1. Introduction

The field of polymer science provides the fundamental knowledge necessary to comprehend the behavior of polymers during the material extrusion process in Additive Manufacturing (AM) technique[

1,

2,

3]. In this process, a thermoplastic filament is melted and extruded through a nozzle, then to create a 3D object. Material extrusion is popular among 3D printing techniques due to its low cost, simplicity, and versatility. It is used in a wide range of applications, from rapid prototyping to production manufacturing [

4,

5,

6].

Numerical simulations have become an important tool in investigating and analyzing material extrusion Additive Manufacturing (AM) [

7,

8,

9,

10,

11]. Numerical simulations can help researchers better understand the system being studied and design experiments that are more focused and efficient. Computational Fluid Dynamics (CFD) simulations are commonly used to study the extrusion flow in material extrusion AM [

12]. These simulations can provide valuable information about the behavior of the molten material as it is extruded through the nozzle, such as the temperature distribution, velocity profile, and shear stress. High gravity material extrusion is a challenging process in additive manufacturing due to the increased forces acting on the material. Simulation can be a powerful tool in understanding and optimizing this process, as it allows for the evaluation of various design parameters and material properties without the need for physical prototyping. By simulating high gravity material extrusion, it is possible to predict the behavior of the material during the printing process and optimize the process parameters for improved print quality and efficiency.

The deposition of a liquid drop onto the surface is a common process used in many scientific investigations across various fields [

13,

14,

15,

16]. In fluid mechanics, it is used to study the behavior of droplets in various fluid environments. Additionally, in biomedical sciences, the deposition of liquid drops is used to simulate biological processes such as the interaction of drugs with bodily fluids or the behavior of cells in a liquid environment [

17]. The study of the liquid drops is therefore an important tool in understanding many different scientific phenomena [

18]. When a liquid drop, surface tension will attempt to minimize its surface area, thereby reducing its surface energy. The surface tension of the liquid influence the droplet to form a shape [

19,

20,

21,

22]. In material extrusion processes, the effective gravity acting on the extruded material can influence the properties of the final product. Conducting MEX under high gravity conditions is an important area of research that has the potential to advance our understanding of materials science and engineering, as well as space exploration and other fields that rely on materials that can withstand extreme conditions. We study the influence of effective gravity on the product.

This paper presents a methodology to simulate the extrusion of material in high gravity by changing the gravity from 1 to 32 G. In this work, we investigate the impact of high gravity conditions on material extrusion and numerical study by refer to development of high gravity material extrusion system (HG-MEX). By analyzing the interplay between polymer behavior and gravity, we provide insights into the effects of high gravity on extrusion processes, including filament flow, material deposition, and resulting fabrication characteristics. The established HG-MEX and numerical study in additive manufacturing is a meaningful and valuable approach to improving the quality and efficiency of the process.

2. High gravity in material extrusion

2.1. Applications of centrifugal acceleration and material extrusion

Centrifugal acceleration is used to simulate the effects of high-gravity conditions on components and systems. Centrifugal acceleration, also known as the apparent force, that creates the sensation of an outward force [

23,

24,

25]. This force is a result of an object's inertia in motion and its tendency to move in a straight line. By subjecting components to high centrifugal forces, we can test their performance under extreme conditions. In HG-MEX system, we combined the characteristics of centrifugal and MEX, HG-MEX system were designed, the characteristics of the gravity field on the material extrusion process are analyzed.

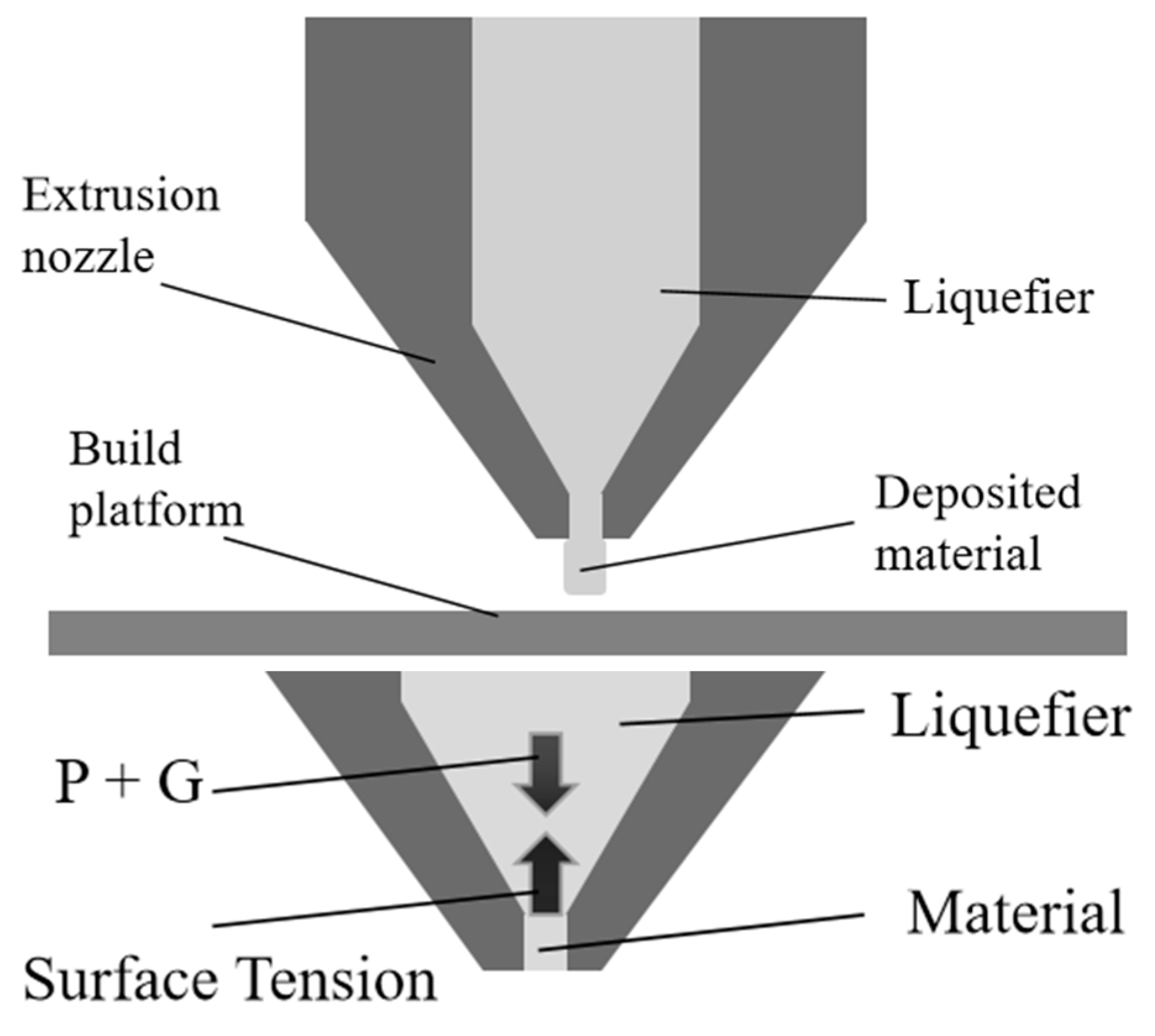

Figure 1. presents schematics of the relation between the surface tension and gravity force in material extrusion process.

We evaluated the surface tension in polymer science. Surface tension is the tendency of the surface of a liquid to contract and minimize its surface area. Some pressure and gravity change can be applied to overcome this and let the material to flow out of the hole. The Eötvös number, also called the bond number, is a dimensionless number measuring the importance of gravitational forces compared to surface tension forces, and is used to characterize the shape of drops moving in a surrounding fluid [

26,

27,

28]. The Eötvös number equals the product of gravitational acceleration, density difference and the characteristic length squared divided by the surface tension. The Eötvös number

decreases by times when the hole diameter becomes times, and the surface tension becomes dominant resulting in the material cannot go out of the nozzle. The scale factors in n- or n

2-times gravity was summarized, and this similarity rules is named as "Analogy of different gravitational fields" by Dr. Koike [

29,

30]. Where E

0 is given as equation (1) below:

where

is the density difference,

is the gravitational acceleration,

is the hole diameter, and γ is the surface tension of the droplet geometry.

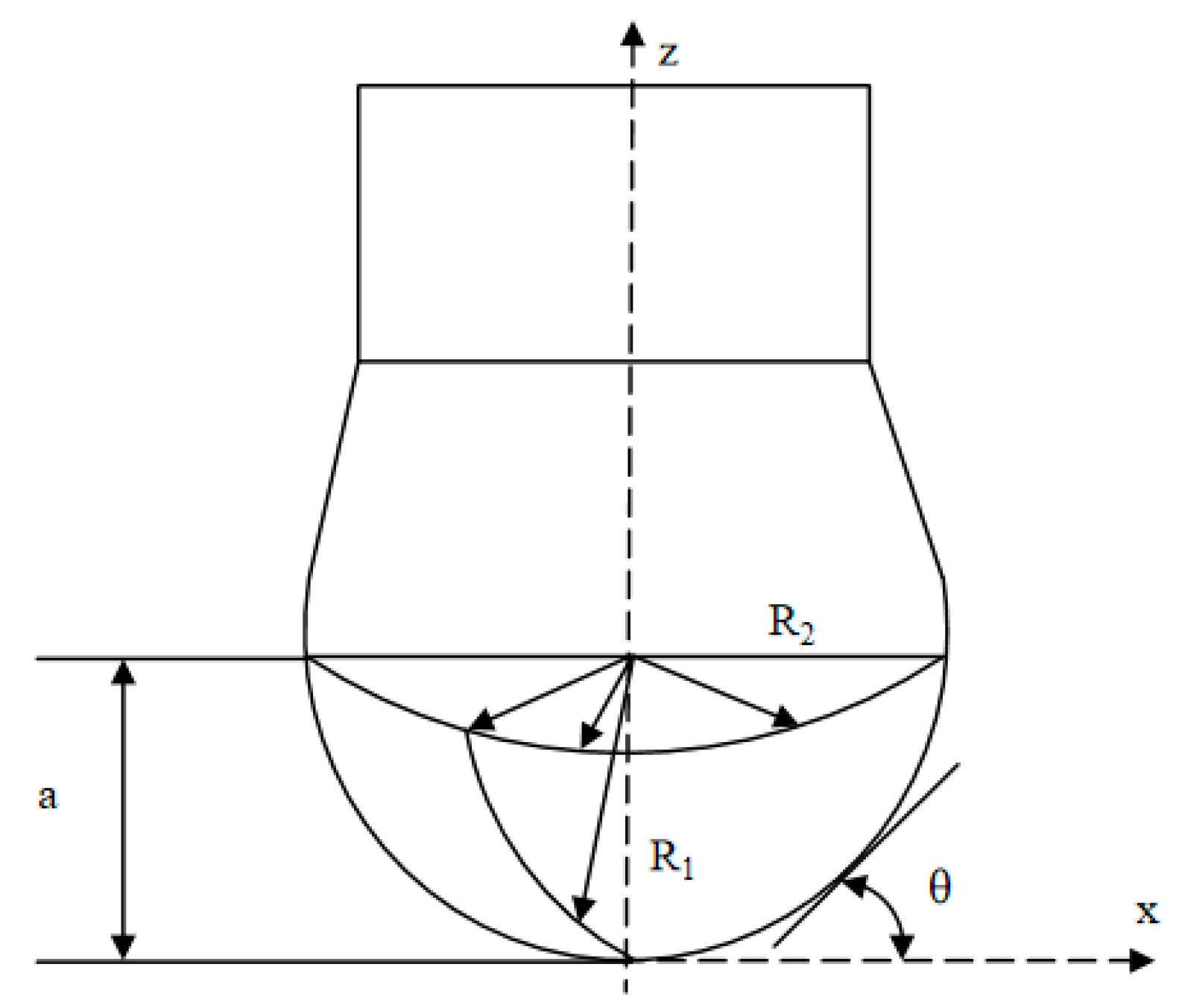

Figure 2 presents the pedant drop geometry.

The pendant drop method involves the determination of the profile of a drop of one liquid suspended in another liquid at mechanical equilibrium, Laplace’s equation also need to be considered [

31,

32]. The profile of a drop of liquid suspended in another is determined by gravity and surface forces. The drop profile to the interfacial tension through a nonlinear differential equation which is given as equation (2) below:

Where a is the radius of curvature at the apex of the drop, x, z are the coordinates defined as in Figure 9 above, and R

1 is the radius of curvature at the point with coordinates (x, z).

can be defined geometrically as equation (3) below:

We also consider the force on drop geometry. The most significant force acting on the drop is the force of gravity, which pulls the drop downwards. This force is proportional to the mass of the drop and the strength of the gravitational field.

Due to the surface tension, the tensile force is acting on the entire surface of the droplet. Let the pressure difference of outside and inside pressure be ΔP. ΔP is known as the Laplace pressure. Tensile force due to surface tension around the circumference of the water droplet. In physics, the Young–Laplace equation is a nonlinear partial differential equation that describes the equilibrium pressure difference sustained across the interface between two static fluids, such as water and air, due to the phenomenon of surface tension.

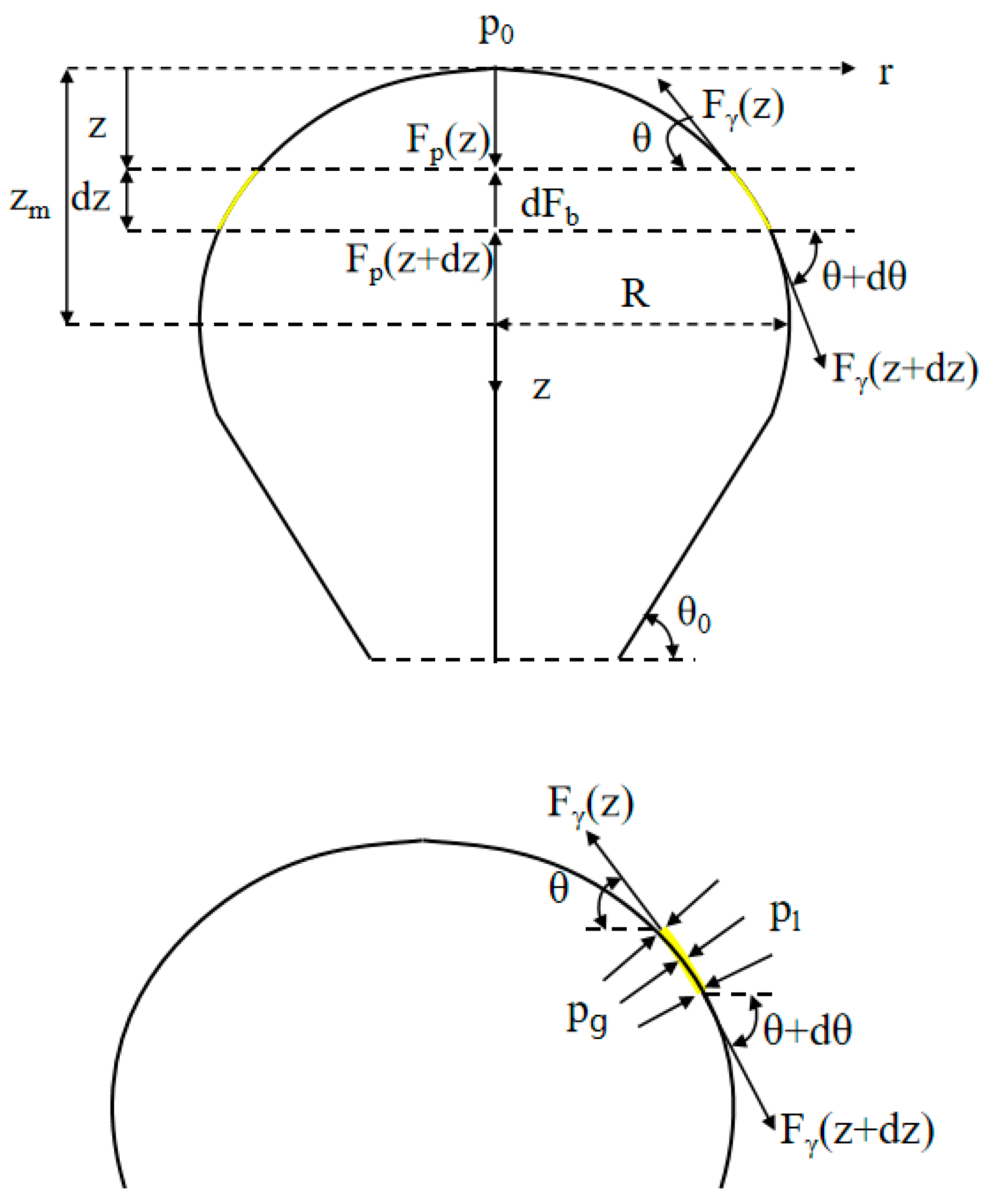

Figure 3 presents a schematic view of effective forces along the vertical axis.

Modification of the Young–Laplace equation can be used [

33,

34,

35,

36]. The force balance equation is written along the vertical direction on a slice of a bubble as equation (4) below:

and

are respectively forces due to buoyancy, pressure and surface tension. In this study, we mainly consider the state of liquid flowing into the air surface tension. Equation (4) can be simplified as equation (5) below:

The individual elements of equation (6) include the buoyancy force,

the force due to pressure difference as equation (7) below:

and the force due to the surface tension

as equation (8) below:

where

is the pressure difference between gravity

, and outside pressure caused by air

. We can obtain

is inside pressure,

is outside pressure. Different pressure will effect the shape of the geometry.

2.2. HG-MEX system

By analyzing the characteristics of the system, we get the appropriate construction method in HG-MEX system. The rotating in HG-MEX system are around vertical axis, the centrifugal force will act perpendicular to the axis of rotation, while the gravitational force will act vertically downwards. In this case, the resultant acceleration will be directed diagonally downwards and away from the axis of rotation. The acceleration that acts on the modeling surface is gravitational acceleration:, centrifugal acceleration : with resultant acceleration :.

The centrifugal acceleration

[m/s

2] is expressed as shown in equation (9):

where

[m] is the distance from the center of the rotating body to build surface and

[rad/s] is the rotational speed. The rotation speed of

[min

-1] is expressed as shown in equation (10):

The

[m/s

2] is resultant acceleration, expressed as shown in equation (11):

where centrifugal acceleration is

[m/s

2] and

[m/s

2] is the natural gravitational acceleration (1G) . We can get the relationship between the resultant acceleration and rotation speed N [min

-1]. Once a suitable rotational speed is determined, the device can be designed with appropriate components, such as a motor or other power source, to achieve the desired rotation.

3. Experiment and numerical study of high gravity

3.1. HG-MEX system development

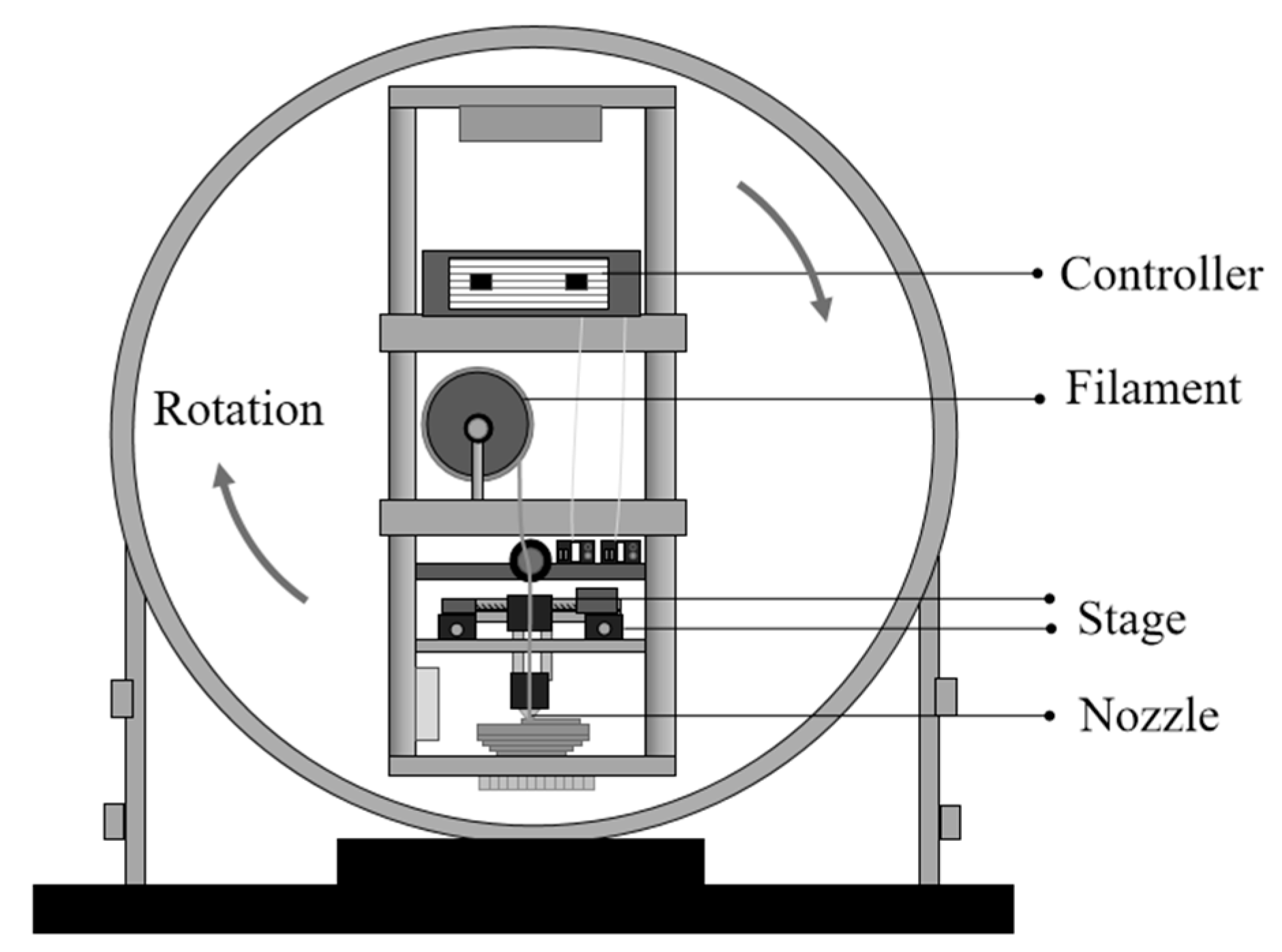

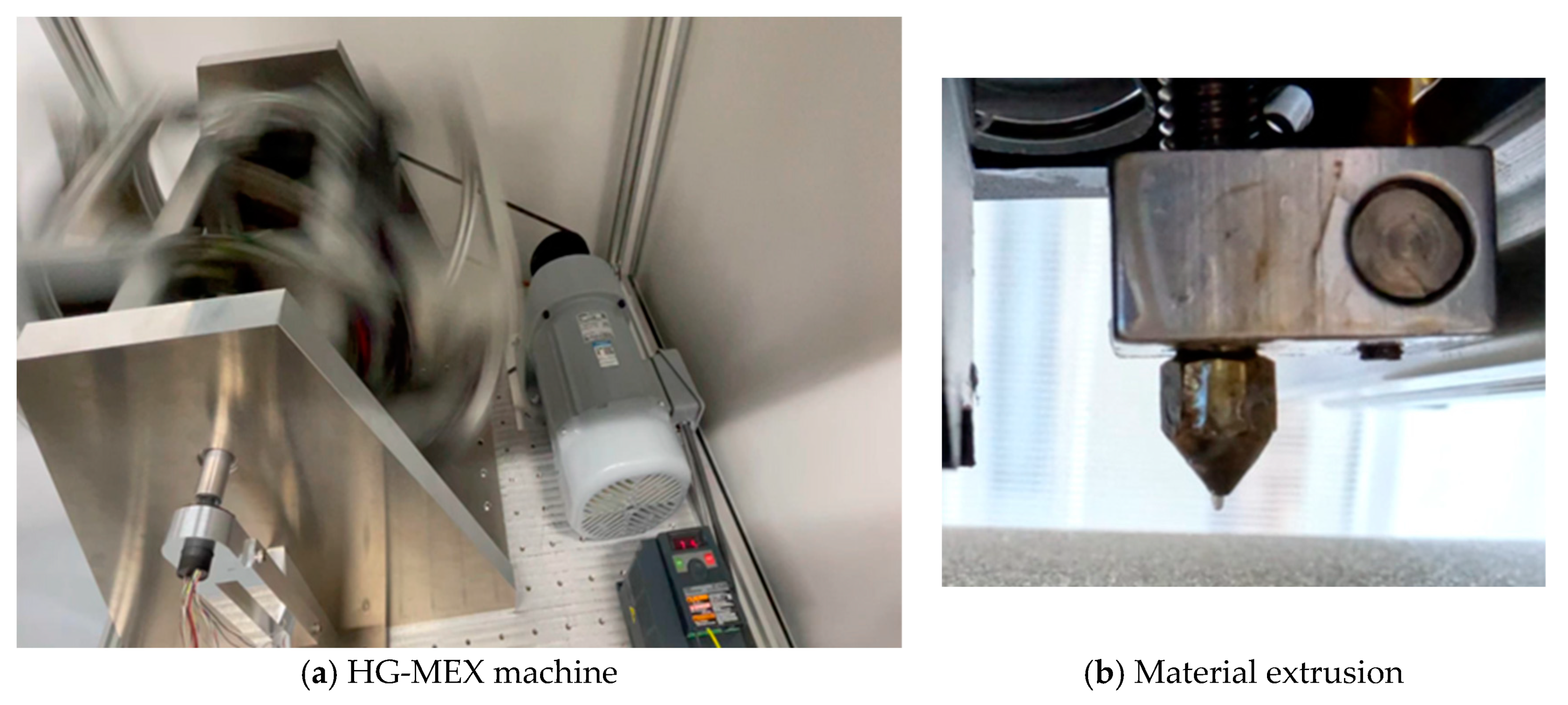

Conducting MEX under high-gravity conditions can provide insights into how materials behave under extreme conditions, which can have important implications for fields such as materials science, engineering, and space exploration. Many machine-tool builders already have excellent techniques for rotating a large-mass object in high speed with high accuracy, the combined machine of a centrifuge and a MEX unit would be a preferable design from the economical viewpoint. This can be done using a centrifuge, which spins the materials at high speeds to create a force equivalent to several times earth's gravity. The special apparatus that was built to conduct MEX under high-gravity conditions is designed to simulate the effects of high gravity on the materials being studied. It is important to note that the specific features and details of the 3D model image would depend on the particular study and the design of the HG-MEX system.

Figure 4 presents the image of the HG-MEX system developed in this study.

3.2. Polymer science and material extrusion conditions

In this research, the HG-MEX system is carried out. The mechanical properties of Polymer (PLA) filament as shown in

Table 1.

The nozzle is indeed a key component in fluid systems, and it plays a critical role in the material extrusion process in additive manufacturing. In the material extrusion process, the filament is fed into the extruder and melted by the heated nozzle. The molten material is then extruded through the nozzle. We focus on the gravity effect about the material extrude from the nozzle, the nozzle size and others factors in this additive manufacturing study are normally. The 0.4mm nozzle size used in this study is a common size.

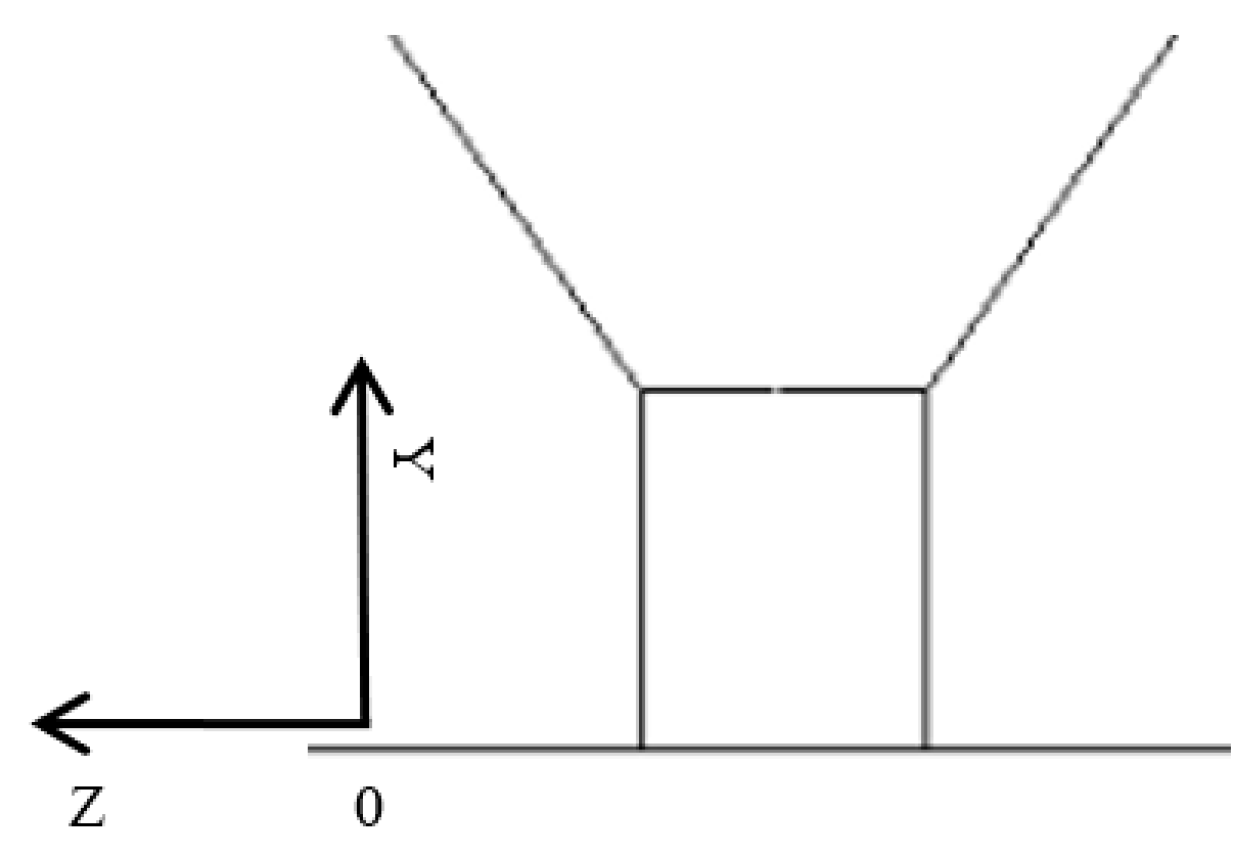

Figure 5 presents the schematics of the material extrusion system.

The coordinate position of the material extrusion system is typically defined using a cartesian coordinate system, where each point in space is represented by a set of three values: X, Y, and Z. The Y and Z values correspond to the horizontal position of the nozzle, while the Y value corresponds to the height of the nozzle above the center of the nozzle, Z value corresponds to the length from the center of the nozzle.

Figure 6. presents the defining the coordinate position of the nozzle.

4. Results and discussion

4.1. Behaviour of material extrusion

In high gravity field, the filament is fed into a heated extruder, the plastic and then extrudes it through a nozzle. The high gravity can increase the forces acting on the molten plastic, which can affect the material properties such as extrusion rate, and surface tension of the material. By changing the working conditions, it is possible to achieve high-quality products with additive manufacturing technology.

Figure 7 presents the experiment of the material extrusion process.

In a high gravity field, extruded materials can experience greater compression and deformation, which can affect their mechanical properties such as strength, toughness, and ductility. This can result in a number of observable phenomena, such as the gravitational field affects the flow of fluid. This means that the geometry is affected by high gravity material extrusion system.

4.2. Filament fabrication by different gravity

By centrifugal acceleration, we can obtain high gravity material extrusion such as from 1G to 32G. We obtained the material extrusion conditions under different gravitational fields.

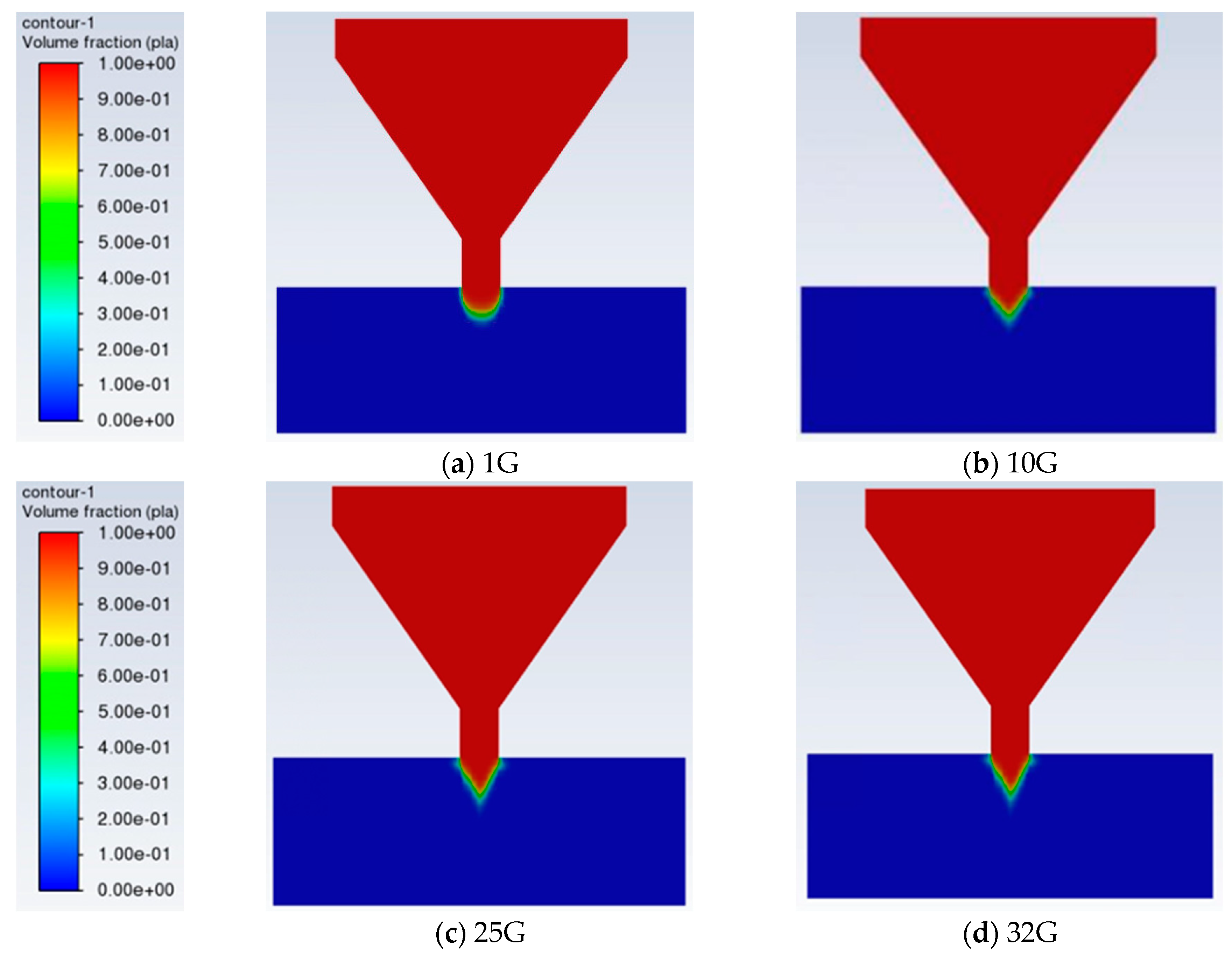

Figure 8 presents the different gravity material extrusion.

Different models of material extrusion under different gravitational conditions can indeed have different performances. We can obtain that from the place of material extrusion out from the nozzle, the material extrusion in high gravity field

Figure 8 (b) overall is smaller in width dimension than 1G gravity field

Figure 8 (a).

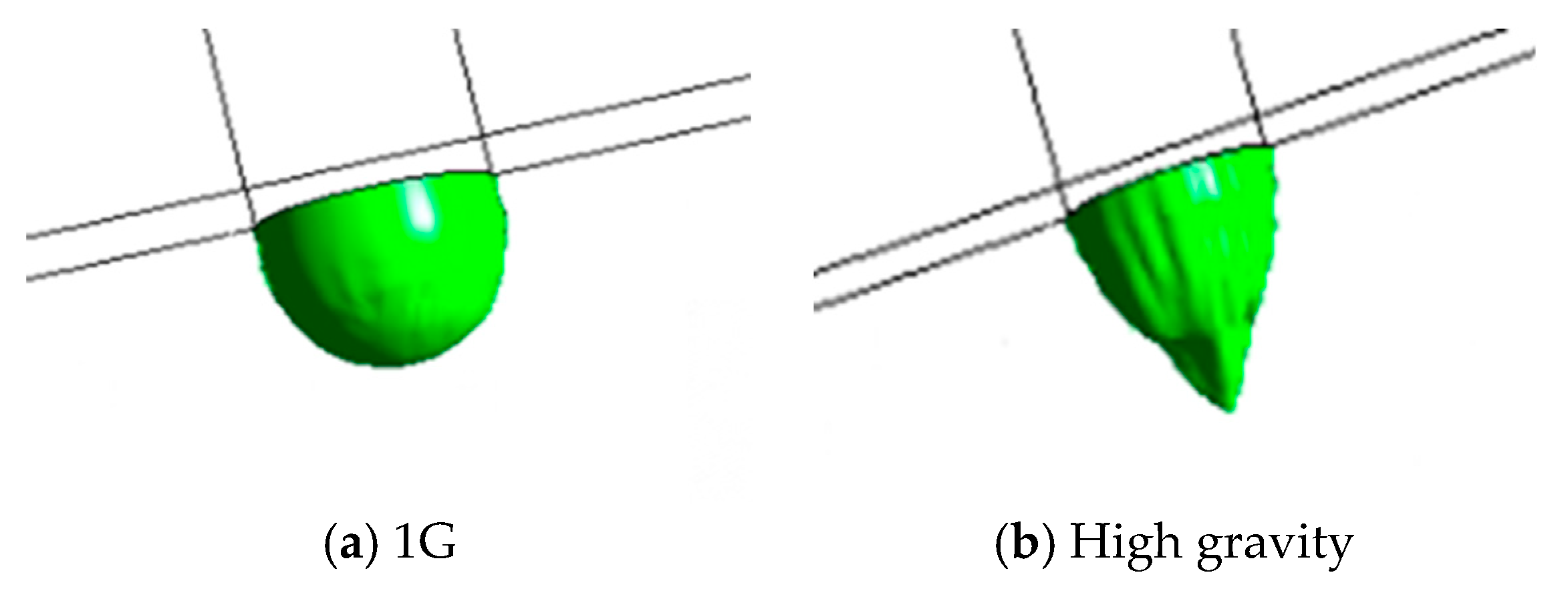

Figure 9. presents evolution of the extruded material for simulations with different gravity.

The evolution of extruded material in simulations can be affected by changes in gravity. When simulating material extrusion under different gravitational conditions, the behavior of the material may due to variations in the forces acting on it. Surface tension and force on surface different caused by gravity may affect the performance. In a low gravity field such as

Figure 9 (a), the extruded material may experience less compression and have less tendency to sag or droop. On the other hand, in a high gravity field, the extruded material may experience stronger compression and be more likely to sag or droop. This can cause the extruded material to be more pliable and easier to shape. The compression can also cause the material to be more dense and stronger. In a low gravity field, the extruded material may form into a more spherical shape due to the absence of gravity pulling it down, In a high gravity field such as

Figure 9 (b),

Figure 9 (c),

Figure 9 (d), the material may become more flattened or elongated due to the stronger forces acting on it. When gravity increases, this phenomenon will become more.

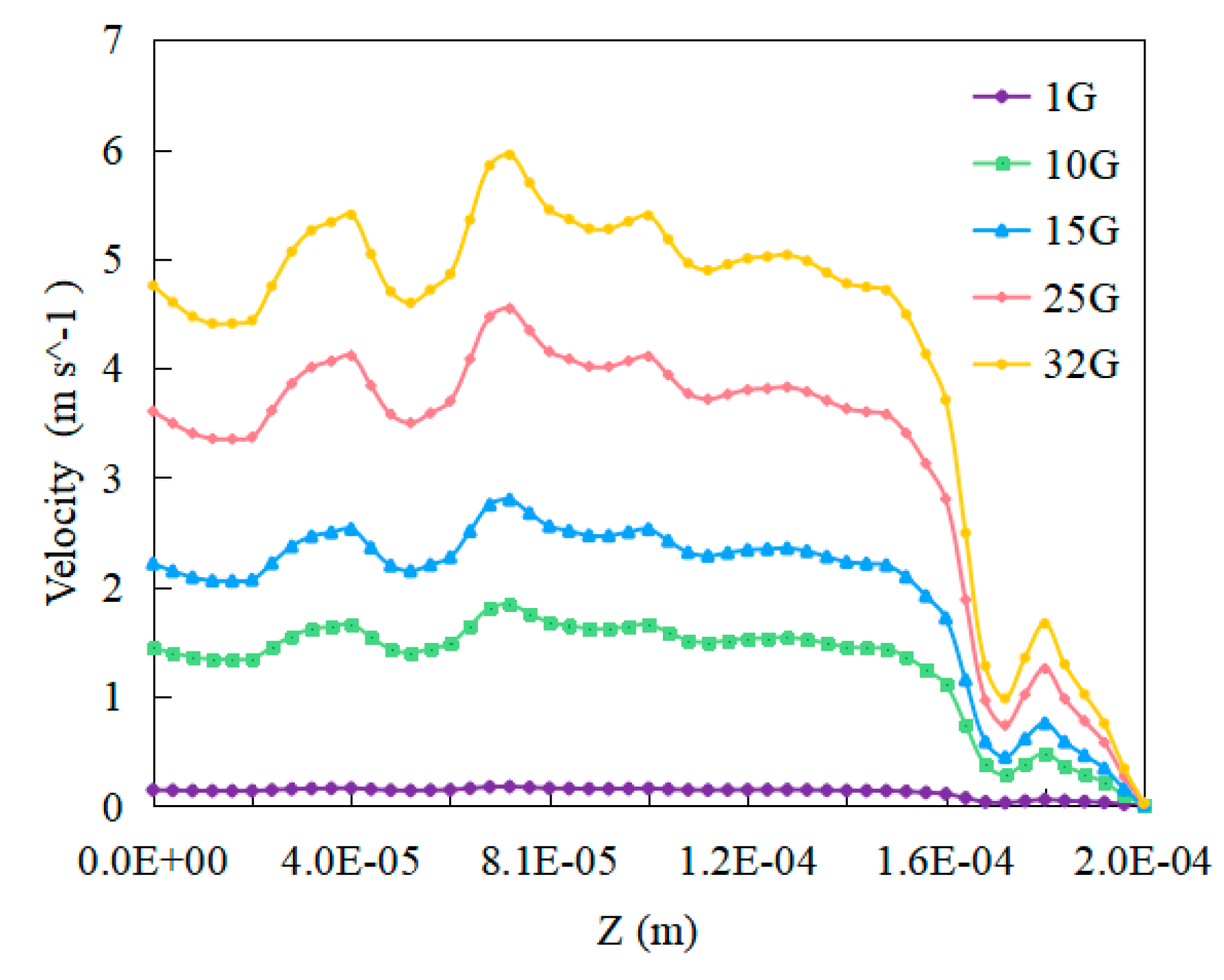

Figure 10. presents material extrusion velocity performance with different gravity fields.

By evaluating the comprehensive factors of material extrusion in a high gravity field, such as the extrusion velocity and pressure, it is possible to achieving the desired material process. The performance of material extrusion velocity can be affected by changes in gravity fields. In a low gravity field, the material extrusion velocity be lower compared to a high gravity environment due to reduced gravitational forces acting on the extruded material. In a high gravity field, the material extrusion velocity higher due to the increased gravitational forces acting on the extruded material. This can allow for faster and more efficient extrusion. We obtained the material flow velocity in the center of the extrusion, 1G velocity is about 0.15 m/s2, 10G velocity is about 1.45 m/s2, 15G velocity is about 2.21 m/s2, 15G velocity is about 3.61 m/s2, 25G velocity is about 4.75 m/s2. When gravity increases, the velocity become higher, such as from 10G to 15G, the ratio of increased velocity is about 52.41%, from 25G to 32G, the ratio of decreased size is about 31.58%. When gravity increases, The the ratio of decreased size become smaller when gravity increases. In a high gravity field, the velocity reach peaks in some places. The velocity at different Z positions are different in the material extrusion process, and this influence the performance of different gravitational material extrusion process. The velocity trend of high gravity different affect the different performance of the material extrusion. Through the evaluation of the comprehensive factors of material extrusion in high gravity field, the material properties can be better obtained.

5. Conclusion

In this work, the polymer characteristics have evaluated in HG-MEX. By analyzing the interplay between polymer behavior and gravity, we provided insights into the effects of high gravity on extrusion processes, including filament flow, material deposition, and resulting fabrication characteristics.

The established numerical study in high gravity material extrusion in additive manufacturing is a meaningful and valuable approach to improving the quality and efficiency of the process. The performance of material extrusion velocity can be affected by changes in gravity fields. In a high gravity field, the material extrusion velocity higher due to the increased gravitational forces acting on the extruded material. The overall printing quality of high gravity field is more precise.

This work is unique in the incorporation of material surface characteristics to represent the performance and contact with the polymer science in additive manufacturing. The findings presented herein contribute to the broader understanding of polymer science and its practical implications for HG-MEX under varying gravitational conditions.

Acknowledgments

This paper is based on results obtained from a project of Kanagawa Institute of Industrial Science and Technology (KISTEC).

References

- Rajan K, Samykano M, Kadirgama K, et al. Fused deposition modeling: Process, materials, parameters, properties, and applications[J]. The International Journal of Advanced Manufacturing Technology 2022, 120, 1531–1570. [Google Scholar] [CrossRef]

- Cleeman J, Bogut A, Mangrolia B, et al. Scalable, flexible and resilient parallelization of fused filament fabrication: Breaking endemic tradeoffs in material extrusion additive manufacturing[J]. Additive Manufacturing 2022, 56, 102926. [Google Scholar] [CrossRef]

- Jiang J, Xu X, Stringer J. Optimization of process planning for reducing material waste in extrusion based additive manufacturing[J]. Robotics and Computer-Integrated Manufacturing 2019, 59, 317–325. [Google Scholar] [CrossRef]

- Vyavahare S, Teraiya S, Panghal D, et al. Fused deposition modelling: a review[J]. Rapid Prototyping Journal 2020, 26, 176–201. [Google Scholar] [CrossRef]

- Goh G D, Yap Y L, Tan H K J, et al. Process–structure–properties in polymer additive manufacturing via material extrusion: A review[J]. Critical Reviews in Solid State and Materials Sciences 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Romanczuk-Ruszuk E, Sztorch B, Pakuła D, et al. 3D Printing Ceramics—Materials for Direct Extrusion Process[J]. Ceramics 2023, 6, 364–385. [Google Scholar] [CrossRef]

- Serdeczny M P, Comminal R, Pedersen D B, et al. Numerical simulations of the mesostructure formation in material extrusion additive manufacturing[J]. Additive Manufacturing 2019, 28, 419–429. [Google Scholar] [CrossRef]

- Comminal R, Serdeczny M P, Pedersen D B, et al. Numerical modeling of the strand deposition flow in extrusion-based additive manufacturing[J]. Additive Manufacturing 2018, 20, 68–76. [Google Scholar] [CrossRef]

- Kattinger J, Ebinger T, Kurz R, et al. Numerical simulation of the complex flow during material extrusion in fused filament fabrication[J]. Additive Manufacturing 2022, 49, 102476. [Google Scholar] [CrossRef]

- Bikas H, Stavropoulos P, Chryssolouris G. Additive manufacturing methods and modelling approaches: a critical review[J]. The International Journal of Advanced Manufacturing Technology 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Nzebuka G C, Ufodike C O, Rahman A M, et al. Numerical modeling of the effect of nozzle diameter and heat flux on the polymer flow in fused filament fabrication[J]. Journal of Manufacturing Processes 2022, 82, 585–600. [Google Scholar] [CrossRef]

- Phan D D, Horner J S, Swain Z R, et al. Computational fluid dynamics simulation of the melting process in the fused filament fabrication additive manufacturing technique[J]. Additive Manufacturing 2020, 33, 101161. [Google Scholar] [CrossRef]

- Moghtadernejad S, Lee C, Jadidi M. An introduction of droplet impact dynamics to engineering students[J]. Fluids 2020, 5, 107. [Google Scholar] [CrossRef]

- Sontti S G, Atta A. CFD analysis of microfluidic droplet formation in non–Newtonian liquid[J]. Chemical Engineering Journal 2017, 330, 245–261. [Google Scholar] [CrossRef]

- Cai Z, Song Y. Implementing Contact Angle Hysteresis in Moving Mesh-Based Two-Phase Flow Numerical Simulations[J]. ACS omega 2021, 6, 35711–35717. [Google Scholar] [CrossRef]

- Mohammadi-Khanaposhtani M, Kazemzadeh Y, Daneshfar R. Positive coupling effect in gas condensate flow: Role of capillary number, Scheludko number and Weber number[J]. Journal of Petroleum Science and Engineering 2021, 203, 108490. [Google Scholar] [CrossRef]

- Placone J K, Engler A J. Recent advances in extrusion-based 3D printing for biomedical applications[J]. Advanced healthcare materials 2018, 7, 1701161. [Google Scholar] [CrossRef]

- Sontti S G, Atta A. Numerical insights on controlled droplet formation in a microfluidic flow-focusing device[J]. Industrial & Engineering Chemistry Research 2019, 59, 3702–3716. [Google Scholar]

- Knoche S, Vella D, Aumaitre E, et al. Elastometry of deflated capsules: Elastic moduli from shape and wrinkle analysis[J]. Langmuir 2013, 29, 12463–12471. [Google Scholar] [CrossRef]

- Lei M, Wei Q, Li M, et al. Numerical Simulation and Experimental Study the Effects of Process Parameters on Filament Morphology and Mechanical Properties of FDM 3D Printed PLA/GNPs Nanocomposite[J]. Polymers 2022, 14, 3081. [Google Scholar] [CrossRef]

- Keller J B, Miksis M J. Surface tension driven flows[J]. SIAM Journal on Applied Mathematics 1983, 43, 268–277. [Google Scholar] [CrossRef]

- Xu X, Jagota A, Peng S, et al. Gravity and surface tension effects on the shape change of soft materials[J]. Langmuir 2013, 29, 8665–8674. [Google Scholar] [CrossRef]

- Ramshaw, C. The opportunities for exploiting centrifugal fields[J]. Heat recovery Systems and CHP 1993, 13, 493–513. [Google Scholar] [CrossRef]

- Scott R, F. Centrifuge model testing at Caltech[J]. International Journal of Soil Dynamics and Earthquake Engineering 1983, 2, 188–198. [Google Scholar] [CrossRef]

- Koike R, AlKhaled A, Kashimoto T. Basic study for lunar regolith powder bed fusion in high gravity[J]. CIRP Annals 2023.

- Hua J, Lou J. Numerical simulation of bubble rising in viscous liquid[J]. Journal of Computational Physics 2007, 222, 769–795. [Google Scholar] [CrossRef]

- Sharaf D M, Premlata A R, Tripathi M K, et al. Shapes and paths of an air bubble rising in quiescent liquids[J]. Physics of Fluids 2017, 29, 122104. [Google Scholar] [CrossRef]

- Chatterjee, J. Critical Eotvos numbers for buoyancy-induced oil drop detachment based on shape analysis[J]. Advances in colloid and interface science 2002, 98, 265–283. [Google Scholar] [CrossRef]

- Koike R, Sugiura Y. Metal powder bed fusion in high gravity[J]. CIRP Annals 2021, 70, 191–194. [Google Scholar] [CrossRef]

- Sugiura Y, Koike R. High-gravitational effect on process stabilization for metal powder bed fusion[J]. Additive Manufacturing 2021, 46, 102153. [Google Scholar] [CrossRef]

- Lecacheux L, Sadoudi A, Duri A, et al. The role of Laplace pressure in the maximal weight of pendant drops[J]. Journal of Colloid and Interface Science 2022, 606, 920–928. [Google Scholar] [CrossRef]

- Arashiro E Y, Demarquette N R. Use of the pendant drop method to measure interfacial tension between molten polymers[J]. Materials Research 1999, 2, 23–32. [Google Scholar] [CrossRef]

- Vafaei S, Wen D. Modification of the Young–Laplace equation and prediction of bubble interface in the presence of nanoparticles[J]. Advances in Colloid and Interface Science 2015, 225, 1–15. [Google Scholar] [CrossRef]

- Mhatre S, Simon S, Sjöblom J. Methodology to calculate interfacial tension under electric field using pendent drop profile analysis[J]. Proceedings of the Royal Society A 2019, 475, 20180852. [Google Scholar] [CrossRef] [PubMed]

- Ghassemi H, Panahi S, Kohnsal A R. Solving the Laplace’s equation by FDM and BEM using mixed boundary conditions[J]. American Journal of Applied Mathematics and Statistics 2016, 4, 37–42. [Google Scholar]

- Mo J, Sha J, Li D, et al. Fluid release pressure for nanochannels: the Young–Laplace equation using the effective contact angle[J]. Nanoscale 2019, 11, 8408–8415. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).