Submitted:

04 May 2023

Posted:

08 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

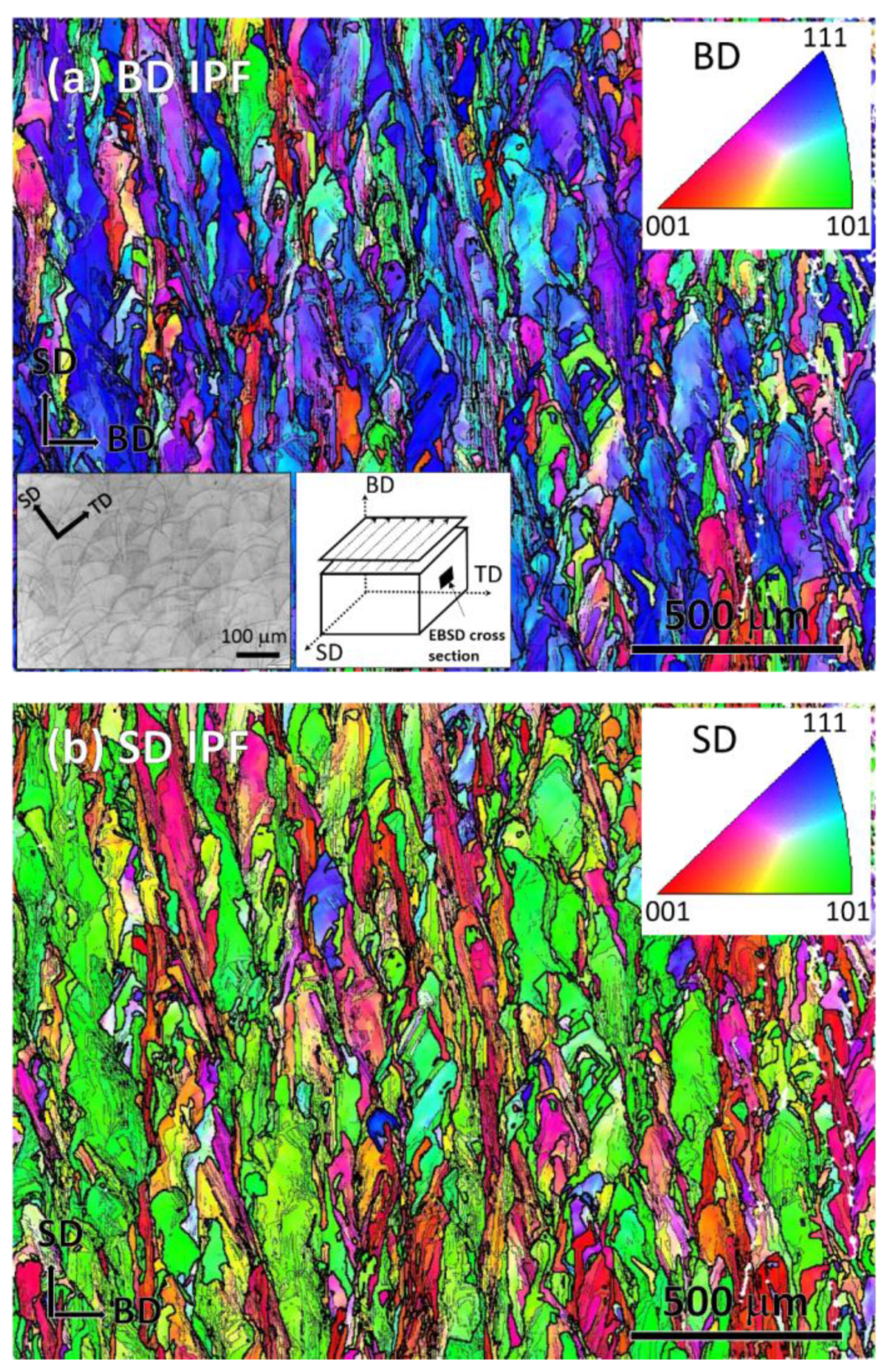

3.1. Structural symmetry and crystallographic texture

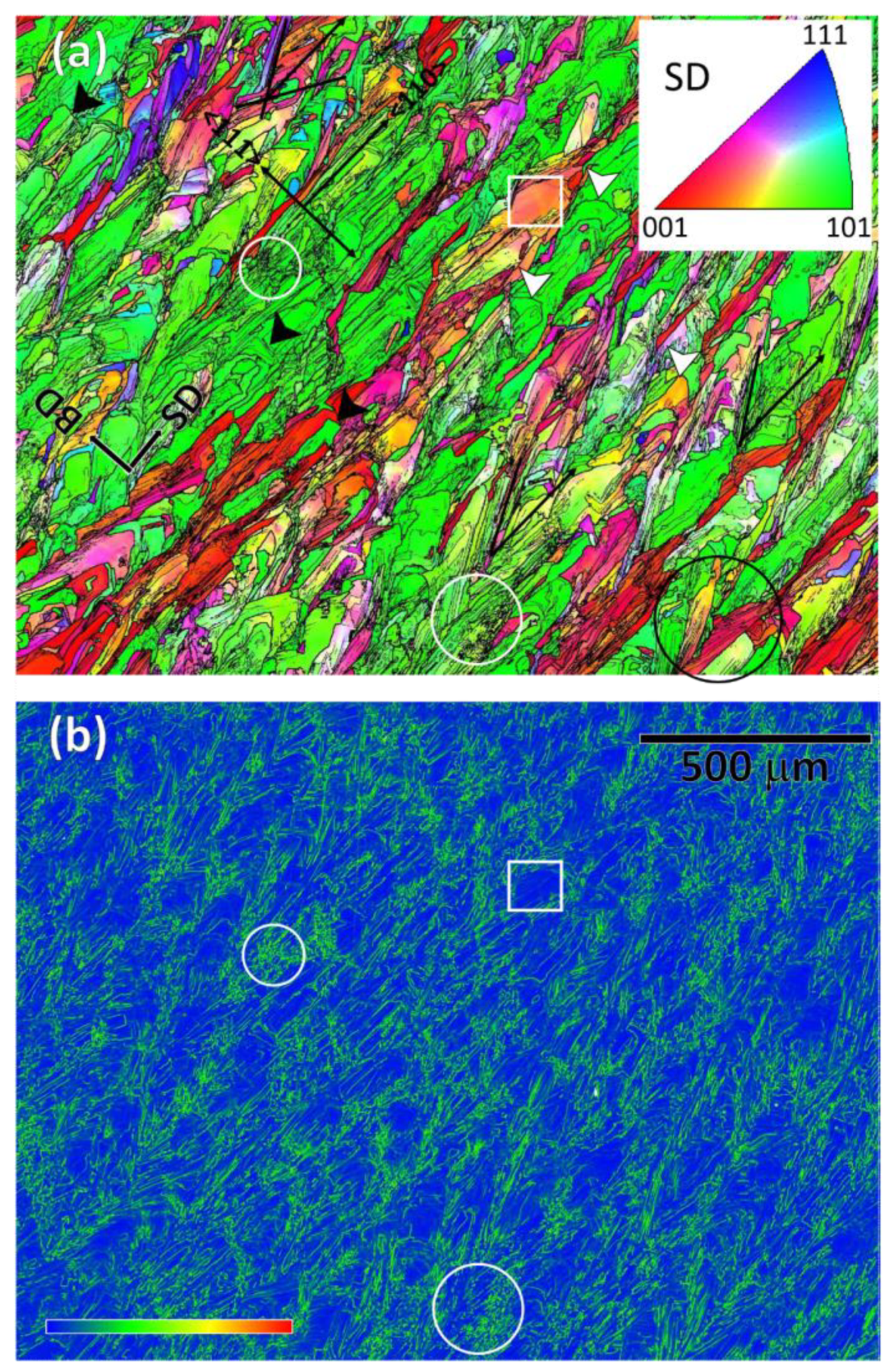

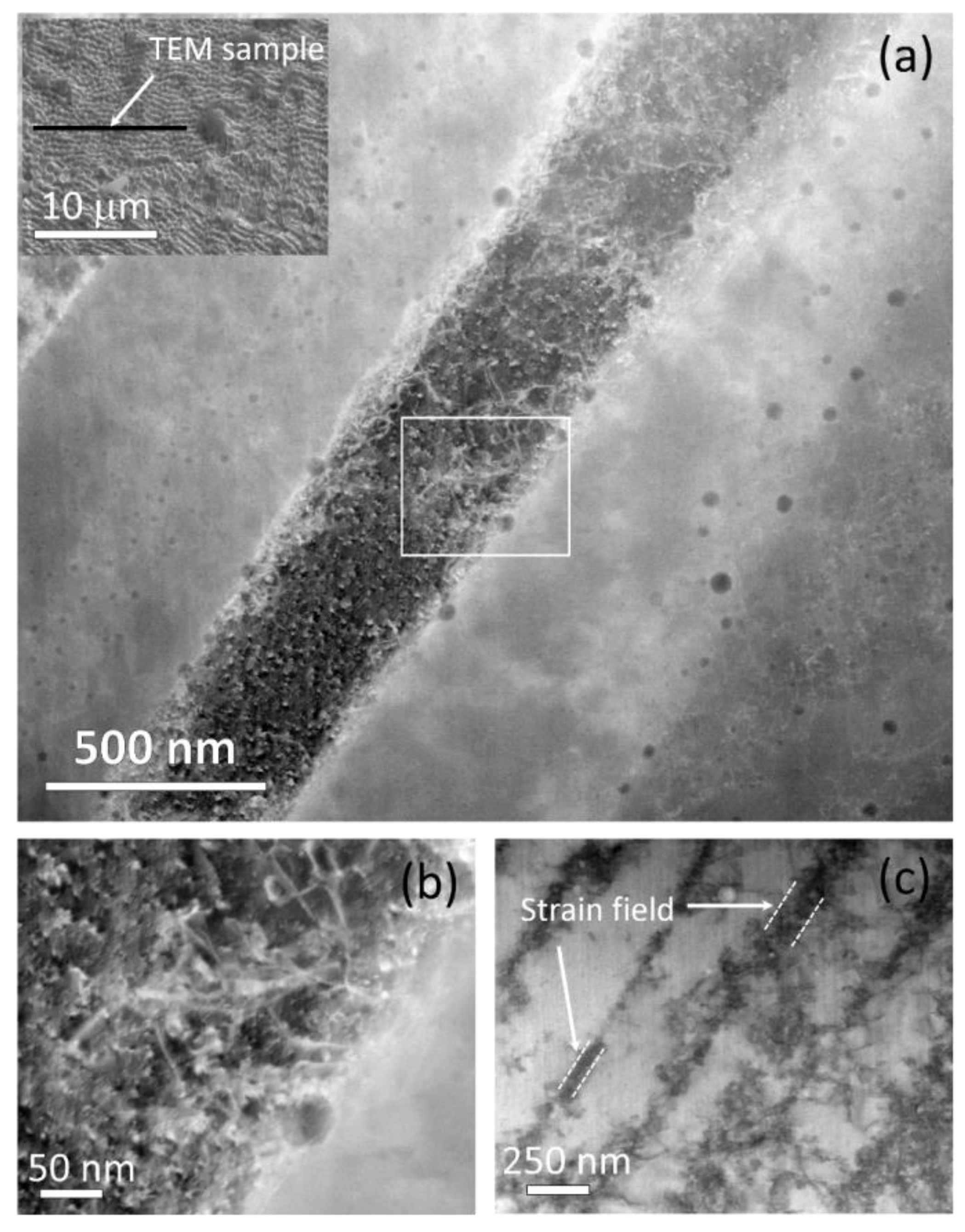

3.2. Substructural features

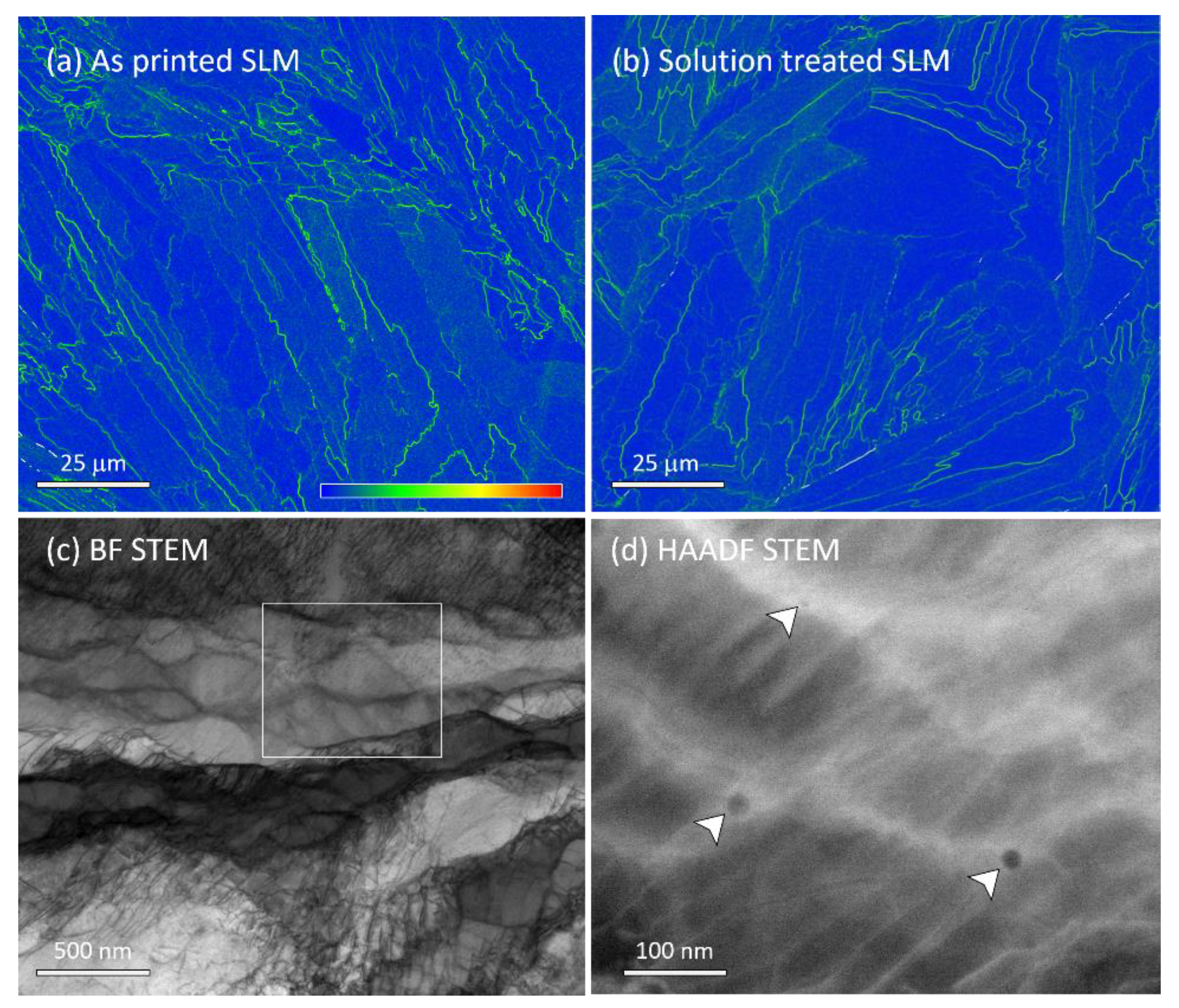

3.3. Solution treatment structures

4. Conclusions

- SLM printed material possess asymmetric crystallographic texture and material structure. The microstructures have a distinctive structural morphology along the sample orthogonal axes and develops crystallographic textures of SD ||<101> and BD ||<111>.

- A heterogeneous distribution of misorientation boundaries and stored energy were found throughout the SLM printed structures. Twin boundary formation was not observed in either the as-printed or solution-annealed samples.

- In the as-printed structures, the typical straight misorientation boundaries were characterized as non-crystallographic. The boundaries maintained general alignments with the SD within an angular range, irrespective of the matrix’s crystal orientation, although there were occasional coincidences with crystal plane traces.

- The high angle boundaries in the SLM substructures underwent thermal restoration, which were activated by the heat source from the subsequent layer printing. Pinning by the nano inclusions hindered classical recrystallization, and thus, prevented the formation of a defect-free annealing structure, even after 4 hours of solution treatment at 1050 °C.

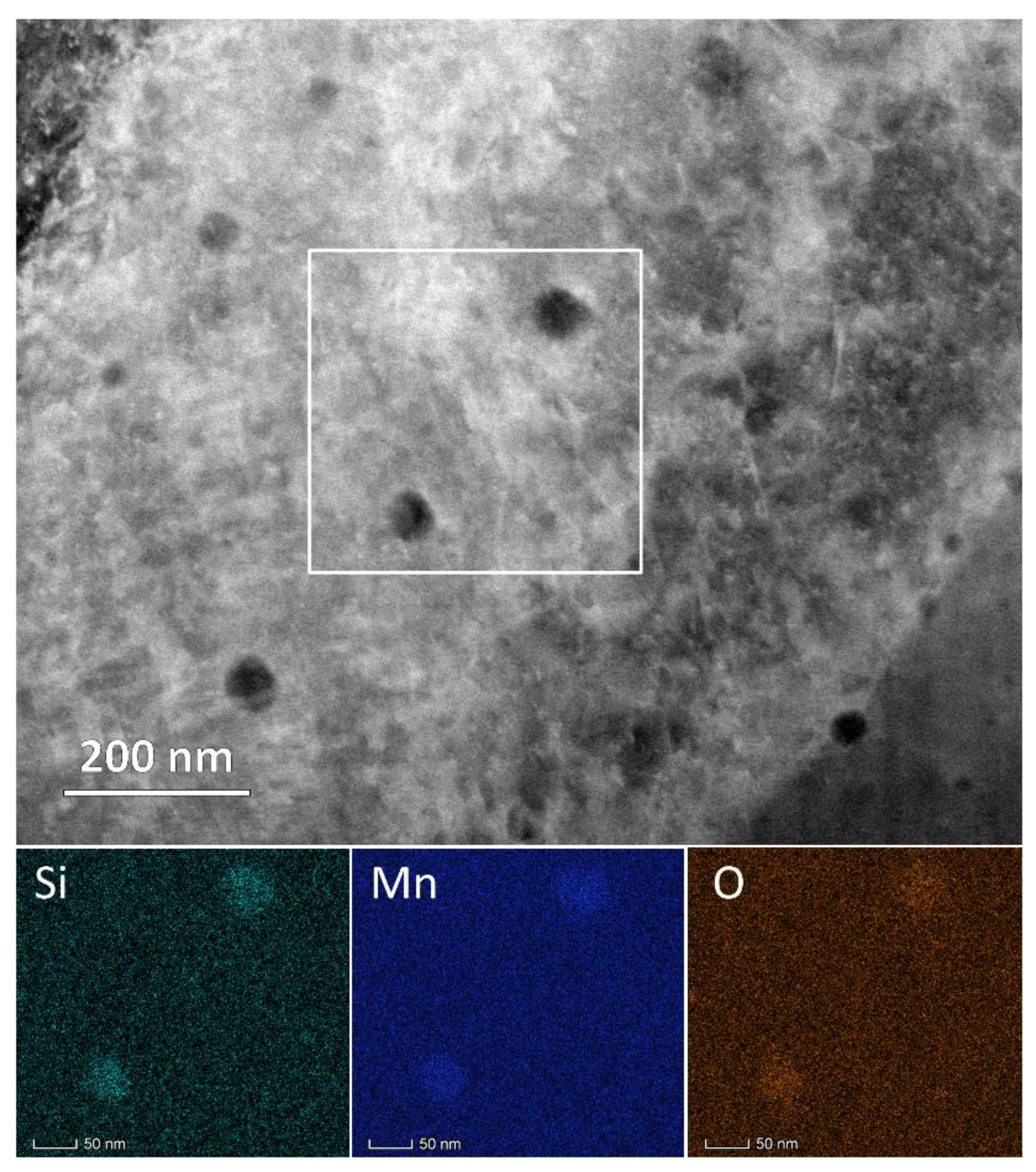

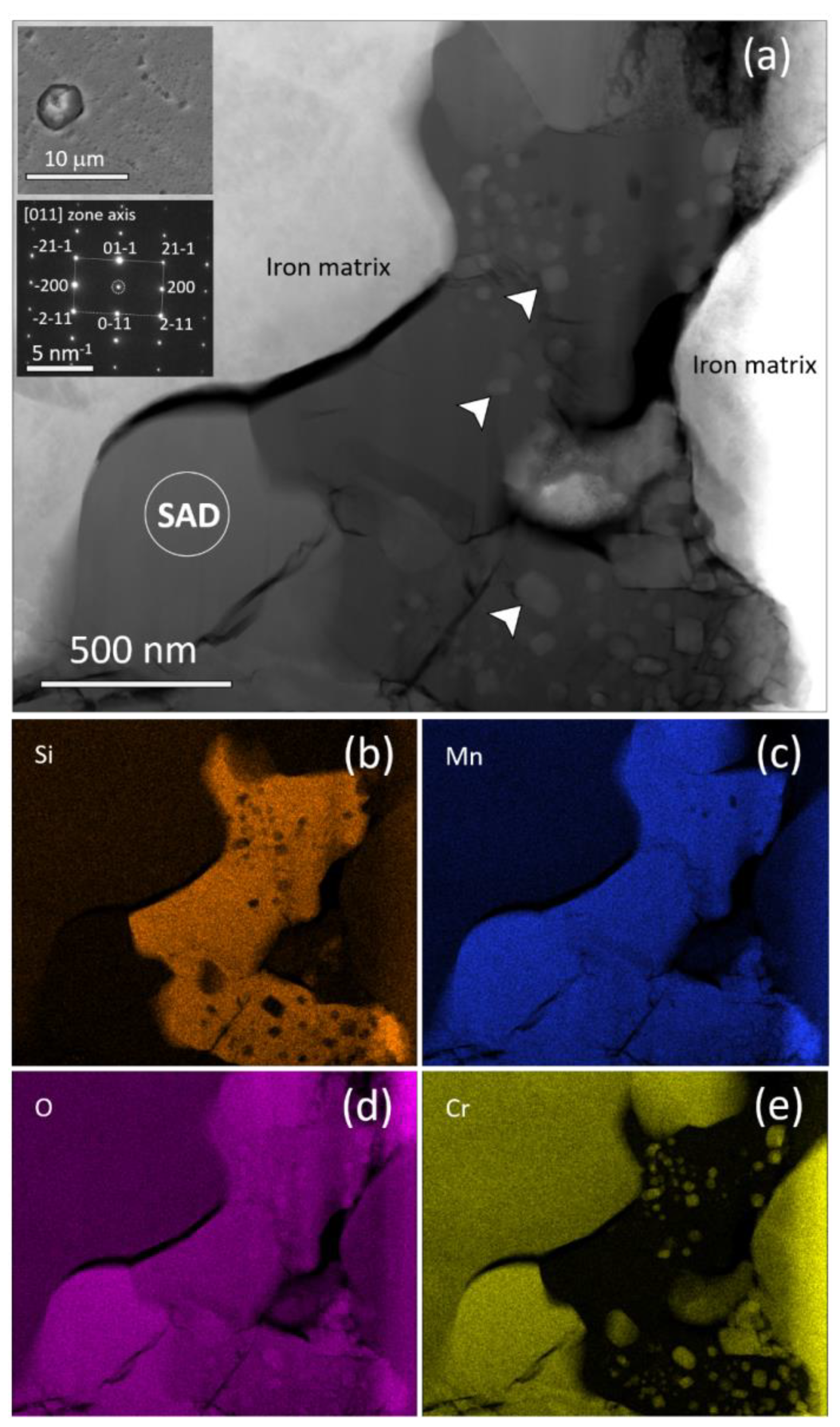

- A nano-scale lamellar structure, of 500±200 nm width, homogeneously formed throughout the printed material. Depending on the orientation, the structures appeared in cell or columnar morphologies in SEM and TEM images. Their boundaries contained dense dislocation structures tangled with fine amorphous inclusions containing Mn, Si and O. Cr was not detected in the inclusions above the detection limit. Hence, Cr remains in the matrix to provide the stainless properties.

- Some degree of dissociation of the dislocation boundaries occurred during the solution treatment, but the overall refined structures are retained. Additionally, 2-4 μm large inclusions formed, comprising of composite structures and chemical distributions. These inclusions had detrimental characteristics for stainless performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meiners W, Wissenbach K, Gasser A (1998) Shaped body especially prototype or replacement part production. DE Patent 19.

- DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components – Process, structure and properties. Progress in Materials Science 92:112-224. [CrossRef]

- Harun W, Kamariah M, Muhamad N, Ghani S, Ahmad F, Mohamed Z (2018) A review of powder additive manufacturing processes for metallic biomaterials. Powder Technology 327:128-151. [CrossRef]

- Song B, Dong S, Deng S, Liao H, Coddet C (2014) Microstructure and tensile properties of iron parts fabricated by selective laser melting. Optics & Laser Technology 56:451-460. [CrossRef]

- Olakanmi EO, Cochrane RF, Dalgarno KW (2015) A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Progress in Materials Science 74:401-477. [CrossRef]

- Liu Z, Zhang D, Sing S, Chua C, Loh L (2014) Interfacial characterization of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Materials Characterization 94:116-125. [CrossRef]

- Shi R, Khairallah SA, Roehling TT, Heo TW, McKeown JT, Matthews MJ (2020) Microstructural control in metal laser powder bed fusion additive manufacturing using laser beam shaping strategy. Acta Materialia 184:284-305. [CrossRef]

- Mower TM, Long MJ (2016) Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Materials Science and Engineering: A 651:198-213. [CrossRef]

- Maconachie T, Leary M, Lozanovski B, Zhang X, Qian M, Faruque O, Brandt M (2019) SLM lattice structures: Properties, performance, applications and challenges. Materials & Design 183:108137. [CrossRef]

- Maskery I, Aremu A, Simonelli M, Tuck C, Wildman R, Ashcroft I, Hague R (2015) Mechanical properties of Ti-6Al-4V selectively laser melted parts with body-centred-cubic lattices of varying cell size. Experimental Mechanics 55:1261-1272. [CrossRef]

- Maskery I, Aboulkhair N, Aremu A, Tuck C, Ashcroft I, Wildman RD, Hague R (2016) A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Materials Science and Engineering: A 670:264-274. [CrossRef]

- Hamilton RF, Bimber BA, Andani MT, Elahinia M (2017) Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. Journal of Materials Processing Technology 250:55-64. [CrossRef]

- Visser CW, Pohl R, Sun C, Römer GW, Huis in ‘t Veld B, Lohse D (2015) Toward 3D printing of pure metals by laser-induced forward transfer. Advanced materials 27 (27):4087-4092. [CrossRef]

- Li Y, Gu D (2014) Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Materials & design 63:856-867. [CrossRef]

- Averyanova M, Cicala E, Bertrand P, Grevey D (2012) Experimental design approach to optimize selective laser melting of martensitic 17-4 PH powder: part I–single laser tracks and first layer. Rapid Prototyping Journal. [CrossRef]

- Lott P, Schleifenbaum H, Meiners W, Wissenbach K, Hinke C, Bültmann J (2011) Design of an optical system for the in situ process monitoring of selective laser melting (SLM). Physics Procedia 12:683-690. [CrossRef]

- Brecher C (2015) Advances in production technology.

- Aboulkhair NT, Simonelli M, Parry L, Ashcroft I, Tuck C, Hague R (2019) 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Progress in materials science 106:100578. [CrossRef]

- Aboulkhair NT, Everitt NM, Ashcroft I, Tuck C (2014) Reducing porosity in AlSi10Mg parts processed by selective laser melting. Additive manufacturing 1:77-86. [CrossRef]

- Langelaar M (2016) Topology optimization of 3D self-supporting structures for additive manufacturing. Additive manufacturing 12:60-70. [CrossRef]

- Read N, Wang W, Essa K, Attallah MM (2015) Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Materials & Design (1980-2015) 65:417-424. [CrossRef]

- Aboulkhair NT, Everitt NM, Maskery I, Ashcroft I, Tuck C (2017) Selective laser melting of aluminum alloys. MRS Bulletin 42 (4):311-319. [CrossRef]

- Simonelli M, Tse YY, Tuck C (2014) Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Materials Science and Engineering: A 616:1-11. [CrossRef]

- Simonelli M, Tse YY, Tuck C (2014) On the texture formation of selective laser melted Ti-6Al-4V. Metallurgical and Materials Transactions A 45:2863-2872. [CrossRef]

- Kamath C, El-Dasher B, Gallegos GF, King WE, Sisto A (2014) Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. The International Journal of Advanced Manufacturing Technology 74:65-78. [CrossRef]

- Garibaldi M, Ashcroft I, Lemke J, Simonelli M, Hague R (2018) Effect of annealing on the microstructure and magnetic properties of soft magnetic Fe-Si produced via laser additive manufacturing. Scripta Materialia 142:121-125. [CrossRef]

- Garibaldi M, Ashcroft I, Simonelli M, Hague R (2016) Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Materialia 110:207-216. [CrossRef]

- Lemke J, Simonelli M, Garibaldi M, Ashcroft I, Hague R, Vedani M, Wildman R, Tuck C (2017) Calorimetric study and microstructure analysis of the order-disorder phase transformation in silicon steel built by SLM. Journal of Alloys and Compounds 722:293-301. [CrossRef]

- Catchpole-Smith S, Aboulkhair N, Parry L, Tuck C, Ashcroft IA, Clare A (2017) Fractal scan strategies for selective laser melting of ‘unweldable’nickel superalloys. Additive Manufacturing 15:113-122. [CrossRef]

- Choi J-P, Shin G-H, Yang S, Yang D-Y, Lee J-S, Brochu M, Yu J-H (2017) Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technology 310:60-66. [CrossRef]

- Marchese G, Garmendia Colera X, Calignano F, Lorusso M, Biamino S, Minetola P, Manfredi D (2017) Characterization and comparison of Inconel 625 processed by selective laser melting and laser metal deposition. Advanced Engineering Materials 19 (3):1600635. [CrossRef]

- Carter LN, Martin C, Withers PJ, Attallah MM (2014) The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. Journal of Alloys and Compounds 615:338-347. [CrossRef]

- Ciurana J, Hernandez L, Delgado J (2013) Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material. The International Journal of Advanced Manufacturing Technology 68:1103-1110. [CrossRef]

- Pupo Y, Delgado J, Serenó L, Ciurana J (2013) Scanning space analysis in selective laser melting for CoCrMo powder. Procedia Engineering 63:370-378. [CrossRef]

- Monroy K, Delgado J, Ciurana J (2013) Study of the pore formation on CoCrMo alloys by selective laser melting manufacturing process. Procedia Engineering 63:361-369. [CrossRef]

- Takaichi A, Nakamoto T, Joko N, Nomura N, Tsutsumi Y, Migita S, Doi H, Kurosu S, Chiba A, Wakabayashi N (2013) Microstructures and mechanical properties of Co–29Cr–6Mo alloy fabricated by selective laser melting process for dental applications. Journal of the mechanical behavior of biomedical materials 21:67-76. [CrossRef]

- Yadroitsev I, Gusarov A, Yadroitsava I, Smurov I (2010) Single track formation in selective laser melting of metal powders. Journal of Materials Processing Technology 210 (12):1624-1631. [CrossRef]

- Zhang B, Liao H, Coddet C (2012) Effects of processing parameters on properties of selective laser melting Mg–9% Al powder mixture. Materials & Design 34:753-758. [CrossRef]

- Galy C, Le Guen E, Lacoste E, Arvieu C (2018) Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Additive Manufacturing 22:165-175. [CrossRef]

- Suryawanshi J, Prashanth KG, Ramamurty U (2017) Mechanical behavior of selective laser melted 316L stainless steel. Materials Science and Engineering: A 696:113-121. [CrossRef]

- Michiuchi M, Kokawa H, Wang Z, Sato Y, Sakai K (2006) Twin-induced grain boundary engineering for 316 austenitic stainless steel. Acta materialia 54 (19):5179-5184. [CrossRef]

- Godec M, Zaefferer S, Podgornik B, Šinko M, Tchernychova E (2020) Quantitative multiscale correlative microstructure analysis of additive manufacturing of stainless steel 316L processed by selective laser melting. Materials Characterization 160:110074. [CrossRef]

- Sun S-h, Ishimoto T, Hagihara K, Tsutsumi Y, Hanawa T, Nakano T (2019) Excellent mechanical and corrosion properties of austenitic stainless steel with a unique crystallographic lamellar microstructure via selective laser melting. Scripta Materialia 159:89-93. [CrossRef]

- Sun S-H, Hagihara K, Nakano T (2018) Effect of scanning strategy on texture formation in Ni-25 at.% Mo alloys fabricated by selective laser melting. Materials & Design 140:307-316. [CrossRef]

- Thijs L, Sistiaga MLM, Wauthle R, Xie Q, Kruth J-P, Van Humbeeck J (2013) Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Materialia 61 (12):4657-4668. [CrossRef]

- Pham M-S, Dovgyy B, Hooper PA, Gourlay CM, Piglione A (2020) The role of side-branching in microstructure development in laser powder-bed fusion. Nature communications 11 (1):749. [CrossRef]

- Humphreys F, Hatherly M (2004) Chapter 12-recrystallization textures. 3: Recrystallization and Related Annealing Phenomena, second ed, Elsevier, Oxford.

- Prashanth K, Shahabi HS, Attar H, Srivastava V, Ellendt N, Uhlenwinkel V, Eckert J, Scudino S (2015) Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Additive Manufacturing 6:1-5. [CrossRef]

- Qi T, Zhu H, Zhang H, Yin J, Ke L, Zeng X (2017) Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Materials & Design 135:257-266. [CrossRef]

- Dinda G, Dasgupta A, Mazumder J (2012) Evolution of microstructure in laser deposited Al–11.28% Si alloy. Surface and Coatings Technology 206 (8-9):2152-2160. [CrossRef]

- Wei H, Mazumder J, DebRoy T (2015) Evolution of solidification texture during additive manufacturing. Scientific reports 5 (1):1-7. [CrossRef]

- Bhattacharya S, Dinda GP, Dasgupta AK, Mazumder J (2014) A comparative study of microstructure and mechanical behavior of CO 2 and diode laser deposited Cu–38Ni alloy. Journal of Materials Science 49:2415-2429. [CrossRef]

- Parimi LL, Ravi G, Clark D, Attallah MM (2014) Microstructural and texture development in direct laser fabricated IN718. Materials Characterization 89:102-111. [CrossRef]

- Yadollahi A, Shamsaei N, Thompson SM, Seely DW (2015) Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Materials Science and Engineering: A 644:171-183. [CrossRef]

- Dinda G, Dasgupta A, Bhattacharya S, Natu H, Dutta B, Mazumder J (2013) Microstructural characterization of laser-deposited Al 4047 alloy. Metallurgical and Materials Transactions A 44:2233-2242. [CrossRef]

- Ishimoto T, Hagihara K, Hisamoto K, Sun S-H, Nakano T (2017) Crystallographic texture control of beta-type Ti–15Mo–5Zr–3Al alloy by selective laser melting for the development of novel implants with a biocompatible low Young's modulus. Scripta Materialia 132:34-38. [CrossRef]

- Winther G, Jensen DJ, Hansen N (1997) Dense dislocation walls and microbands aligned with slip planes—theoretical considerations. Acta materialia 45 (12):5059-5068. [CrossRef]

- Hurley P, Bate P, Humphreys F (2003) An objective study of substructural boundary alignment in aluminium. Acta Materialia 51 (16):4737-4750. [CrossRef]

- Afrin N, Quadir MZ, Xu W, Ferry M (2012) Spatial orientations and structural irregularities associated with the formation of microbands in a cold deformed Goss oriented Ni single crystal. Acta materialia 60 (18):6288-6300. [CrossRef]

- Afrin N, Quadir MZ, Bassman L, Driver J, Albou A, Ferry M (2011) The three-dimensional nature of microbands in a channel die compressed Goss-oriented Ni single crystal. Scripta Materialia 64 (3):221-224. [CrossRef]

- Wei H, Elmer J, DebRoy T (2016) Origin of grain orientation during solidification of an aluminum alloy. Acta Materialia 115:123-131. [CrossRef]

- Wang Y, Shi J (2020) Developing very strong texture in a nickel-based superalloy by selective laser melting with an ultra-high power and flat-top laser beam. Materials Characterization 165:110372. [CrossRef]

- 6Wang YM, Voisin T, McKeown JT, Ye J, Calta NP, Li Z, Zeng Z, Zhang Y, Chen W, Roehling TT (2018) Additively manufactured hierarchical stainless steels with high strength and ductility. Nature materials 17 (1):63-71. [CrossRef]

- Salman O, Gammer C, Chaubey A, Eckert J, Scudino S (2019) Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Materials Science and Engineering: A 748:205-212. [CrossRef]

- Huang C, Yan X, Zhao L, Liu M, Ma W, Wang W, Soete J, Simar A (2019) Ductilization of selective laser melted Ti6Al4V alloy by friction stir processing. Materials Science and Engineering: A 755:85-96. [CrossRef]

- Shibata H, Tanaka T, Kimura K, Kitamura S-Y (2010) Composition change in oxide inclusions of stainless steel by heat treatment. Ironmaking & Steelmaking 37 (7):522-528. [CrossRef]

- Dossett J, Totten G (2014) Heat Treating of Austenitic and Duplex Stainless Steels. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).