1. Introduction

Admittedly the increase in the number of motor vehicles is an important manifestation of social and economic development and improvement in people’s living standards but with the continuous increase in the number of motor vehicles pollution problems related to motor vehicles have also followed. The use maintenance and scrapping of motor vehicles are accompanied by more or less environmental problems. For example, exhaust gas problems caused by the use of motor vehicles (fuel vehicles) increasing demand for charging leading to increased load on the power grid and pollution problems caused by increased demand for power generation at the source level (new energy vehicles or electric cars) tire wear plastic (TWP) problems caused by low-tech tires increased unit energy consumption and increased accident rates due to tire wear air pollution soil pollution and water pollution caused by dismantling recycling and landfilling of scrapped cars due to age or other reasons.

The harm of greenhouse gases is well known and the problem of exhaust emissions caused by the operation of internal combustion engines has become the focus of policy formulation by governments around the world. A series of policies have been successfully implemented to reduce this part of traffic-related exhaust emissions. In fact with the further promotion and use of new energy vehicles PM (particulate matter) exhaust emissions will be further alleviated. However, the attention paid to pollution caused by waste generated by friction between tires and the ground is still not enough. For a long time research on microplastics has focused only on thermoplastic materials such as polyethylene or polystyrene without considering elastomeric materials such as rubber. According to ISO’s definition, rubber is not included in the definition of plastic. In contrast, some academics have suggested a broader and more common sense definition of microplastics that includes common macromolecular materials, hence the inclusion of rubber[

1].

The technical content of tires should receive attention for its impact on the environment and driving safety. Tires a round black object that seems to have little technical content but is not cheap. Consumers usually make tire purchase decisions based on price. In fact in a typical radial passenger car tire there are 20 or more components and 15 or more rubber compounds. Tires are highly engineered structural composites whose performance design can meet the smoothness handling and traction standards of automobile manufacturers as well as customer expectations for quality and performance. A medium-sized car’s tires rotate more than 1200 times per kilometer and within 50,000 kilometers each tire component undergoes more than 24 million loading and unloading cycles requiring extremely high endurance[

2]. The waste generated by the friction between a single tire and the ground seems insignificant but on a global scale it is considerable and it is predicted that in the near future pollution caused by this type of frictional wear will not decrease[

3,

4].

Microplastics are considered a global threat by many studies due to their widespread presence in all regions inhabited by humans as a result of the extensive use of automobiles. They permeate all ecosystems and have the potential to impact the health of aquatic and terrestrial organisms, including humans, through various exposure pathways such as food chains, drinking water and air[

5,

6,

7,

8]. According to the definition of academic and industry, microplastics are polymer materials with a maximum diameter of no more than 5 mm, insoluble in water and extremely low degradation rate[

9]. Particles released from tire wear fit this description and were recognized as a new type of potential pollutant by industry scholars as early as the 1970s[

10]. Because of their insoluble and non-degradable nature, the distribution and residues of microplastics remain highly uncertain after decades of self-processing in nature[

11]. The composition of tire wear varies depending on the brand and intended use of the original tire. In fact, a typical passenger tire may contain 30 types of styrene-butadiene rubber, 8 types of natural rubber, 8 types of carbon black and over 40 different chemicals as well as polyester and nylon fibers[

12,

13]. Different ingredient ratios result in a large number of tire formulations. The main components include 40-60% rubber content (including synthetic and natural rubber), 20-35% fillers (carbon black and silica) and 12-15% various oils[

14]. The physical and chemical properties of tire wear particles(TWP) have not been sufficiently studied, as they can also absorb materials from the road and the surrounding environment[

13]. The rate of tire particle (TWP) production due to road wear has been reported to vary between 10% to 50%, which may be related to road surface materials, including asphalt, road dust, gravel, oil, and plasticizers, all of which have an impact on the production of TWPs[

8]. The amount and rate of tire wear particle production varies according to a number of factors and, according to studies, increases due to vehicle loads, under- or over-inflation of tires, wheel alignment deviations, wheel position (front wheels wear first), transitional exposure to the elements, sudden braking, acceleration, or sustained high speeds[

9,

15]. Kole et al. estimated data on TWPs from tire wear and based on the global population and the number of motor vehicles of all types, it is estimated that emissions have reached nearly 6 million tons per year[

15], equivalent to about 0.81 kg per capita per year . Some components of tires have been proven to be toxic. Therefore, it is necessary to reduce the amount of these harmful substances released into the external environment [

16,

17,

25].

As cars travel, the continuous wear of tires releases microplastic particles into the environment. Excessive tire wear can also further affect driving safety. According to statistics from the World Health Organization, more than 1.3 million people die each year from road traffic accidents. It is one of the top ten causes of death for all age groups and this trend is on the rise, especially for young people[

18]. The health of a moving vehicle’s tires is only one of the causes of road traffic accidents, but road traffic accidents related to tire health problems can lead to more grievous injury to life and damage to property[

19]. A study using seven years of Louisiana crash data shows that sudden tire failure and excessive tire wear significantly affect the severity of road crashes[

20]. A substantial proportion of traffic accidents are caused by lack of vehicle maintenance and tire defects. For example, data from the United States shows that in the National Motor Vehicle Crash Causation Survey (NMVCCS) conducted from 2005 to 2007, out of approximately 44,000 traffic accidents related to vehicle defects, more than 15,000 were related to tire defects, accounting for over 35%; According to a report from the National Highway Traffic Safety Administration (NHTSA), an average of nearly 11,000 tire-related motor vehicle accidents occur annually in the United States, resulting in approximately 200 fatalities.In 2017, a total of 738 people died in tire-related traffic accidents on American roads. These fatalities have drawn attention to the study of factors that cause tire failure and the analysis of the severity of injuries in tire-related accidents.

Therefore, it is necessary to develop green tires with better environmental performance (e.g. more wear-resistant, better air-tightness and better anti-burst performance), both for environmental protection and for the safety of people and property. Because of the increasingly serious environmental problems and the systematic promotion of the concept of green development, the cultivation of a green supply chain operation model is also gaining more and more attention from the government and upstream and downstream enterprises in the supply chain.

The development and production of green tires can be traced back to 1992 when Michelin produced the first recognized green tire. This product strategy, which focuses on environmental protection, has brought Michelin both economic and social benefits[

21]. In 2012, the European Union officially implemented the European tire labelling Regulation. This regulation requires that car tires, light truck tires, truck tires and bus tires sold in the EU must have a label indicating the tire’s rolling resistance (fuel efficiency), rolling noise and wet grip performance levels. The introduction of this regulation is seen as a sign of the official promotion of high-quality green tires[

22]. Subsequently, various countries have introduced labelling regulations related to tire rolling resistance. In 2016, China also issued a tire labelling law requiring that energy consumption, wet grip and noise be indicated on tires. Although green tires are relatively more expensive than ordinary tires, their superior performance, more user-friendly experience, lower fuel consumption and more environmentally friendly energy-saving features have made them increasingly popular among consumers.

Generally speaking, the development of green products requires relatively high research and development costs and their selling prices are also higher. As China’s economy has entered a new stage in recent years and society has increasingly valued green environmental protection, consumers have also paid more attention to the low-carbon economy. Improving the greenness of products is one of the important ways to achieve this. Many studies have pointed out that today’s consumer concept makes buyers willing to choose products with carbon emission labels. Market demand changes with consumer willingness, prompting product manufacturers to innovate technology to produce low-carbon and environmentally friendly green products to enhance their competitiveness in the market[

26].

The green product market is still in its infancy. In order to further expand the market and gain a competitive advantage while also making long-term plans, it is necessary for companies to actively invest in the research and development of green products and produce green environmental protection products that meet government policy guidance, social development and consumer preferences. This article considers that when green product manufacturers increase investment in research and development and reduce carbon emissions, retailers can also effectively participate in it, which is conducive to promoting benign cooperation between manufacturers and retailers, increasing economic income and further enhancing the core competitiveness of enterprises. Conducting research on the current situation of green economy and carbon emissions development, and based on systematic observations of green supply chain repurchase contracts, combined with supply chain theory, in-depth research is conducted on supply chain repurchase coordination and cost-sharing. Strive to propose suggestions for effectively ensuring the coordination of the green supply chain system and provide research support for further enhancing the competitive advantage of the green supply chain in the rapid development process of the current market economy.

Based on the analysis above, there are three important questions: 1)when the random demand is related to the product green level and considering carbon emissions trading, how to coordinate the green supply chain? 2)How does carbon emissions trading affect the supply chain profit and coordination? 3)How to share the cost between the parties in the green supply chain? The main purpose and significance of this study are to investigate these questions. The main contribution and results of this work is as follows:

Different from the classic literature, the random demand is related to the product green level. In addition, the cost is shared between the manufacturer and the retailer. Under the green supply chain buy-back contract, both the product green level and order quantity need to be decided. In order to coordinate the green supply chain, the manufacturer needs to share both the risk of good salvage and the cost.

Under the green supply chain buy-back contract, we find that both the wholesale price and buy-back price increase in the manufacturer’s proposition of the cost, but decrease in emission reduction efficiency coefficient or carbon trading price.

Both the product green level and the optimal order quantity increase in emission reduction efficiency coefficient, but decrease in the cost coefficient of the product green level. The channel profit increases in emission reduction efficiency coefficient, but decreases in the cost coefficient of product green level.

If the carbon trading price is low, the manufacturer will set a low product green level and the product carbon emission trading is a cost for the supply chain. The increment of the carbon trading price leads to a higher cost such that the channel profit is decreased. However, if the carbon trading price is high, the manufacturer will set a high product green level and the product carbon emission trading is a revenue for the supply chain. The increment of the carbon trading price leads to a higher revenue such that the channel profit is increased.

The structure of this work is organized as follows. The background, motivation and main contribution of this work are introduced in

Section 1. We review the related literature in section 2. In section 3, we describe the model for the parties of the supply chain and show the centralized decisions and decentralized decisions: the product green level and the order quantity. In section 4, we use a buy-back contract with the

cost sharing between the manufacturer and the retailer to coordinate the supply chain. In section 5, we analyze the impact of the green emissions trading on the optimal channel profit. We conclude our work and show further research in section 6.

2. Literature Review

Supply chain is essentially strategic alliances between companies with different core production businesses that have established long-term cooperation relationships[

23]. The Green Supply Chain (GSC) has a strong orientation to the direction of change in the industrial environment. Since the introduction of the concept of green development, the focus of society has been on the study of green supply chains and the evolution of green coordination contracts in conjunction with various environmental factors. This study is closely related to four streams of literature: buy-back contract, green supply chain, carbon emissions

2.1. Buy-back contract

Emmons and Gilbert [

36] argue that traditional models such as revenue sharing, and buyback contracts can have positive effects and help to coordinate the supply chain by addressing discrepancies between the retailer’s order quantity and actual demandx. However, when demand is significantly influenced by other factors, Cachon [

37] argues that although traditional contracts and buyback contracts are fundamentally different, they may become ineffective when other factors affect product demand. Xuyou and Jing [

44] found that there is a positional relationship between retailers and market demand. However, reasonable predictions can be made based on past sales experience. Assuming that the prediction error is negligible, the retailer can make corresponding promotional efforts and design a coordination mechanism that combines profit contribution with cost sharing. Taylor [

38] argues that in buybacks, the wholesale price and buyback price are determined by the supplier while the order quantity and retail price are determined by the retailer. When the buyback price is much lower than the wholesale price, more than one condition must be met for supply chain coordination to be successful.

2.2. Carbon emissions

In the relevant literature on emission estimation, it is easy to find a fact: the content of the greenhouse inventory has a great impact on early national policies related to carbon emissions. By analyzing the emission inventories of different emission sources, Giri and Roy [

24] further pointed out that fossil fuel combustion is currently the largest influencing factor in climate change and is also the focus of current human social and economic improvement. This study further estimated greenhouse gas emissions from dozens of international metropolises using carbon emission coefficients and defined measurement factors. Wang Daoping [

35] estimated the energy consumption and carbon emissions of 20 mega-cities in China and found that carbon emissions per capita are increasing rapidly by more than 20%, so it is imperative to further control carbon emissions in large cities with the help of high technology. Liu Mingwu and Maozeng [

39] used the life cycle method to carry out relevant calculations on the direct carbon emissions from energy combustion in China. The results showed that in 2017, China’s direct carbon emissions from energy consumption increased by more than 300% compared to 1979. Yang Aifeng and Xiaojian [

40] used the LMDI decomposition method to conduct an empirical analysis of China’s data from 1995-2017. They believed that carbon emission factors have the following four components: energy structure, energy efficiency, energy intensity and economic development. The results were summarized into categories such as total energy consumption, technical factors, energy consumption structure and industrial structure. The carbon emission quota trading mechanism is a highly effective emission reduction measure at present. It can encourage more enterprises to follow the market development trend and promote the stable and long-term development of enterprises. Experts and scholars use simulation methods to study how carbon quotas and carbon emission rights can play a reasonable constraint among enterprises, thereby effectively reducing carbon emissions[

41].

Most related research provides references for production choices during enterprise production. Yuan and Daozhi [

42] believe that under the current background where the government has agreed on carbon emission quotas and given a carbon emission trading market, when retailers possess and have fair preferences, the type of contract will have a differential impact on coordinating the supply chain. Fan Tijun and Ruiling [

43] explored how enterprises can carry out technical emission reduction when facing constraints and how to make decisions on production, manufacturing, inventory and other issues. The focus is on analyzing the weight of carbon emission trading and the proportion of enterprise production operations. The type of product has a great impact on carbon emissions. Limited by current green emission reduction technology, some green products may actually cause higher carbon emissions. More research can focus on the issue of enterprise green product development under multi-cycle conditions.

After analyzing the literature on carbon emissions research, it can be seen that by using different models to clarify the impact of carbon emission trading on the entire supply chain and further provide scientific and effective guidance for enterprise production. Existing literature on carbon emissions has conducted an in-depth analysis on the effects and significance of considering carbon emissions, which can provide a solid theoretical reference for this study.

2.3. Green supply chains

The concept of the green supply chain has been defined through numerous papers in view of its practical application to the development of modern enterprises and to further enhance the value of its application. Giri and Roy [

24] argues that Green Supply Chain Management (GSCM) was initially studied as a secondary aspect of the logistics management research process, and that changes in supply chain management have occurred as a result of environmental factors.

Kouvelis and Zhao [

27] pointed out that the Manufacturing Research Association of Michigan State University launched an ‘Environmentally Responsible Manufacturing’ survey with the support of a foundation and first proposed the concept of a green supply chain in 1996. Therefore, based on the relevant research on green supply chain management by representative foreign scholars, it can be seen that the definition of green supply chain management is: environmentally conscious supply chain management. Measures must be taken to address environmental issues at every stage of the daily supply chain. By studying the impact of numerous factors on the environment and the overall economy, effective protection can be achieved while balancing both economic and environmental considerations.

Green supply chain management is now being practiced in all of China’s hotspot industries, and the concept of green supply chains will be gradually introduced in more and more areas as the global research on green supply chains intensifies. In the manufacturing industry,Yu and Zihao [

28] wanted to seek synergies between green management and performance development in enterprises at this stage, and further derived contract negotiation coordination mechanisms such as negotiation coordination and decentralized balanced decision making based on green management coordination. In the field of construction, Zhang Lihao and Guolong [

29] pointed out that under the guidance of government policies, an experimental simulation was conducted to analyze the impact of government policies on the green supply chain at this stage, based on the game behaviors of various participants, and then a model was constructed to protect the construction industry, resulting in a green supply chain implementation tool that can effectively satisfy the economic interests of different parties. In the financial field, Zhou Yanju and Xuanhua [

30] believe that green supply chain finance continues to promote the upgrading and transformation of the financial industry. Research shows that at this stage, electronic order financing models and B2B e-commerce credit scoring can promote long-term cooperation between upstream and downstream enterprises in green supply chains and build trust between them. In the field of logistics, with the increasing demand for fruits and vegetables, He Lihong and Chun [

31] pointed out the current development status of fruit and vegetable cold chain logistics. The actual operating efficiency of cold chain logistics in our country and the suggestions and countermeasures proposed under the green supply chain, the application of green supply chains is currently expanding horizontally at all levels, but the specific research is uneven and not in-depth, making it difficult to implement the application of green supply chain management practices.

The practical implementation of green supply chains faces a variety of issues, such as the inability to conduct objective performance evaluations. Effective performance evaluations can provide support for the development of more systematic management policies. Fuzzy evaluation and analytic hierarchy process are qualitative methods among effective performance evaluation methods and are widely used. Wang Daoping and Boqing [

32] believe that multi-objective decision-making exists in the process of green supply chain evaluation. It should be conducted from multiple links and use the network analytic hierarchy process to start from the four basic links of the supply chain. Shi Ping and Song [

33] pointed out that based on the DEMTEL method, the green supply chain performance evaluation indicators are classified and identified on the basis of comprehensive management of processes, information and services. Key evaluation indicators are obtained and their secondary evaluation indicator system is evaluated comprehensively from four standards: environmental reputation, environmental impact, resource reusability and energy consumption using the analytic hierarchy process. Qu You and Jin [

34] innovatively developed a three-level indicator system based on the grey correlation analysis method from the basis of the connotation and characteristics of green supply chains.

In conclusion, there are three points to summarize the theory and practice of green supply chain management. Firstly, there are some deficiencies in both the content and definition of green supply chain research in our country. Secondly, it is not difficult to see from the relevant research literature that in the manufacturing industry, significant progress has been made in green supply chain management in terms of processes, operational indicators and related policy research. Moreover, it has been widely practised in the management application of actual enterprises. However, the development of industries such as finance, agriculture and logistics is still relatively immature. Finally, in terms of performance evaluation research, scholars have further developed their research based on various perspectives to effectively enrich performance evaluation-related indicators and obtain a more accurate evaluation indicator system.

3. Basic Model for Green Supply Chains Considering Carbon Emissions.

As economic development enters a new stage and people’s mindset changes, people pay more attention to low-carbon economy because of the economic development and the importance of green environmental protection in recent years. Local governments have explicitly proposed to actively promote low-carbon green development, accelerate the construction of innovative incentives for practice and strengthen green and environmental industries.

Consumers are paying more attention to carbon emissions or energy efficiency labels when shopping, and this is driving manufacturers to innovate and upgrade their industries. manufacturers are increasing the market demand for their products by increasing the greenness of their products, while adding additional research and development costs that are only borne by the manufacturers, leaving them to make decisions between the cost of research and development and increasing market demand. At the same time, retailers are ordering to meet market demand but are concerned about the possibility of a backlog of stock. A contract is therefore needed to reconcile the decision to order with the decision to green the product to eliminate this conflict arising from the double marginal effect of the green supply chain. This chapter will discuss the optimal decision of green manufacturers and retailers in the case of random demand and decide the greenness of products based on the consideration of tradable carbon emissions.

3.1. Description of the problem and main parameters

We consider a buy-back contract between a single green product manufacturer and a single retailer. The manufacturer decides the green level of the product (denoted as k), and the retailer decides how much to order (denoted as q). Both the manufacturer and the retailer are risk-neutral.

The retail price is denoted as p. The manufacturer’s production cost per unit is denoted as and the retailer’s sales cost per unit is ; : The retailer’s marginal cost is incurred upon procuring a unit (rather than upon selling a unit). For notational convenience, we let . The retailer earns per unit unsold at the end of the sales period, where v is the salvage value of the unit. We consider a buyback contract between the manufacturer and the retailer. With a buy-back contract, the manufacturer charges the retailer w per unit purchased but pays the retailer b per unit remaining at the end of the season.

We assume that the normal product demand y is random. Let F be the distribution function of demand and f its density function: F is strictly increasing and differentiable, where , , , .

Due to the popularization of environmental education in recent years, people increasingly like green products. Then, we assume that the demand for the green product (denoted as ) increases at the green level of the product (denoted as k) i.e. , where . Therefore, When , the product is the normal product and its demand is y.

The cost of the green product manufacturer is convex increasing in product green level k, i.e. , where h is R&D cost coefficient. The manufacturer has a free carbon credit, denoted as E. The actual carbon emission decrease in the product green level i.e. , where e is the normal product carbon emissions () and a is denoted as emission reduction efficiency coefficient. Then, is the trading carbon emission of the manufacturer and the unit trading price is denoted as .

All of the parameters can be found in

Table 1.

We assume to ensure profitability for the retailer and to ensure profitability for the manufacturer.

In the green supply chain system, manufacturers of green products are subject to government-regulated carbon emission quotas. Initially, companies are allocated a certain amount of carbon emissions for free by the government. Any excess can be purchased on the market. If a company reduces its carbon emissions by improving its production technology and saves its carbon quota, it can sell the surplus quota on the carbon trading market and earn revenue.

3.2. Centralized decision model

Considering the situation of carbon emissions and carbon trading quotas, the overall supply chain profit

. Then

Where

represents the expected sales volume. Referring to [

37], coupled with the green level of the product

k, we obtain

.

represents the expected inventory volume, that is

, it can be derived that

.

represents the R&D cost of green product manufacturers and

represents the income or expenditure of carbon trading. We denoted

as the normal product carbon emission trading. Since the free carbon credit

E is set for the carbon emission reduction, and the carbon emission of the normal product

e should be less than

E, so we assume that

. Therefore equation (

1) can be simplified as:

Considering the situation of carbon emissions and carbon trading quotas, the order quantity q and the product green level k is determined to maximize the supply chain profit. We obtain the following proposition.

Proposition 1.

Under the centralized decision scenario, the optimal product green level is

and the optimal order quantity is

Under government-regulated carbon quotas and with increasing consumer awareness of environmental protection, companies can improve the overall profitability of their supply chain by making centralized decisions to enhance the eco-friendliness of their products. The product green level and the order quantity are jointly concave. We find that the optimal product green level and the optimal order quantity are affected by the other parameters, such as retail price, salve value, R&D cost coefficient and et al. Then, we do the sensitivity analysis and obtain the following proposition.

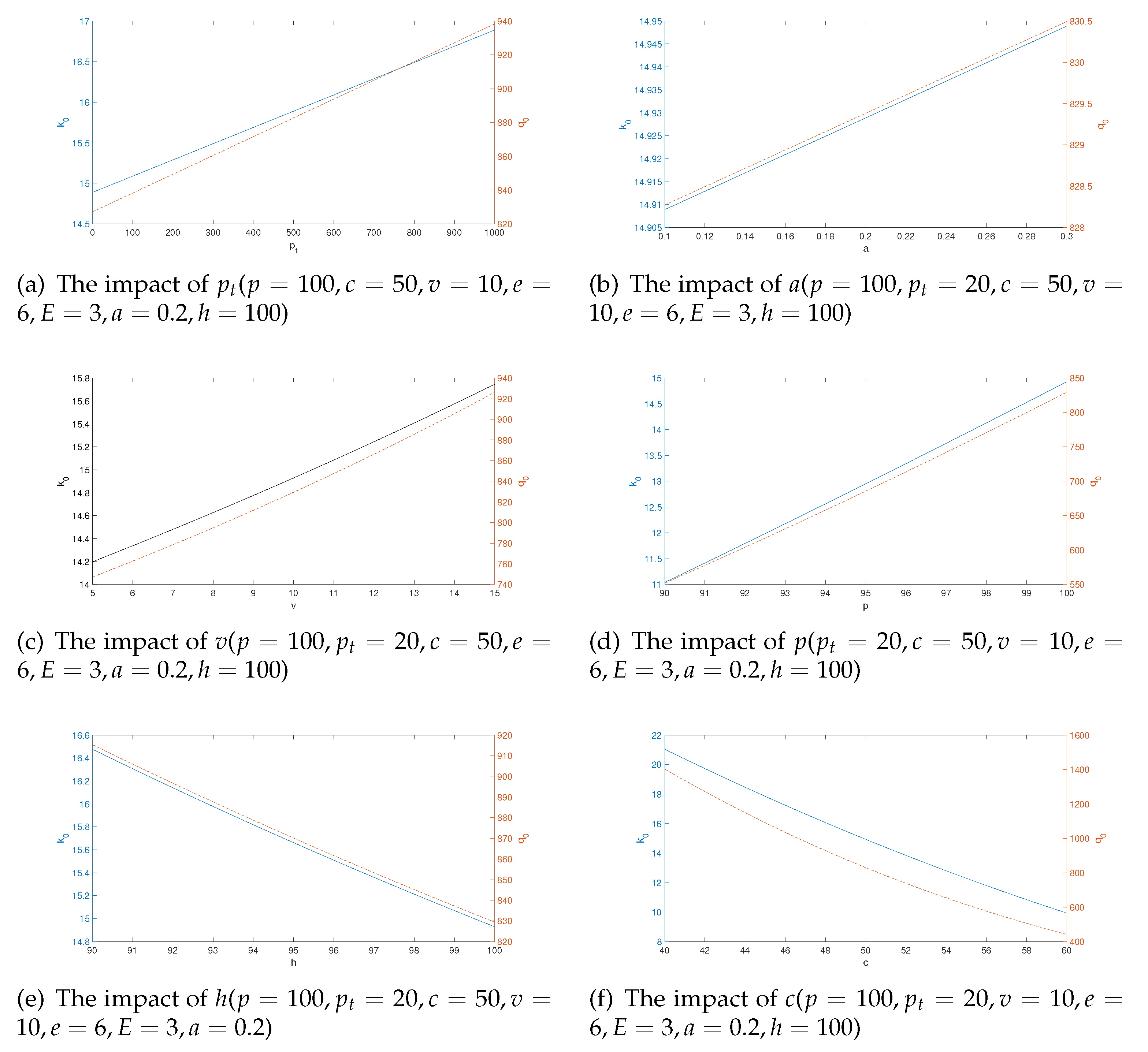

Proposition 2. Both and increase in , a, v and p, but decrease in h and c.

As retail price

p or salvage value

v increases, the goods are more profitable from sales or lose less from salvage, so both the optimal product green level and the optimal order quantity should be increased to advance the probability of goods sales. (See

Figure 1 (c) and (d).) However, as the total unit cost

c decreases, the profitability of goods is decreased such that both the optimal product green level and the optimal order quantity should be decreased to avoid of the loss from salvage. (See

Figure 1 (f).) As emission reduction efficiency coefficient

a or carbon trading price

increases, the product green level can be increased to improve the supply chain’s revenue. However, as R&D cost coefficient of product green level

h increases, the product green level should be decreased to reduce the supply chain’s cost. Since the optimal order quantity increases in the optimal product green level, then the optimal order quantity increases in emission reduction efficiency coefficient

a or carbon trading price

(See

Figure 1 (a) and (b)), but decreases in R&D cost coefficient of product green level. (See

Figure 1 (e).)

3.3. Decentralized decision model under the buy-back contract

Under a buy-back contract with the green product

cost-sharing, the retailer helps the green product manufacturer bear part of the research and development costs at a ratio of

, while the green product manufacturer bears a proportion of

. The manufacturer and retailer reach an agreement in advance that the retailer can obtain products from the manufacturer at a wholesale price

w. At the end of the sales period, the manufacturer will compensate for unsold products at a repurchase price

b. However, since transportation of remaining products also incurs costs, these products will not be shipped back to the manufacturer and their residual value still belongs to the retailer. In the green supply chain buyback model, the expected profit functions for retailers and green product manufacturers are

and

respectively:

Proposition 3.

Under the decentralized decision scenario, there is an equilibrium between the manufacturer and the retailer, the equilibrium green level of products is

and the equilibrium order quantity is

Under the decentralized decision scenario, the manufacturer and the retailer make their own decisions: green level of products and product order quantity. We obtain a unique equilibrium, in which both the green level of products and the order quantity are affected by other parameters, such as retail price, salve value, cost coefficient and et al. Then, we do the sensitivity analysis under the decentralized decision scenario and obtain the following proposition.

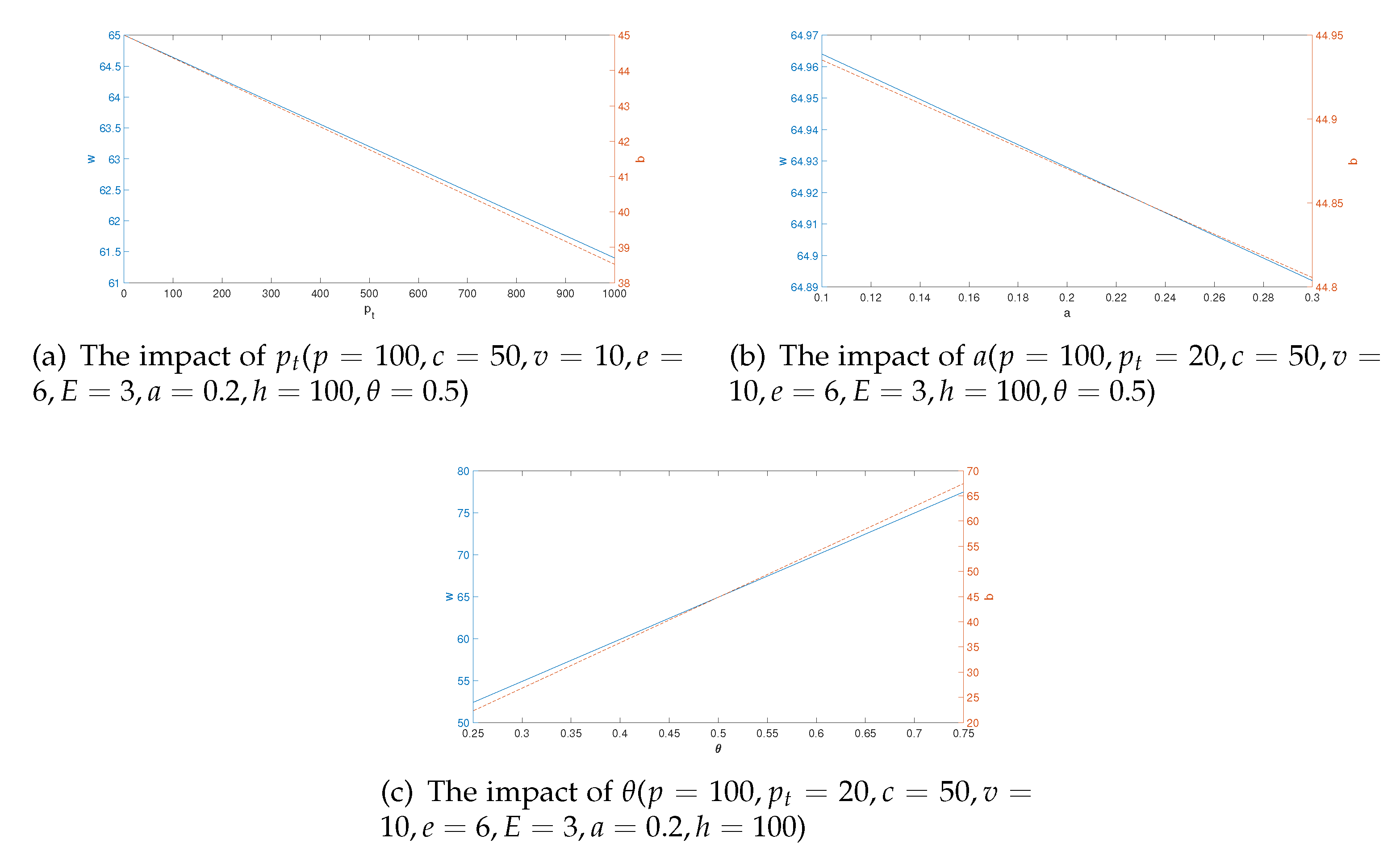

Proposition 4. Both and increase in , a, v, b and p, but decrease in h, θ and .

Under the decentralized decision scenario, in equilibrium, as retail price p or salvage value v increases, the goods are more profitable from sales or lose less from salvage, so both the equilibrium product green level and the equilibrium order quantity should be increased to advance the probability of goods sales. However, as the unit marginal cost increases, the profitability of goods is decreased such that both the equilibrium product green level and the equilibrium order quantity should be decreased to avoid the loss from salvage. As emission reduction efficiency coefficient a or carbon trading price increases, the product green level can be increased to improve the ’s revenue, so as to increase the ’s profit. However, as the cost coefficient of product green level h increases, the product green level should be decreased to reduce the supply chain’s cost. As the ’s proportion of the cost increases, the should set a lower equilibrium product green level to retain its profit. Since the equilibrium order quantity increases in the equilibrium product green level, then the equilibrium order quantity increases in emission reduction efficiency coefficient a or carbon trading price , but decreases in the cost coefficient of product green level and the ’s proportion of the cost.

4. Coordination under the Buy-back Contract

In research on coordinating supply chain systems through the buy-back contract, many studies have found that real-world the buy-back contract can indeed help participants at all levels of the supply chain effectively enhance their optimal interests. The buy-back contract has gradually become one of the measures for s and retailers to expand sales volume. According to Guo, Meng Yuexia and Qin Kaida (2018), on the one hand, it promotes further cooperation between the manufacturer and the retailer and encourages both parties to make decisions from the perspective of maximizing the benefits of the supply chain system; on the other hand, it is conducive to increasing the benefits of the green product retailer and manufacturer and improving system performance.

When the retailer’s order quantity decision is the same as the previous centralized decision and the manufacturer’s product eco-friendliness is the same as the centralized decision, the green supply chain reaches coordination and should satisfy the conditions: , .

Proposition 5.

For a contract combining buybacks and research and development cost-sharing to achieve perfect coordination of the system, the following parameters must meet the conditions:

Under the contract, the manufacturer and the retailer share the risk of demand uncertainty by the cost share of the and buy-back behaviour from the manufacturer to the retailer. Specifically, the retailer bears of the manufacturer’s research and development costs and the manufacturer compensates the retailer for unsold products at a repurchase price b at the end of the sales period, and the supply chain is coordinated. The wholesale price and buy-back price are both affected by other parameters, such as retail price, salvage value and et al. Nest, we will do the sensitivity analysis and obtain the following proposition.

Proposition 6. When the supply chain is coordinated, w increases in θ, but decreases in and a; b increases in θ, but decreases in and a.

As emission reduction efficiency coefficient

a or carbon trading price

increases, the product green level can be increased to improve the ’s revenue, so as to increase the ’s profit. Since the equilibrium order quantity increases in the equilibrium product green level, then the equilibrium order quantity and channel optimal order quantity increases in emission reduction efficiency coefficient

a or carbon trading price

. However, due to the

cost sharing between the manufacturer and the retailer, the equilibrium order quantity increases more such that the buy-back price need to be reduced to slow the equilibrium order quantity increment range to keep consistent with the optimal order quantity. As the manufacturer’s proposition of the

cost

increases, the equilibrium order quantity’s increment is close to the channel optimal order quantity’s increment, such that the motivation of the buy-back price decrement is diminished. Since the wholesale price increases in the buy-back price, then the wholesale price increases in the manufacturer’s proposition of the

cost (See

Figure 2 (c)), but decreases in emission reduction efficiency coefficient or carbon trading price. (See

Figure 2 (a) and (b).)

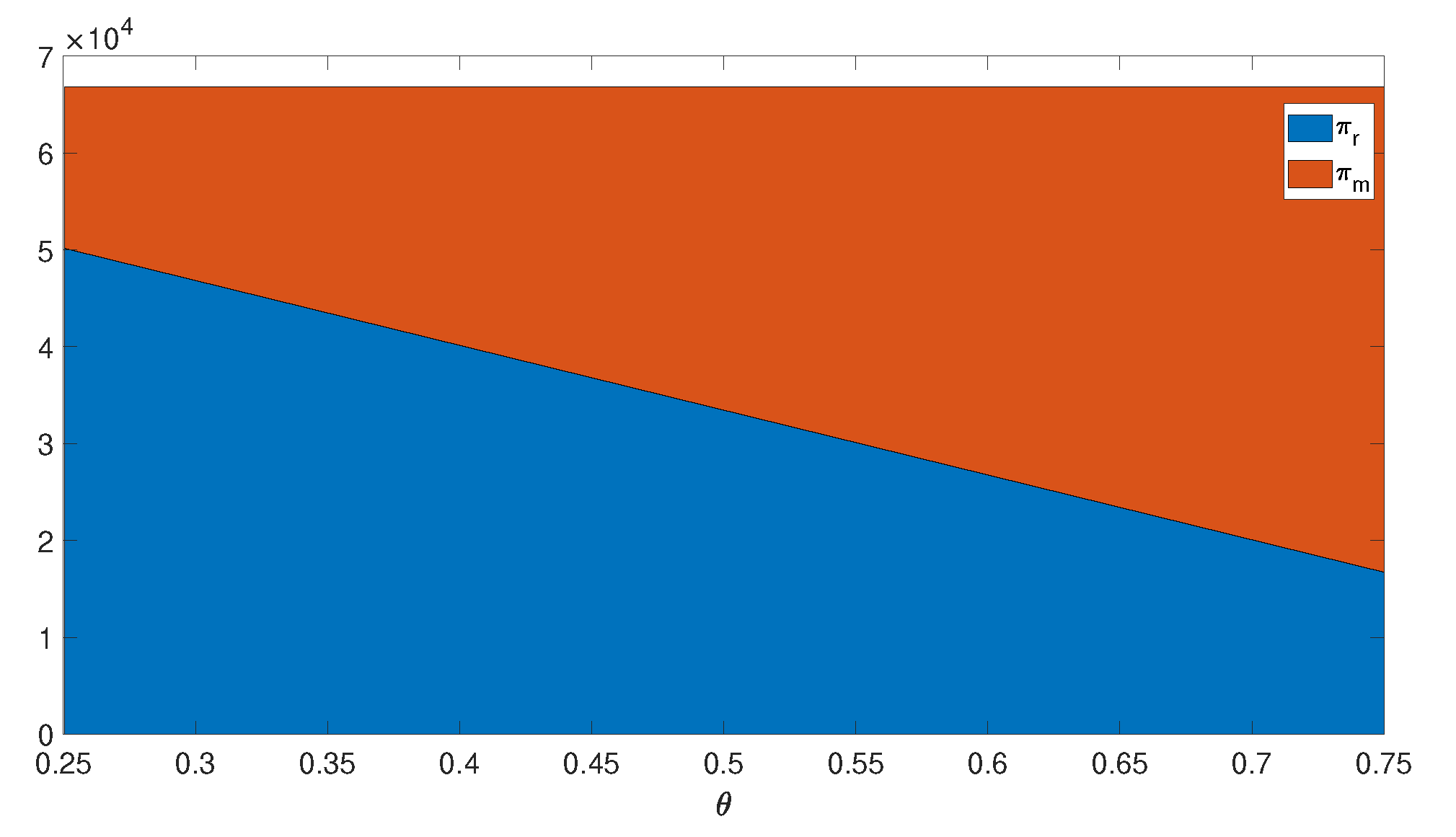

With the wholesale price and buy-back price, the supply chain can be coordinated and the supply chain profit can be maximized. Due to the cost sharing between the manufacturer and the retailer, can be used to distribute the total optimal supply chain to the manufacturer and the retailer.

In decentralized decision-making, the green product manufacturer decides the optimal product green level

k and the retailer decides the optimal order quantity

q on this basis. When the supply chain is coordinated, due to the

cost sharing between the manufacturer and the retailer,

can be used to distribute the total optimal supply chain between the manufacturer and the retailer. As

increases, the changes in profits of all parties are shown in

Figure 3. Under the buy-back and

cost-sharing contract, when

, the retailer’s profit is

and the green manufacturer’s profit is

when the supply chain is coordinated and the channel profit is

. As

increases, the retailer profit decreases but the manufacturer increases, and the channel profit is unchanged. Therefore, the

cost sharing,

can be used to distribute the optimal channel supply chain between the manufacturer and the retailer.

5. Sensitivity Analysis on the Optimal Channel Profit

With the channel optimal product green level and the channel optimal order quantity, the optimal channel profit is

where

.

Next, we analyze the impacts of parameters on the optimal channel profit and have the following proposition.

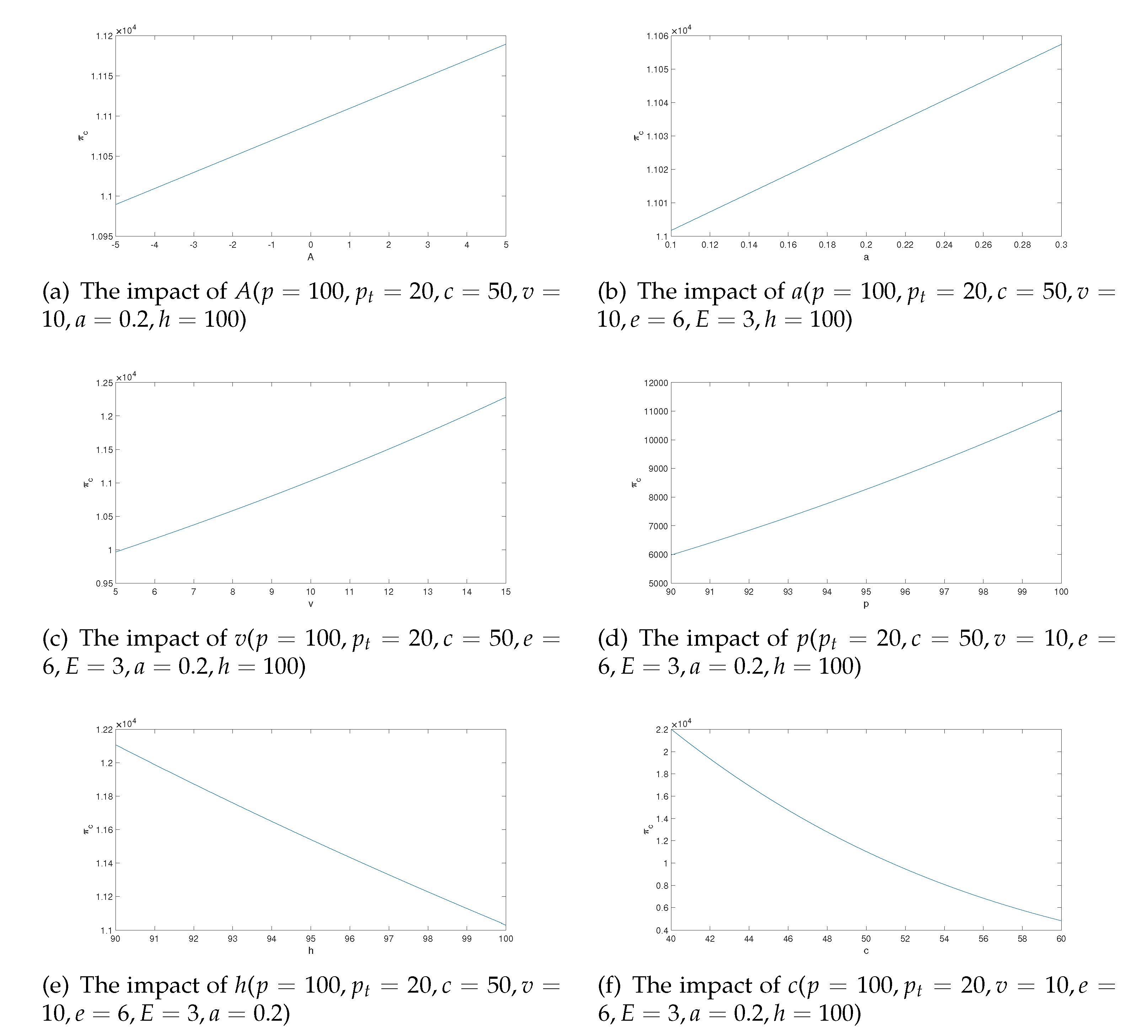

Proposition 7. The channel profit increases in a, p, v and A, but decreases in c and h.

As retail price

p or salvage value

v increases, the goods are more profitable from sales or lose less from salvage, so the channel profit is increased. (See

Figure 4 (c) and (d).) However, as the total unit cost

c or

cost coefficient

h decreases, the profitability of goods is decreased such that the channel profit is decreased. (See

Figure 4 (e) and (f).) As the normal product carbon emission trading

A or Emission reduction efficiency coefficient

a increases, the manufacturer can obtain more profit from the product carbon emission trading such that the channel profit is increased. (See

Figure 4 (a) and (b).)

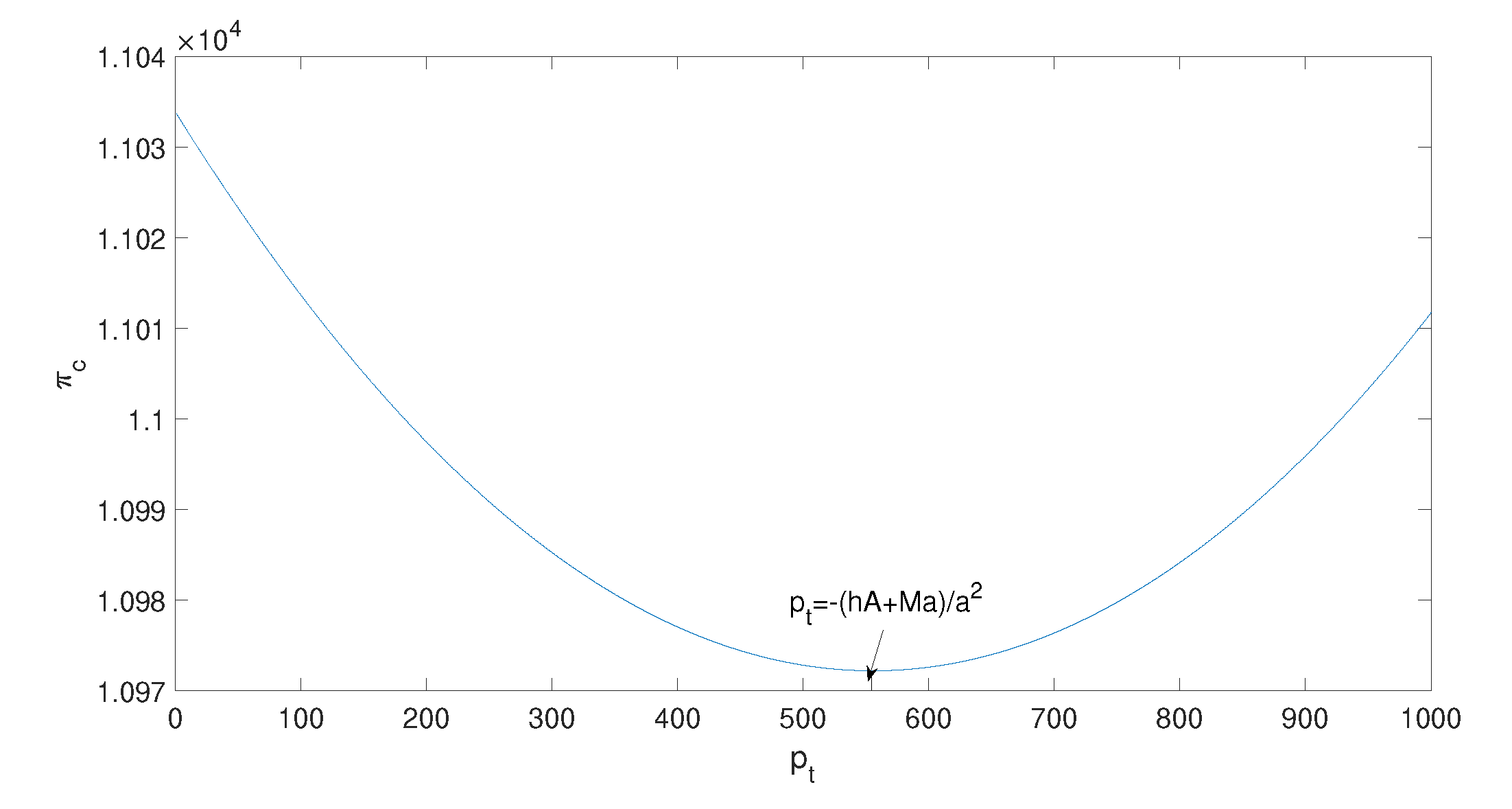

Proposition 8. The channel profit decreases in when , but increases in when , where .

The increment of

always leads to the increment of the optimal product green level

and the optimal order quantity

. If the carbon trading price

is low (

), the manufacturer will set a low product green level and the product carbon emission trading is a cost for the supply chain (

). The increment of

leads to a higher cost such that the channel profit

is decreased. However, if the carbon trading price

is high (

), the manufacturer will set a high product green level and the product carbon emission trading is a revenue for the supply chain (

). The increment of

leads to a higher revenue such that the channel profit

is increased. (See

Figure 5.)

Whether the product carbon emission trading is a revenue or a cost for the green supply chain depends on the threshold of the carbon trading price . Then, we analyze the impact of parameters on the threshold of the carbon trading price and have the following proposition.

Proposition 9. The threshold decreases in A, p and v but increases in c and h.

When , the threshold decreases in a; When , is negative and always hold.

Whether the product carbon emission trading is a revenue or a cost for the green supply chain depends on the threshold of the carbon trading price . Consequently, when increases, it is more possible that and the product carbon emission trading is a cost for the supply chain; when decreases, it is more possible that and the product carbon emission trading is a revenue for the supply chain.

The increment of the retail price p or salvage value v leads to a higher product green level , so it is more possible that carbon emission trading is a revenue. However, the increment of the total unit cost c leads to a lower product green level , so it is more possible that carbon emission trading is a cost.

The increment of the cost h always leads to a higher product green level , so it is more possible that carbon emission trading is a revenue. As the normal product carbon emission trading A increases, the product green level is unchanged but it is more possible that the product carbon emission trading is a revenue () for the supply chain such that decreases.

When the emission reduction efficiency coefficient a is low (), is low such that the product carbon emission trading is a cost for the supply chain, so the increment of a leads to the increment of such that the product carbon emission trading becomes the revenue for the supply chain and it is more possible that ; when the emission reduction efficiency coefficient a is high enough (), is high such that the product carbon emission trading is a revenue for the supply chain and always holds.

6. Conclusion and Further Research

6.1. Conclusion

Different from the traditional buy-back contract, under the green supply chain buy-back contract, both the product green level and order quantity need to be decided and the product green level is related to the random demand. In addition, the cost is shared between the manufacturer and the retailer. In order to coordinate the green supply chain, the manufacturer needs to share both the risk of good salvage and the cost.

Under the green supply chain buy-back contract, we find that both the wholesale price and buy-back price increase in the manufacturer’s proposition of the cost, but decrease in emission reduction efficiency coefficient or carbon trading price.

As retail price or salvage value increases, the goods are more profitable from sales or lose less from salvage, so both the optimal product green level and the optimal order quantity should be increased to advance the probability of goods sales, such that the channel profit is increased. However, as the total unit cost increases, the profitability of goods is decreased such that both the optimal product green level and the optimal order quantity should be decreased to avoid of the loss from salvage such that the channel profit is decreased.

As the emission reduction efficiency coefficient increases, the product green level can be increased to improve the supply chain’s revenue, so as to increase the supply chain profit. However, as the cost coefficient of the product green level increases, the product green level should be decreased to reduce the supply chain’s cost. Since the optimal order quantity increases in the optimal product green level, then the optimal order quantity increases in emission reduction efficiency coefficient but decreases in the cost coefficient of the product green level. The channel profit increases in emission reduction efficiency coefficient, but decreases in the cost coefficient of product green level.

As carbon trading price increases, the product green level can be increased to improve the supply chain’s revenue, so as to increase the supply chain profit. Since the optimal order quantity increases in the optimal product green level, then the optimal order quantity increases in the carbon trading price. If the carbon trading price is low, the manufacturer will set a low product green level and the product carbon emission trading is a cost for the supply chain. The increment of the carbon trading price leads to a higher cost such that the channel profit is decreased. However, if the carbon trading price is high, the manufacturer will set a high product green level and the product carbon emission trading is a revenue for the supply chain. The increment of the carbon trading price leads to a higher revenue such that the channel profit is increased.

6.2. Further research

For the convenience of research and modelling, this paper simplifies the actual situation of the supply chain. This results in a certain degree of deviation between the research results and the actual situation. The main shortcomings are as follows: The relationship between members of the supply chain is complex and changeable, so it is not appropriate to discuss them together. On the one hand, there is not much attention paid to the quantitative relationship between buyers and suppliers. On the other hand, whether there is competition or cooperation between s has not been considered. In reality, game behaviour often occurs under conditions where information among members of the supply chain is not equal and decision-making is not completely rational. This study assumes that product greenness and consumer purchase preferences are not completely positively correlated; that is, consumers do not completely pursue green consumption.

Under the current premise of carbon emissions, the exploration of green supply chain repurchase contracts can be extended to the following areas:

Firstly, green supply chain coordination can also be studied in multiple s and multiple stages of products. At present, most repurchase contract explorations are basically focused on the coordination between a single cycle, a single and a single retailer. However, in practice, the structure of the supply chain involved in practical life is much more complicated than that in theory. Therefore, it is possible to consider further expanding the exploration of repurchase contracts involved in green supply chains to one-to-many or many-to-one modes between supply chains and retailers. It can even be further expanded to multi-cycle, multi-level and multi-product type supply chain network structures.

Secondly, during the period when productivity constraints arise in green supply chains. At present, the exploration of green supply chain repurchase contracts is based on the assumption that the production and supply capacity of manufacturers or suppliers is infinite. There are few related literatures that consider the situation where the production capacity of manufacturers is limited. However, in practice, most enterprises have significant constraints on their production capacity. Therefore, in actual operation, how to reasonably arrange the production capacity of suppliers or manufacturers to effectively improve their own resource utilization rate has become a major concern for most enterprises in actual operation.

The issue of information asymmetry in green supply chains is also a difficult problem that we need to carefully consider. In cooperation, both parties will base their decisions on their own interests and valuable information cannot flow smoothly, resulting in a significant reduction in the overall efficiency of supply chain collaboration. Therefore, in the future, some treaties and parameters can be set to associate with some effective information. Of course, the ultimate goal is to make the upstream and downstream information of the green supply chain fully flow and further improve the overall collaborative efficiency.

Author Contributions

Conceptualization, Li, Xin.; Zhu, Guanlai.; methodology, Li, Xin.; software, Zhu, Guanlai.; validation, Li, Xin.;Zhu, Guanlai.; formal analysis, Li, Xin.;Zhu, Guanlai.; investigation, Li, Xin.;Zhu, Guanlai.; resources, Li, Xin.; data curation, Zhu, Guanlai.; writing—original draft preparation, Li, Xin.; Zhu, Guanlai.; writing—review and editing, Li, Xin.; Zhu, Guanlai.; visualization, Zhu, Guanlai.; supervision, Li, Xin.; project administration, Li, Xin.; Zhu, Guanlai.; funding acquisition, Li, Xin. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Macau University of Science and Technology Faculty Research Grants through FRG-22-057-MSB.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Acknowledgments

This research was funded by Macau University of Science and Technology Faculty Research Grants through FRG-22-057-MSB.

Appendix A

Proof of Proposition 1:

According to Equation (

2), for the overall supply chain profit function

, find the first and second derivatives of order quantities

q and greenness

k:

of which,

According to the above, the determinant of the Hessian matrix respect to

q and

k can be obtained:

Since and, thenis strictly negative definite. Therefore, it can be judged that is a joint concave function with respect to q and k. represents the optimal order quantity of the supply chain system and represents the optimal greenness of the supply chain system. Hence there exists such that the overall supply chain profit is maximized.

Let Equation (

5) equal to 0, and

satisfies the formula:

Let Equation (

6) equal to 0, and

satisfies the formula:

Proof of Proposition 3 The first and second derivatives of Equation (

13) with respect to

q are:

Where , , it can be derived that . Therefore, there exists a unique optimal solution q* within the range of that maximizes .

By setting Equation (

15) equal to 0, it can be determined that under the conditions of a cost-sharing contract for buybacks and research and development, the retailer’s optimal order quantity

satisfies:

The first and second derivatives of Equation (

14) with respect to

k are:

Where , , it can be derived that . Therefore, there exists a unique optimal solution q* within the range of that maximizes .

By setting Equation (

18) equal to 0, it can be determined that under the conditions of a cost-sharing contract for buybacks and research and development, the manufacturer’s optimal product eco-friendliness

satisfies the formula:

Then we obtain the result.

Proof of Proposition 2

Taking the first-order derivatives of

with respect to

p,

c,

v,

h,

a and

, we obtain

Proof of Proposition 3 and 4

The proof of Proposition 3 is similar with the proof of Proposition 1 and the proof of Proposition 4 is similar with the proof of Proposition 2.

Proof of Proposition 5

When the retailer’s order quantity decision is the same as the previous centralized decision and the manufacturer’s product eco-friendliness is the same as the centralized decision, the green supply chain reaches coordination and should satisfy the conditions:

,

. Coupled with equation (

3), we obtain that

Proof of Proposition 6

Based on Proposition 5, taking the first-order derivatives of

w and

b with respect to

,

a and

, we obtain

Proof of Proposition 7

Taking the first-order derivatives of

with respect to

a,

h,

A,

M, we obtain

Taking the first-order derivative of

M with respect to

p,

c and

v, we obtain

Then we obtain the results.

Proof of Proposition 8

Taking the first-order and second-order derivatives of

with respect to

, we obtain

Then, the channel profit decreases in when , but increases in when . Let .

Proof of Proposition 9

Taking the first-order derivatives of

with respect to

h,

A,

M, we obtain

Taking the first-order derivative of

M with respect to

p,

c and

v, we obtain

Then we obtain the results.

Taking the first-order derivative of

with respect to

a, we obtain

If , , while if , .

When , is negative such that always hold. When , always holds such that . Then we obtain the results.

References

- Verschoor, A. Towards a Definition of Microplastics Considerations for the Specification of Physico-chemical Properties (No. 2015-116). RIVM Letter Report, RIVM Letter report. Bilthoven 2015.

- Gent, A.N.; Walter, J.D. Pneumatic tire 2006.

- Amato, F.; Karanasiou, A.; Moreno, T.; Alastuey, A.; Orza, J.; Lumbreras, J.; Borge, R.; Boldo, E.; Linares, C.; Querol, X. Emission factors from road dust resuspension in a Mediterranean freeway. Atmospheric Environment 2012, 61, 580–587. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: a review. Environmental Science and Pollution Research 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Pu, S.; Liu, S.; Bai, Y.; Mandal, S.; Xing, B. Microplastics in aquatic environments: Toxicity to trigger ecological consequences. Environmental Pollution 2020, 261, 114089. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Zhou, X.; Su, Y.; Wang, H.; Yu, R.; Zhou, S.; Xu, E.G.; Xing, B. Environmental occurrence, fate, impact, and potential solution of tire microplastics: Similarities and differences with tire wear particles. Science of the Total Environment 2021, 795, 148902. [Google Scholar] [CrossRef] [PubMed]

- Ng, E.L.; Lwanga, E.H.; Eldridge, S.M.; Johnston, P.; Hu, H.W.; Geissen, V.; Chen, D. An overview of microplastic and nanoplastic pollution in agroecosystems. Science of the total environment 2018, 627, 1377–1388. [Google Scholar] [CrossRef] [PubMed]

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R.; et al. Tire abrasion as a major source of microplastics in the environment. Aerosol and air quality research 2018, 18, 2014–2028. [Google Scholar] [CrossRef]

- Verschoor, A.; De Poorter, L.; Dröge, R.; Kuenen, J.; de Valk, E. Emission of microplastics and potential mitigation measures: Abrasive cleaning agents, paints and tyre wear 2016.

- Cadle, S.; Williams, R. Gas and particle emissions from automobile tires in laboratory and field studies. Rubber Chemistry and Technology 1979, 52, 146–158. [Google Scholar] [CrossRef]

- Magnusson, K.; Eliaeson, K.; Fråne, A.; Haikonen, K.; Olshammar, M.; Stadmark, J.; Hultén, J. Swedish sources and pathways for microplastics to the marine environment, 2016.

- Lassen, C.; Hansen, S.F.; Magnusson, K.; Norén, F.; Hartmann, N.I.B.; Jensen, P.R.; Nielsen, T.G.; Brinch, A. Microplastics-Occurrence, effects and sources of. Significance 2012, 2. [Google Scholar]

- Kreider, M.L.; Panko, J.M.; McAtee, B.L.; Sweet, L.I.; Finley, B.L. Physical and chemical characterization of tire-related particles: Comparison of particles generated using different methodologies. Science of the Total Environment 2010, 408, 652–659. [Google Scholar] [CrossRef]

- Wagner, S.; Hüffer, T.; Klöckner, P.; Wehrhahn, M.; Hofmann, T.; Reemtsma, T. Tire wear particles in the aquatic environment-a review on generation, analysis, occurrence, fate and effects. Water research 2018, 139, 83–100. [Google Scholar] [CrossRef]

- Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.; Ragas, A.M. Wear and tear of tyres: a stealthy source of microplastics in the environment. International journal of environmental research and public health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Wik, A.; Dave, G. Acute toxicity of leachates of tire wear material to Daphnia magna—Variability and toxic components. Chemosphere 2006, 64, 1777–1784. [Google Scholar] [CrossRef] [PubMed]

- Marwood, C.; McAtee, B.; Kreider, M.; Ogle, R.S.; Finley, B.; Sweet, L.; Panko, J. Acute aquatic toxicity of tire and road wear particles to alga, daphnid, and fish. Ecotoxicology 2011, 20, 2079. [Google Scholar] [CrossRef] [PubMed]

- Organization, W.H. Global status report on road safety 2015; World Health Organization, 2015.

- Haq, M.T.; Zlatkovic, M.; Ksaibati, K. Assessment of tire failure related crashes and injury severity on a mountainous freeway: Bayesian binary logit approach. Accident Analysis & Prevention 2020, 145, 105693. [Google Scholar]

- Das, S.; Dutta, A.; Geedipally, S.R. Applying Bayesian data mining to measure the effect of vehicular defects on crash severity. Journal of Transportation Safety & Security 2021, 13, 605–621. [Google Scholar]

- Hanoteau, J. Competitiveness through political environmental strategies: The case of Michelin’s green tires. Global business and organizational excellence 2009, 29, 32–40. [Google Scholar] [CrossRef]

- Berge, T.; Sandberg, U. Five years of EU tyre labelling-Success or failure? In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings. Institute of Noise Control Engineering, 2017, Vol. 255, pp. 876–887.

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. Journal of Business logistics 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Giri, B.; Roy, B. Dual-channel competition: the impact of pricing strategies, sales effort and market share. International Journal of Management Science and Engineering Management 2016, 11, 203–212. [Google Scholar] [CrossRef]

- Bejgarn, Sofia and MacLeod, Matthew and Bogdal, Christian and Breitholtz, Magnus. Toxicity of leachate from weathering plastics: An exploratory screening study with Nitocra spinipes. Chemosphere 2015, 132, 114–119. [Google Scholar] [CrossRef]

- Vanclay, Jerome K and Shortiss, John and Aulsebrook, Scott and Gillespie, Angus M and Howell, Ben C and Johanni, Rhoda and Maher, Michael J and Mitchell, Kelly M and Stewart, Mark D and Yates, Jim. Customer response to carbon labelling of groceries. Journal of Consumer Policy 2015, 132, 153–160. [Google Scholar]

- Kouvelis, P.; Zhao, W. The newsvendor problem and price-only contract when bankruptcy costs exist. Production and Operations Management 2011, 20, 921–936. [Google Scholar] [CrossRef]

- Yu, C.; Zihao, L. A feasibility analysis for practicing green supply chain management without government policy incentives. Journal of Industrial Engineering/Engineering Management 2017, 31, 119–127. [Google Scholar]

- Zhang Lihao, Song Xiangbo, Z. G.; Guolong, L. Adoption and coordination of carbon reduction technology in supply chain based on carbon tax. Computer Integrated Manufacturing System 2017, 23, 883–891. [Google Scholar]

- Zhou Yanju, Bao Maojing, C. X.; Xuanhua, X. Co-op Advertising and Emission Reduction Cost Sharing Contract and Coordination in Low-carbon Supply Chain Based on Fairness Concerns. Chinese Journal of Management Science 2017, 25, 121–129. [Google Scholar]

- He Lihong, Liao Qian, L. M.; Chun, Y. A Game Analysis of Optimal Advertising Efforts and Direct Price Discount Strategy for the Two-level Supply Chain. Chinese Journal of Management Science 2017, 25, 130–138. [Google Scholar]

- Wang Daoping, L.X.; Boqing, Z. Study on the Decision of Supply Chain Based on Information Asymmetry Considering the Retailers’ Competition on Promotion Effort. Industrial Engineering and Management 2017, 22, 27–35. [Google Scholar]

- Shi Ping, Y.B.; Song, S. Pricing and Product Green Degree Decisions in Green Supply Chain with Fairness Concerns. Systems Engineering –Theory & Practice 2016, 36, 1937–1950. [Google Scholar]

- Qu You, Guan Zhimin, Y. T.; Jin, T. Supply Chain Coordination for Green Innovation-advertisement Decisions Based on Mixture CVaR Criterion. Chinese Journal of Management Science 2018, 36, 89–101. [Google Scholar]

- Wang Daoping, L.X. .Z.L. Study on the Coordination of Supply Chain Based on Carbon Emissions Trading Considering the Manufacturers’ Competition. Operations Research and Management Science 2018, 27, 1007–3221. [Google Scholar]

- Emmons, H.; Gilbert, S.M. The role of returns policies in pricing and inventory decisions for catalogue goods. JOT-Journal fur Oberflachentechnik 1997, 37, 276. [Google Scholar] [CrossRef]

- Cachon, G.P. Supply chain coordination with contracts. Handbooks in operations research and management science 2003, 11, 227–339. [Google Scholar]

- Taylor, T.A. Supply chain coordination under channel rebates with sales effort effects. Management science 2002, 48, 992–1007. [Google Scholar] [CrossRef]

- Liu Mingwu, Wu Kailan, F. H.; Maozeng, X. Cooperation on Carbon Emission Reduction in a Retailer-led Supply Chain with Consumer’s Low-carbon Performance. Systems Engineering –Theory & Practice 2017, 31, 3109–3117. [Google Scholar]

- Yang Aifeng, W.J.; Xiaojian, H. Study on the Third-party Remanufacturing Problem under Carbon Tax Mechanism. Management Science Theory and Method 2017, 31, 13–139. [Google Scholar]

- Chen, X.; Benjaafar, S.; Elomri, A. The carbon-constrained EOQ. Operations Research Letters 2013, 41, 172–179. [Google Scholar] [CrossRef]

- Yuan, L.; Daozhi, Z. Low-Carbonization Supply Chain Coordination with Contracts Considering Fairness Preference. Journal of Industrial Engineering and Engineering Management 2015, 29, 156–161. [Google Scholar]

- Fan Tijun, Y.J.; Ruiling, L. Production and Inventory Based on Carbon Emission Trading Mechanism and Investment of Emission Reducing Technology. Journal of Beijing Institute of Technology (Social Sciences Edition) 2012, 14, 14–21. [Google Scholar]

- Xuyou, S.; Jing, Q. Study on the Coordination of Supply Chain with Supplier’s Sales Effort. Science and Technology Management Research 2012, 32, 231–236. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).