1. Introduction

Concrete is a dominant construction material used worldwide; its manufacture involves the release of quantities of greenhouse-gas emissions into the atmosphere each year [

1]. Hence, the material selection for the design and manufacture of a sustainable product plays a vital role in the field of engineering design. Therefore, researchers have shown a lot of interest in the development of materials that can contribute to reducing greenhouse-gas emissions and helping the environment [

2]. The most used is conventional concrete, which is known as reinforced concrete, due to modern structural elements requiring high strength, toughness, and long-term durability [

3]. However, it is generally robust in compression, but not in tension, so steel bars are often used to improve its tensile characteristics [

4]. So, to develop high-strength concrete, the addition of different types of fibers is proposed, and to reach this issue, researchers consider that is necessary to use alternative renewable resources, different from metallic and synthetic fibers, in the production of concrete to maintain the ecological balance, such as natural fibers [

5].

Natural fibers are currently one of the most widely used reinforcement materials in terms of sustainability and biodegradability because they have large-scale industrial production. Hence, for the building sector, natural fibers used in structural elements can replace a portion of nonrenewable natural resources used and improve their mechanical characteristics, helping in the reduction of CO

2 emissions from the surrounding environment. In addition, they can be found all over the world, are cheaper than manmade fibers, have higher stiffness, and compared with synthetic fibers, they have many advantages due to their abundance and availability [

2,

6,

7]. As a result, there is an increase in the demand for the commercial use of natural fibers and natural fiber-based composites in various industrial sectors. Consequently, researchers are studying different natural fibers such as hemp, jute, sisal, banana, coconut, and bamboo.

The coconut fiber is obtained from the husk of the coconut fruit, which compared to other typical natural fibers, has higher lignin, lower cellulose, and hemicellulose, together with its high microfibrillar angle offers various valuable properties such as resilience, strength, and damping [

2]. It can be used as cement composite, and to reinforce concrete columns together with other types of fibers, because it can improve the properties of concrete due to its versatility. Furthermore, it is exceptional for controlling cracks produced by plastic shrinkage, it can also help distribute stresses more uniformly throughout the material which increases its overall tensile strength [

8,

9].

As disadvantages of natural fibers, it is their higher variability in physical and mechanical properties, lower durability, low resistance to microbial attack, and low moisture resistance, which depend mainly on the plant species, growing conditions, fiber cell geometry, each type of cellulose, so is important to this type of material need to apply chemical treatments to help prolong its durability [

10]. Among the treatments that help us to prolong the durability of coconut fiber and improve its mechanical properties before implementing it in concrete, we find alkaline and pozzolanic treatments. Therefore, in the present research, the application of mercerization and gum arabic together with silica fume was chosen [

11,

12].

Fiber mercerization consists of applying NaOH in amounts of 2% to 10% before implementation in the concrete mix because it cleans the fiber surfaces, promotes interfacial bonding, and improves the mechanical properties of composites developed from such treated natural fibers. However, it is necessary to understand the proper amount of NaOH concentration needed to produce better mechanical properties desirable for such natural fibers [

13]. Another chemical treatment is silica fume, which together with gum arabic produces beneficial effects by reducing fiber degradation and increasing protection against chlorides, as shown by Vivek and Prabalini [

14].

Nevertheless, it is considered that there are variables that can affect the performance of composites reinforced with coconut fiber, such as the origin of the fiber, the amount to be implemented, and the length of the fiber. It is known that coconut fibers have a hydrophilic nature and the characteristics of composites that have been reinforced with coconut fiber may be altered [

15]. In general, adequate content is of utmost importance since it will depend on it to obtain high performance and optimum behavior of the concrete. Although it is worth mentioning that the knowledge about coconut fiber in concrete is scattered and unimportant, this article focuses on the mechanical properties of coconut fiber-reinforced concrete under flexural tests to analyze its feasibility.

2. Materials and Methods

2.1. Materials

2.1.1. Aggregates and concrete

The coarse and fine aggregate are extracted and processed from andesites in Pifo, Ecuador, while the cement “Holcim Fuerte TM type I” was acquired from Holcim, Ecuador. Aggregates and cement were analyzed to determine their properties and the mix design. The properties of coarse and fine aggregates are presented in

Table 1, while concrete properties are shown in

Table 2.

2.1.2. Coconut fiber

The coconut husk, also called tow, was acquired from a local producer in Cojimíes-Ecuador, which is an important coconut production site, where the extraction of the fruit is done manually, while the coconut tow is set aside by order because it is considered organic waste. It is considered an important fiber that can be used in industry and construction, due to it is a multicellular fiber with a high degree of stiffness and hardness due to its two components, cellulose, and wood. Among its main characteristics, it presents low heat conductivity, resistance to bacteria and water impact, durability, and resilience, which make it the right material for thermal and acoustic insulation works. Each coconut can generate 125 grams of fiber and the extraction of these fibers from the husk also produces about 250 grams of coconut powder [

23].

The coconut fiber had a manual extraction process, which had to be carried out by hand. The process consists of separating the exocarp and endocarp, with the stems in the acquired state, but only the mesocarp was preserved because it contains the fibers and the medulla. The fragments of very short garnet were removed because of the use of the machete in the extraction of the fruit and the presence of mold. Then, the mesocarp was then dried by the sun for ease of storage and to temporarily remove the moisture acquired at the extraction site. As aggregates and cement, the coconut fiber was analyzed, and its properties were shown in

Table 3, which were used to determine the amount of coconut fiber to be used in the mixture.

The length of the fiber included in the concrete mix is a variable of notorious influence on the mechanical performance of the final product. As demonstrated by Ahmad et al. [

24], the best results are generally obtained with coir fiber lengths close to 50 mm. Similarly, ACI 544.1R-96 [

25] indicates that the recommended length for cutting coir fibers is 1.5 inches (3.77 cm). Taking into consideration the references [

24,

25], the length of fiber was determined as a value closer to the average between 5 cm and 3.77 cm, therefore, a length of 4 cm (40 mm) was defined.

2.1.3. Chemical products

The natural fibers are treated with an alkali, usually a sodium hydroxide solution, which leads to fibrillation and causes the fiber’s bundles to break into smaller fibers. In turn, it induces the fibers to develop a rough surface which results in a better interfacial adhesion with the matrix and thus improves the mechanical properties. Another consequence of mercerization treatment is increased thermal stability due to the partial removal of lignin and hemicellulose, substances more vulnerable to degradation [

26].

It is a type of resin extracted from certain species of acacia, which has been used in the formation of composite materials as a binder, together with metakaolin (pozzolan), lime, and hemp fibers. Its combination has positive results in the increase of flexural and compressive strength, as shown in the study by Brzyski (2021) [

27].

By using a pozzolan applied superficially to the fibers, it is intended to reduce the degradation of the fibers [

28], and the use of silica fume is recommended to improve the durability of natural fibers in concrete, as it increases the resistance to acid and chloride attack in concrete with coconut fibers.

Silica fume in contact with concrete causes a pozzolanic effect, which generates silicates and calcium aluminates that consequently reduce the local pH, increasing the strength and cohesion of the mix [

29].

2.2. Chemical treatments

To develop the chemical treatments applied, the caustic soda and gum arabic were obtained from La Casa del Químico S.A., while the silica fume (SikaFumeTM ) was acquired from Aplika S.A. The application of the chemical treatments was developed to preserve the coconut filament and improve its properties [

3].

2.2.1. Mercerization

This process involves immersing the cut fibers in a sodium hydroxide or NaOH solution at 4% by weight. The fibers were submerged in the solution for 24 hours and then rinsed with ordinary water until the fibers reached a neutral pH, followed by drying at room temperature [

3]. During the rinsing phase, it was observed that the water was brown due to the amount of lignin and other components removed from the fibers (

Figure 1a).

2.2.2. Silica fume + resin

Silica fume treatment together with gum arabic looks for beneficial effects of both materials, in reducing fiber degradation at the local level, as Vivek and Prabalini (2020) [

30] called: in the vicinity of the fibers.

For the application of this treatment (

Figure 1b), the powdered gum arabic solution was prepared with ordinary water, so that the mixture obtained adequate adhesion. After that, the cut fiber was immersed in the solution for one minute, the fiber was drained, and then the silica fume was added to cover the whole fiber, and finally left to dry at room temperature [

3].

A sample of uncut coconut fiber was taken and subjected to the treatments described, another part of the sample was not treated. Fifty specimens were obtained for each of the typologies indicated above. Data such as weight and length were taken for subsequent labeling. Tests were carried out at the Textile Polytechnic Center of the National Polytechnic School (EPN). The criteria described in ASTM D2256 [

31] were followed and Instron 3345 tensile testing equipment was used.

After placing the specimens in the test equipment, a load of ten silos was applied at a 30 mm/minute crosshead speed until they reached breakage. The breaking force (N) and elongation (mm/mm) were measured with the machine, which did not allow obtaining the toughness (N/tex), being the result of the breaking force divided by the linear density (tex), the latter being obtained by calculating the weight of the specimen and its length.

2.3. Dosing process

The dosing process follows phases before starting the dosage process in a laboratory. First, is necessary to determine the required strength which is greater than the f’c, and in the absence of a test history, it was calculated based on

Table 5.3.2.2. presented in ACI 318-08 (2008) [

32]. Second, to define the type of settlement Table A1.5.3.1 was used, which is presented in ACI 211.1-91 (2009) [

33]. Third, to define the nominal maximum size selection is necessary to determine the particle size analysis of coarse aggregate, the sections or dimensions of the element, and the type of work; to define that we used the ACI 211.1-91 (1991) [

34], also this normative was used to define the quantity of water for 1m

3 based on the second and third step. Fourth, to select the water/cement ratio (w/c), compressive strength is needed, which is found for different compressive strengths, with or without air inclusion [

34]. Finally, to estimate the aggregate quantity, the volume of compacted coarse aggregate, which is dry at room temperature per unit volume, is needed. The apparent volume of coarse aggregate, in m³, per unit volume of concrete is selected according to [

34].

Once all components for the dosage have been reached, the ACI 211.1 (2016) [

35] criteria will be followed. The ACI method proposes the use of tables, which contain design values and these values depend on the materials to be used in the mix. The following dosages, presented in

Table 4, were proposed as a proportion by the weight of cement, which were the starting point until the final dosage was reached.

To verify that the dosage is adequate, a compression test was carried out after 7 days of curing two concrete cylinders and it was observed that it did not reach the reference resistance, which must be 65% of the design resistance. Therefore, this dosage was modified, until it reached the reference resistance after 7 days. Consequently, the dosages present in

Table 5 have been taken as the definitive dosages.

Table 5.

Final dosage for the strength of 20.59 and 23.54 MPa.

Table 5.

Final dosage for the strength of 20.59 and 23.54 MPa.

| Code |

Design f‘c (MPa) |

Cement |

fa/c |

ca/c |

w/c |

| M1 |

20.59 |

1 |

2.07 |

1.66 |

0.57 |

| M2 |

23.54 |

1 |

1.77 |

1.36 |

0.50 |

2.4. Specimen Preparation and Analysis

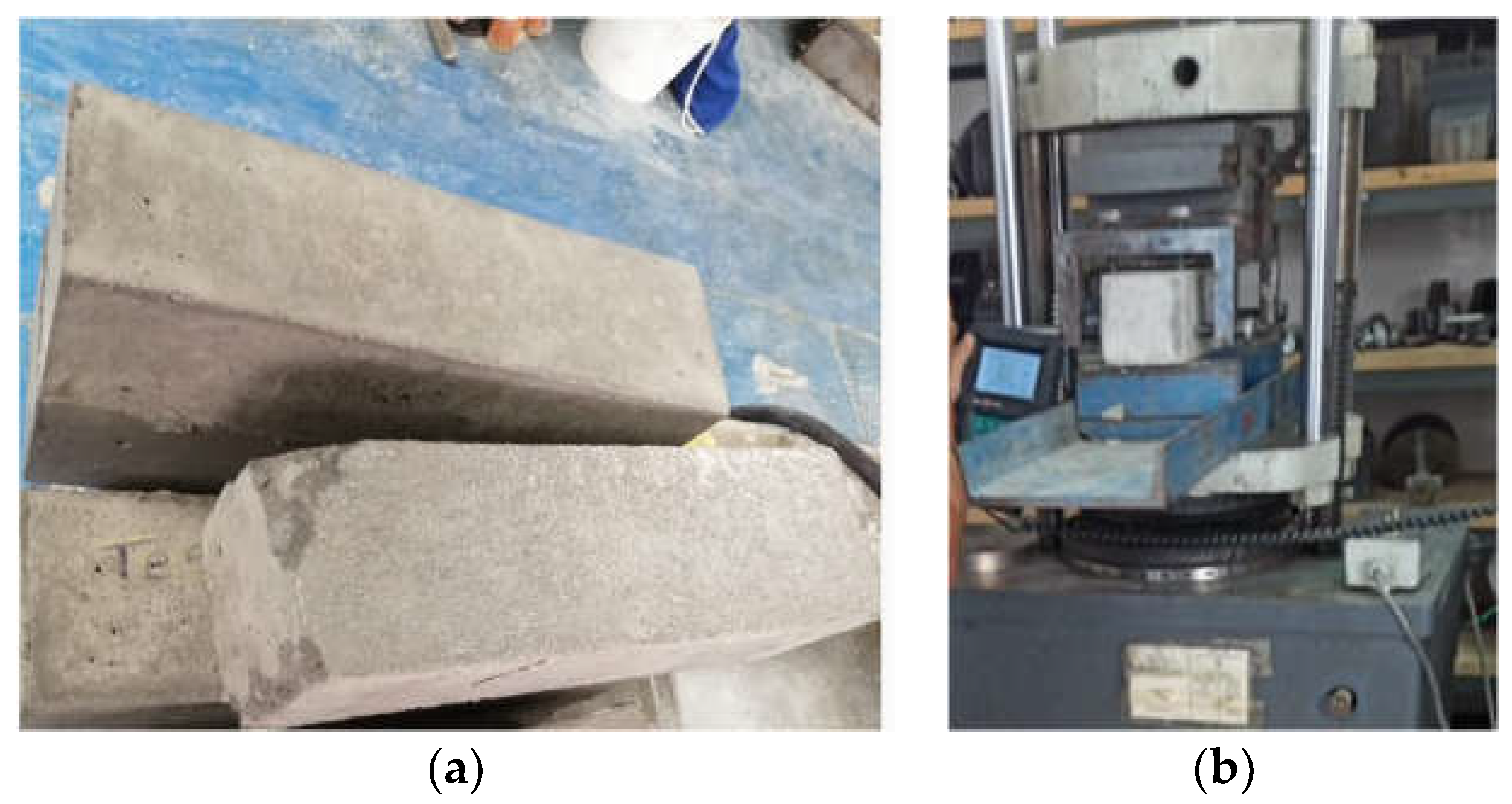

The joists were prepared and tested at the Laboratory of Strength of Materials, Soil Mechanics, Pavement, and Geotechnical Engineering of the Pontificia Universidad Católica del Ecuador. Joists of 100 x 100 x 350 mm ASTM C1399/C1399 M-10 (2015) [

36] were prepared. Joists with and without coconut fiber were manufactured for design strengths of 20.59 and 23.54 MPa at 14, 28, and 56 days of age. Coir fiber was used in a volume percentage of 0.5% and 1% and similarly distinguished by the chemical treatment to which the fiber was subjected (mercerization and silica fume treatment), based on the mixes detailed in

Table 5.

Seven joists were manufactured for each of the categories, i.e., by mix design, fiber content, fiber treatment, and cylinder age, for a total of 210 joists (

Figure 2a).

At the corresponding ages, the joists were tested according to the guidelines indicated in ACTM C1399/C1399 M-10 [

36]. The modulus of rupture was also determined based on the failure third of the joist, as seen in

Figure 2b [

37].

2.5. Determination of residual strength and modulus of rupture

Having performed the test, which provides us with data that allows us to obtain the load-deflection curve distant from where significant cracking damage has occurred providing a post-cracking resistance being affected by the fiber reinforcement. In calculating the average residual strength, the deflections of the beam are used.

To calculate the average residual strength (ARS), the loads determined at the curve deflections of 0.50, 0.75, 1.00, and 1.25 mm are used by applying the following formula:

Where:

K: , .

ARS: Average Residual Strength, MPa.

PA+PB+PC+PD: Sum of recorded loads in the specified time – deflections, N.

L: Length of section, mm.

b: average beam width, mm.

d: average depth of the beam, mm.

The modulus of rupture is obtained by loading the joist with equal concentrated loads on the thirds of the span, such loads increasing until cracking failure at the tension face of the beam [

37]. The calculation of the modulus of rupture is obtained in two ways:

Where:

fr: Modulus of rupture, MPa.

P: Maximum applied load of the machine, N.

L: Length, mm.

b: Average sample width, mm.

d: Average depth of the sample, mm.

a: average distance between the fracture line and the nearest support, mm.

In the application of the above equations, it is necessary to have the dimensions of the beam to be tested. Furthermore, it is worth mentioning that, for the calculation of the modulus of rupture, the fracture of the joist occurred in the middle third of the total length of the joists, therefore, equation 2 was used.

The theoretical modulus of rupture was calculated based on ACI 318-19 [

38], paragraph 19.2.4, which uses the following expression:

Where:

fr: Modulus of rupture, MPa.

f'c: Concrete strength, MPa.

λ: Modification factor that takes into account the reduced mechanical properties of lightweight concrete as those of normal weight concrete as well as the compressive strength. The value of λ is to be determined based on tables 19.2.4.1 (a) and 19.2.4.1 (b) of ACI 318-19, or as permitted in sections 19.2.4.2 and 19.2.43.

3. Results and Discussion

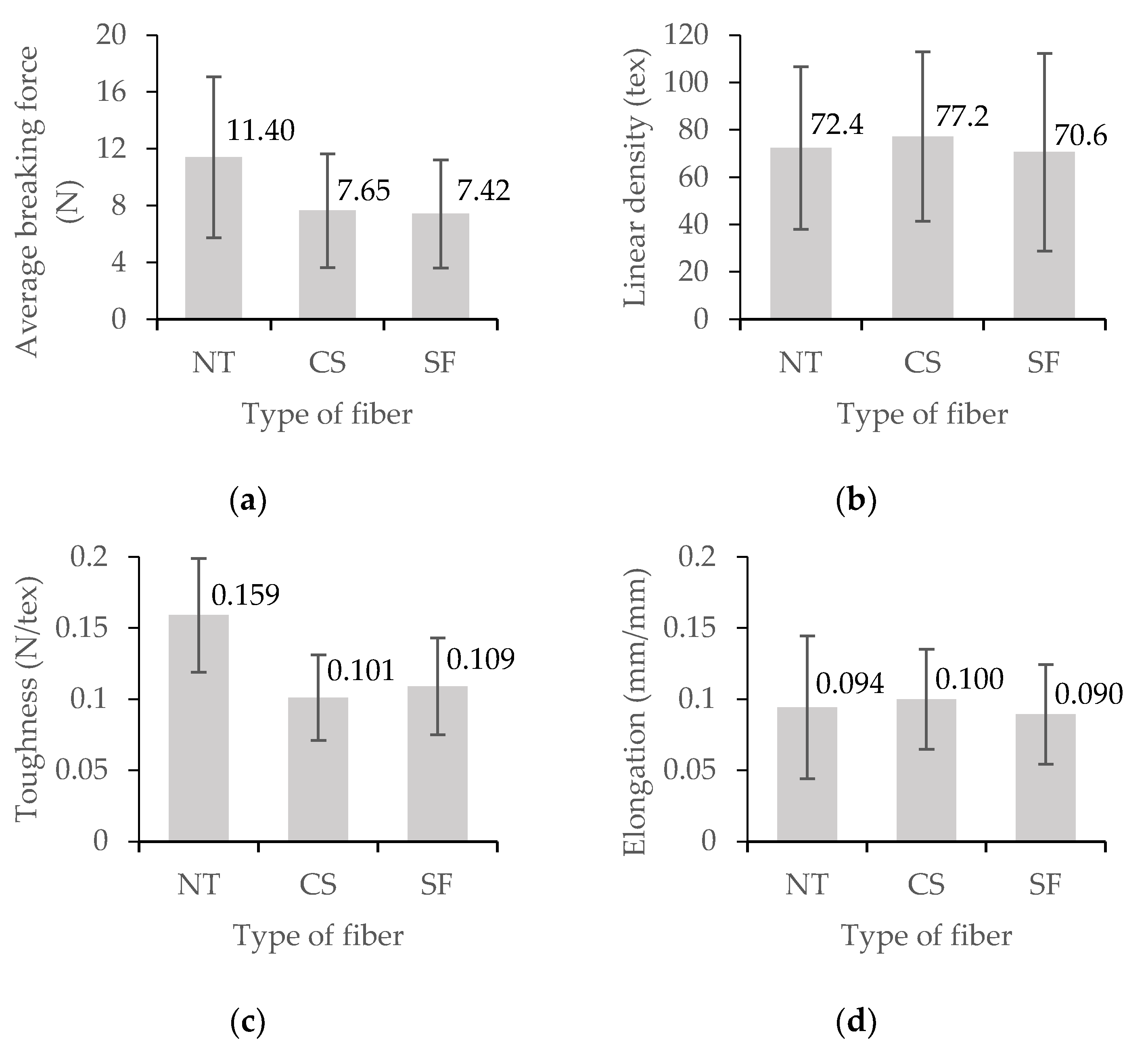

3.1. Physical and Mechanical Characteristics of the Fiber

Three typologies were determined: NT (fibers without any treatment), CS (fibers treated with caustic soda or NaOH), and SF (fibers treated with silica fume and gum arabic).

The treatment with caustic soda or NaOH shows a slight increase in the maximum elongation of the fibers compared to the untreated fibers or the treatment with silica fume. It was also found that there is a higher line density compared to the other two typologies. However, a lower value of the average breaking strength was obtained for the CS fibers compared to the NT and SF fibers.

The dissociation of results is due to the heterogeneity of the coconut fibers, presenting imperfections and defects in considerable quantities [

39].

The mechanical properties of coconut fiber were inferior to the rest of natural and synthetic fibers, which could result in lower strength of the composite. However, the decrease in CS and SF properties would be counterbalanced by a better adhesion between the coconut fiber and the other components of the concrete mix resulting in a composite material with optimum properties [

40].

3.2. Composite Concrete Density

We found that the addition of fibers in the percentage dosage of the joists caused a slight change in the density of the composite concrete, reflecting values in the joists without fiber of 2.395 t/m3 and 2.396 t/m3 for the design strengths of 20. 59 MPa and 23.54 MPa respectively compared to the density of concrete with fiber, giving us values between 2.403 t/m3 and 2.418 t/m3 for the design strength of 20.59 MPa and between 2.4082 and 2.4356 for the design strength of 23.54 MPa.

Higher values were obtained as the percentage of fiber increased in the mixture and the volume of voids was also considered [

3].

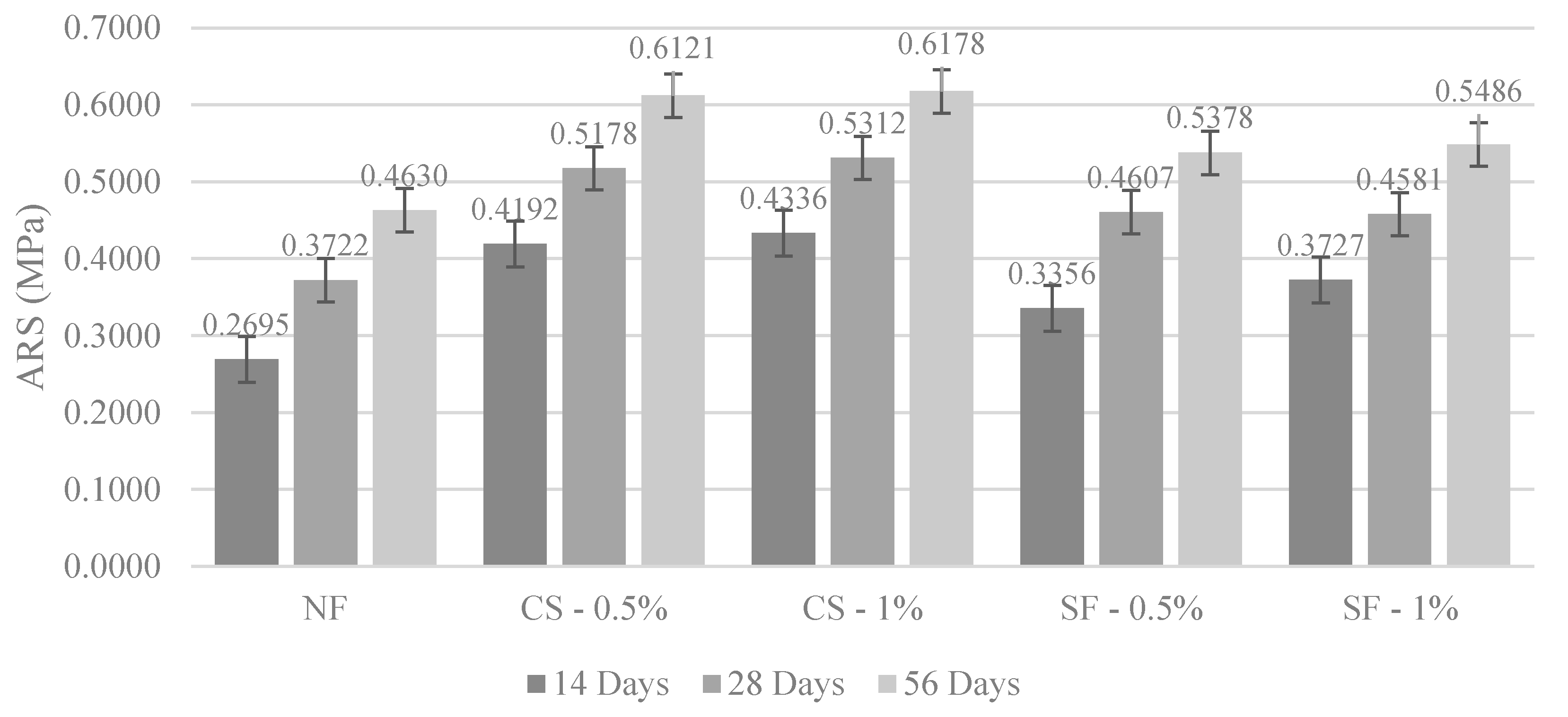

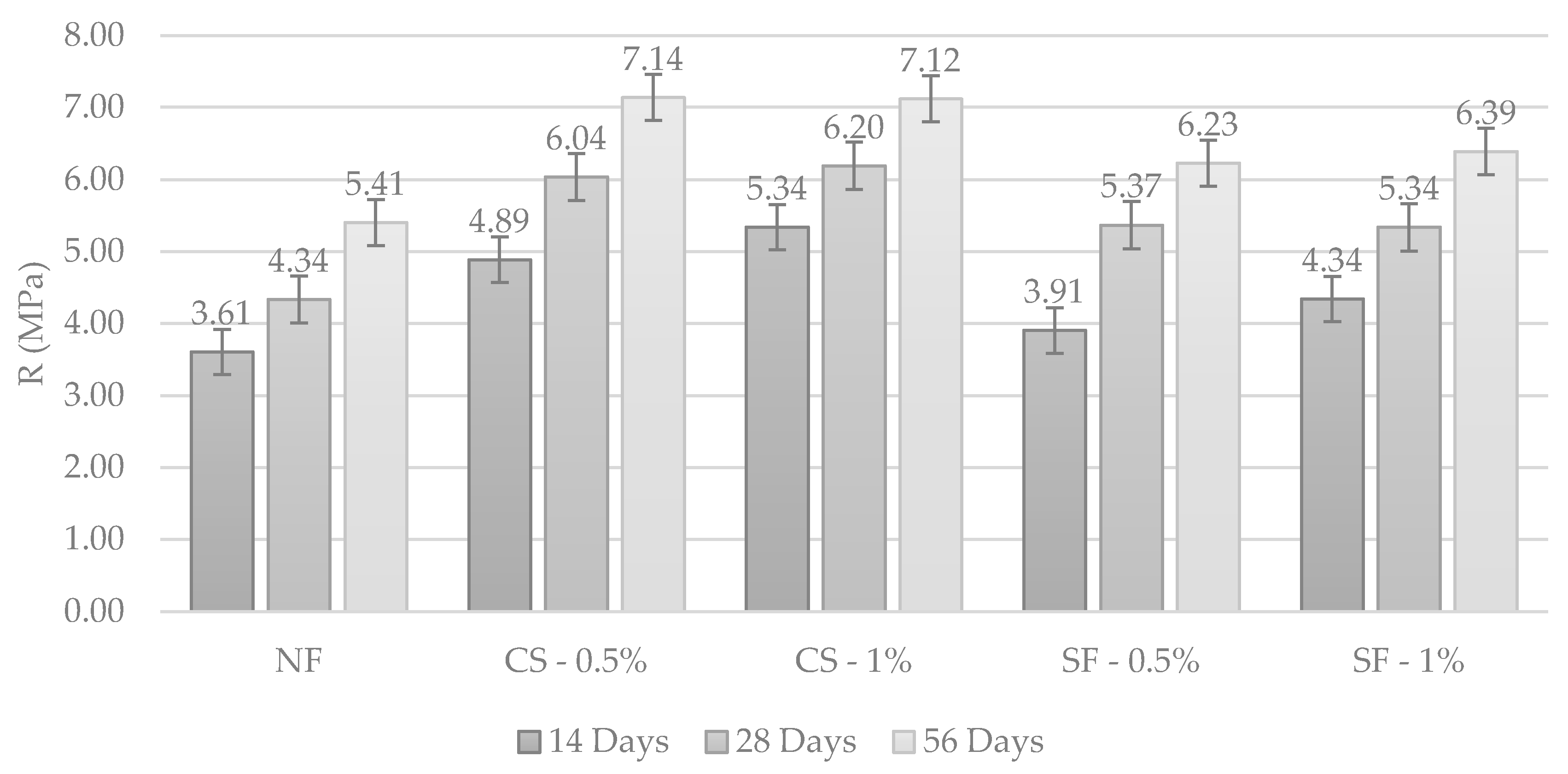

3.3. Average residual strength

Table 6 shows the average residual strength of the joists at design strength 20.59 MPa for each of the types, i.e., without fiber (NT), joists with coir fiber treated with caustic soda (CS), and joists with coir fibers treated with silica fume (SF) and with fiber contents of 0.5% and 1% at ages 14, 28 and 56 days.

In general, better results were obtained for joists containing coconut fiber treated with caustic soda, as seen in

Figure 4 [

3].

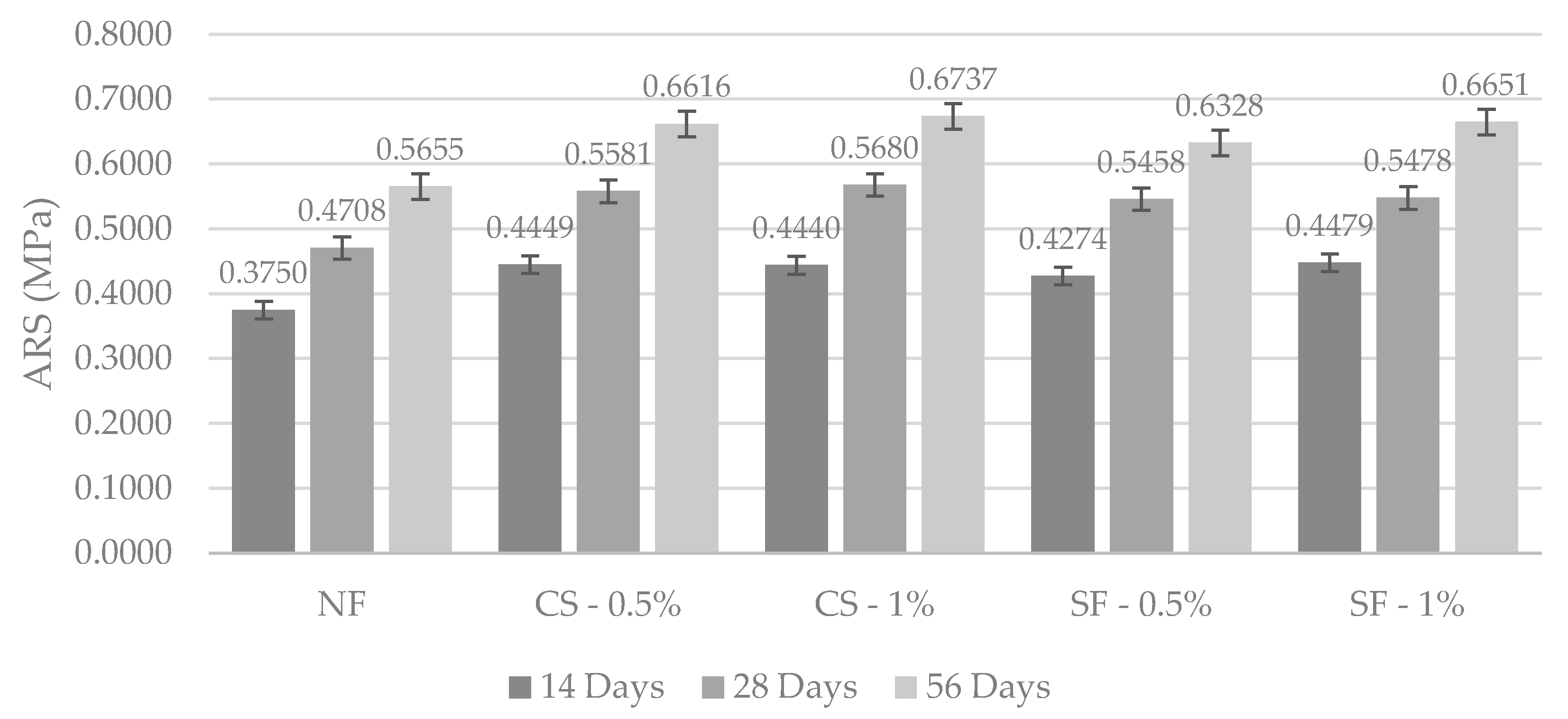

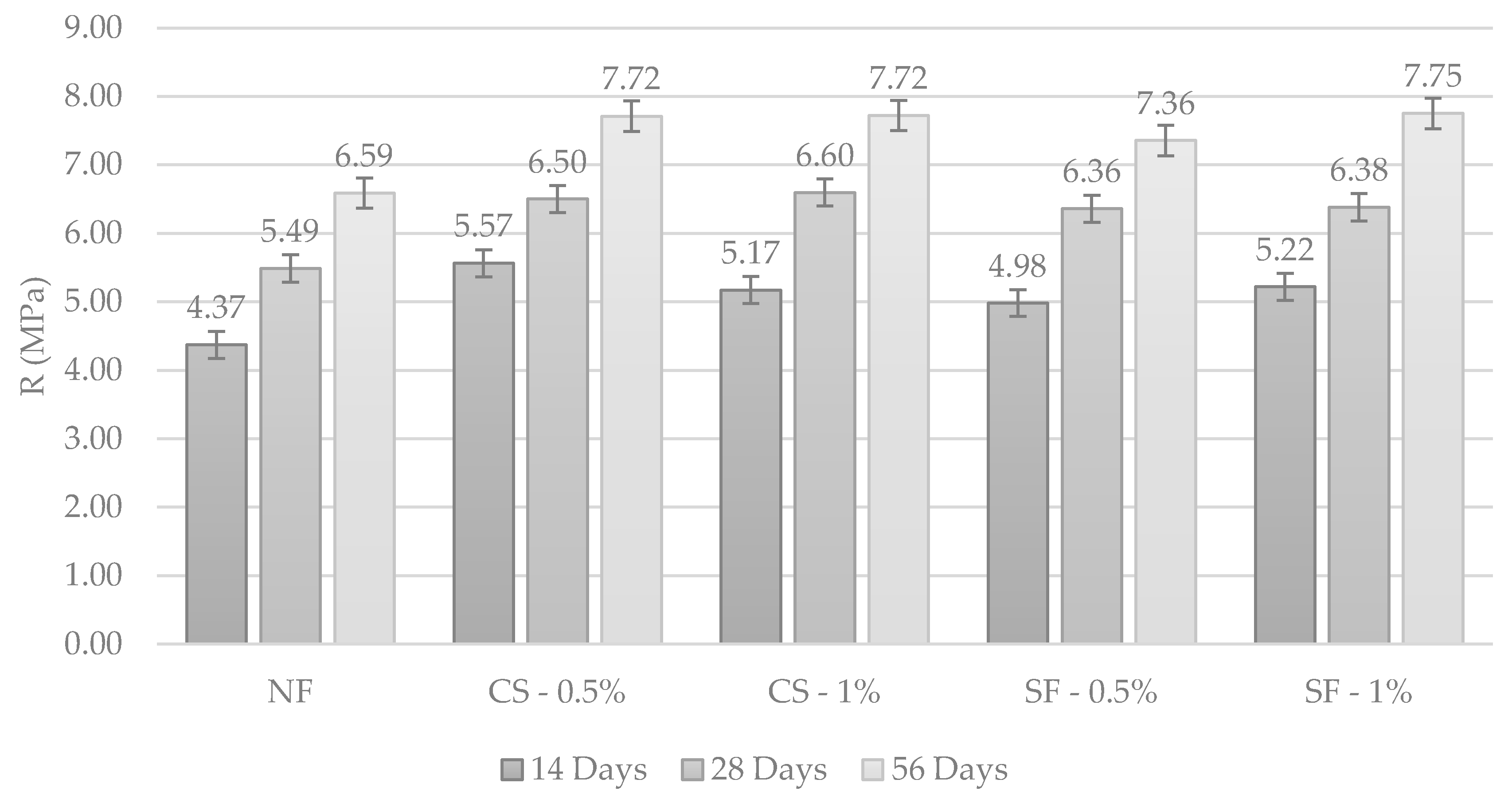

Table 7 shows the average residual strength obtained from the joists with a design strength of 23.54 MPa, for the ages of 14, 28, and 56 days.

Figure 5 shows the effect of coconut fibers with their respective chemical treatments on the average residual strength of the joists. It is observed that there are higher strengths in the joists with treated fibers compared to the joists that did not contain fiber. There is an increase in the resistance from 14 days in the joists with fibers treated with both chemical treatments about the joists without fiber, however, a slight difference is observed in the results of the treated joists, and it is determined that the treatment with caustic soda presents optimum values.

3.4. Modulus of Rupture

The theoretical modulus of rupture was determined based on ACI 318-19 [

41], paragraph 19.2.4. It was determined that for a design strength of 20.59 MPa, a theoretical modulus of rupture of 2.81 MPa was obtained and for a design strength of 23.54 MPa, a theoretical modulus of rupture of 3.01 MPa was obtained.

In general, modulus of rupture values higher than the theoretical modulus of rupture was obtained, in the case of a design strength of 20.59 MPa, as shown in

Table 8.

Figure 6 shows the modulus of rupture respectively for each of the typologies, and it can be observed that optimum values are obtained in the joists with coir fibers treated with caustic soda, with a slight difference with silica fume treatment. However, higher values are obtained with a fiber volume of 1% with a small difference at 56 days.

Similarly,

Table 9 shows the values obtained for the modulus of rupture for a design strength of 23.54 MPa, in which it can be observed that values higher than the theoretical modulus of rupture have been obtained.

As in the previous case,

Figure 7 shows the results obtained for the modulus of rupture, and in the case of the joists treated with caustic soda for each of the specified volumes, values considerably higher than the rest of the typologies were obtained, with a slight similarity with the joists with coconut fibers treated with silica fume with a fiber volume of 1%, in which a slightly higher value was obtained. However, it is considered that the CS joists yield optimal values compared to the SF joists.

4. Conclusions

The coconut fiber composite concrete was made with different chemical treatments, different volume proportions of coconut fiber, and different test ages for the joists. High values of the indicated properties were obtained for the coconut fibers treated with caustic soda or NaOH with a lower fiber volume ratio and higher design strength. By adhering to the coconut fibers as another component of the concrete, a higher performance was observed in the CS joists than the SF joists, even though there was an unfavorable impact on the coconut fiber due to the application of the chemical treatments. Based on the results obtained we can conclude:

One of the properties of the concrete that changed is the density, as the proportion of coconut fiber increased up to 1% the density in relation to the joists that did not contain coconut fiber. Similarly, this increase in density is because the water absorption of concrete reinforced with coconut fibers is greater than that of conventional concrete because the coconut fiber retains air spaces within its structure and therefore can absorb a large amount of water, filling these voids.

The application of chemical treatments helps in the conservation of the fiber within the mixture, since it is a biodegradable material, its durability is affected. The treatments applied provided superior mechanical properties; however, the caustic soda treatment achieved better results concerning breaking strength, maximum elongation, and linear density, which is why it is considered the most appropriate to apply to the fibers, since it enhances the toughness of the concrete, allowing the reinforced concrete components to work as a single element, providing response efforts to the cracks that may occur, preventing their propagation.

The workability was affected as the coconut fiber content increased in the mix since the fresh mix has a higher hardness.

A higher modulus of rupture values was obtained for the joists with coconut fiber tested compared to the joists without coconut fiber. However, the inclusion of 1% coconut fiber gave optimum results about the 0.5% proportion and conventional concrete, because the coconut fibers increase the bending capacity by inhibiting the development of fractures due to the interface of the coconut fiber around the cracks. Discontinuous stresses are produced in a composite action that decreases the brittleness of the plain concrete.

The application of coconut fibers in the concrete mix allowed the average residual strength of the joists to improve considerably, as evidenced in the tests performed under ASTM C1399/C1399M-10 [

36], which allowed us to verify the effectiveness of coconut fibers in concrete since the concrete joists were tested with and without fiber, which were tested at 14, 28 and 56 days. Having performed the tests, it was evidenced an improvement of up to 33% of the joists with coconut fiber compared to the joists without fiber, thus concluding that the addition of coconut fibers in concrete improves its mechanical properties, increasing its energy absorption capacity and decreasing its brittleness even after cracking.

Author Contributions

Conceptualization, A.M., A.R., and J.A.-S.; methodology, N.B.Y.G. and J.A.-S.; software, A.M.; validation, A.R., A.M., J.A.-S., and N.B.Y.G.; formal analysis, N.B.Y.G. and M.A.; investigation, A.M. and A.R.; resources, J.A.-S., N.B.Y.G., A.M. and A.R.; data curation, N.B.Y.G.; writing—original draft preparation, A.M. and A.R.; writing—review and editing, A.M., A.R. and M.A.; visualization, A.M. and A.R.; supervision, L.H. and E.M.; project administration, L.H.; funding acquisition, N.B.Y.G. and J.A.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors acknowledge Hilda Trujillo of the Department of Chemical Engineering—Polytechnic Textile Center, National Polytechnic School (EPN) for her support in fiber testing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1. E. Vélez et al., “Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits,” Fibers, vol. 10, no. 11, Nov. 2022, doi: 10.3390/fib10110096. [CrossRef]

- Y. G. Thyavihalli Girijappa, S. Mavinkere Rangappa, J. Parameswaranpillai, and S. Siengchin, “Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review,” Frontiers in Materials, vol. 6. Frontiers Media S.A., Sep. 27, 2019. doi: 10.3389/fmats.2019.00226. [CrossRef]

- B. Ali, A. Hawreen, N. Ben Kahla, M. Talha Amir, M. Azab, and A. Raza, “A critical review on the utilization of coir (coconut fiber) in cementitious materials,” Constr Build Mater, vol. 351, p. 128957, Oct. 2022, doi: 10.1016/J.CONBUILDMAT.2022.128957. [CrossRef]

- 4. J. Ahmad et al., “Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review,” Materials, vol. 15, no. 10. MDPI, May 01, 2022. doi: 10.3390/ma15103601. [CrossRef]

- 5. M. Gu et al., “Scientometric Analysis and Research Mapping Knowledge of Coconut Fibers in Concrete,” Materials, vol. 15, no. 16. MDPI, Aug. 01, 2022. doi: 10.3390/ma15165639. [CrossRef]

- 6. J. Ahmad et al., “Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review,” Materials, vol. 15, no. 10. MDPI, May 01, 2022. doi: 10.3390/ma15103601. [CrossRef]

- 7. M. Hussain et al., “Analysis of physical and mechanical characteristics of tropical natural fibers for their use in civil engineering applications,” Journal of Natural Fibers, vol. 20, no. 1, 2023, doi: 10.1080/15440478.2022.2164104. [CrossRef]

- M. Amaguaña, L. Guamán, N. B. Y. Gómez, M. Khorami, M. Calvo, and J. Albuja-Sánchez, “Test Method for Studying the Shrinkage Effect under Controlled Environmental Conditions for Concrete Reinforced with Coconut Fibres,” Materials, vol. 16, no. 8, p. 3247, Apr. 2023, doi: 10.3390/ma16083247. [CrossRef]

- 9. N. Beskopylny et al., “Improving the Physical and Mechanical Characteristics of Modified Aerated Concrete by Reinforcing with Plant Fibers,” Fibers, vol. 11, no. 4, Apr. 2023, doi: 10.3390/fib11040033. [CrossRef]

- 10. R. Prakash et al., “Effect of Steel Fiber on the Strength and Flexural Characteristics of Coconut Shell Concrete Partially Blended with Fly Ash,” Materials, vol. 15, no. 12, Jun. 2022, doi: 10.3390/ma15124272. [CrossRef]

- 11. K. S. Natarajan, D. Ramalingasekar, S. Palanisamy, and M. Ashokan, “Effect on mechanical properties of lightweight sustainable concrete with the use of waste coconut shell as replacement for coarse aggregate,” Environmental Science and Pollution Research, vol. 29, no. 26, pp. 39421–39426, 2022, doi: 10.1007/s11356-022-18905-9. [CrossRef]

- F. R. B. Martinelli, F. R. C. Ribeiro, M. T. Marvila, S. N. Monteiro, F. da C. G. Filho, and A. R. G. de Azevedo, “A Review of the Use of Coconut Fiber in Cement Composites,” Polymers, vol. 15, no. 5. MDPI, Mar. 01, 2023. doi: 10.3390/polym15051309. [CrossRef]

- M. A. O. Mydin, N. Md. Noordin, N. Utaberta, M. Y. Mohd Yunos, and S. Segeranazan, “PHYSICAL PROPERTIES OF FOAMED CONCRETE INCORPORATING COCONUT FIBRE,” J Teknol, vol. 78, no. 5, Apr. 2016, doi: 10.11113/jt.v78.8250. [CrossRef]

- 14. S. S. Vivek and C. Prabalini, “Experimental and microstructure study on coconut fibre reinforced self compacting concrete (CFRSCC),” Asian Journal of Civil Engineering, vol. 22, no. 1, pp. 111–123, 2021, doi: 10.1007/s42107-020-00302-7. [CrossRef]

- T. Puspaningrum, Y. H. Haris, I. Sailah, M. Yani, and N. S. Indrasti, “Physical and mechanical properties of binderless medium density fiberboard (MDF) from coconut fiber,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics Publishing, Jun. 2020. doi: 10.1088/1755-1315/472/1/012011. [CrossRef]

- American Society for Testing and Materials: West Conshohocken, “ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates.,” PA, USA, 2012.

- American Society for Testing and Materials: West Conshohocken, “ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ,” PA, USA, 2016.

- American Society for Testing and Materials: West Conshohocken, “ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate.,” PA, USA, 2016.

- American Society for Testing and Materials: West Conshohocken, “ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete.,” PA, USA, 2017.

- American Society for Testing and Materials: West Conshohocken, “ASTM C566; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying.,” PA, USA, 2019.

- American Society for Testing and Materials: West Conshohocken, “ASTM C188; Standard Test Method for Density of Hydraulic Cement.,” PA, USA, 2017.

- American Society for Testing and Materials: West Conshohocken, “ASTM C187; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste,” PA, USA, 2016.

- R. Nuñez, “Estudio tecnológico del componente fibra de dos variedades de Coco Enano (Cocos nucifera) de los distritos de Lamas, Tarapoto y Pucacaca en la Región San Martín,” Universidad Nacional de San Martín., Tarapoto, Perú., 2010.

- 24. W. Ahmad et al., “Effect of coconut fiber length and content on properties of high strength concrete,” Materials, vol. 13, no. 5, Mar. 2020, doi: 10.3390/ma13051075. [CrossRef]

- American Concrete Institute: Farmington Hills, ACI 544.1R-96; (Reapproved 2009) State-of-the-art report on fiber reinforced concrete. MI, USA, 1997.

- S. Ali, “Hydrophobic treatment of natural fibers and their composites.,” A review: Journal of Industrial Textiles, 47(8), pp. 2156–2183, 2016.

- P. Brzyski, “The Influence of Gum Arabic Admixture on the Mechanical Properties of Lime-Metakaolin Paste Used as Binder in Hemp Concrete.,” Materials, 14(22), pp. 1–22, 2021.

- M. , S. M. y K. S. Sudhakaran Pillai, “Effect of silica fume surface treatment on natural fibres in resisting chloride resistance in concrete. ,” Material Science Research India., pp. 209–214, 2010. [CrossRef]

- E. J. Silva, “A new treatment for coconut fibers to improve the properties of cement-based composites – Combined effect of natural latex/pozzolanic materials. .,” Sustainable Materials and Technologies, 12, pp. 44–51, 2017. [CrossRef]

- 30. S. S. y P. C. Vivek, “Experimental and microstructure study on coconut fibre reinforced self compacting concrete (CFRSCC).,” Asian Journal of Civil Engineering, 22(1), pp. 111–123, 2020. [CrossRef]

- American Society for Testing and Materials: West Conshohocken, “ASTM D2256; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. ,” PA, USA, 2021.

- ACI 318-08, Requisitos de Reglamento para Concreto Estructural. 2008.

- ACI 211.1-91, Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. 2009.

- American Concrete Institute: Farmington Hills, ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. MI, USA, 1991.

- ACI 211.1, Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. 2016.

- American Society for Testing and Materials: West Conshohocken, “ASTM C1399/1399 M-10.Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete,” PA, USA, 2015.

- American Society for Testing and Materials: West Conshohocken, ASTM C78/C78M-22. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). PA, USA, 2022.

- ACI 318-19, “ACI 318R-19, Requisitos de Reglamento para Concreto Estructural,” American Concrete Institute. Michigan, Estados Unidos., 2019.

- S. N. Monteiro, F. M. Margem, H. P. Guimarães Santafé Júnior, L. B. de Souza Martins, and M. P. Oliveira, “Correlation between the diameter and the density of coir fiber using the weibull statistic methodology,” in Materials Science Forum, Trans Tech Publications Ltd, 2014, pp. 266–271. doi: 10.4028/www.scientific.net/MSF.775-776.266. [CrossRef]

- D. L. Rocha, L. U. D. T. Júnior, M. T. Marvila, E. C. Pereira, D. Souza, and A. R. G. de Azevedo, “A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History,” Polymers, vol. 14, no. 10. MDPI, May 01, 2022. doi: 10.3390/polym14102043. [CrossRef]

- American Concrete Institute., “ACI 318R-19, Requisitos de Reglamento para Concreto Estructural.” Michigan, Estados Unidos., 2019.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).