conclusions

Thus, the operation of a set of solar-powered cooling systems with different approaches to the design (aggregation; battery, thermal, and implicit storage) and regulation («Start-Stop»; frequency control; adaptive load) was simulated. An analysis of the energy systems design approaches and the economic and technical effect of their application has been carried out.

If it is possible to organize the load following energy generation in RES systems, it is possible to achieve a system efficiency increase as compared to the classic approaches. It was found that considering HP as an adaptive load in the thermal stabilisation system will reduce CAPEX by 28% and TCO by 44% while preserving the soil freezing quality. The HPs frequency control availability leads to an increase in system efficiency of 35% (average). And in poorly optimized (in terms of regulation) systems (such as «Start-Stop»), the aggregation method application results in a 30-35% both CAPEX and TCO reduction. Those not taking into account the increase in annual motor-hours per HP unit though. However, for systems based on inverter HPs, aggregation brings no significant advantages and, in some cases, makes the system more expensive.

As a result of calculations it was found that for thermal stabilisation of 100 m2 area in northern Norway the best configuration of active thermal stabilisation system is a system with 2 inverter HPs (installed power of about 3.25 kWe each) and power supply system based on PV (total installed power capacity of about 47 kW without BES). However, in terms of installing a real system, it is recommended to install a slightly more expensive system with power supply system based on PV (43.5 kW) and BES (4.35 kW×h) to increase the HP operation reliability in cloudy weather conditions.

Author Contributions

Conceptualisation, E.Y.L. and E.S.S.; methodology, A.A.K. and A.V.K.; software, A.S.T.; validation, E.Y.L.; formal analysis, A.A.K. and A.V.K.; investigation, E.Y.L. and A.V.K.; resources, E.Y.L. and E.S.S.; data curation, A.S.T.; writing—original draft preparation, A.V.K. and E.Y.L.; writing—review and editing, E.Y.L. and A.A.K.; visualisation, A.V.K. and A.S.T.; supervision, E.Y.L. and A.A.K.; project administration, E.Y.L. and A.A.K.; funding acquisition, E.Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported financially by the Russian Science Foundation and the Arkhangelsk Region (grant No. 22-19-20026).

Data Availability Statement

Not applicable.

Acknowledgments

Data acquisition and analysis were performed using the equipment of the «Beam-M» facility (Bauman Moscow State Technical University).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ACBESBOS |

Alternating currentBattery Energy StorageBalance of system equipment (inverter and maximum power point tracker) |

| CAPEX |

CAPital EXpenditure, $1K |

| EBinst

|

Battery energy storage installed capacity, J |

| EC

|

Heat pump consumed energy for operation season, J |

| E’C

|

Heat pump consumed energy for a certain time period, J |

| f |

Heat pump compressor AC frequency, Hz |

| fmax

|

Minimum limiting heat pump compressor AC frequency, Hz |

| fmin

|

Maximum limiting heat pump compressor AC frequency, Hz |

| fRated

|

Rated heat pump compressor AC frequency, Hz |

| HP |

Heat Pump |

| GHI |

Global Horisontal Irradiance, W/m2

|

| KT |

Service life temperature coefficient |

| LT |

Number of discharge cycles |

| PV |

Photo-Voltaic module |

| PW

|

WT instaled capacity, W |

| RES |

Renewable Energy Sources |

| RPS |

Reliability of Power Supply |

| SoC |

BES State of Charge |

| Tamb

|

Ambient air temperature, °C |

| TCO |

Total Cost of Ownership, $1K |

| TMY |

Typical Meteorological Year |

| ULT |

Portion of a service life consumed as a result of discharge process |

| P E

|

Total installed PV power capacity, W |

| PHP

|

Heat pump power consumption, We |

| PHP_Rated

|

Heat pump rated electrical power, We |

| PR

|

Heat pump electrical power necessary for thermal stabilisation, We |

| PVGIS |

Photovoltaic Geographic Information System |

| Δt |

Certain time period, s |

| η |

Complex efficiency factor of the controller devices |

References

- Wang, L.; Wang, L.; Li, Y.; Wang, J. A century-long analysis of global warming and earth temperature using a random walk with drift approach. Decision Analytics Journal 2023, 7, 100237. [Google Scholar] [CrossRef]

- Post, E.; Alley, R.B.; Christensen, T.R.; Macias-Fauria, M.; Forbes, B.C.; Gooseff, M.N.; Iler, A.; Kerby, J.T.; Laidre, K.L.; Mann, M.E.; Olofsson, J.; Stroeve, J.C.; Ulmer, F.; Virginia, R.A.; Wang, M. The polar regions in a 2°C warmer world. Science Advances 2019, 5. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, X.; Cao, C.; Ma, X.; Yao, X.; Wang, W.; Zhou, R.; Wang, L. Study on stability of permafrost slopes during thawing. Research in Cold and Arid Regions 2022, 14(5), 293–297. [Google Scholar] [CrossRef]

- Gianniou, S.K.; Antonopoulos, V.Z. Evaporation and energy budget in Lake Vegoritis, Greece. Journal of Hydrology 2007, 345, 212–223. [Google Scholar] [CrossRef]

- Melelli, A.; Durand, S.; Alvarado, C.; Kervoëlen, A.; Foucat, L.; Grégoire, M.; Arnould, O.; Falourd, X.; Callebert, F.; Ouagne, P.; Geairon, A.; Daniel, S.; Jamme, F.; Mauve, C.; Gakière, B.; Bourmaud, A.; Beaugrand, J. Anticipating global warming effects: A comprehensive study of drought impact of both flax plants and fibres. Industrial Crops and Products 2022, 184, 115011. [Google Scholar] [CrossRef]

- Jurasz, J.; Beluco, A. Complementarity of Variable Renewable Energy Sources. Complementarity of Variable Renewable Energy Sources 2022, 1–720. [Google Scholar] [CrossRef]

- Obringer, R.; Nateghi, R.; Maia-Silva, D.; Mukherjee, S.; Vineeth, C.R.; McRoberts, D.B.; Kumar, R. Implications of Increasing Household Air Conditioning Use Across the United States Under a Warming Climate. Earth’s Future 2022, 10, e2021EF002434. [Google Scholar] [CrossRef]

- ESharaborova, S.; Shepitko, T.V.; Loktionov, E.Y. Experimental proof of a solar-powered heat pump system for soil thermal stabilization. Energies 2022, 15, 2118. [Google Scholar] [CrossRef]

- Vidović, *!!! REPLACE !!!*; V, *!!! REPLACE !!!*; Krajačić, *!!! REPLACE !!!*; G, *!!! REPLACE !!!*; Matak, N.; Stunjek, G.; Mimica, M. Review of the potentials for implementation of floating solar panels on lakes and water reservoirs. Renewable and Sustainable Energy Reviews 2023, 178, 113237. [Google Scholar] [CrossRef]

- Rezazadeh, A.; Akbarzadeh, P.; Aminzadeh, M. The effect of floating balls density on evaporation suppression of water reservoirs in the presence of surface flows. Journal of Hydrology 2020, 591, 125323. [Google Scholar] [CrossRef]

- Manoj Kumar, N.; Chakraborty, S.; Kumar Yadav, S.; Singh, J.; Chopra, S.S. Advancing simulation tools specific to floating solar photovoltaic systems—Comparative analysis of field-measured and simulated energy performance. Sustainable Energy Technologies and Assessments 2022, 52, 102168. [Google Scholar] [CrossRef]

- Klokov A v Loktionov, E.Y.; Loktionov Y v Panchenko, V.A.; Sharaborova, E.S. A Mini-Review of Current Activities and Future Trends in Agrivoltaics. Energies 2023, 16, 3009. [Google Scholar] [CrossRef]

- Aliyu, M.; Hassan, G.; Said, S.A.; Siddiqui, M.U.; Alawami, A.T.; Elamin, I.M. A review of solar-powered water pumping systems. Renewable and Sustainable Energy Reviews 2018, 87, 61–76. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó; M; Arıcı; M. A review on solar-powered cooling and air-conditioning systems for building applications. Energy Reports 2022, 8, 2888–2907. [Google Scholar] [CrossRef]

- Tutunin, A.; Loktionov, E. A Coordination of the Capacities of the Hybrid Renewable Energy System and the Seasonal Variable Load Following the Intermittent Generation. In Proceedings of the 2023 5th International Youth Conference on Radio Electronics, Electrical and Power Engineering, REEPE; 2023. [Google Scholar] [CrossRef]

- Pierro, M.; Barba, M.; Perez, R.; Perez, M.; Moser, D.; Cornaro, C. Ancillary Services via Flexible Photovoltaic/Wind Systems and “Implicit” Storage to Balance Demand and Supply. Solar RRL 2023, 7, 2200704. [Google Scholar] [CrossRef]

- Klokov, A.V. ; Loktionov, E.Y. Temporal Resolution of Input Weather Data Strongly Affects an Off-Grid PV System Layout and Reliability. Solar 2023, 3, 49–61. [Google Scholar] [CrossRef]

- Typical Meteorological Year (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html (accessed on 1 June 2023).

- Loktionov, E.Y.; Sharaborova, E.S.; Shepitko T,v. A sustainable concept for permafrost thermal stabilisation. Sustainable Energy Technologies and Assessments 2022, 52, 102003. [Google Scholar] [CrossRef]

- Cormen, T.H.; Leiserson, C.E.; Rivest, R.L.; Stein, C. Introduction to Algorithms, Third Edition, 3rd. edThe MIT Press, 2009. [Google Scholar]

- Klokov, A.; Loktionov, E. Configuring an Off-Grid Hybrid Renewable Energy System in the Arctic Zone. In Proceedings of the 2023 5th International Youth Conference on Radio Electronics, 2023, Electrical and Power Engineering (REEPE); pp. 1–5. [CrossRef]

- Mira-Hernández, C.; Weibel, J.A.; Groll, E.A.; Garimella S, v. Compressed-liquid energy storage with an adsorption-based vapor accumulator for solar-driven vapor compression systems in residential cooling. International Journal of Refrigeration 2016, 64, 176–186. [Google Scholar] [CrossRef]

- Murthy, A.A.; Norris, S.; Subiantoro, A. Experimental analysis of a refurbished heat pump refrigeration system with a four-intersecting-vane expander. Applied Thermal Engineering 2021, 183, 116209. [Google Scholar] [CrossRef]

Figure 1.

Detailed and monthly averaged GHI.

Figure 1.

Detailed and monthly averaged GHI.

Figure 2.

Detailed and monthly averaged wind speed.

Figure 2.

Detailed and monthly averaged wind speed.

Figure 3.

Detailed and monthly averaged air temperature.

Figure 3.

Detailed and monthly averaged air temperature.

Figure 4.

Required electric power of heat pump.

Figure 4.

Required electric power of heat pump.

Figure 5.

Temperature dependence of the BES capacity relative to the nominal value at 25 °C.

Figure 5.

Temperature dependence of the BES capacity relative to the nominal value at 25 °C.

Figure 6.

Temperature dependence of the correction factor KT.

Figure 6.

Temperature dependence of the correction factor KT.

Figure 7.

Dependence of LiFePO4 lifetime (LT) on the depth of discharge.

Figure 7.

Dependence of LiFePO4 lifetime (LT) on the depth of discharge.

Figure 8.

Comparison of the classic and the adaptive load approaches in terms of CAPEX (a) and TCO (b).

Figure 8.

Comparison of the classic and the adaptive load approaches in terms of CAPEX (a) and TCO (b).

Figure 9.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 1-3 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 9.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 1-3 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 10.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 4-6 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 10.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 4-6 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 11.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 7-10 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 11.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 7-10 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 12.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 11-14 (for systems with aggregation, the number of HPs is given in parentheses).

Figure 12.

Dependence of CAPEX (a) and TCO (b) on the performance of the thermal stabilisation system for layouts 11-14 (for systems with aggregation, the number of HPs is given in parentheses).

Table 1.

Considered configurations and operation modes of the thermal stabilisation system.

Table 1.

Considered configurations and operation modes of the thermal stabilisation system.

| Number |

Layout |

Load |

| 1 |

PV |

Inverter |

| 2 |

PV |

Start-Stop + Aggregation |

| 3 |

PV |

Inverter + Aggregation |

| 4 |

PV + BES |

Inverter |

| 5 |

PV + BES |

Start-Stop + Aggregation |

| 6 |

PV + BES |

Inverter + Aggregation |

| 7 |

PV |

Adaptive + Start-Stop |

| 8 |

PV |

Adaptive + Inverter |

| 9 |

PV |

Adaptive + Start-Stop + Aggregation |

| 10 |

PV |

Adaptive + Inverter + Aggregation |

| 11 |

PV + BES |

Adaptive + Start-Stop |

| 12 |

PV + BES |

Adaptive + Inverter |

| 13 |

PV + BES |

Adaptive + Start-Stop + Aggregation |

| 14 |

PV + BES |

Adaptive + Inverter + Aggregation |

Table 2.

Power system parameters.

Table 2.

Power system parameters.

| Parameters |

Values |

| Total installed PV capacity, P E |

(1–20, step 0.05)PHP_Rated, W |

| BES Capacity, EBinst |

(0–5, step 0.1)P E, Wh |

| Amount of HPs |

1–4, step 1 |

Table 3.

Technical specifications and specific cost of the HP.

Table 3.

Technical specifications and specific cost of the HP.

|

, Hz |

, Hz |

, Hz |

, kWe |

Lifetime, year |

Cost, $

|

| 30 |

70 |

50 |

6.5 |

10 |

4,000 |

Table 4.

Polynomial dependence coefficients for lifetime estimation and specific cost of BES.

Table 4.

Polynomial dependence coefficients for lifetime estimation and specific cost of BES.

|

|

|

|

Cost, $/(A×h) |

| 0 |

5,714 |

−14,571 |

11,857 |

2.75 |

Table 5.

Polynomial coefficients for estimating the temperature correction for BES lifetime.

Table 5.

Polynomial coefficients for estimating the temperature correction for BES lifetime.

|

|

|

|

|

|

|

| -3.218*10-10 |

4.323*10-8 |

-1.348*10-6 |

-2.906*10-5 |

8.922*10-4 |

2.740*10-2 |

3.624*10-1 |

Table 6.

Technical specifications and specific cost of the PV.

Table 6.

Technical specifications and specific cost of the PV.

|

, 1/°С |

|

Lifetime, year |

Cost, $/kW |

| 38.8 |

2.85*10-3 |

30 |

700 |

Table 7.

Technical characteristics of optimal CAPEX configurations.

Table 7.

Technical characteristics of optimal CAPEX configurations.

| RPS |

Adaptive |

Classic |

| CAPEX, $1K |

PE, kW |

EBinst, kW*h |

Control |

HP count |

CAPEX, $1K |

PE, kW |

EBinst, kW*h |

Control |

HP count |

| 0.7 |

24.1 |

27.950 |

0 |

Inverter |

2 |

27.0 |

26.0 |

13.00 |

Inverter |

3 |

| 0.75 |

25.7 |

30.225 |

0 |

Inverter |

2 |

33.4 |

33.8 |

16.90 |

Inverter |

3 |

| 0.8 |

27.7 |

32.825 |

0 |

Inverter |

2 |

39.7 |

36.4 |

36.40 |

Inverter |

3 |

| 0.85 |

29.5 |

29.900 |

14.95 |

Inverter |

2 |

39.7 |

42.9 |

21.45 |

Start-Stop |

2 |

| 0.9 |

31.4 |

32.500 |

16.25 |

Inverter |

2 |

42.1 |

40.3 |

40.30 |

Start-Stop |

2 |

| 0.95 |

33.6 |

35.100 |

17.55 |

Inverter |

2 |

46.3 |

44.2 |

44.20 |

Start-Stop |

2 |

| 1 |

36.3 |

39.000 |

19.50 |

Inverter |

2 |

50.5 |

49.4 |

49.40 |

Start-Stop |

2 |

Table 8.

Technical characteristics of optimal TCO configurations.

Table 8.

Technical characteristics of optimal TCO configurations.

| RPS |

Adaptive |

Classic |

| TCO, $1K |

PE, kW |

EBinst, kW*h |

Control |

HP count |

TCO, $1K |

PE, kW |

EBinst, kW*h |

Control |

HP count |

| 0.7 |

33.7 |

27.950 |

0 |

Inverter |

2 |

46.0 |

30.550 |

6.110 |

Inverter |

3 |

| 0.75 |

35.4 |

30.225 |

0 |

Inverter |

2 |

52.0 |

46.475 |

4.648 |

Start-Stop |

2 |

| 0.8 |

37.3 |

32.825 |

0 |

Inverter |

2 |

57.4 |

54.600 |

5.460 |

Start-Stop |

2 |

| 0.85 |

39.5 |

36.075 |

0 |

Inverter |

2 |

64.1 |

53.625 |

10.725 |

Start-Stop |

2 |

| 0.9 |

41.8 |

39.325 |

0 |

Inverter |

2 |

71.5 |

61.750 |

12.350 |

Start-Stop |

2 |

| 0.95 |

44.2 |

42.900 |

0 |

Inverter |

2 |

80.5 |

51.025 |

30.615 |

Start-Stop |

2 |

| 1 |

47.4 |

46.800 |

0 |

Inverter |

2 |

85.4 |

73.125 |

21.940 |

Start-Stop |

2 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).