Submitted:

29 May 2023

Posted:

30 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

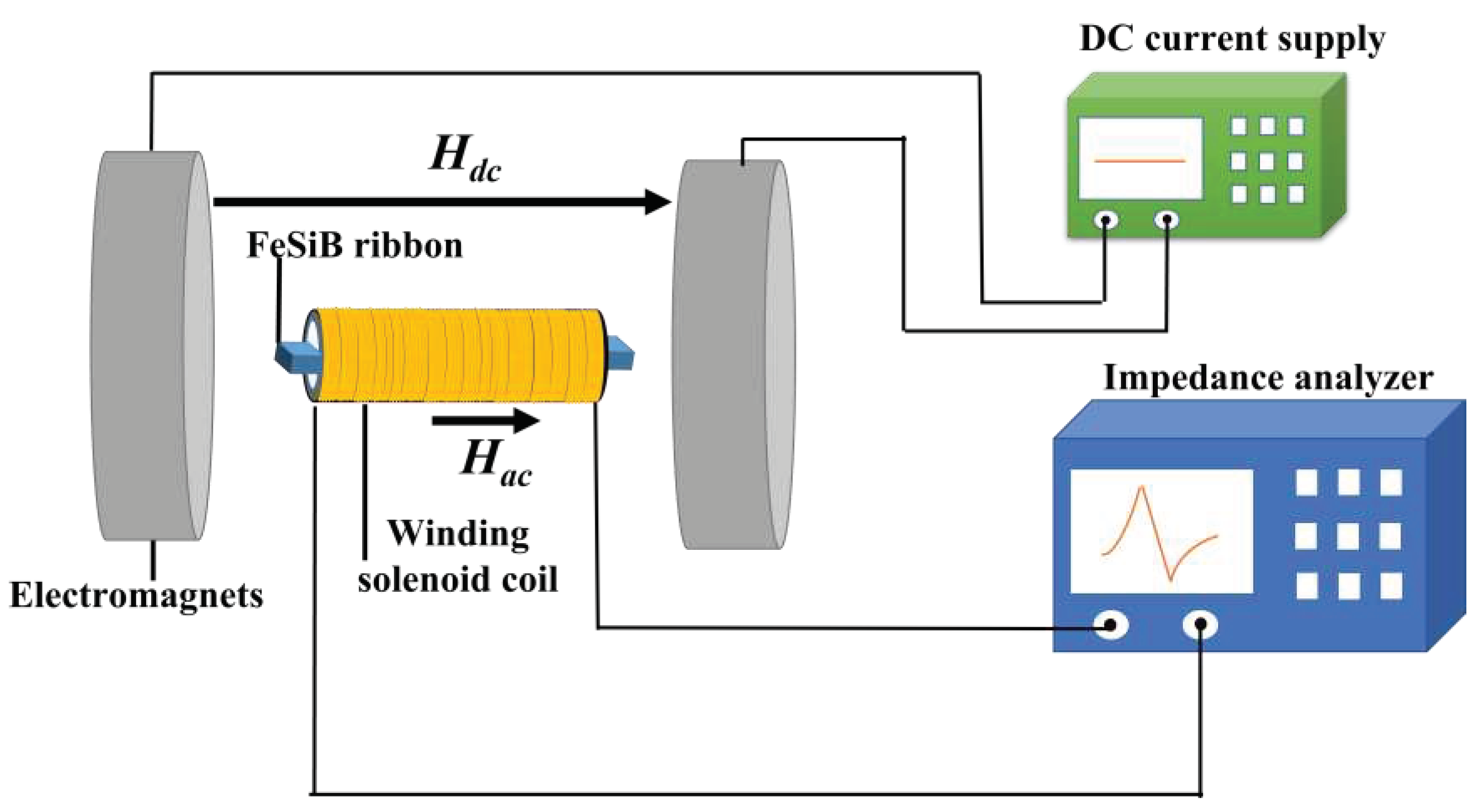

2. Experiment method

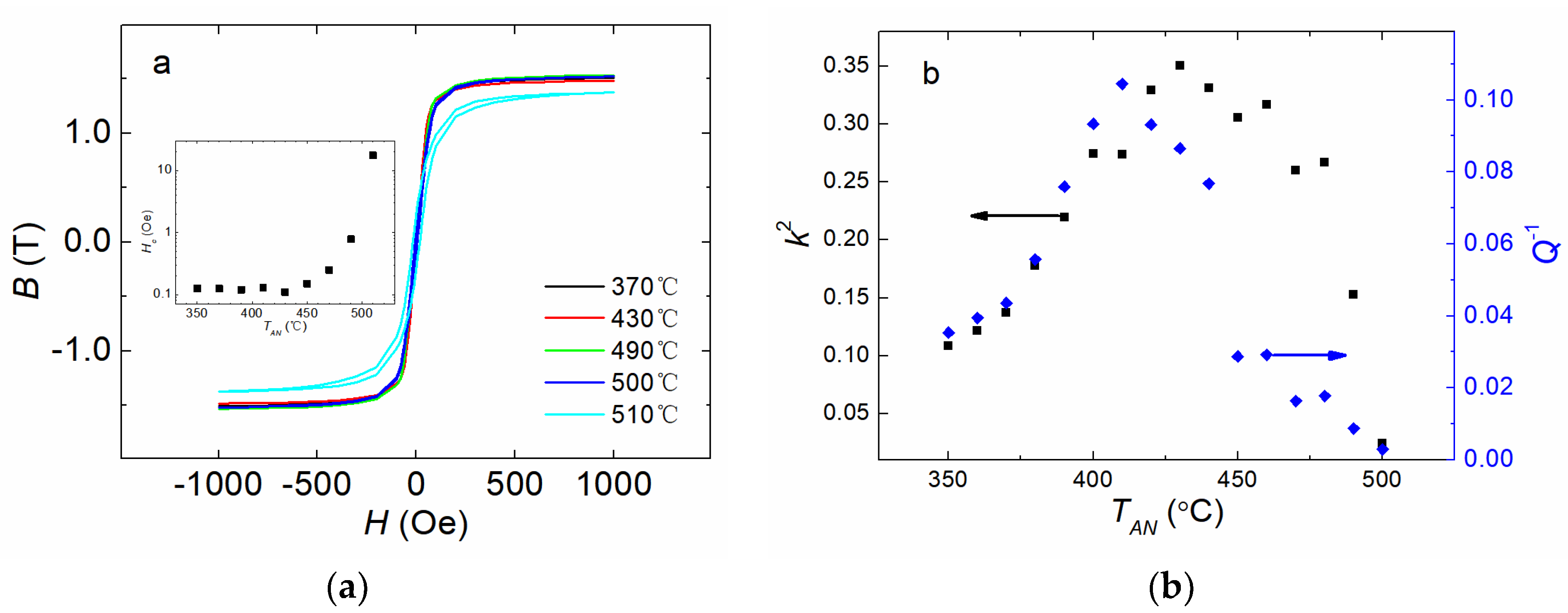

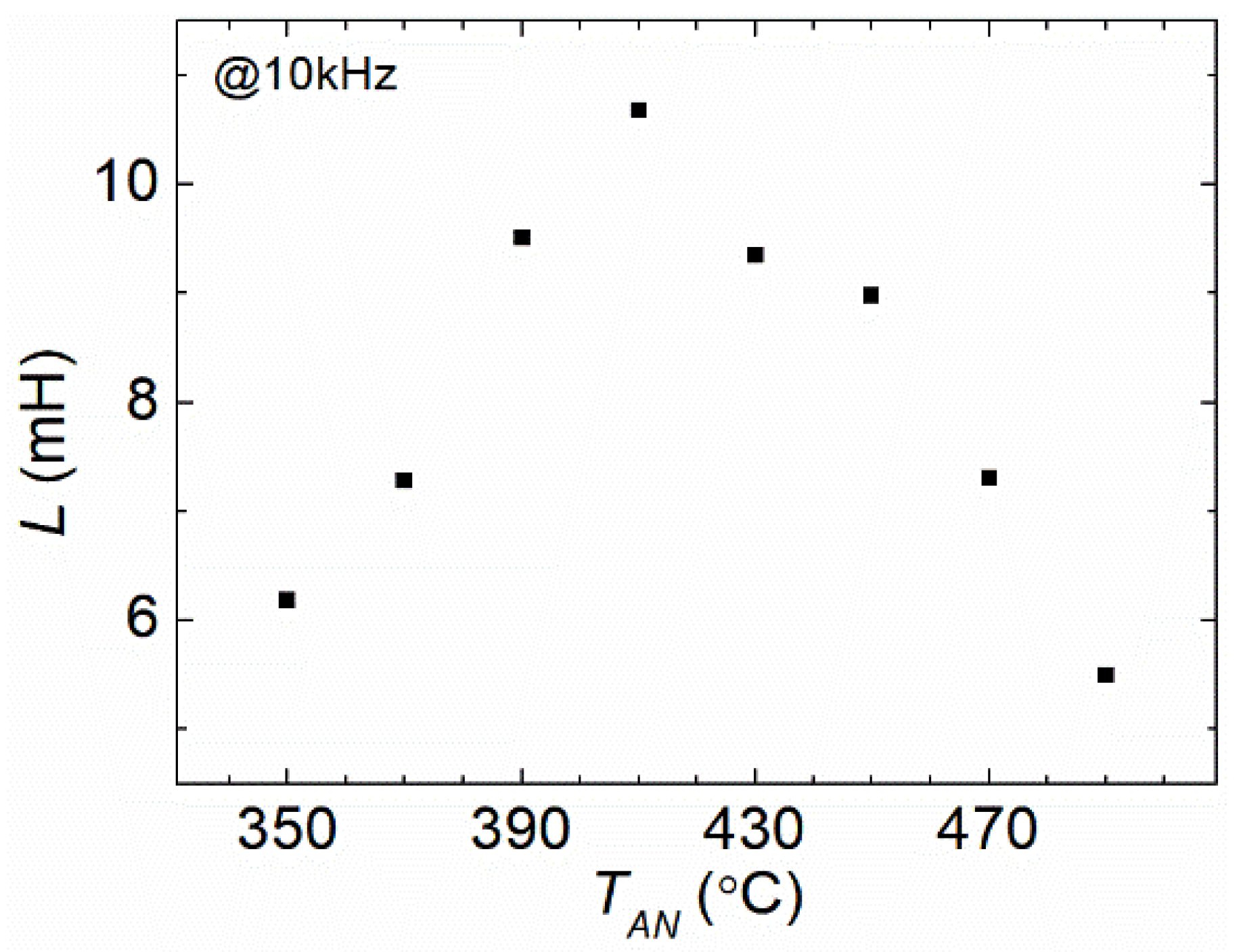

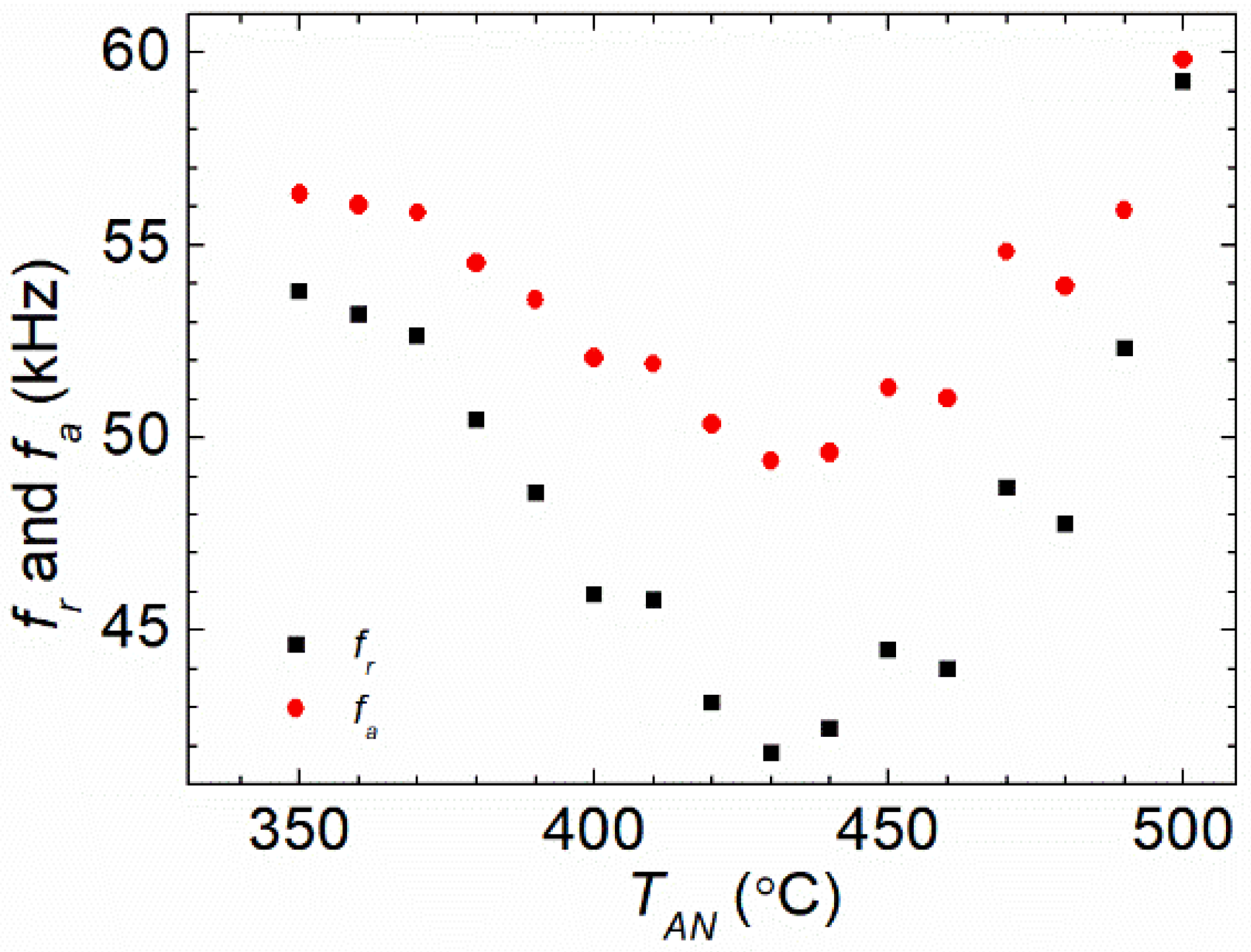

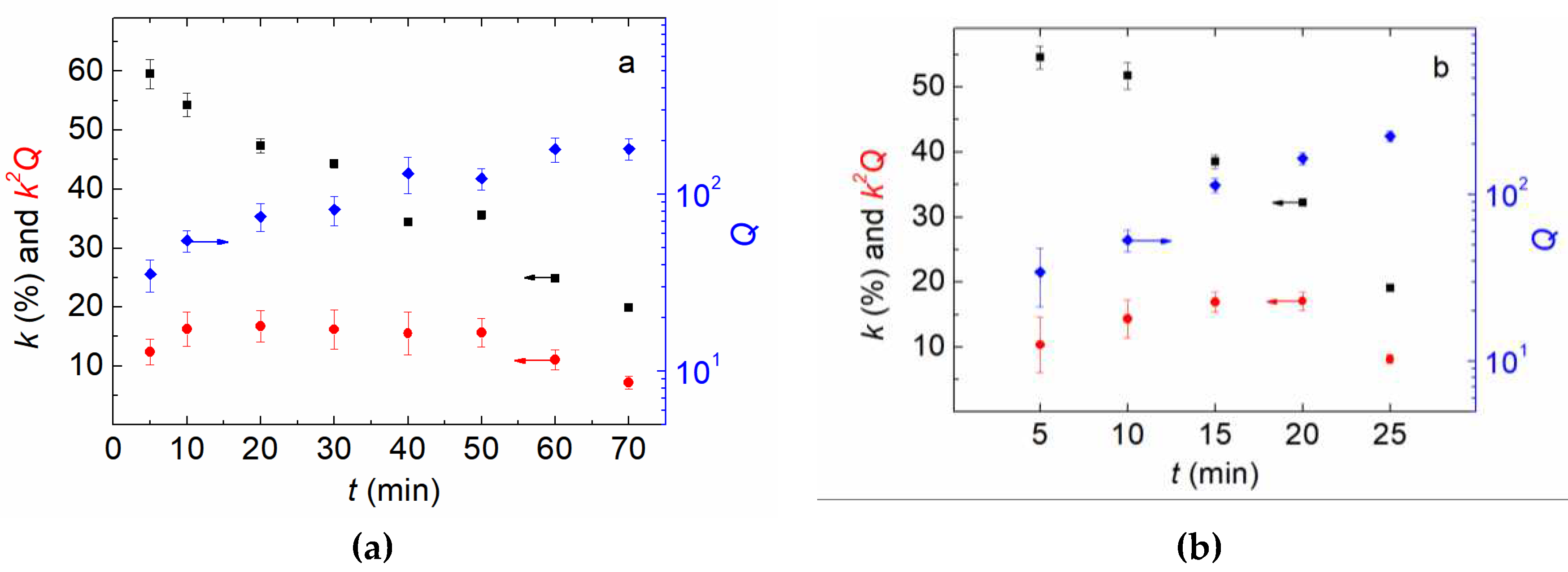

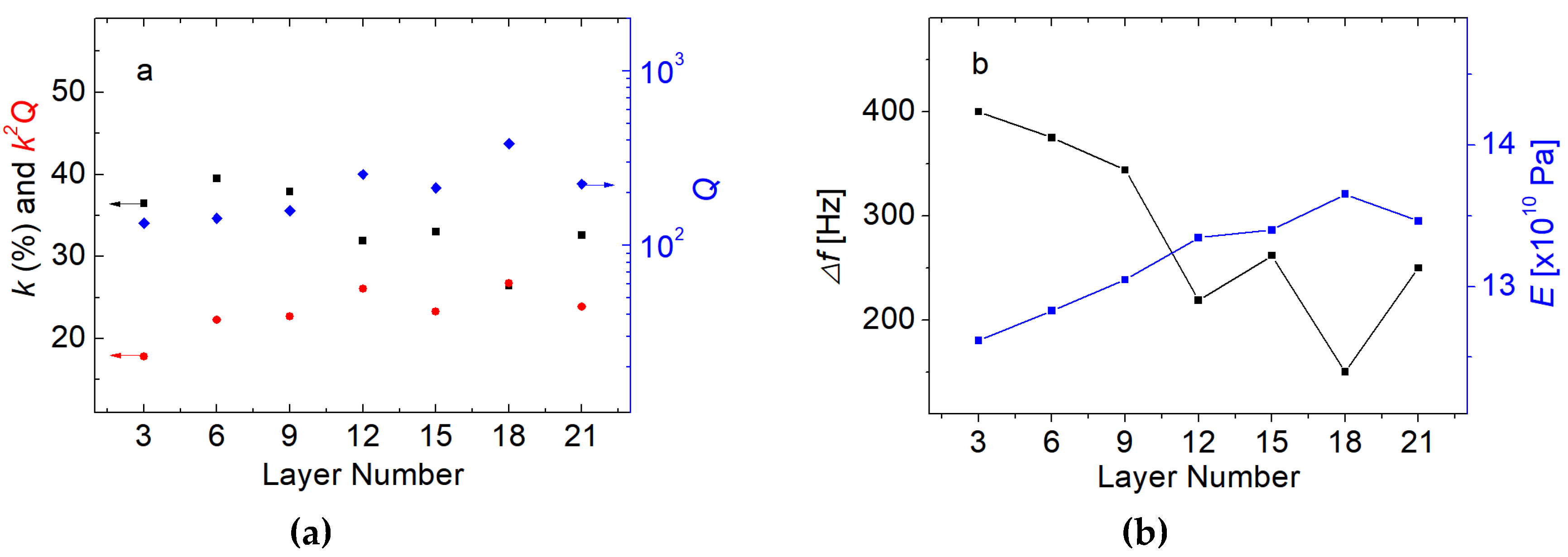

3. Theoretical analysis and Measurement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Papadopoulou, C.-A. Chapter 4 - Technology and SDGs in Smart Cities Context. In Smart Cities and the un SDGs; Visvizi, A., Pérez del Hoyo, R., Eds.; Elsevier, 2021; pp. 45–58 ISBN 978-0-323-85151-0.

- Ortiz-Repiso, V. Chapter 11 - The 2030 Agenda and the Information Professionals. In Boosting the Knowledge Economy; Calzada-Prado, F.-J., Ed.; Chandos Information Professional Series; Chandos Publishing: Oxford, 2022; pp. 189–208 ISBN 978-1-84334-772-9.

- Channagoudra, G.; Dayal, V. Magnetoelectric Coupling in Ferromagnetic/Ferroelectric Heterostructures: A Survey and Perspective. J Alloys Compd 2022, 928. [CrossRef]

- Zhuang, X.; Xu, X.; Zhang, X.; Sun, Y.; Yan, B.; Liu, L.; Lu, Y.; Zhu, W.; Fang, G. Tailoring the Magnetomechanical Power Efficiency of Metallic Glasses for Magneto-Electric Devices. J Appl Phys 2022, 132. [CrossRef]

- Leung, C.M.; Li, J.; Viehland, D.; Zhuang, X. A Review on Applications of Magnetoelectric Composites: From Heterostructural Uncooled Magnetic Sensors, Energy Harvesters to Highly Efficient Power Converters. J Phys D Appl Phys 2018, 51, 263002. [CrossRef]

- Kabacoff, L.T. Thermal, Magnetic, and Magnetomechanical Properties of Metglas 2605 S2 and S3. J Appl Phys 1982, 53, 8098–8100. [CrossRef]

- Savage, H.; Clark, A.; Powers, J. Magnetomechanical Coupling and ΔE Effect in Highly Magnetostrictive Rare Earth - Fe2compounds. IEEE Trans Magn 1975, 11, 1355–1357. [CrossRef]

- Kaczkowski, Z. Magnetomechanical Properties of Rapidly Quenched Materials. Materials Science and Engineering: A 1997, 226–228, 614–625. [CrossRef]

- Qiao, K.; Hu, F.; Zhang, H.; Yu, Z.; Liu, X.; Liang, Y.; Long, Y.; Wang, J.; Sun, J.; Zhao, T.; et al. Unipolar Electric-Field-Controlled Nonvolatile Multistate Magnetic Memory in FeRh/(001)PMN-PT Heterostructures over a Broad Temperature Span. Sci China Phys Mech Astron 2021, 65, 217511. [CrossRef]

- Pal, M.; Srinivas, A.; Asthana, S. Enhanced Magneto-Electric Properties and Magnetodielectric Effect in Lead-Free (1-x)0.94Na0.5Bi0.5TiO3-0.06BaTiO3–x CoFe2O4 Particulate Composites. J Alloys Compd 2022, 900, 163487. [CrossRef]

- Li, T.X.; Li, R.; Lin, Y.; Bu, F.; Li, J.; Li, K.; Hu, Z.; Ju, L. Study of Enhanced Magnetoelectric Coupling Behavior in Asymmetrical Bilayered Multiferroic Heterostructure with Two Resonance Modes. J Alloys Compd 2022, 895, 162674. [CrossRef]

- Röbisch, V.; Salzer, S.; Urs, N.O.; Reermann, J.; Yarar, E.; Piorra, A.; Kirchhof, C.; Lage, E.; Höft, M.; Schmidt, G.U.; et al. Pushing the Detection Limit of Thin Film Magnetoelectric Heterostructures. J Mater Res 2017, 32, 1009–1019. [CrossRef]

- Betal, S.; Saha, A.K.; Ortega, E.; Dutta, M.; Ramasubramanian, A.K.; Bhalla, A.S.; Guo, R. Core-Shell Magnetoelectric Nanorobot – A Remotely Controlled Probe for Targeted Cell Manipulation. Sci Rep 2018, 8, 1755. [CrossRef]

- Narita, F.; Fox, M. A Review on Piezoelectric, Magnetostrictive, and Magnetoelectric Materials and Device Technologies for Energy Harvesting Applications. Adv Eng Mater 2018, 20, 1700743. [CrossRef]

- Gao, J.; Das, J.; Xing, Z.; Li, J.; Viehland, D. Comparison of Noise Floor and Sensitivity for Different Magnetoelectric Laminates. J Appl Phys 2010, 108, 084509. [CrossRef]

- Chen, H.S.; Leamy, H.J.; Barmatz, M. The Elastic and Anelastic Behavior of a Metallic Glass. J Non Cryst Solids 1971, 5, 444–448. [CrossRef]

- Morito, N.; Egami, T. Correlation of the Shear Modulus and Internal Friction in the Reversible Structural Relaxation of a Glassy Metal. J Non Cryst Solids 1984, 61–62, 973–978. [CrossRef]

- Soshiroda, T.; Koiwa, M.; Masumoto, T. The Internal Friction and Elastic Modulus of Amorphous Pd–Si and Fe–P–C Alloys. J Non Cryst Solids 1976, 22, 173–187. [CrossRef]

- Xu, D.D.; Zhou, B.L.; Wang, Q.Q.; Zhou, J.; Yang, W.M.; Yuan, C.C.; Xue, L.; Fan, X.D.; Ma, L.Q.; Shen, B.L. Effects of Cr Addition on Thermal Stability, Soft Magnetic Properties and Corrosion Resistance of FeSiB Amorphous Alloys. Corros Sci 2018, 138, 20–27. [CrossRef]

- Lin, J.; Li, X.; Zhou, S.; Zhang, Q.; Li, Z.; Wang, M.; Shi, G.; Wang, L.; Zhang, G. Effects of Heat Treatment in Air on Soft Magnetic Properties of FeCoSiBPC Amorphous Core. J Non Cryst Solids 2022, 597. [CrossRef]

- Murugaiyan, P.; Mitra, A.; Jena, P.S.M.; Mahato, B.; Ghosh, M.; Roy, R.K.; Panda, A.K. Grain Refinement in Fe-Rich FeSiB(P)NbCu Nanocomposite Alloys through P Compositional Modulation. Mater Lett 2021, 295. [CrossRef]

- Fang, Z.; Nagato, K.; Liu, S.; Sugita, N.; Nakao, M. Investigation into Surface Integrity and Magnetic Property of FeSiB Metallic Glass in Two-Dimensional Cutting. J Manuf Process 2021, 64, 1098–1104. [CrossRef]

- Wang, C.; Guo, Z.; Wang, J.; Sun, H.; Chen, D.; Chen, W.; Liu, X. Industry-Oriented Fe-Based Amorphous Soft Magnetic Composites with SiO2-Coated Layer by One-Pot High-Efficient Synthesis Method. J Magn Magn Mater 2020, 509. [CrossRef]

- Cheng, Y.Q.; Ma, E. Atomic-Level Structure and Structure-Property Relationship in Metallic Glasses. Prog Mater Sci 2011, 56, 379–473. [CrossRef]

- Sun, Y.; Zhang, X.; Wu, S.; Zhuang, X.; Yan, B.; Zhu, W.; Dolabdjian, C.; Fang, G. Magnetomechanical Properties of Fe-Si-B and Fe-Co-Si-B Metallic Glasses by Various Annealing Temperatures for Actuation Applications. Sensors 2023, 23. [CrossRef]

- Czyż, O.; Kusiński, J.; Radziszewska, A.; Liao, Z.; Zschech, E.; Kąc, M.; Ostrowski, R. Study of Structure and Properties of Fe-Based Amorphous Ribbons after Pulsed Laser Interference Heating. J Mater Eng Perform 2020, 29, 6277–6285. [CrossRef]

- Zhang, J.; Shan, G.; Li, J.; Wang, Y.; Shek, C.H. Structures and Physical Properties of Two Magnetic Fe-Based Metallic Glasses. J Alloys Compd 2018, 747, 636–639. [CrossRef]

- Li, Y.; Chen, W. zhi; Dong, B. shao; Zhou, S. xiong Effects of Phosphorus and Carbon Content on the Surface Tension of FeSiBPC Glass-Forming Alloy Melts. J Non Cryst Solids 2018, 496, 13–17. [CrossRef]

- Li, T.X.; Li, R.; Lin, Y.; Bu, F.; Li, J.; Li, K.; Hu, Z.; Ju, L. Study of Enhanced Magnetoelectric Coupling Behavior in Asymmetrical Bilayered Multiferroic Heterostructure with Two Resonance Modes. J Alloys Compd 2022, 895, 162674. [CrossRef]

- Kabacoff, L.T. Thermal, Magnetic, and Magnetomechanical Properties of Metglas 2605 S2 and S3. J Appl Phys 1982, 53, 8098–8100. [CrossRef]

- Lopatina, E.; Soldatov, I.; Budinsky, V.; Marsilius, M.; Schultz, L.; Herzer, G.; Schäfer, R. Surface Crystallization and Magnetic Properties of Fe84.3Cu0.7Si4B8P3 Soft Magnetic Ribbons. Acta Mater 2015, 96, 10–17. [CrossRef]

- Ok, H.N.; Morrish, A.H. Origin of the Perpendicular Anisotropy in Amorphous Fe82B12Si6 Ribbons. Phys Rev B 1981, 23, 2257–2261. [CrossRef]

- Gemperle, R.; Kraus, L.; Kroupa, F.; Schneider, J. Influence of Surface Oxidization on Induced Anisotropy of Amorphous (FeNi) PB Wires. physica status solidi (a) 1980, 60, 265–272. [CrossRef]

- Ok, H.N.; Morrish, A.H. Amorphous-to-Crystalline Transformation of Fe82B12Si6. Phys Rev B 1980, 22, 3471–3480. [CrossRef]

- Keupers, A.; De Schepper, L.; Knuyt, G.; Stals, L.M. Chemical and Topological Short Range Order in Amorphous Fe40Ni38Mo4B18 (Metglas 2826MB). J Non Cryst Solids 1985, 72, 267–278. [CrossRef]

- Morito, N. Surface Crystallization Induced by Selective Oxidation of Boron in Fe-B-Si Amorphous Alloy. Key Eng Mater 1990, 40–41, 63–68. [CrossRef]

- Herzer, G. Magnetomechanical Damping in Amorphous Ribbons with Uniaxial Anisotropy. Materials Science and Engineering: A 1997, 226–228, 631–635. [CrossRef]

- Tong, X.; Zhang, Y.; Wang, Y.; Liang, X.; Zhang, K.; Zhang, F.; Cai, Y.; Ke, H.; Wang, G.; Shen, J.; et al. Structural Origin of Magnetic Softening in a Fe-Based Amorphous Alloy upon Annealing. J Mater Sci Technol 2022, 96, 233–240. [CrossRef]

- Stoyanov, P.G.; Grimes, C.A. A Remote Query Magnetostrictive Viscosity Sensor. Sens Actuators A Phys 2000, 80, 8–14. [CrossRef]

- Herrero-Gómez, C.; Marín, P.; Hernando, A. Bias Free Magnetomechanical Coupling on Magnetic Microwires for Sensing Applications. Appl Phys Lett 2013, 103, 142414. [CrossRef]

- Hernando, A.; Madurga, V.; Barandiarán, J.M.; Liniers, M. Anomalous Eddy Currents in Magnetostrictive Amorphous Ferromagnets: A Large Contribution from Magnetoelastic Effects. J Magn Magn Mater 1982, 28, 109–116. [CrossRef]

- Gutiérrez, J.; Barandiarán, J.M.; Nielsen, O. V Magnetoelastic Properties of Some Fe-Rich FeCoSiB Metallic Glasses. physica status solidi (a) 1989, 111, 279–283. [CrossRef]

- Leung, C.M.; Zhuang, X.; Xu, J.; Li, J.; Zhang, J.; Srinivasan, G.; Viehland, D. Enhanced Tunability of Magneto-Impedance and Magneto-Capacitance in Annealed Metglas/PZT Magnetoelectric Composites. AIP Adv 2017, 8, 055803. [CrossRef]

- Kaczkowski, Z.; Vlasák, G.; Švec, P.; Duhaj, P.; Ruuskanen, P.; Barandiarán, J.M.; Gutiérrez, J.; Minguez, P. Influence of Heat-Treatment on Magnetic, Magnetostrictive and Piezomagnetic Properties and Structure of Fe64Ni10Nb3Cu1Si13B9 Metallic Glass. Materials Science and Engineering: A 2004, 375–377, 1065–1068. [CrossRef]

- Setiadi, R.N.; Schilling, M. Sideband Sensitivity of Fluxgate Sensors Theory and Experiment. Sens Actuators A Phys 2019, 285, 573–580. [CrossRef]

- Savage, H.; Clark, A.; Powers, J. Magnetomechanical Coupling and ΔE Effect in Highly Magnetostrictive Rare Earth - Fe2compounds. IEEE Trans Magn 1975, 11, 1355–1357. [CrossRef]

- Egami, T. Structural Relaxation in Amorphous Fe40Ni40P14 B6 Studied by Energy Dispersive X-Ray Diffraction. J Mater Sci 1978, 13, 2587–2599. [CrossRef]

- Herzer, G. Effect of Domain Size on the Magneto-Elastic Damping in Amorphous Ferromagnetic Metals. International Journal of Materials Research 2022, 93, 978–982.

- Egami, T. Structural Relaxation in Amorphous Alloys - Compositional Short Range Ordering. Mater Res Bull 1978, 13, 557–562. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).