Submitted:

24 May 2023

Posted:

31 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiments

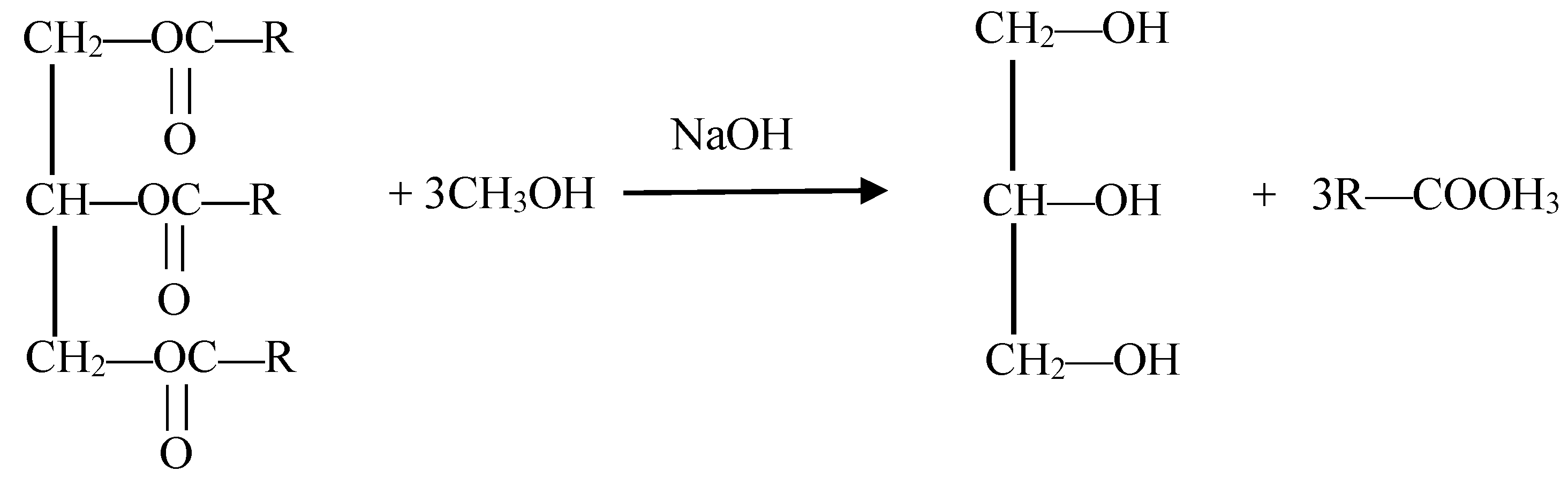

2.1. Preparation and properties of biodiesel

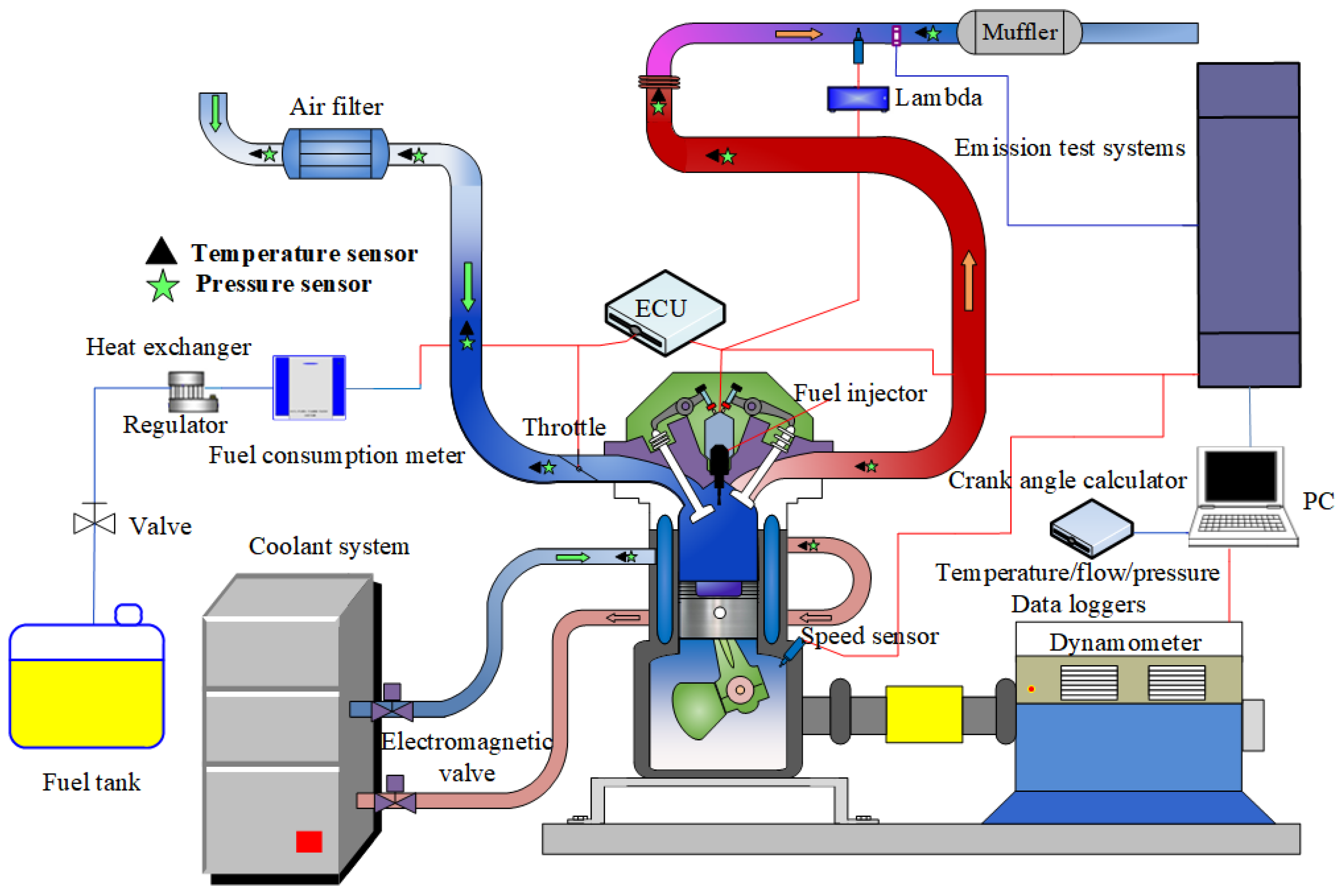

2.2. Experimental setup and test engine

2.3. Experimental test conditions

3. Results and discussion

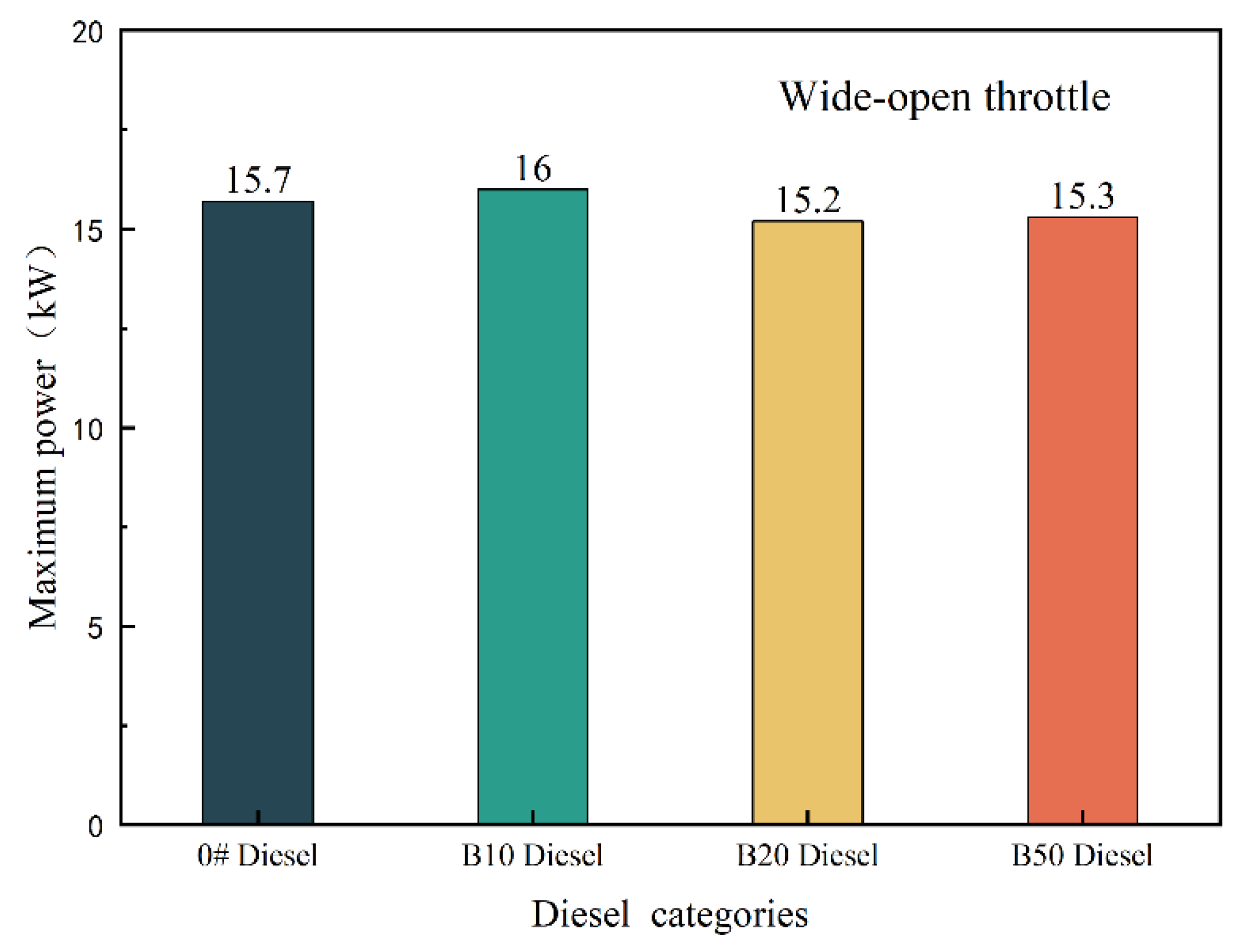

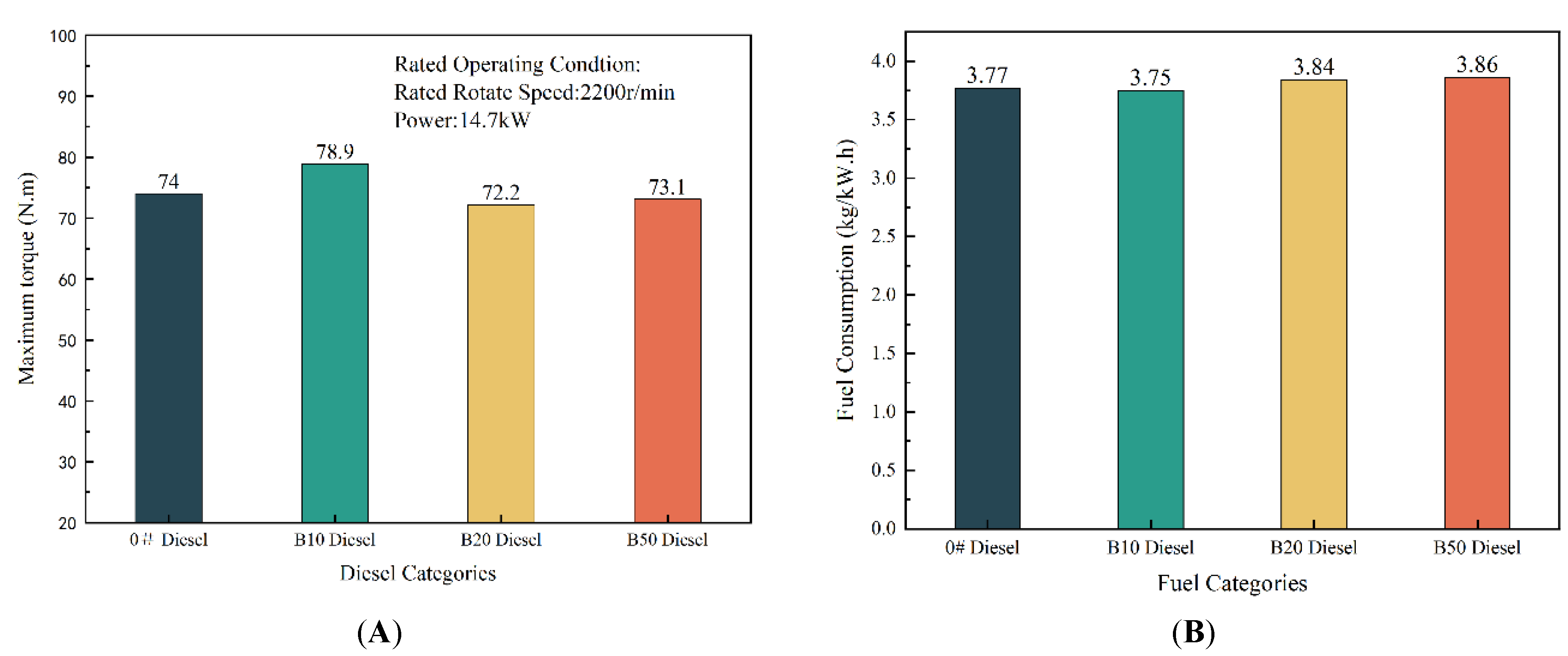

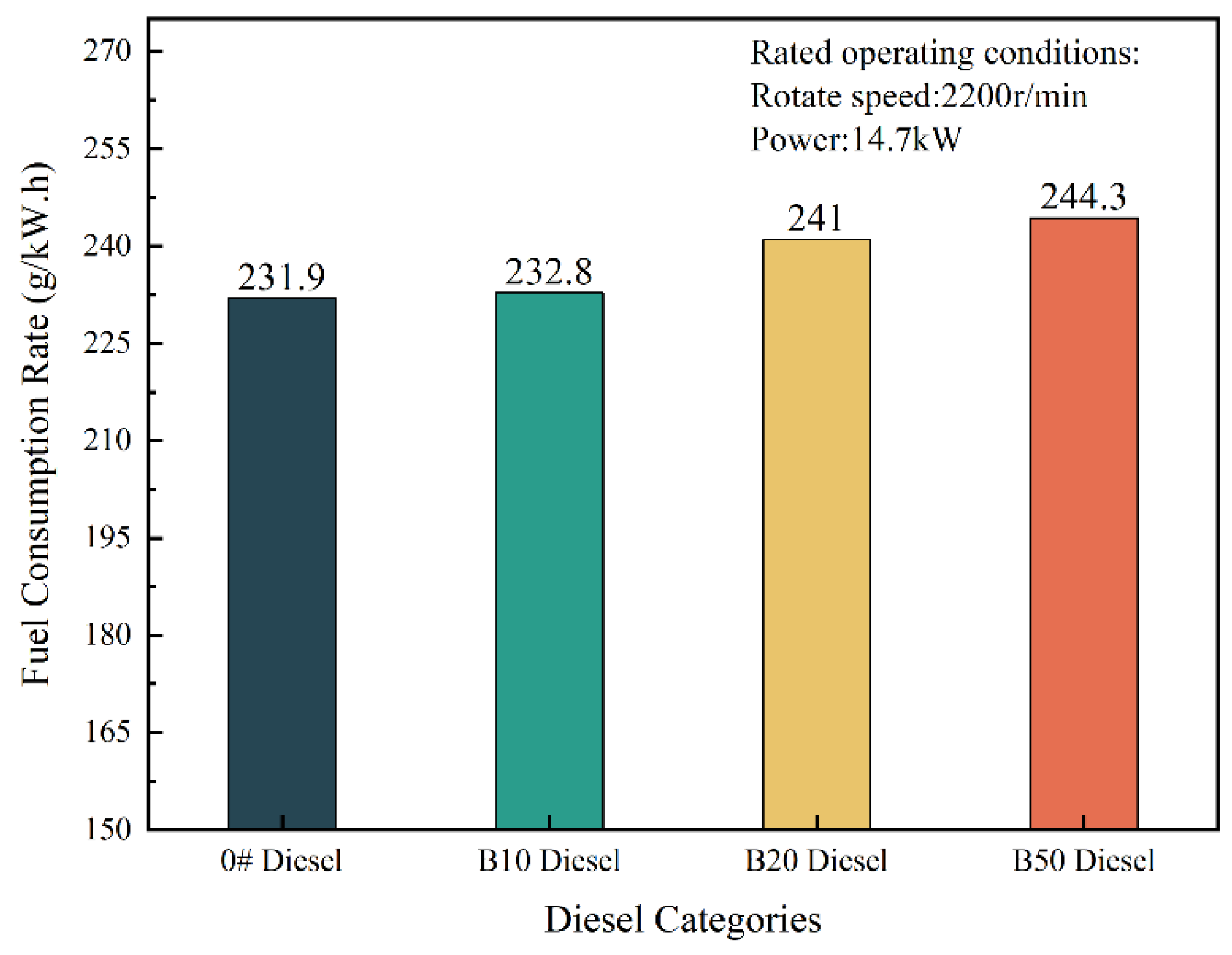

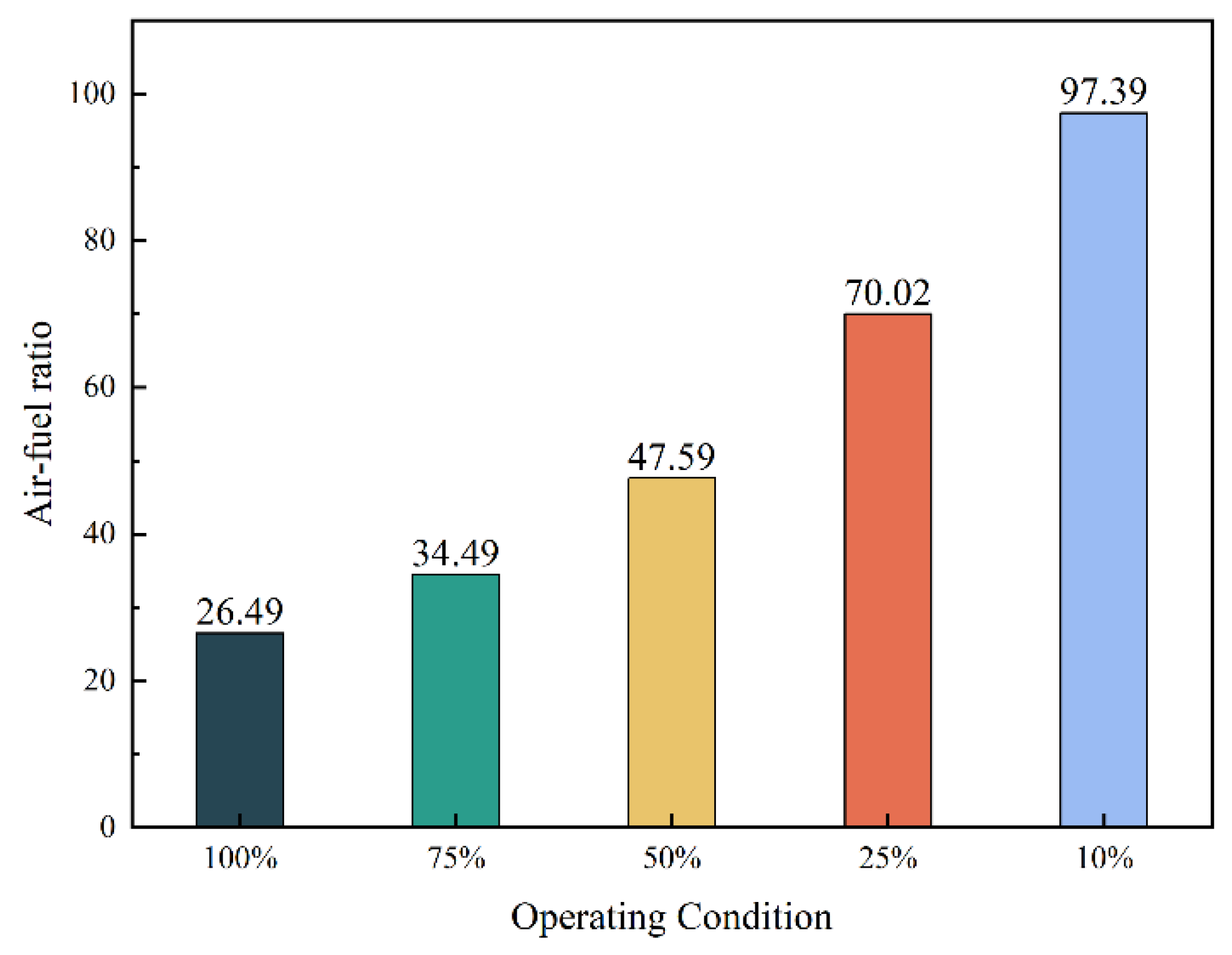

3.1. Load characteristics and external characteristics

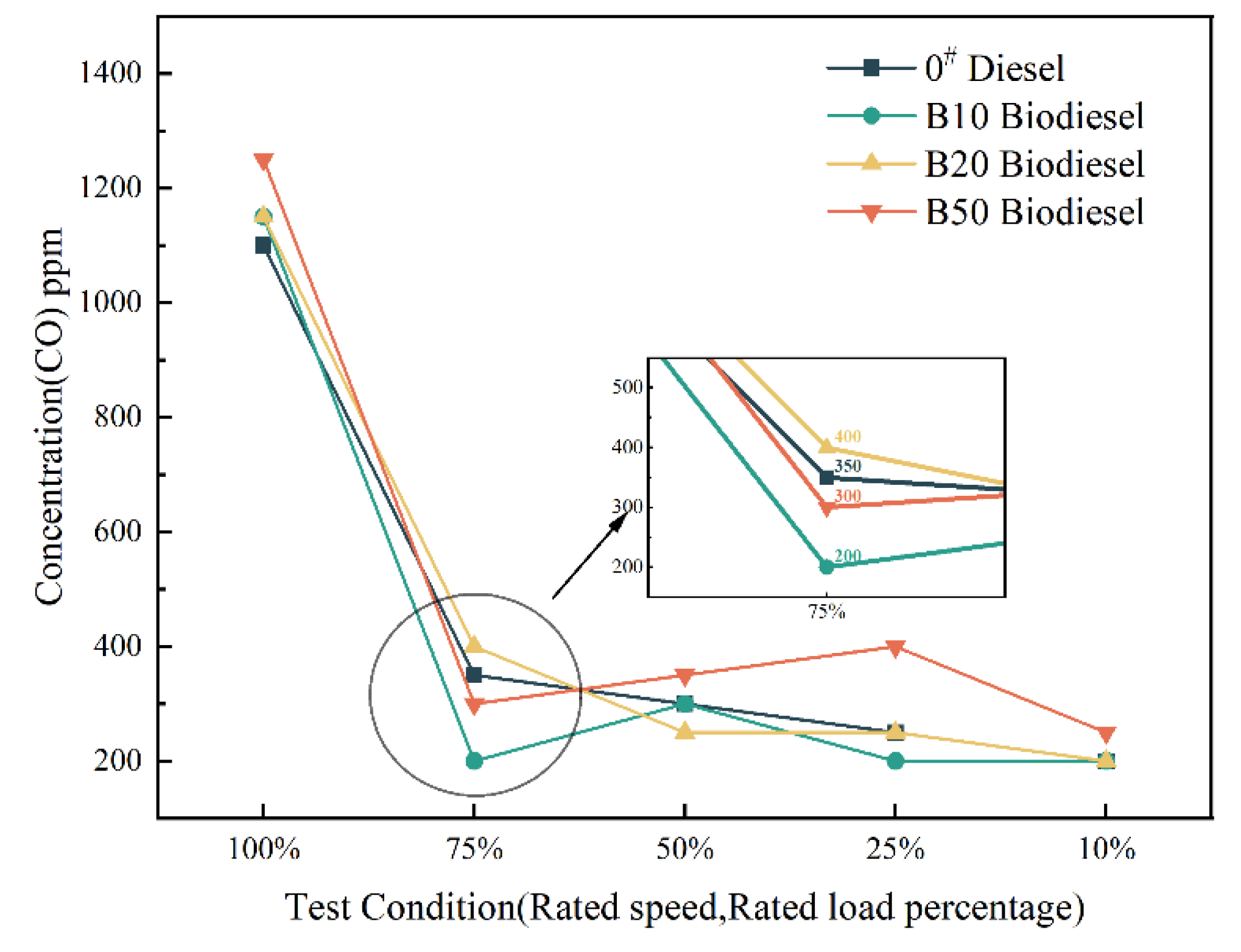

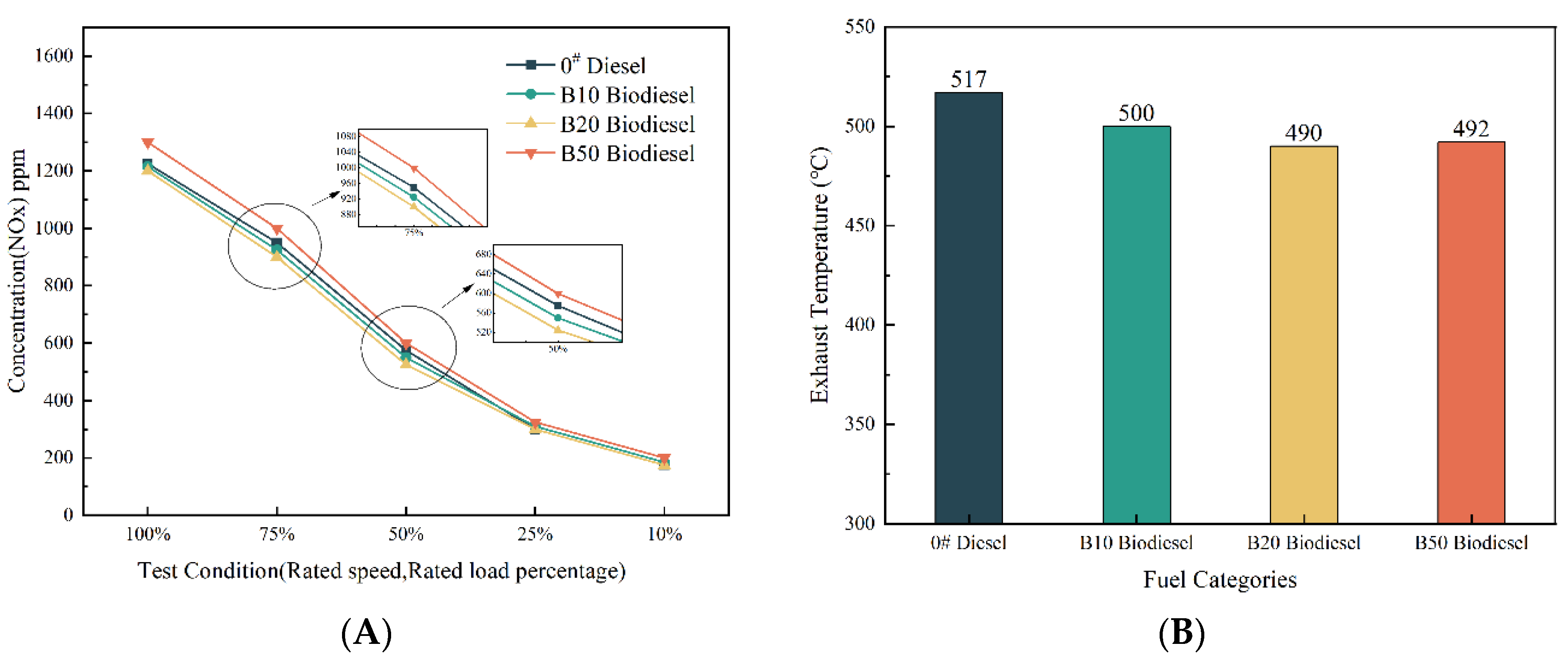

3.2. Emission characteristic

4. Conclusion

Acknowledgments

Nomenclature

| ASTM | American Society of Testing Materials |

| AV | Acid value |

| B10 | 10% Tung oil, 90% 0#diesel |

| B20 | 20% Tung oil, 80% 0#diesel |

| B50 | 50% Tung oil, 50% 0#diesel |

| CFPP | Cold filter plugging point |

| CN | Cetane number |

| EGR | Exhaust Gas Recirculation |

| KV | Kinematic viscosity |

| NOx | Oxides of nitrogen |

| SFC | Specific Fuel Consumption |

| Φ | Equivalence ratio |

References

- Wang, B., Wang, Z., Shuai, S., Yang, H., & Wang, J. (2014). Combustion and emission characteristics of Multiple Premixed Compression Ignition (MPCI) fuelled with naphtha and gasoline in wide load range. Energy conversion and management, 88, 79-87. [CrossRef]

- Tang, C., Zhang, Y., & Huang, Z. (2014). Progress in combustion investigations of hydrogen enriched hydrocarbons. Renewable and Sustainable Energy Reviews, 30, 195-216. [CrossRef]

- Zhao, L., Moiz, A. A., Som, S., Fogla, N., Bybee, M., Wahiduzzaman, S., ... & Kodavasal, J. (2018). Examining the role of flame topologies and in-cylinder flow fields on cyclic variability in spark-ignited engines using large-eddy simulation. International Journal of Engine Research, 19(8), 886-904. [CrossRef]

- Huang, Z., Wang, J., Liu, B., Zeng, K., Yu, J., & Jiang, D. (2007). Combustion characteristics of a direct-injection engine fueled with natural gas–hydrogen blends under different ignition timings. Fuel, 86(3), 381-387. [CrossRef]

- Huang, Y., Hong, G., & Huang, R. (2016). Effect of injection timing on mixture formation and combustion in an ethanol direct injection plus gasoline port injection (EDI+ GPI) engine. Energy, 111, 92-103. [CrossRef]

- Pei, Y., Qin, J., Li, X., Zhang, D., Wang, K., & Liu, Y. (2017). Experimental investigation on free and impingement spray fueled with methanol, ethanol, isooctane, TRF and gasoline. Fuel, 208, 174-183. [CrossRef]

- Bae, C., & Kim, J. (2017). Alternative fuels for internal combustion engines. Proceedings of the Combustion Institute, 36(3), 3389-3413. [CrossRef]

- Awad, O. I., Mamat, R., Ali, O. M., Sidik, N. C., Yusaf, T., Kadirgama, K., & Kettner, M. (2018). Alcohol and ether as alternative fuels in spark ignition engine: A review. Renewable and Sustainable Energy Reviews, 82, 2586-2605. [CrossRef]

- Chen, Z., Zhang, F., Xu, B., Zhang, Q., & Liu, J. (2017). Influence of methane content on a LNG heavy-duty engine with high compression ratio. Energy, 128, 329-336. [CrossRef]

- Lee, S., Speight, J. G., & Loyalka, S. K. (Eds.). (2014). Handbook of alternative fuel technologies. crc Press.

- Mofijur, M., Masjuki, H. H., Kalam, M. A., & Atabani, A. E. (2013). Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy, 55, 879-887. [CrossRef]

- Liaquat, A. M., Masjuki, H. H., Kalam, M. A., & Fattah, I. R. (2014). Impact of biodiesel blend on injector deposit formation. Energy, 72, 813-823. [CrossRef]

- Jayed, M. H., Masjuki, H. H., Kalam, M. A., Mahlia, T. M. I., Husnawan, M., & Liaquat, A. M. (2011). Prospects of dedicated biodiesel engine vehicles in Malaysia and Indonesia. Renewable and Sustainable Energy Reviews, 15(1), 220-235. [CrossRef]

- Lim, S., & Teong, L. K. (2010). Recent trends, opportunities and challenges of biodiesel in Malaysia: an overview. Renewable and Sustainable Energy Reviews, 14(3), 938-954. [CrossRef]

- Atadashi, I. M., Aroua, M. K., & Aziz, A. A. (2010). High quality biodiesel and its diesel engine application: a review. Renewable and sustainable energy reviews, 14(7), 1999-2008. [CrossRef]

- Imtenan, S., Varman, M., Masjuki, H. H., Kalam, M. A., Sajjad, H., Arbab, M. I., & Fattah, I. R. (2014). Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Conversion and Management, 80, 329-356. [CrossRef]

- Ming, C., Fattah, I. R., Chan, Q. N., Pham, P. X., Medwell, P. R., Kook, S., ... & Masri, A. R. (2018). Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel, 224, 167-177. [CrossRef]

- Rahman, S. M. A., Fattah, I. M. R., Maitra, S., & Mahlia, T. M. I. (2021). A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Conversion and Management, 229, 113742. [CrossRef]

- Umar, M., Ji, X., Kirikkaleli, D., & Alola, A. A. (2021). The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. Journal of Cleaner Production, 285, 124863. [CrossRef]

- Torkashvand, M., Hasan-Zadeh, A., & Torkashvand, A. (2022). Mini Review on Importance, Application, Advantages and Disadvantages of Biofuels. J. Mater. Environ. Sci, 2022(6).

- Blackmon, G. H. (1943). The tung-oil industry. The Botanical Review, 9, 1-40. [CrossRef]

- Qi, D. H., Yang, K., Zhang, D., & Chen, B. (2017). Combustion and emission characteristics of diesel-tung oil-ethanol blended fuels used in a CRDI diesel engine with different injection strategies. Applied Thermal Engineering, 111, 927-935. [CrossRef]

- Chen, Y. H., Chen, J. H., Chang, C. Y., & Chang, C. C. (2010). Biodiesel production from tung (Vernicia montana) oil and its blending properties in different fatty acid compositions. Bioresource Technology, 101(24), 9521-9526.

- Ithnin, A. M., Ahmad, M. A., Bakar, M. A. A., Rajoo, S., & Yahya, W. J. (2015). Combustion performance and emission analysis of diesel engine fuelled with water-in-diesel emulsion fuel made from low-grade diesel fuel. Energy Conversion and Management, 90, 375-382. [CrossRef]

- Valente, O. S., Da Silva, M. J., Pasa, V. M. D., Belchior, C. R. P., & Sodre, J. R. (2010). Fuel consumption and emissions from a diesel power generator fuelled with castor oil and soybean biodiesel. Fuel, 89(12), 3637-3642. [CrossRef]

- Can, Ö. (2014). Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Conversion and Management, 87, 676-686. [CrossRef]

- Park, J. Y., Kim, D. K., Wang, Z. M., Lu, P., Park, S. C., & Lee, J. S. (2008). Production and characterization of biodiesel from tung oil. In Biotechnology for Fuels and Chemicals: Proceedings of the Twenty-Ninth Symposium on Biotechnology for Fuels and Chemicals Held April 29–May 2, 2007, in Denver, Colorado (pp. 627-635). Humana Press.

- Shang, Q., Jiang, W., Lu, H., & Liang, B. (2010). Properties of Tung oil biodiesel and its blends with 0# diesel. Bioresource technology, 101(2), 826-828. [CrossRef]

- Deshmane, V. G., & Adewuyi, Y. G. (2013). Synthesis and kinetics of biodiesel formation via calcium methoxide base catalyzed transesterification reaction in the absence and presence of ultrasound. Fuel, 107, 474-482. [CrossRef]

- Cardone, M., Prati, M. V., Rocco, V., Seggiani, M., Senatore, A., & Vitolo, S. (2002). Brassica carinata as an alternative oil crop for the production of biodiesel in Italy: engine performance and regulated and unregulated exhaust emissions. Environmental science & technology, 36(21), 4656-4662. [CrossRef]

- Genbao, L., Longbao, Z., & Deming, J. (2004). Effects of Biodiesel Blended Fuel on the Combustion and Emissions of DI Diesel Engines. Diesel Engine, (2), 17-20.

- Goering, C. E., Schwab, A. W., Daugherty, M. J., Pryde, E. H., & Heakin, A. J. (1982). Fuel properties of eleven vegetable oils. Transactions of the ASAE, 25(6), 1472-1477. [CrossRef]

- Alptekin, E., & Canakci, M. (2008). Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renewable energy, 33(12), 2623-2630. [CrossRef]

- Candeia, R. A., Silva, M. C. D., Carvalho Filho, J. R., Brasilino, M. G. A., Bicudo, T. C., Santos, I. M. G., & Souza, A. G. (2009). Influence of soybean biodiesel content on basic properties of biodiesel–diesel blends. Fuel, 88(4), 738-743. [CrossRef]

- Heywood, J. B. (2018). Internal combustion engine fundamentals. McGraw-Hill Education.

- Hu, S., Deng, B., Wu, D., & Hou, K. (2021). Energy flow behavior and emission reduction of a turbo-charging and EGR non-road diesel engine equipped with DOC and DPF under NRTC (non-road transient cycle). Fuel, 305, 121571. [CrossRef]

- Duan, X., Xu, Z., Sun, X., Deng, B., & Liu, J. (2021). Effects of injection timing and EGR on combustion and emissions characteristics of the diesel engine fuelled with acetone–butanol–ethanol/diesel blend fuels. Energy, 231, 121069. [CrossRef]

- Miyamoto, N., Ogawa, H., Nurun, N. M., Obata, K., & Arima, T. (1998). Smokeless, low NOx, high thermal efficiency, and low noise diesel combustion with oxygenated agents as main fuel. SAE transactions, 171-177. [CrossRef]

- Westbrook, C. K., Pitz, W. J., & Curran, H. J. (2006). Chemical kinetic modeling study of the effects of oxygenated hydrocarbons on soot emissions from diesel engines. The journal of physical chemistry A, 110(21), 6912-6922. [CrossRef]

- Li, G., Dai, J., Li, Y., & Lee, T. H. (2021). Optical investigation on combustion and soot formation characteristics of isopropanol-butanol-ethanol (IBE)/diesel blends. Energy Science & Engineering, 9(12), 2311-2320.

| Items | Target Requirement | Biodiesel | 0# Diesel | Detection Method |

|---|---|---|---|---|

| Density(20℃)kg·m-3 | 820-900 | 893 | 830 | GB/T2540 |

| Acidity/mg KOH·g-1 | ≤0.8 | 0.56 | ≤0.7 | GB/T264 |

| 10% Steam residue charcoal / % | ≤0.3 | 0.27 | ≤0.3 | GB/T17144 |

| Sulfated ash / % | ≤0.020 | 0.012 | 一 | GB/T2433 |

| Mechanical impurities | None | None | 一 | GB/T511 |

| Water content / % | ≤0.05 | 0.03 | 一 | SH/T0246 |

| Sulfur content / % | ≤0.05 | 0.003 | <0.2 | SH/T0689 |

| Copper corrosion(50℃,3h) | ≤1 | 1 | 1 | GB/T5096 |

| Kinematic viscosity(40℃)/ mm2·s-1 | 1.9-6.0 | 5.02 | 3.0-8.0 | GB/T265 |

| Cold filter point/ ℃ | ≤0 | -8.0 | ≤4 | SH/T0248 |

| Flashpoint/ ℃ | ≥130 | 140 | ≥60 | GB/T261 |

| Cetane number | ≥49 | 56 | ≥49 | GB/T386 |

| 90℃ Recovered temperature/ ℃ | ≤360 | 345 | ≤365 | GB/T6536 |

| Oxidation stability (110℃)/ h | ≥6.0 | 6.5 | 一 | EN14112 |

| Free glycerol content/ % | ≤0.02 | 0.01 | 一 | ASTM D6584 |

| Total glycerol content/ % | ≤0.24 | 0.12 | 一 | ASTM D6584 |

| Calorific value/ kJ·g-1 | 一 | 38.96 | 45.4 | 一 |

| Item | Content |

|---|---|

| Model | ZS1115GM |

| Number of Valves per Cylinder | 4 |

| Compression Ratio | 17:1 |

| Bore | 115mm |

| Stroke | 115mm |

| Engine Speed | 2200rpm |

| Continuous output | 14.71kW |

| Maximum output | 16.18kW |

| Fuel consumption | ≤244.8 |

| Lubrication mode | Pressure and splash lubrication |

| Cooling method | Water-cooled evaporative |

| Starting mode | Electric starting |

| Appearance size (length ×width × height) (mm) | 970×463×699 |

| Instruments | Type | Precision |

|---|---|---|

| Dynamometer | Xiangyi Electronic Dynamometer | Torque:±0.2%F.S; Speed: ±5 rpm |

| Exhaust gas analyzer | AVL DiGas 4000 Light | CO: 0.01% vol HC: 1ppm vol CO2: 0.02% vol O2: 0.01% vol NO: 1ppm vol |

| Smoke meter | FBY-1 | ±2%F.S |

| Fuel consumption meter Oil temperature regulator Water temperature regulator |

Xiangyi FC2210 Xiangyi FC2430T2 Xiangyi FC2422 |

±0.4% ±2℃ ±2℃ |

| Lambda meter | ETAS Lambda Meter | ±0.01 |

| Air flow meter | ToCeil-LFE100 | ±0.1% |

| Intake gas temperature sensor | PT100 | ±0.16℃ |

| Exhaust gas temperature sensor | K type thermocouple | ±0.18℃ |

| Item | B10 Biodiesel | B20 Biodiesel | B50 Biodiesel | 0# Diesel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Exhaust gas | NOx (10-6) |

HC (10-6) |

CO (10-6) |

NOx (10-6) |

HC (10-6) |

CO (10-6) |

NOx (10-6) |

HC (10-6) |

CO (10-6) |

NOx (10-6) |

HC (10-6) |

CO (10-6) |

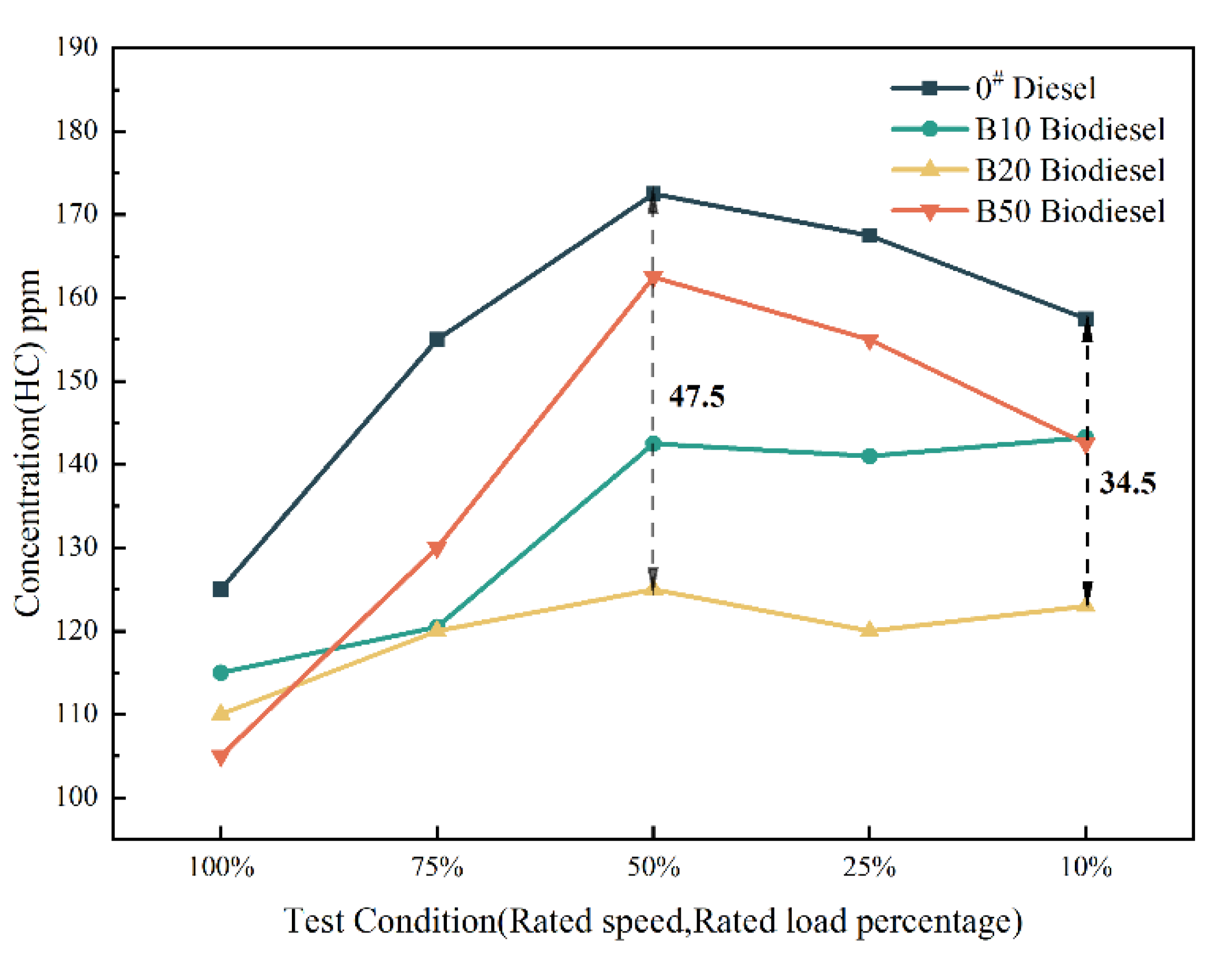

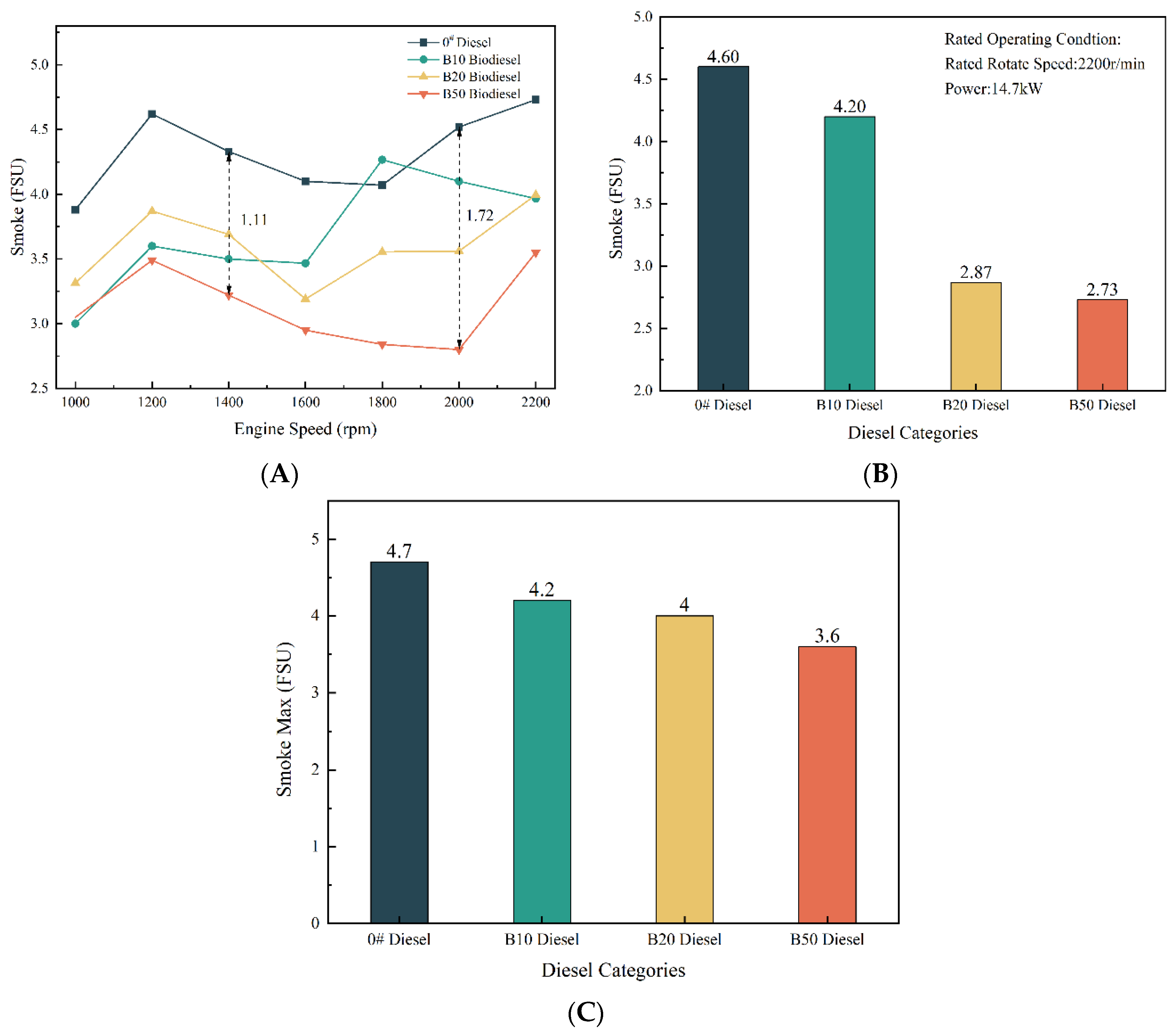

| 100 % rated load | 1215 | 115 | 1150 | 1200 | 110 | 1150 | 1300 | 105 | 1250 | 1225 | 125 | 1100 |

| 75 % rated load | 925 | 121 | 200 | 900 | 120 | 400 | 1000 | 130 | 300 | 950 | 155 | 350 |

| 50 % rated load | 550 | 143 | 300 | 525 | 125 | 250 | 600 | 163 | 350 | 575 | 173 | 300 |

| 25 % rated load | 310 | 141 | 200 | 300 | 120 | 250 | 325 | 155 | 400 | 300 | 168 | 250 |

| 10 % rated load | 185 | 143 | 200 | 175 | 123 | 200 | 200 | 143 | 250 | 175 | 158 | 200 |

| Specific emission (g/kW·h) | 12.3 | 0.80 | 3.50 | 8.64 | 0.60 | 3.70 | 9.48 | 0.80 | 4.30 | 8.89 | 0.90 | 3.70 |

| Specific emission reduction(g/kW·h) | -3.41 | 0.10 | 0.20 | 0.25 | 0.30 | 0.00 | -0.59 | 0.10 | -0.60 | / | / | / |

| Specific emission reduction rate % | -38.3 | 11.1 | 5.41 | 2.8 | 33.3 | 0.0 | -6.6 | 11.1 | -16.2 | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).