Submitted:

19 May 2023

Posted:

22 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results and discussion

2.1. Chemical characterization of raw materials

2.2. Biochemical Methane Potential (BMP) of different strategies with PWP

2.3. Different pretreatment for assays semi-continuous with PM and PWP

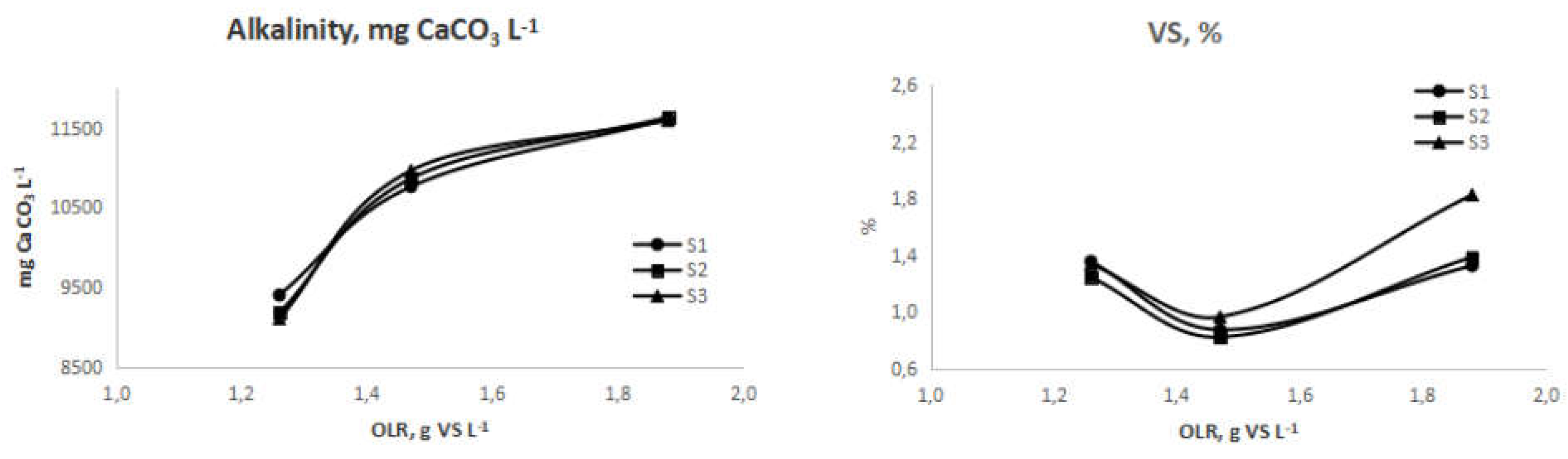

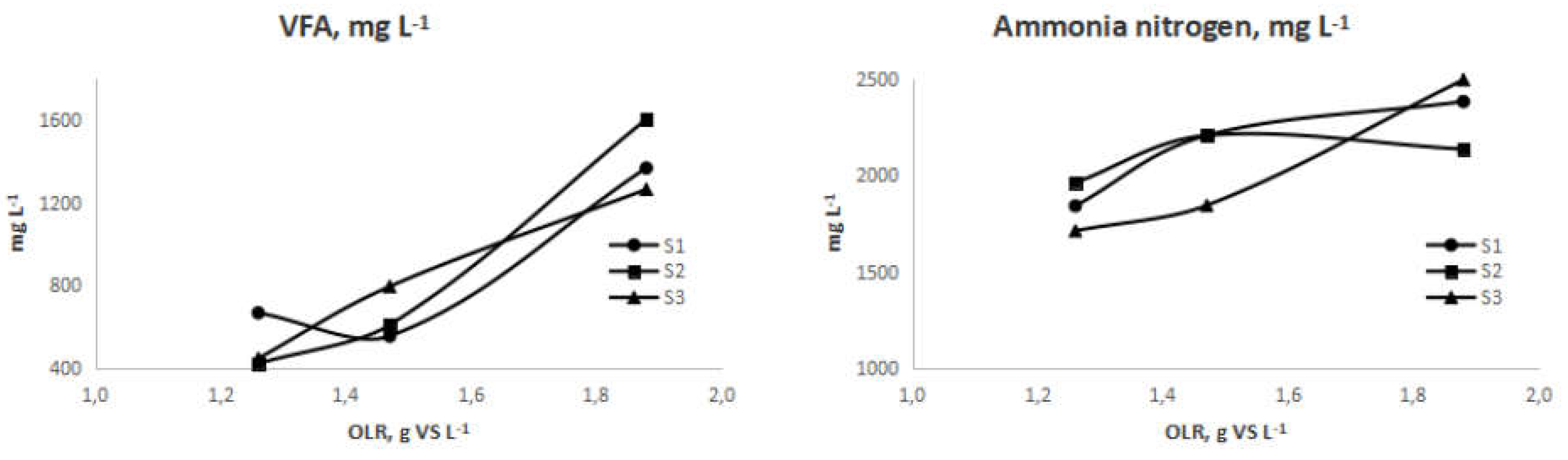

2.4. Effect of OLR on different parameter

2.5. Digestate pilot plant experiment

3. Materials and Methods

3.1. Evaluated raw materials

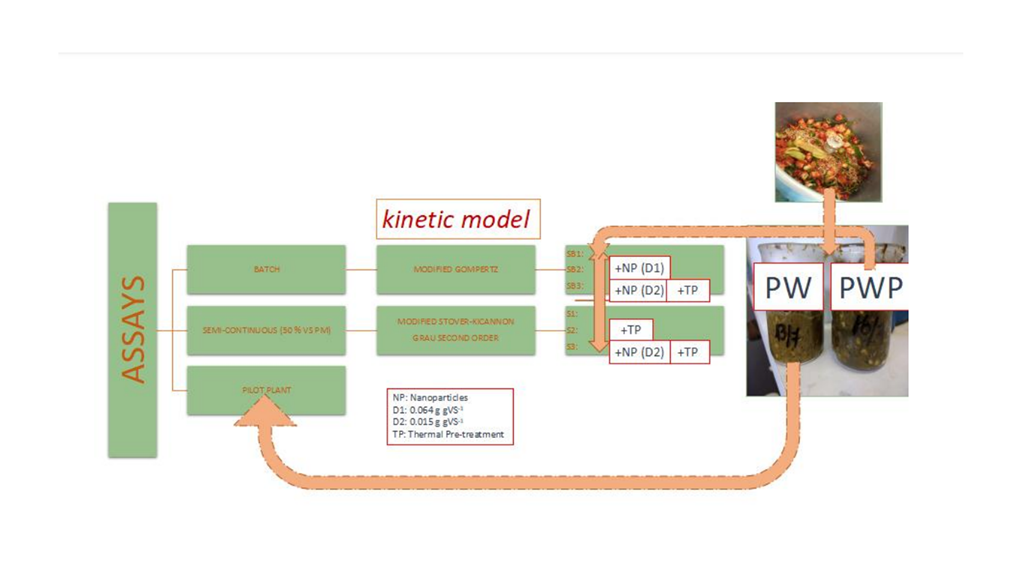

3.2. Digester used and experimental design

3.3. Analytical methods

3.4. Evaluation of substrate removal kinetic models

4. Conclusions

Acknowledgments

References

- Directiva (UE) 2018/2001 del Parlamento Europeo y del Consejo de 11 de Diciembre de 2018 relativa al fomento del uso de energía procedente de fuentes renovables. Estrasburgo, Francia. 2018.

- Manual sobre las Biorrefinerías en España. Spain. 2017.

- VII Plan Regional de Investigación, Desarrollo Tecnológico e Investigación de Extremadura 2022-2025. Mérida, España. 2022.

- Instituto Nacional de Estadística. Available online: https://www.ine.es/jaxi/Datos.htm?path=/t26/p067/p02/residuos/serie/l0/&file=02001.px (accessed on 3 January 2023).

- Ministerio de Agricultura, Pesca y Alimentación: Cifras del sector de frutas y hortalizas. Madrid, España, 2022.

- Ros, M.; Pascual, JA.; Ayuso, M.; Morales, AB.; Miralles, JR.; Solera, C. Salidas valorizables de los residuos y subproductos orgánicos de la industria de los transformados de frutas y hortalizas: proyecto LIFE+Agrowaste. Residuos: Revista Técnica, 2012, 22, 28–35. [Google Scholar]

- Vulic, J.; Seregelj, V.; Kalusevic, A.; Levic, S.; Nedovic, V.; Saponjac, VT.; Canadanovic-Brunet, J.; Cetkovic, G. Bioavailability and bioactivity of encapsulated phenolics and carotenoids isolated from red pepper wastes. Molecules, 2019, 24, 2837. [Google Scholar] [CrossRef] [PubMed]

- Mórtola, N.; Romaniuk, R.; Consentino, V.; Eiza, M.; Carfagno, P.; Rizzo, P.; Bres, P.; Riera, N.; Roba, M.; Butti, M.; Sainz, D.; Brutti, L. Potential Use of a Poultry Manure Digestate as a Biofertiliser: Evaluation of Soil Properties and Lactuca sativa Growth, Pedosphere, 2019, 29, 60-69; [CrossRef]

- Riaño, B.; Molinuevo-Salcés, B.; Parralejo, A.; Royano, L.; González, J.; García-González, MC. Techno-economic evaluation of anaerobic co-digestion fo pepper waste and swine manure. Biomass Conversion and Biorefinery, 2021. [Google Scholar] [CrossRef]

- Li, R.; Tan, W.; Zhao, X.; Dang, Q.; Song, Q.; Xi, B.; Zhang, X. Evaluation on the Methane Production Potential of Wood Waste Pretreated with NaOH and Co-Digested with Pig Manure. Catalysts, 2019, 9, 539. [Google Scholar] [CrossRef]

- Madondo, N.I.; Tetteh, E.K.; Rathilal, S.; Femi Bakare, B. Application of Bioelectrochemical System and Magnetite Nanoparticles on the Anaerobic Digestion of Sewage Sludge: Effect of Electrode Configuration. Catalysts, 2022, 12, 642. [Google Scholar] [CrossRef]

- Goswami, L.; Kushwaha, A.; Singh, A.; Saha, P.; Choi, Y.; Maharana, M.; Patil, S.V.; Kim, B.S. Nano-Biochar as a Sustainable Catalyst for Anaerobic Digestion: A Synergetic Closed-Loop Approach. Catalysts, 2022, 12, 186. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Rathilal, S. Kinetics and Nanoparticle Catalytic Enhancement of Biogas Production from Wastewater Using a Magnetized Biochemical Methane Potential (MBMP) System. Catalysts, 2020, 10, 1200. [Google Scholar] [CrossRef]

- Somridhivej, B.; Boyd, C.E. An assessment of factors affecting the reliability of total alkalinity measurements. Aquaculture, 2016, 459, 99–109. [Google Scholar] [CrossRef]

- Flotats, X.; Bonmatí, A.; Campos, E.; Antúnez, M. Ensayos en discontinuo de co-digestión anaerobia termofílica de purines de cerdo y lodos residuales. Información Tecnológica, 1999, 10, 79–85. [Google Scholar]

- Zhang, W.; Kong, T.; Xing, W.; Li, R.; Yang, T.; Yao, N.; Lv, D. Links between carbon/nitrogen ratio, synergy and microbial characteristics of long-term semi-continuous anaerobic co-digestion of food waste, cattle manure and corn straw. Bioresource Technology, 2022, 343, 126094. [Google Scholar] [CrossRef]

- Xiao, Y.; Zan, F.; Zhang, W.; Hao, T. Alleviating nutrient imbalance of low carbon-to-nitrogen ratio food waste in anaerobic digestion by controlling the inoculum-to-substrate ratio. Bioresource Technology, 2022, 346, 126342. [Google Scholar] [CrossRef]

- Slopiecka, K.; Liberti, F.; Massoli, S.; Bartocci, P.; Fantozzi, F. Chemical and physical characterization of food waste to improve its use in anaerobic digestion plants. Energy Nexus, 2022, 5, 100049. [Google Scholar] [CrossRef]

- Samoraj. M.; Mironiuk, M.; Izydorczyk, G.; Witek-Krowiak, A.; Szopa, D.; Moustakas, K.; Chojnacka, K. The challenges and perspectives for anaerobic digestion of animal waste and fertilizer application of the digestate. Chemosphere, 2022, 295, 133799. [Google Scholar] [CrossRef] [PubMed]

- Arhoun, B.; Villen-Guzman, M.; Gomez-Lahoz, C.; Rodriguez-Maroto, J.M.; Garcia-Herruzo, F.; Vereda-Alonso, C. Anaerobic co-digestion of mixed sewage sludge and fruits and vegetable wholesale market waste: Composition and seasonality effect. Journal of Water Process Engineering, 2019, 31, 100848. [Google Scholar] [CrossRef]

- Gallego, L.M.; Portillo, E.; Navarrete, B.; González, R. Estimation of methane production through the anaerobic digestion of greenhouse horticultural waste: A real case study for Almeria region. Science of the Total Environment, 2022, 807, 151012. [Google Scholar] [CrossRef] [PubMed]

- González, J.F.; Parralejo, A.I.; González, J.; Álvarez, A.; Sabio, E. Optimization of the production and quality of biogas in the anaerobic digestion of different types of biomass in a batch laboratory biodigester and pilot plant: Numerical modeling, kinetic study and hydrogen potential. International Journal of Hydrogen Energy,. 2022, 43 (93), 39386-39403.. [CrossRef]

- Chiappero, M.; Cillerai, F.; Berruti, F.; Masek, O.; Fiore, S. Addition of Different Biochars as Catalysts during the Mesophilic Anaerobic Digestion of Mixed Wastewater Sludge. Catalysts, 2021, 11, 1094. [Google Scholar] [CrossRef]

- Chen, J.L.; Steele, T.W.J.; Stuckey, D.C. The effect of Fe2NiO4 and Fe2NiO4Zn magnetic nanoparticles on anaerobic digestion activity. Science of the Total Environment. 2018, 276-284. [CrossRef]

- De la Lama, C.; Borja, R.; Rincón, B. Performance evaluation and substrate removal kinetics in the semi-continuous anaerobic digestion of thermally pretreated two phase olive pomace or “Alperujo”. Process Safety and Environmental Protection, 2017, 105, 288–296. [Google Scholar] [CrossRef]

- Parralejo, A.I.; Royano, L.; Cabanillas, J.; González, J. Biogas from Nitrogen-Rich Biomass as an Alternative to Animal Manure Co-Substrate in Anaerobic Co-Digestion Processes. Enegies, 2022, 15, 5978. [Google Scholar] [CrossRef]

- Drosg, B. Process monitoring in biogas plant.International Energy Agency (IEA) Bioenergy. Task 37 – Energy from Biogas and Landfill Gas, 2017.

- RD 535/2017 sobre productos fertilizantes de 26 de Mayo.

- Agriculture & Horticulture Development Board (AHDB). Nutrient Management Guide (RB209), Section 2: Organic materials, 2017, 35.

- APHA, Standard Methods for Examination of Water and Wastewater, 22 ed. American Public Health Association Washington, DC, 2012.

- EPA-600/4-79-020. Methods for Chemical Analysis of Water and Wastes, Environmental Protection Agency. Environmental Monitoring and Support Laboratory, U.S., 1983.

- Buchauer, K. Titrations verfahren in der Abwasserund Schlam-manalytik zur Bestimmung von flüchtigen organischen Säuren. Das Gas- und Wasserfach (gfw). Wasser Abwasser, 1997, 138, 313–320. [Google Scholar]

- Norma UNE-EN 16948. Biocombustibles sólidos, Determinación de contenido total de C, H y N. Método instrumental, 2015.

| Parameter | PM | PW | PWP |

|---|---|---|---|

| pH | 7.70±0.10 | 4.18±0.04 | 4.10±0.29 |

| Redox potential, mV | -362±23 | -100±1 | 206±10 |

|

Alkalinity, mg CaCO3 L-1 |

9379±75 | - | - |

| N-NH4, mg L-1 | 1860±85 | 870±30 | 390±80 |

| C, % | 2.23±0.30 | 7.12±0.19 | 7.63±1.85 |

| N, % | 0.30±0.03 | 0.36±0.01 | 0.42±0.09 |

| C/N | 7.32±0.36 | 18.04±1.37 | 18.71±2.17 |

| TS, % | 5.71±0.02 | 13.31±0.29 | 17.17±3.33 |

| VS*, % | 3.98±0.12 | 12.32±0.23 | 15.80±3.14 |

| Ca, ppm | 2663±48 | 1003±21 | 1965±18 |

| Fe, ppm | 209±2 | 76±1 | 120±2 |

| K, ppm | 240±30 | 2317±25 | 1953±4 |

| Mg, ppm | 1208±11 | 439±1 | 617±4 |

| Na, ppm | 913±2 | 64±1 | 262±3 |

| P, ppm | 1562±7 | 473±7 | 807±46 |

| Al, ppm | 152±7 | 81±1 | 95±5 |

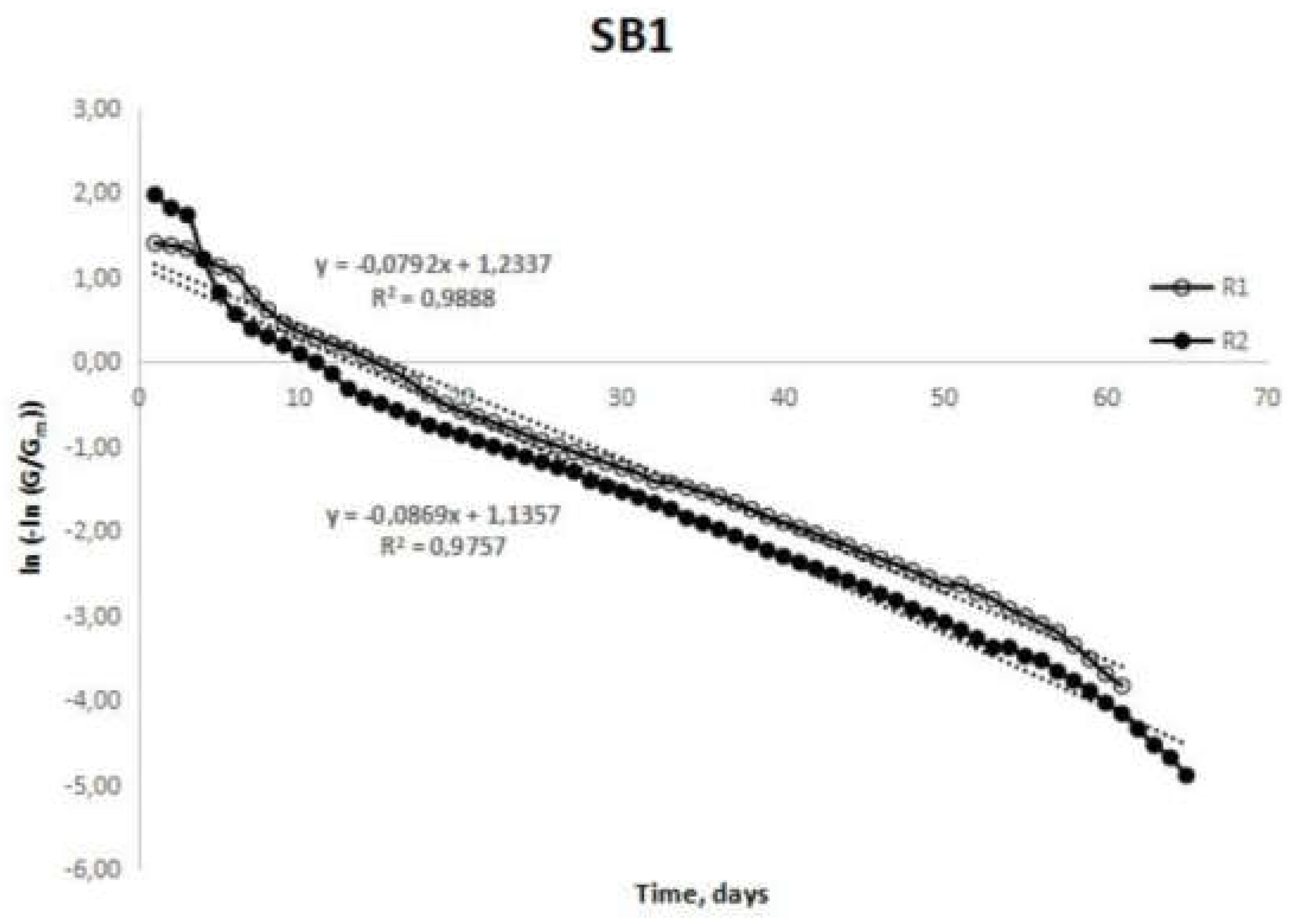

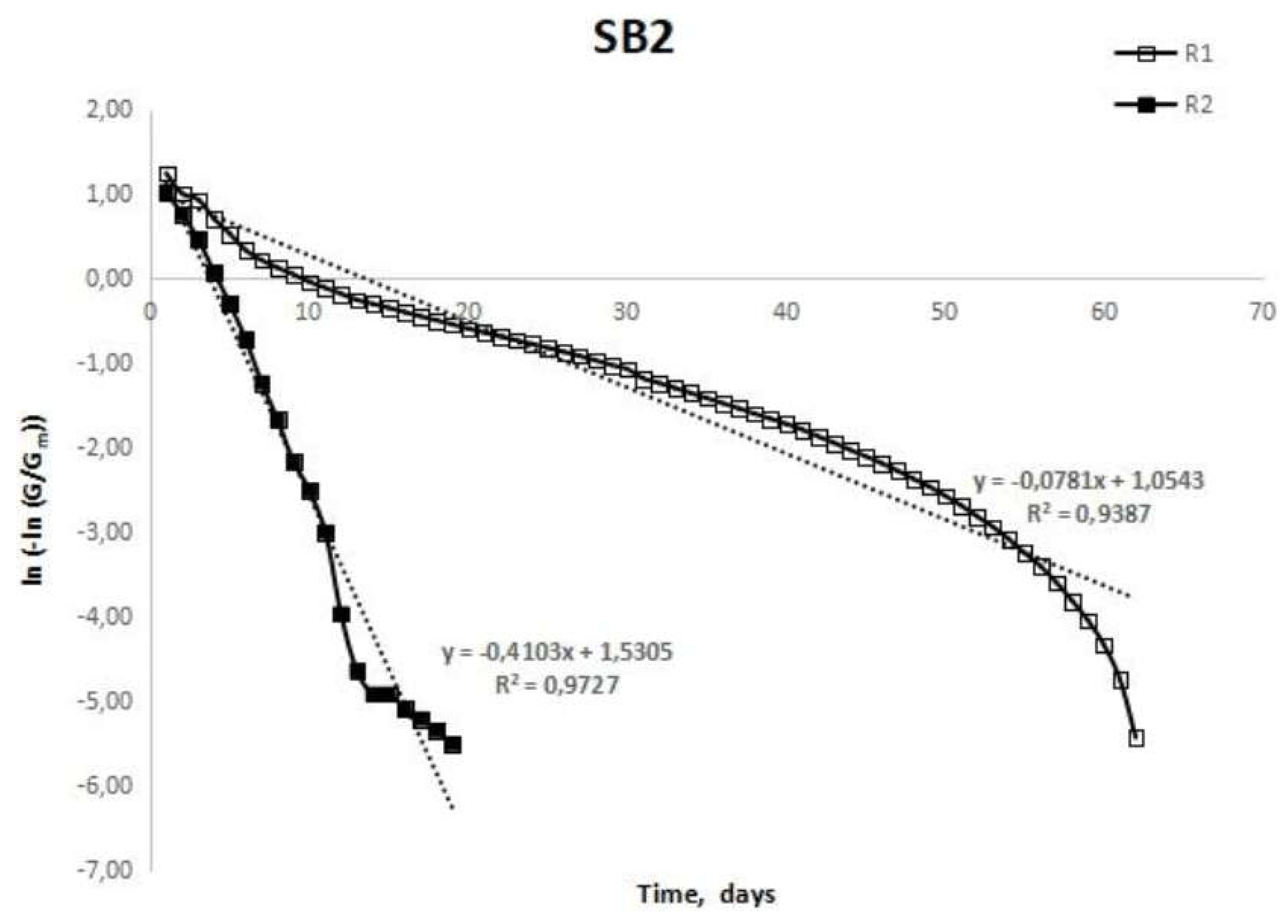

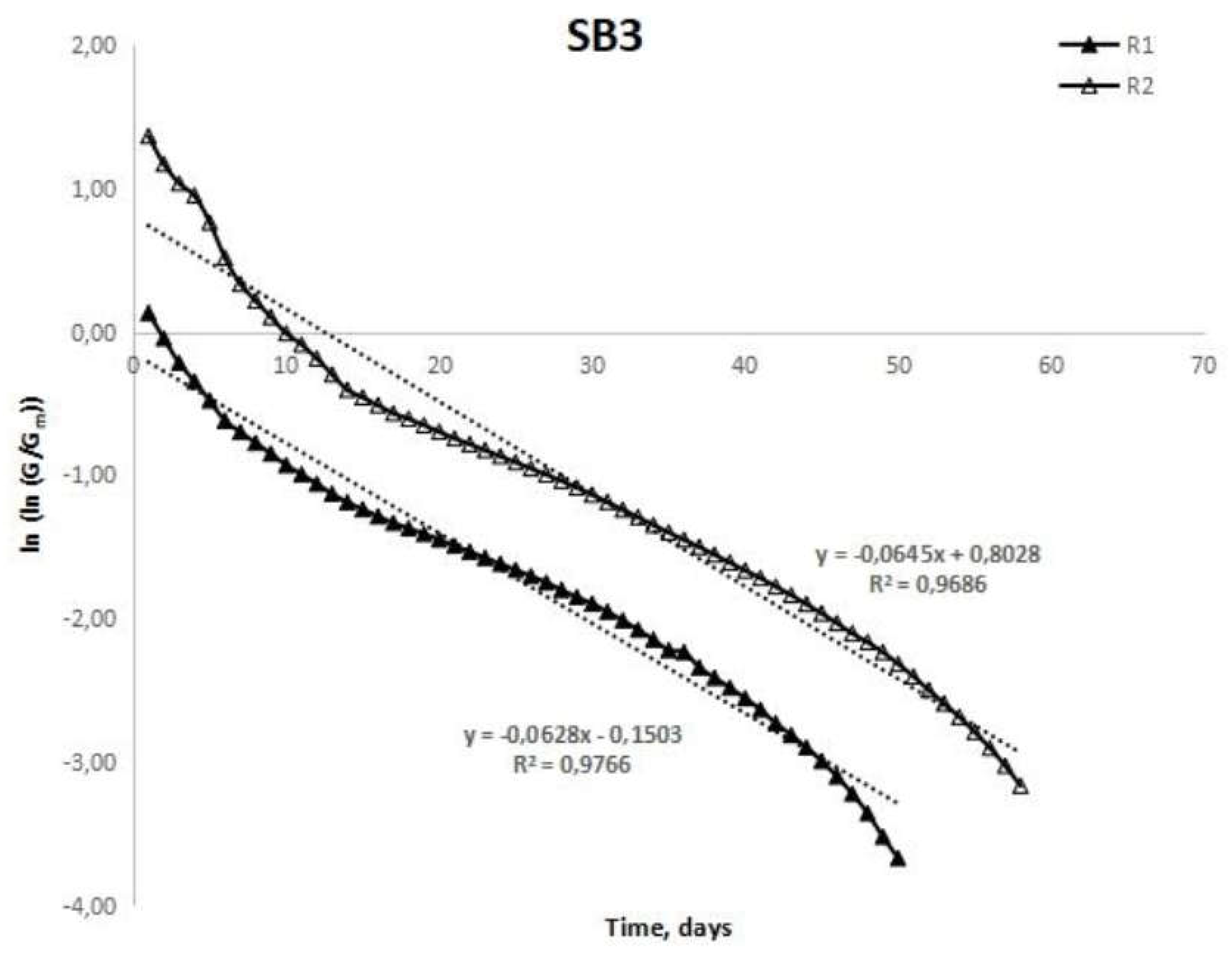

| Parameter | SB1 | SB2 | SB3 | |||

|---|---|---|---|---|---|---|

| Methane average yield, NL kg VS-1 | 464±25 | 331±57 | 364±49 | |||

| Methane average concentration, % | 59±2 | 56±6 | 60±1 | |||

| Replicates | R1 | R2 | R1 | R2 | R1 | R2 |

| Rmax, Nm3 kg VS-1 d-1 | 0.64 | 0.75 | 0.82 | 1.51 | 0.85 | 1.00 |

| l, d | 2.82 | 1.56 | 0.77 | 1.29 | - | - |

| R2 | 0.9888 | 0.9757 | 0.9387 | 0.9727 | 0.9686 | 0.9766 |

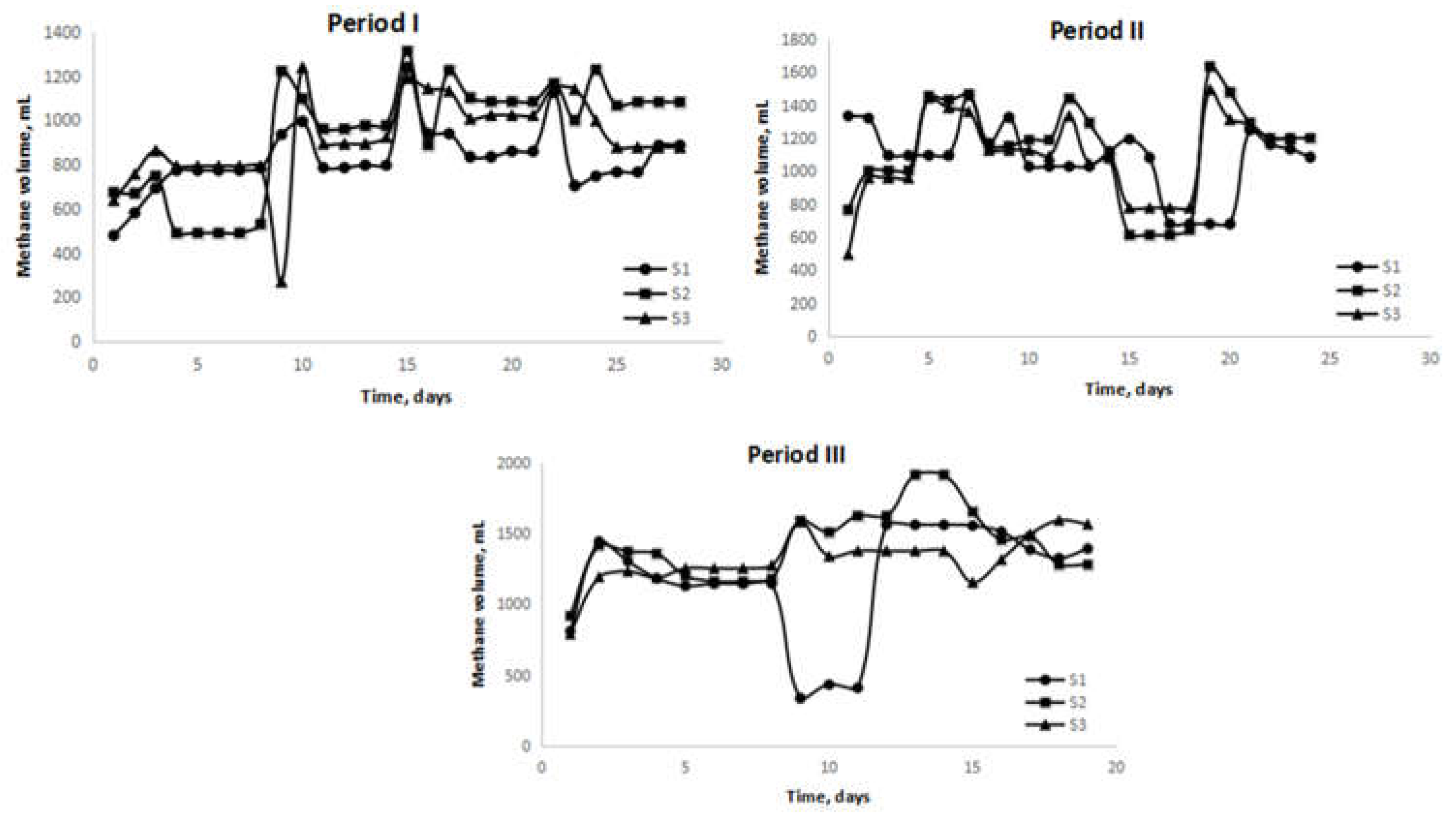

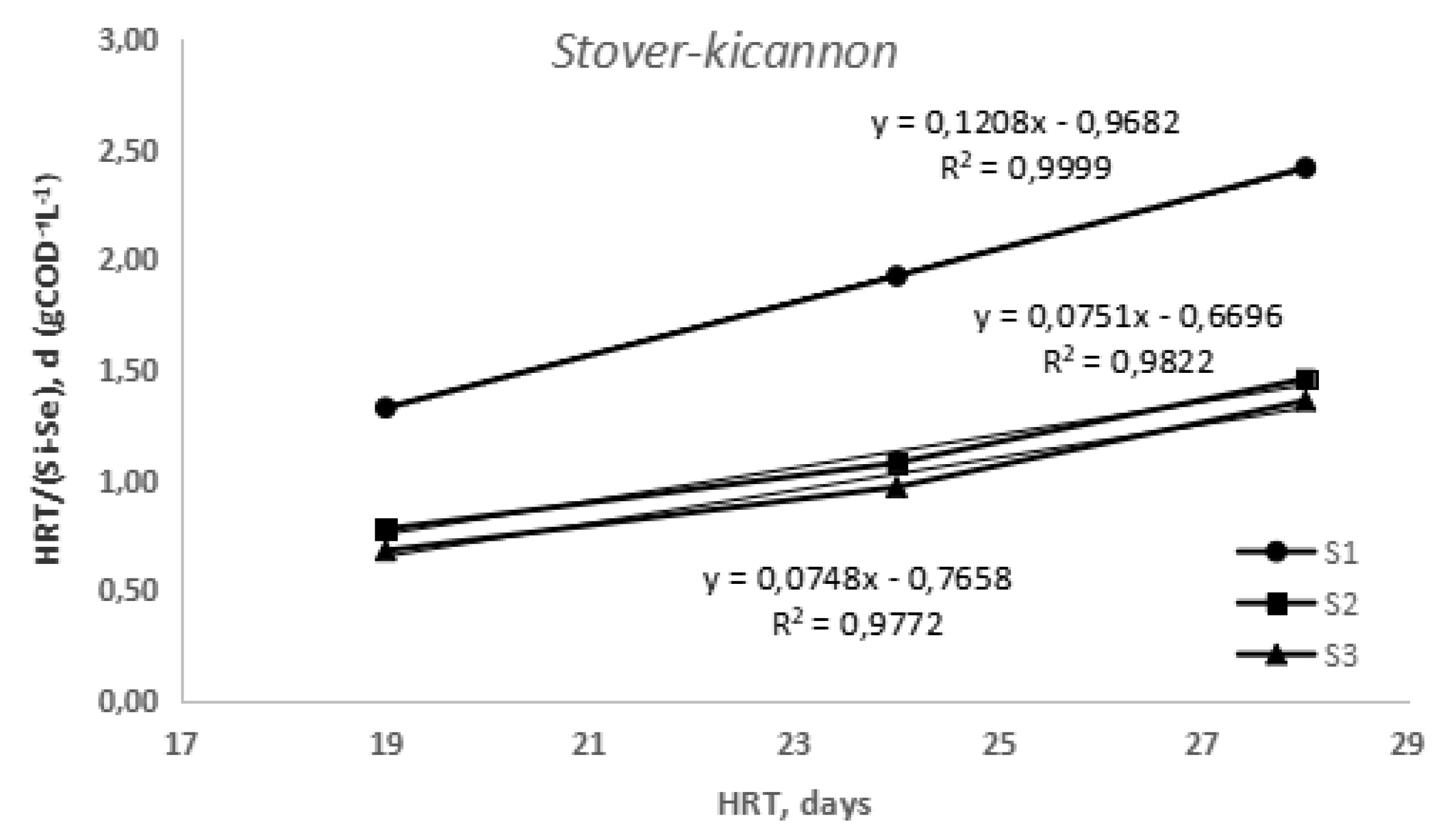

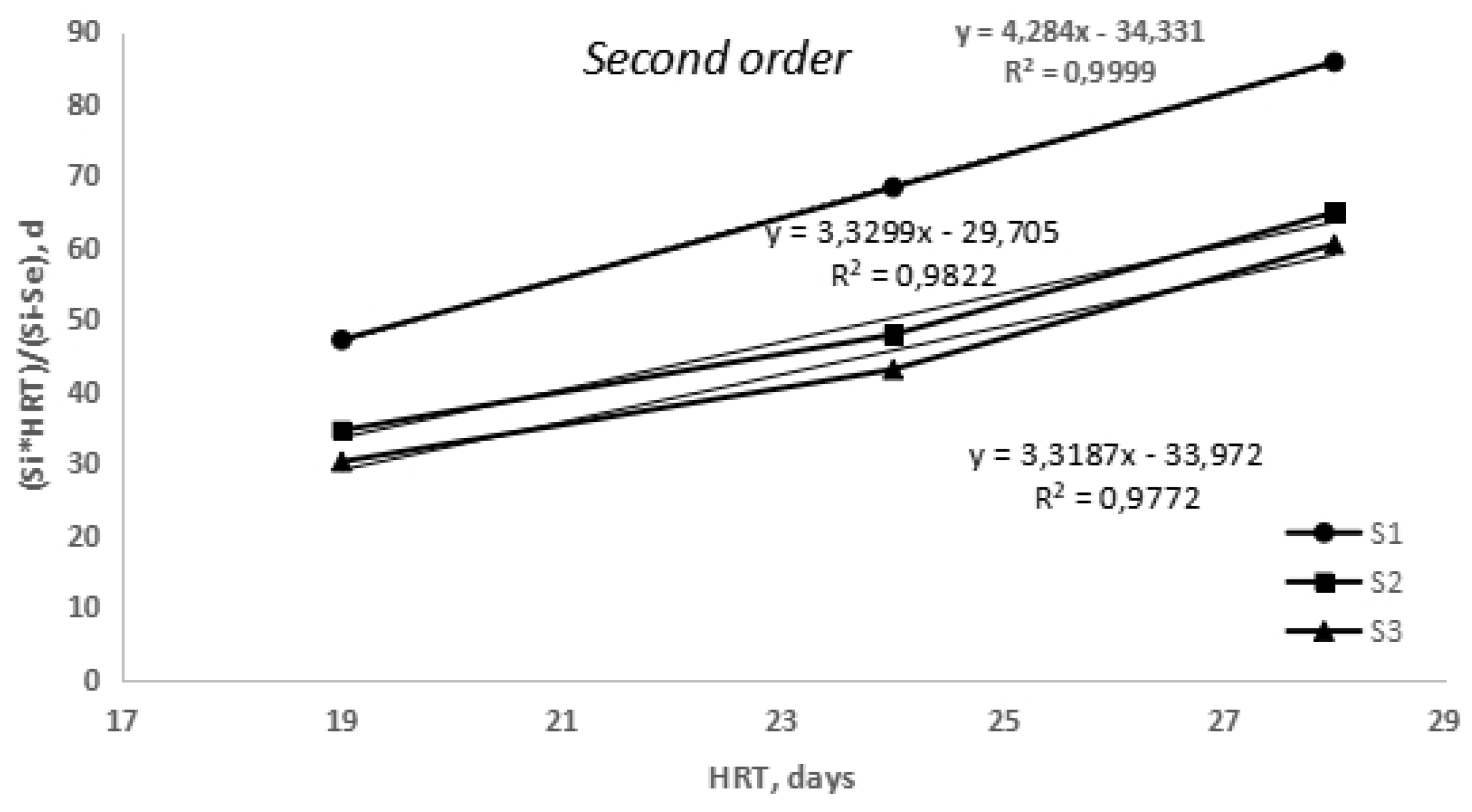

| Period | Period I | Period II | Period III |

|---|---|---|---|

| S1 | |||

| Methane yield, NL kg VS-1 | 139 | 149 | 149 |

| kB, g COD L-1 | 4.42 | ||

| Umax, d-1 | 1.03 | ||

| k2, d-1 | 0.73 | ||

| S2 | |||

| Methane yield, NL kg VS-1 | 158 | 160 | 156 |

| kB, g COD L-1 | 4.98 | ||

| Umax, d-1 | 1.49 | ||

| k2, d-1 | 0.90 | ||

| S3 | |||

| Methane yield, NL kg VS-1 | 153 | 156 | 155 |

| kB, g COD L-1 | 4.33 | ||

| Umax, d-1 | 1.31 | ||

| k2, d-1 | 0.64 | ||

| Parameter | Period I | Period II |

|---|---|---|

| pH | 7.91±0.10 | 7.95±0.05 |

| Redox potential, mV | -388±12 | -409±9 |

|

Alkalinity, mg CaCO3 L-1 |

10892±2 | 10340±37 |

| Methane yield, NL kg VS-1 | 173±45 | 264±55 |

| C, % | 1.06±0.03 | 2.20±0.20 |

| N, % | 0.21±0.01 | 0.37±0.02 |

| C/N | 4.98±0.15 | 6.02±1.14 |

| Ca, ppm | 779±4 | 2259±9 |

| Fe, ppm | 75±2 | 230±2 |

| K, ppm | 1317±28 | 2467±29 |

| Mg, ppm | 526±2 | 1121±3 |

| Na, ppm | 669±2 | 596±6 |

| P, ppm | 359±10 | 1052±15 |

| Al, ppm | 40±2 | 157±2 |

| Zn, ppm | 34±1 | 141±1 |

| Cu, ppm | 10±1 | 38±1 |

| Cr, ppm | <5 | <5 |

| Ni, ppm | <5 | <5 |

| Parameter | Period I | Period II |

|---|---|---|

| Assimilable N content, % | 0.12 | 0.20 |

| Assimilable P2O5 content, % | 0.80 | 2.33 |

| Assimilable K2O content, % | 1.01 | 1.89 |

| Fertilizer classification [28] | A | A |

| ASSAY | OLR, G VS LD-1 D-1 |

MIXTURE COMPOSITION/FEED |

HIDRAULIC RETENTION TIME (HRT), D |

|---|---|---|---|

| SB1 | - | Ratio 1:2 inoculum:PWP | - |

| SB2 | - | Ratio 1:2 inoculum:PWP with nanoparticles (0.064 g g VS-1) | - |

| SB3 | - | Ratio 1:2 inoculum:PWP with nanoparticles (0.015 g g VS-1) and thermal pre-treatment | - |

| S1 | Period I: 1.26 | 50 % PM and 50 % PWP (on VS basis) | 28 |

| Period II: 1.47 | 24 | ||

| Period III: 1.88 | 19 | ||

| S2 | Period I: 1.26 | 50 % PM and 50 % PWP (on VS basis) with thermal pre-treatment | 28 |

| Period II: 1.47 | 24 | ||

| Period III: 1.88 | 19 | ||

| S3 | Period I: 1.26 | 50 % PM and 50 % PWP (on VS basis) with thermal pre-treatment and nanoparticles (0.015 g g VS-1) | 28 |

| Period II: 1.47 | 24 | ||

| Period III: 1.88 | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).