2.1. Contact model theory

The discrete element method (DEM) is utilized to simulate the dynamic behaviors of PEEK/CF composite powders. In the DEM simulation, the particles are modeled as discrete entities to describe the dynamics of particle flow. The translation, rotation, and location of the particles can be characterized by Newton's laws of motion, which is described as [

16,

17]:

where mi, ωi, vi, Ii are the mass, angular velocity, translational velocity, and moment of inertia, respectively. Fc,i is the contact force, Mc,i is the contact torque, Ri is the rotation matrix.

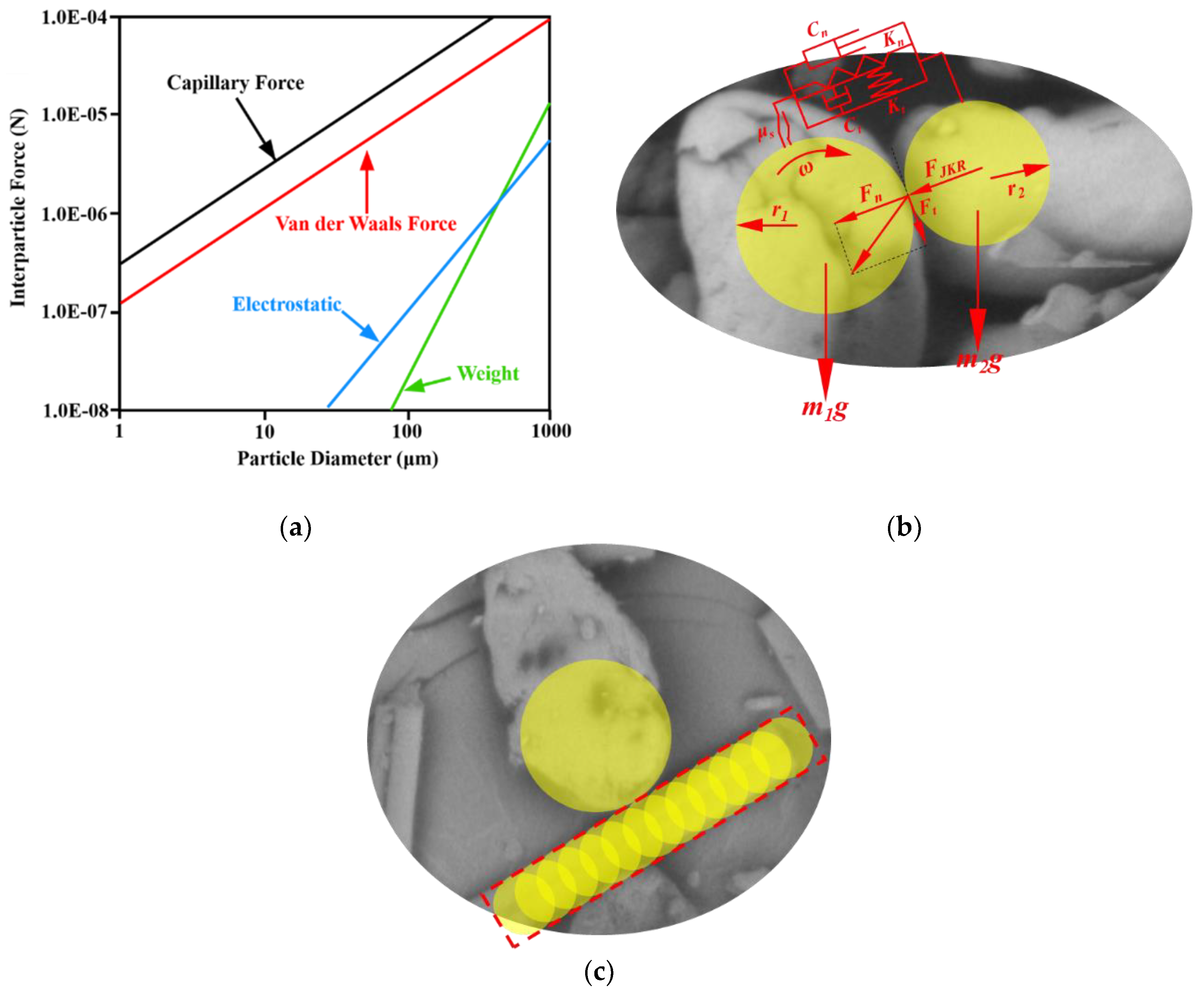

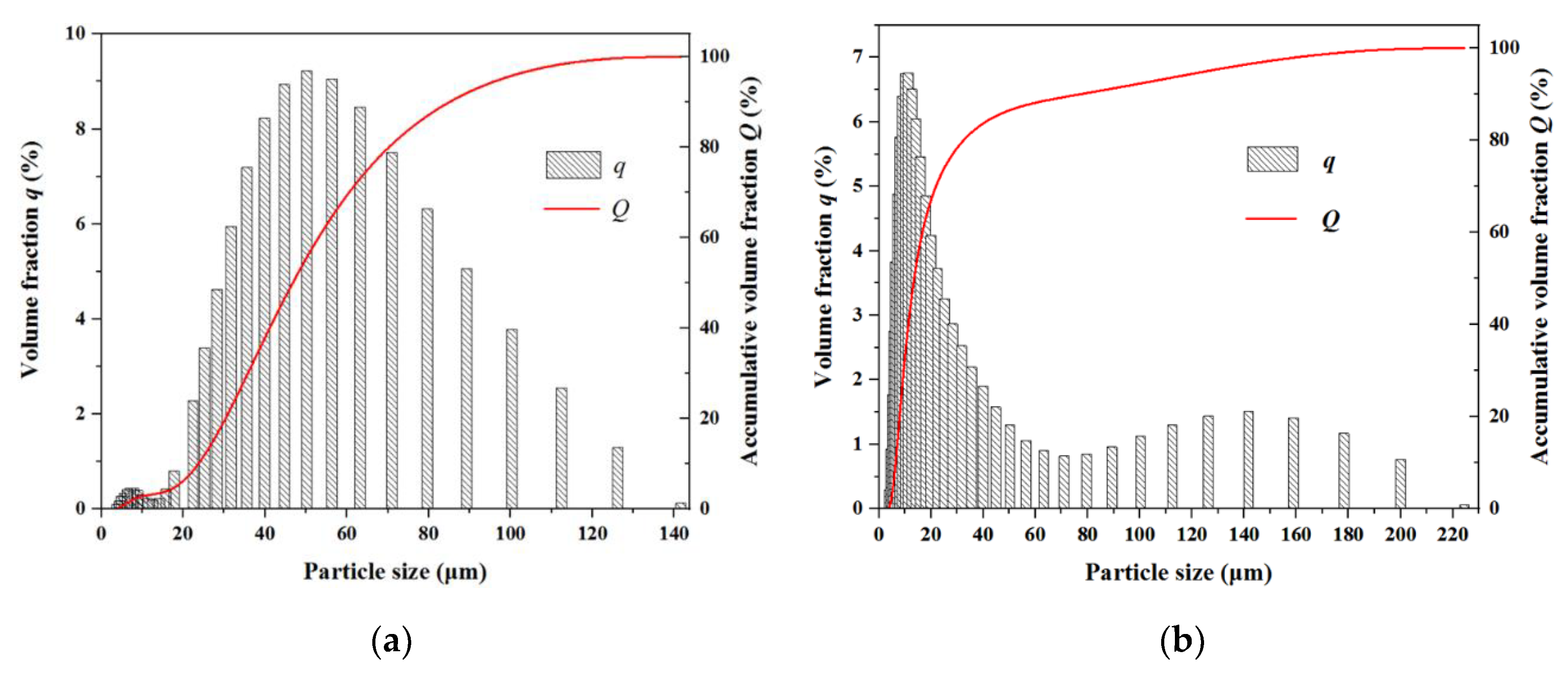

The relationship between cohesive force and particle size is shown in

Figure 1(a) [

18,

19]. It appears that the cohesive forces such as Van der Waals force, electrostatic force, and capillary force are greater than the gravity of particles when the particle size is less than 100 μm, which reduces the powder fluidity and makes inconvenience for the powder-spreading process. In reality, the powder is preheated and dried before the powder-spreading process. Thus, the capillary force can be ignored.

- (1)

Hertz-Mindlin contact model

The rationality of the Hertz-Mindlin contact model has been widely recognized in the particle-related research field [

20,

21]. In order to accurately characterize the stress-strain relationship between particles considering the adhesion, this work adopts Hertz-Mindlin and Johnson Kendall Roberts (JKR) model for polymers and their composite powders, which is implemented using EDEM software. Among them, the Hertz-Mindlin model is the foundation of the DEM method, and the parameter of surface energy in the JKR model can comprehensively characterize the bonding effect between particles caused by the van der Waals force and the electrostatic force [

22]. Therefore, the Hertz Mindlin and JKR models possess universality in the DEM simulation of other thermoplastic polymers and their composite powders.

In the Hertz-Mindlin model, the normal and tangential force components between particles are calculated based on the Hertzian contact theory and the Middlein-Deresiewicz method respectively [

23,

24]. Both normal and tangential force between particles have damping components. The damping coefficient is related to the restitution coefficient [

25].The tangential friction force between particles follows the Coulomb's law of friction, and the rolling friction between particles is computed based on the Contact-Directional-Constant-Torque model [

17,

26].

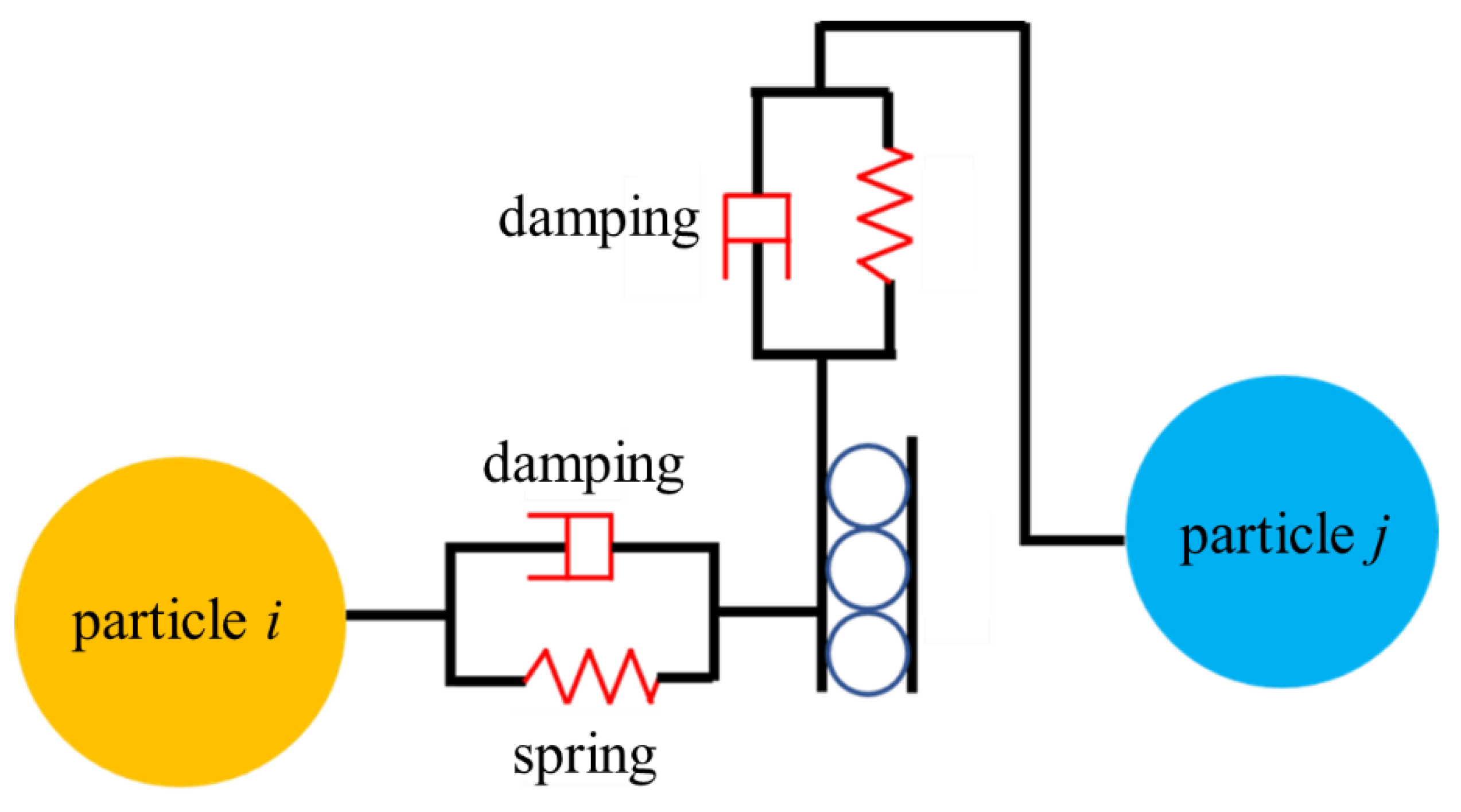

Figure 2 shows the schematic diagram of the Hertz Mindlin model for adjacent particles

i and

j, where the normal contact force on particle i can be expressed as

where

FCN,E is the normal elastic force,

FCN,D is the normal damping force. The

FCN,E is computed based on the Hertz contact theory, which is described as

where

αn is the normal contact displacement (overlap of adjacent particles). The Contact constant

Kn is expressed as

where G is the shear modulus of the particle. r* is the radius of the local curvature. υ is the Poisson's ratio.

The normal damping force

FCN,D between particles is expressed as

where

vre,n is the component of the relative velocity of particle i relative to particle j along the normal direction.

kn is the normal contact stiffness,

β* is the damping coefficient,

m* is the equivalent mass. Therein, the damping coefficient and normal contact stiffness can be expressed as

where

e is the restitution coefficient between particles. The equivalent mass

m* and equivalent curvature radius

r* of particles are respectively described as

where mi and mj represent the masses of adjacent particles i and j. ri and rj are the radiuses of adjacent particles i and j.

The tangential contact force

FCT between adjacent particles can be expressed as

where

FCT,E is the elastic force along the tangential direction,

FCT,D is the damping force along the tangential direction. The tangential elastic force

FCT,E, can be expressed in incremental form as

where

FCT,E,(n-1) is the tangential elastic force of the previous analysis step; ∆

FCT,E is the increment of the tangential elastic force in the current analysis step, which is described as

where

∆αt is the tangential displacement increment,

kt is the tangential spring stiffness, and expressed as

where

vre,t is the relative tangential velocity between particles, ∆

t is the step time. Meanwhile, the tangential damping force between adjacent particles can be expressed as

It is worth noting that the tangential force between adjacent particles is related to the frictional force between particles (

μsFCN,

μs is the static friction coefficient). In the simulation process, the rolling friction can not be ignored, which is achieved by applying a torque to the contact surface of the particles.

where Ri is the distance from the contact point to the mass center, μr is the rolling friction coefficient, ωi is the unit angular velocity vector at the contact point.

- (2)

JKR theory

The Hertz Mindlin with JKR contact model can form an adhesive force contact model between particles, mainly considering the influence of van der Waals forces in the contact area. In this model, the normal elastic contact force between particles is computed based on the JKR theory [

27], including the overlap of particles δ, interaction parameters, and surface energy

γ, which can be described as

where E* is the equivalent Young's modulus, r* is the equivalent curvature radius, α is the contact radius of particles.

It is discovered that several parameters are involved in the aforementioned model, such as static friction coefficient, rolling friction coefficient, restitution coefficient, and surface energy. Therefore, it is essential to carry out the parameter-calibration work through the material characterization.

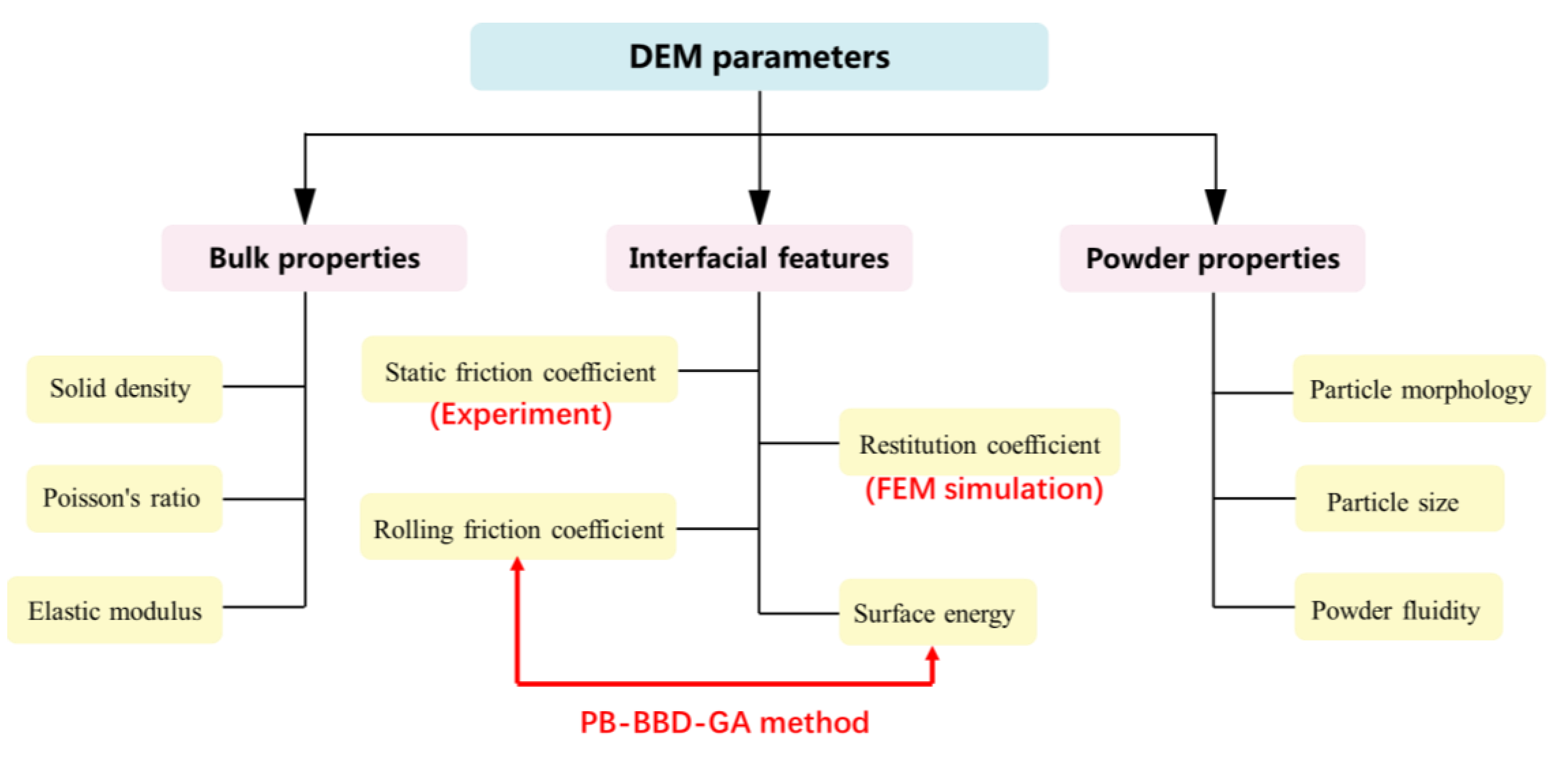

2.2. Parameter classification of the Discrete Element Model

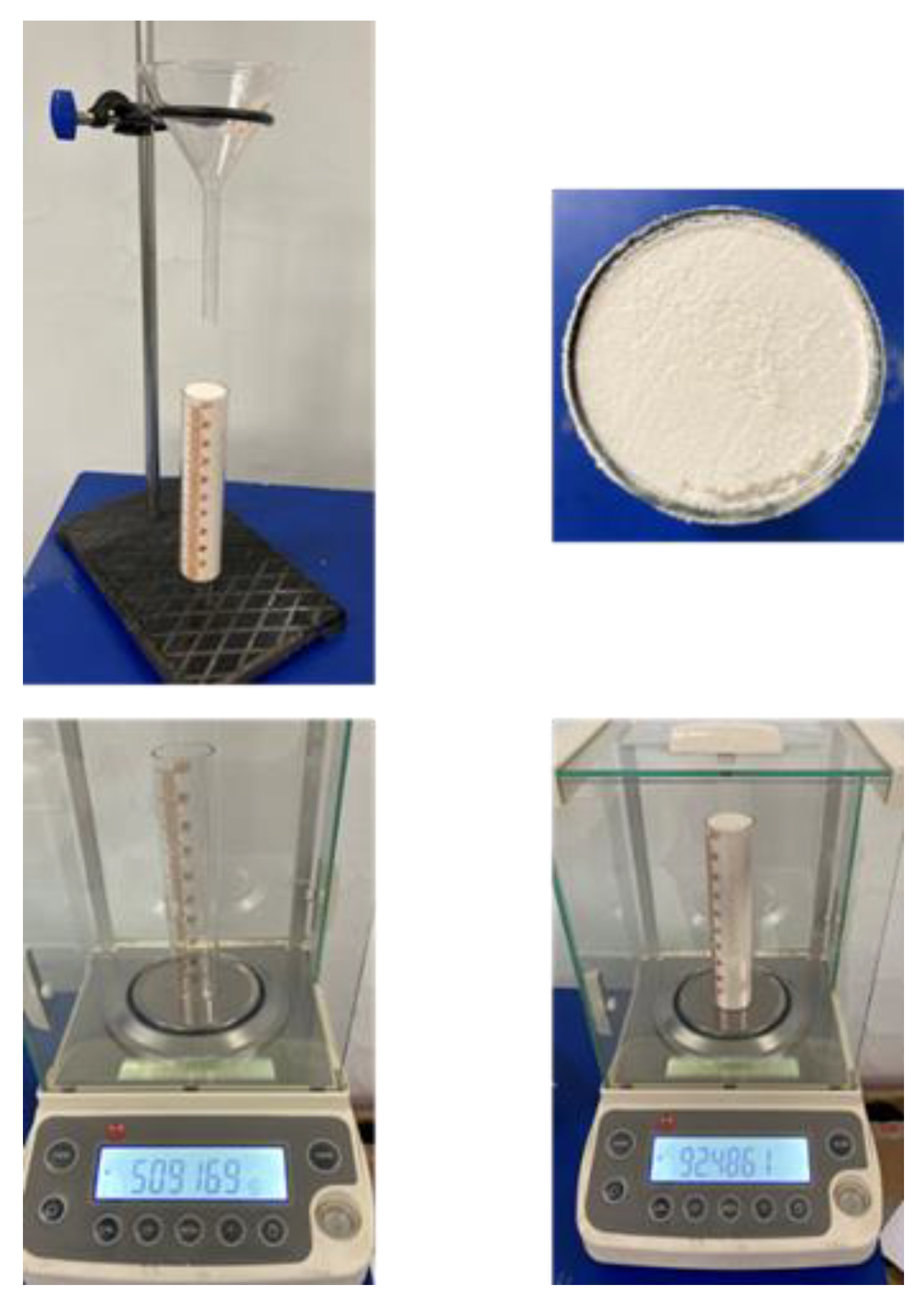

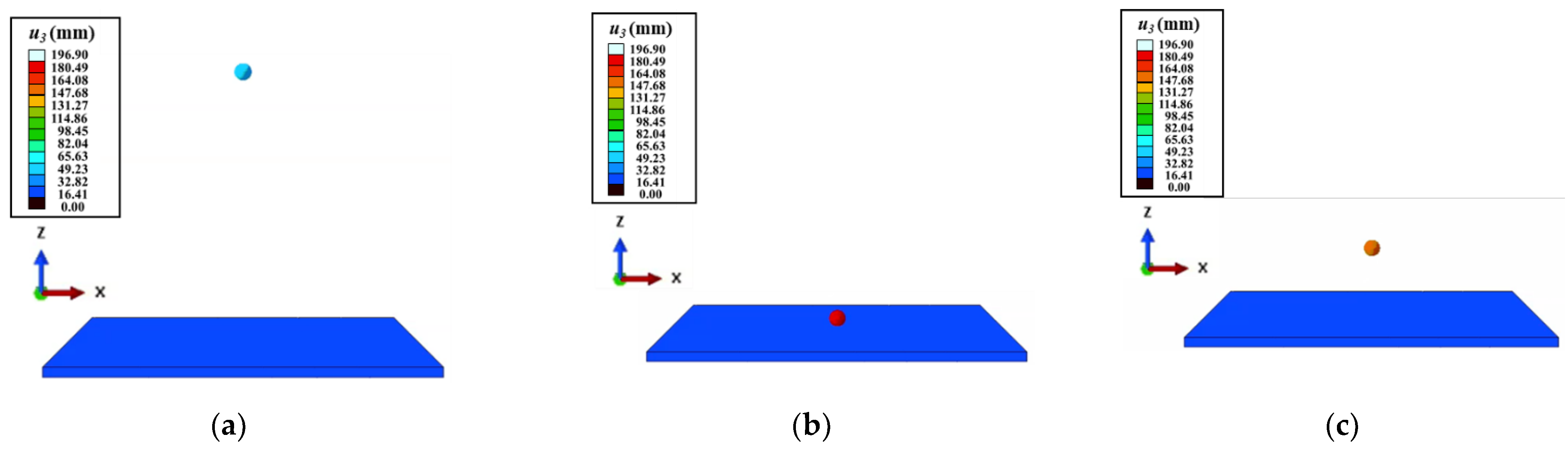

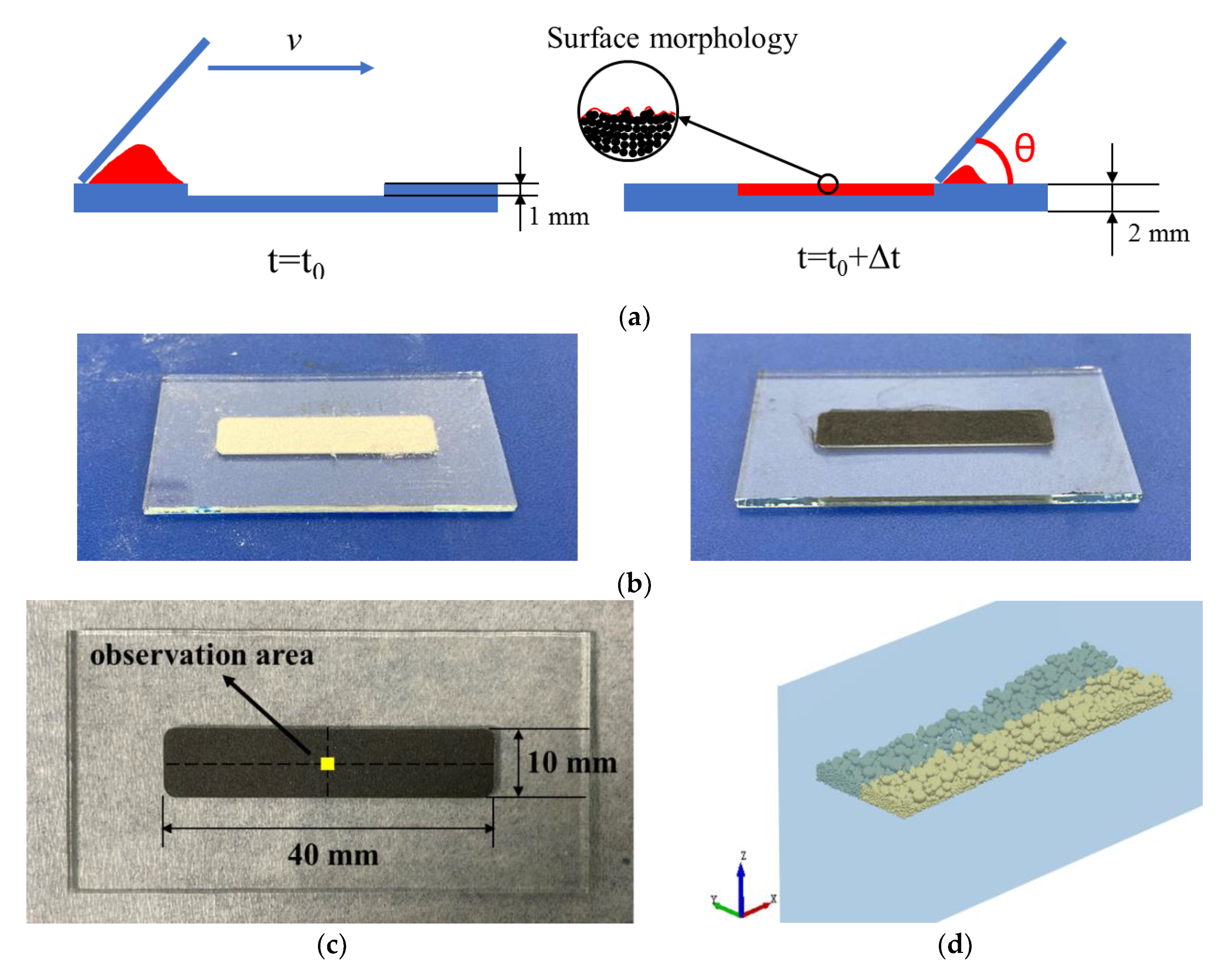

The first step of the DEM simulation is to calibrate numerous parameters through the comprehensive material characterization.

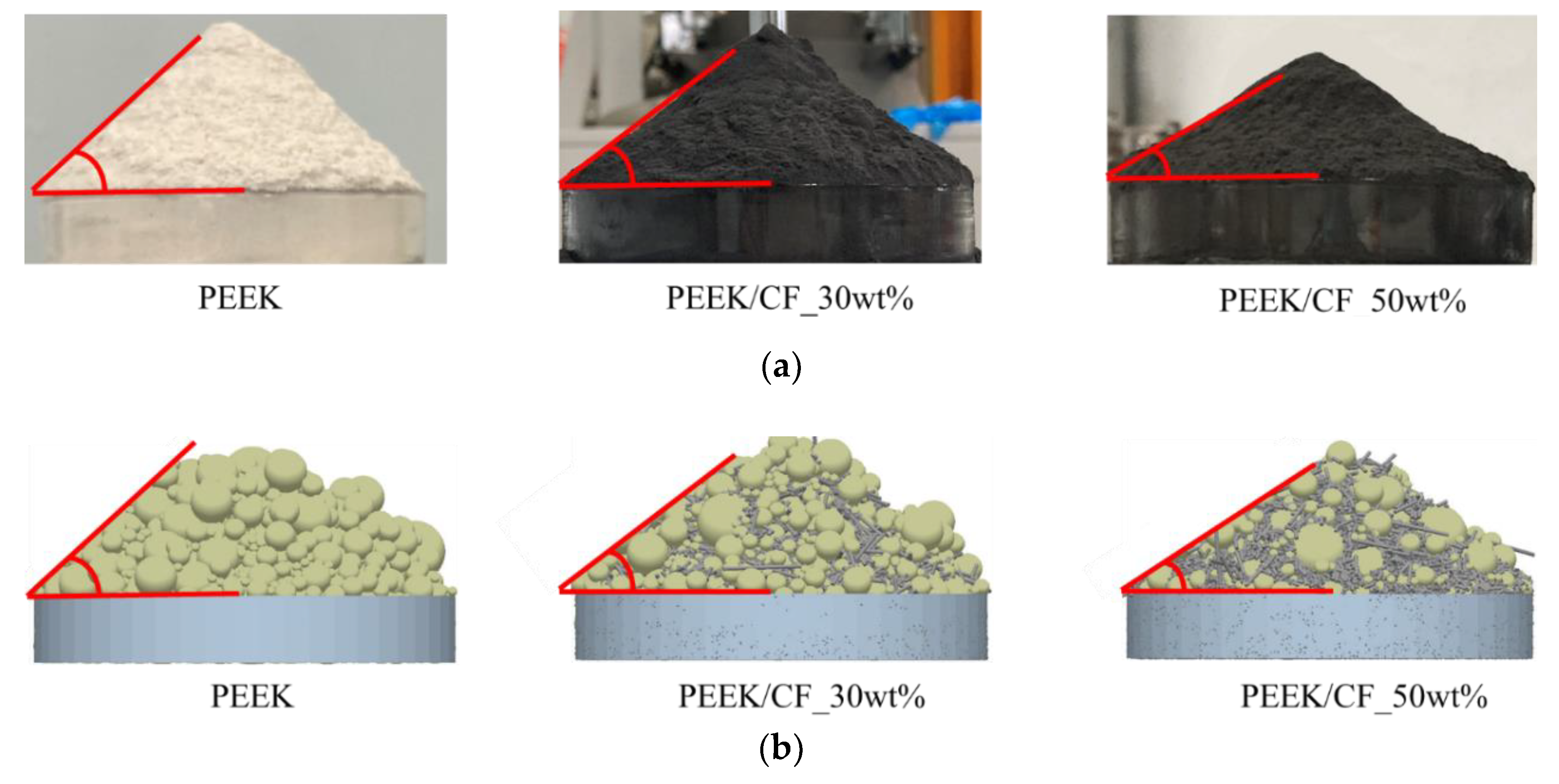

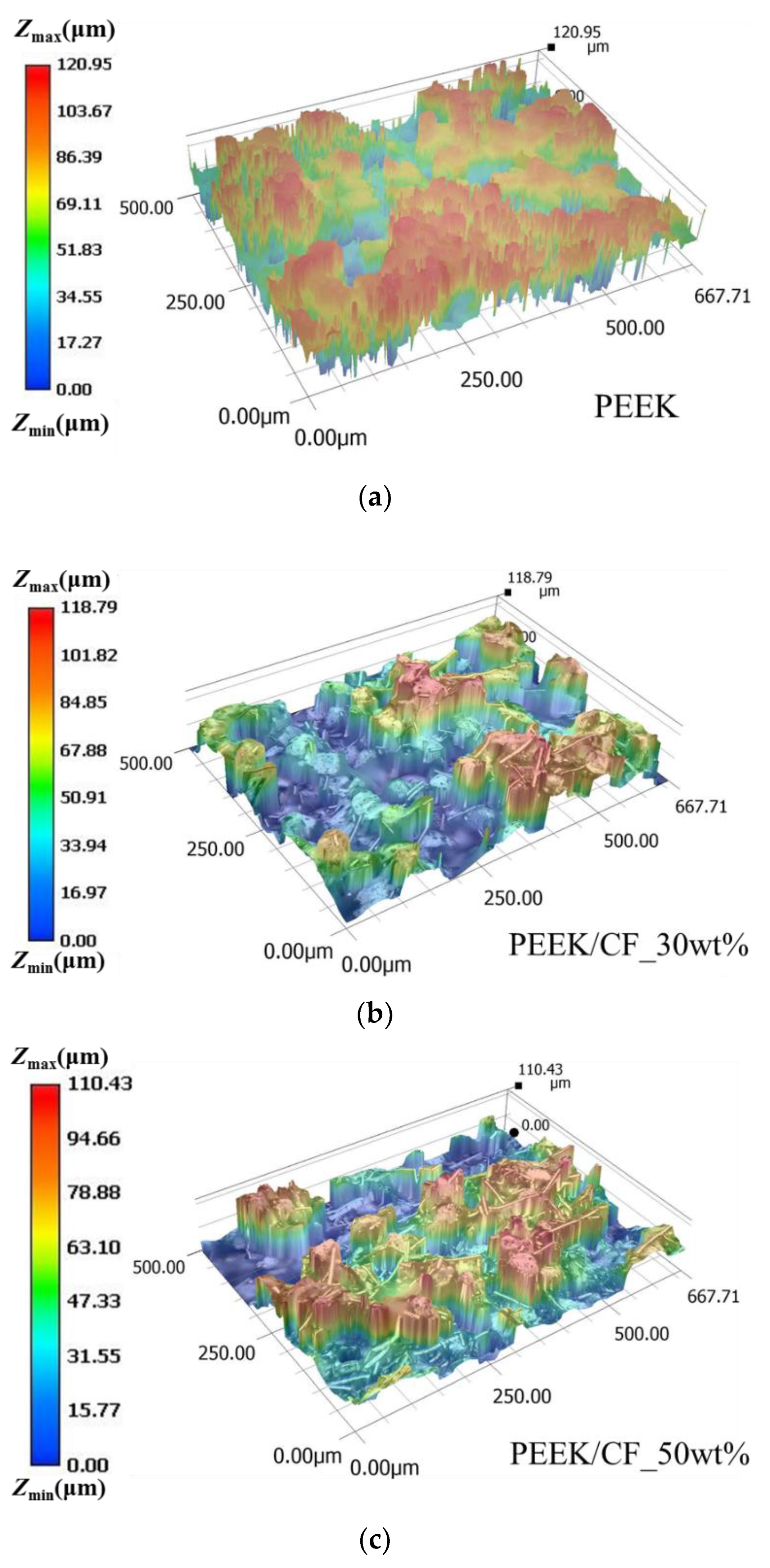

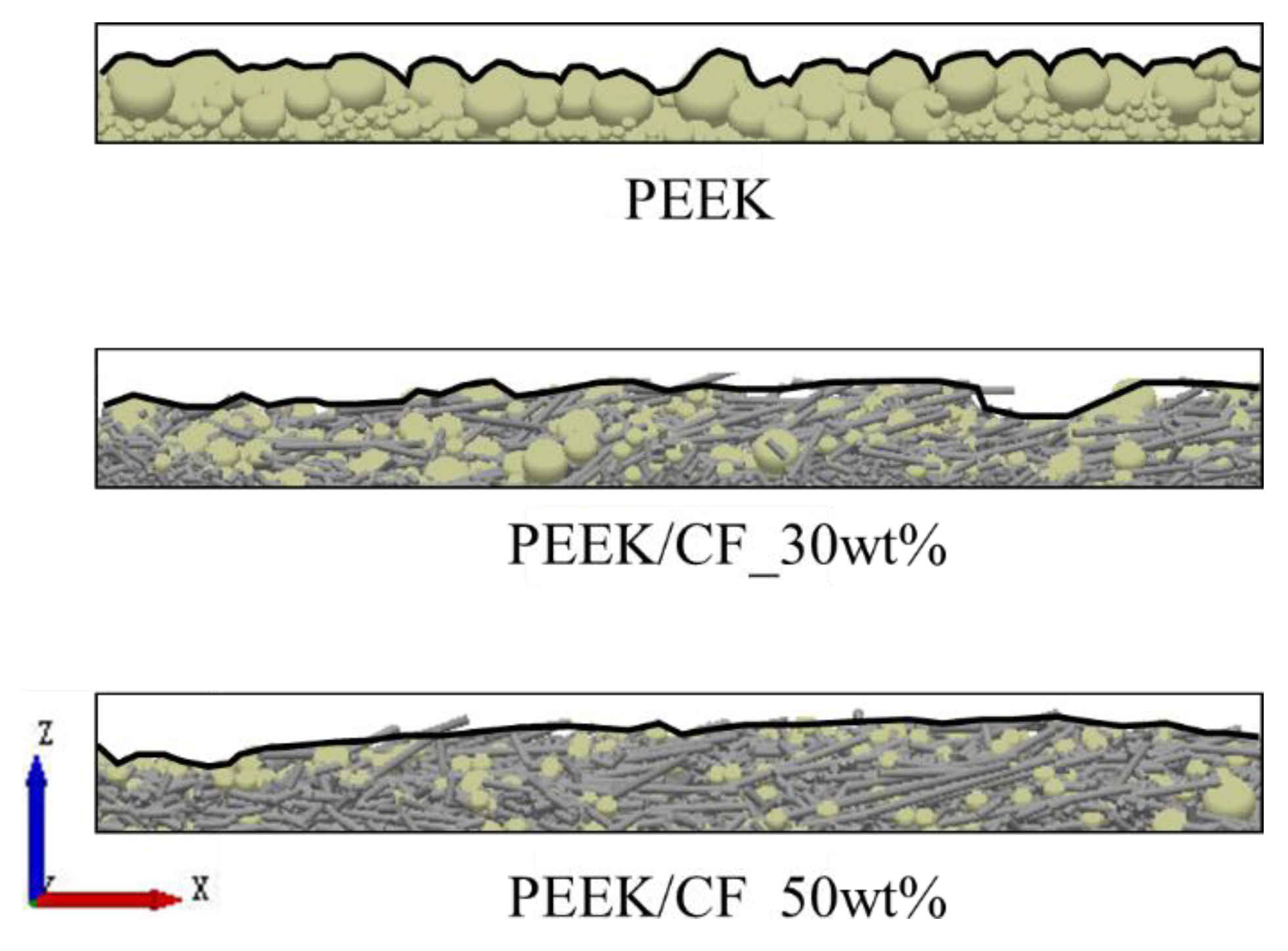

Figure 3 shows the parameters involved in the DEM model, which can be divided into three categories.

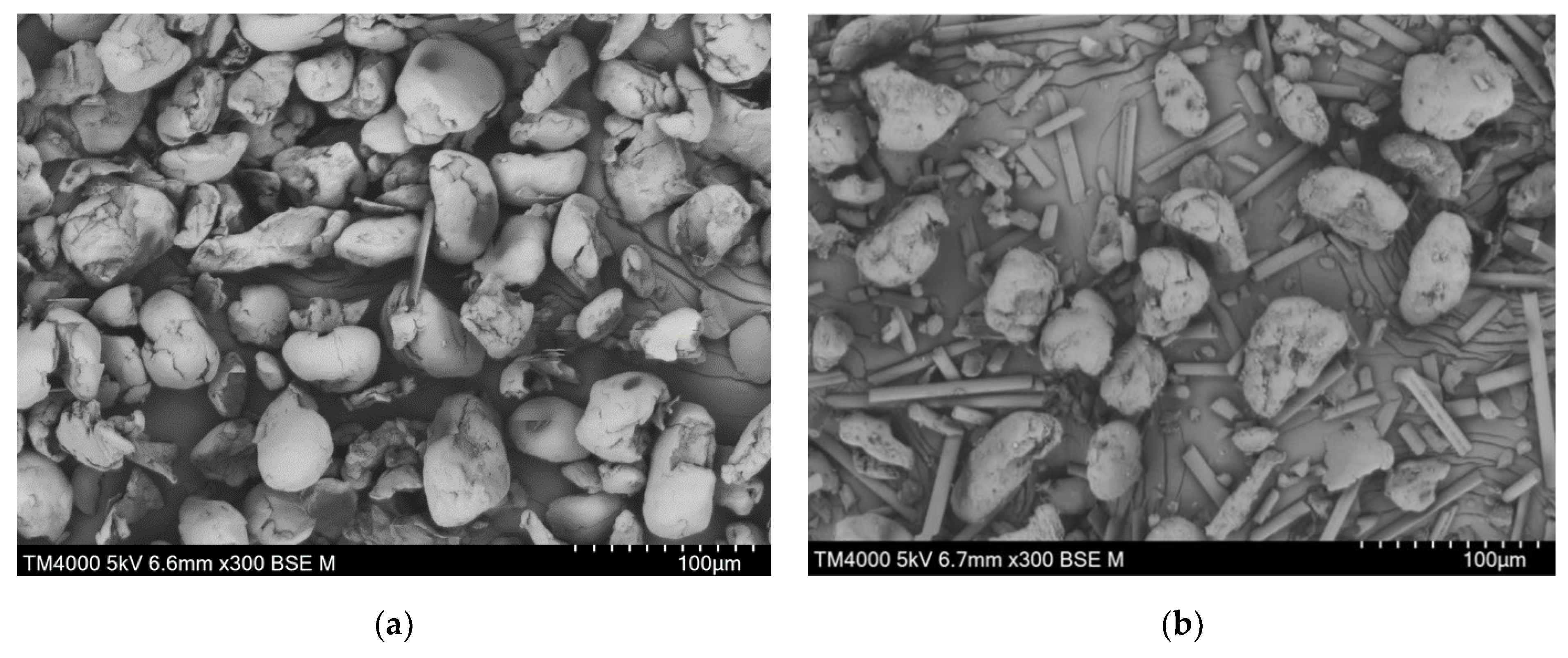

(1) Solid-phase parameters: solid phase density, elastic modulus, and Poisson's ratio;

(2) Contact parameters between particles: static friction coefficient, rolling friction coefficient, restitution coefficient, and surface energy.

(3) Powder-phase parameters: particle morphology, particle size, and powder fluidity.

For composite powders, the contact forms between particles can be further divided into three patterns of "particle-particle", "particle-reinforced phase", and "reinforced phase- reinforced phase". Specifically, the particle size and the static friction coefficient between particles are directly measured. The restitution coefficient is obtained by the FEM simulation. The rolling friction coefficient and surface energy are achieved by the "PB-BBD-GA" parameter-design method. This method extends the GA on the basis of traditional PB and BBD methods, avoiding the uncertainty of traditional methods in predicting the optimal parameter combination. The "PB-BBD-GA" method can quickly obtain the functional relationship between significant parameters and target values, and determine the unknown parameter combination more accurately and efficiently.