Submitted:

10 February 2023

Posted:

10 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Mathematical Model

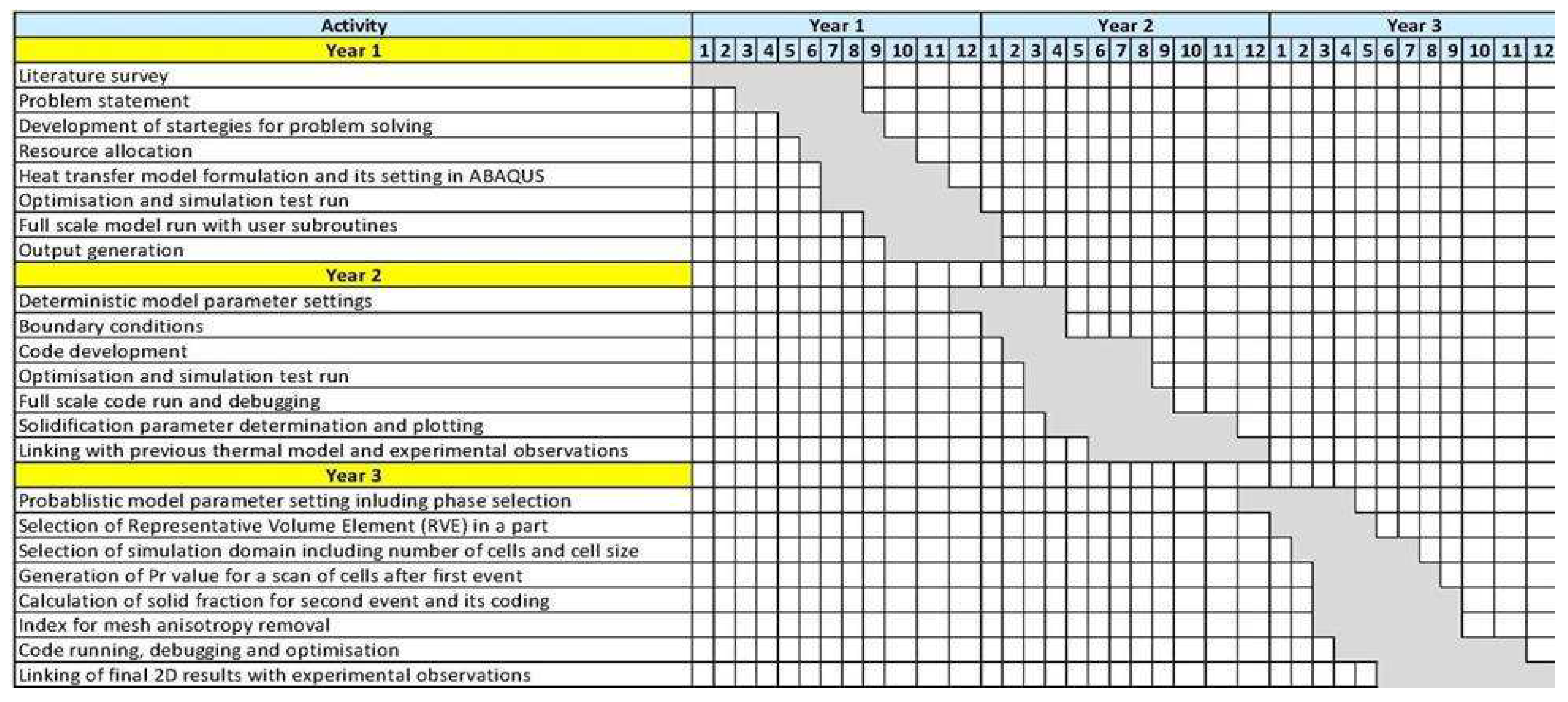

- Hypothesis: Null hypothesis is heat transfer process is difficult to model due to transient nature of process and unavailability of temperature dependent thermophysical data related to bulk metallic glass matrix composites (BMGMC).

- Experimental procedure: It will consist of use of commercial finite element code ABAQUS® 6.14-3 with the application of user defined subroutines (UTEMP and DFLUX) to simulate moving heat source.

- Protocols: Step-by-step standard approach of the use of ABAQUS® with user defined subroutines linked in Intel Parallel Studio XE (consisting of Microsoft Visual FORTRAN®) and Microsoft® Visual Studio will be adopted to generate part drawing, property assignment, meshing, optimisation and running of simulation to arrive at results. Special care will be taken in the use of CFD module rather than thermal module. ABAQUS® explicit mode alongside implicit mode with the extraction of thermal data and its usage in third party softwares e-g JAVA® or MATLAB will also be considered (Liu, Kouadri-Henni, and Gavrus 2016).

- Facilities: A dedicated IBM ThinkPad® P 51 machine with Intel Xeon E3-1505M v6 (Quad Core, 3.0 GHz on the base / up to 4.0 GHz with Intel Turbo, 8MB cache, 2400MHz speed), 32GB DDR4 Memory (upgraded, maximum memory capacity is 64 GB), 512 GB PCIe NVMe M.2 Solid State Drive (SSD), 15.6 Inch IPS FHD (1920x1080) Screen, Anti-glare, NVIDIA Quadro M2200 (4GB) graphics, 6 Cell Battery and Windows 10 Pro 64-bit is aimed to be employed. Average time taken to run one simulation is expected to be 2 to 2.5 hours.

- Techniques of analysing data: Parallel processing available as “in built” function in linked Intel® Parallel studio XE, MS visual studio and ABAQUS 6.14-3 will be used to carefully model and simulate heat transfer phenomena occurring during laser matter interaction in additive manufacturing. Use of loops with standard low to medium iteration will be used to arrive at convergence and refined results.

- Expected results and impact: It is expected that with the use of this protocol a moving heat source with real time temperature dependent data will be generated simulating actual thermofluidic conditions in additive manufacturing melt pool. This will be a value-added contribution towards efforts made to model simultaneous heat and mass transfer phenomena in additive manufacturing melt pool in bulk metallic glass matrix composite (BMGMC) in which, still there is a gap in literature as well as in practice.

- Hypothesis: Null hypothesis is measurement of individual elements and their supersaturation is ineffective means of arriving at quantitative prediction of microstructure parameters of multicomponent bulk metallic glass matrix composites (BMGMC).

- Experimental procedure: Procedure adopted to achieve this objective will employ modifications in original 35 years old solidification theory for rapid solidification (Kurz, Giovanola, and Trivedi 1986) and simulate the resulting model in MATLAB® with open boundary conditions. Aim is to employ temperature dependent thermophysical properties with well-established dimensionless numbers for mass transfer at microscale yielding accurate solidification parameters. MATLAB® programming will be assimilated with use of loops to account for iteration.

- Protocols: Step-by-step standard approach of the use of MATLAB® with user defined functions which lead to generation of vectors, loops and outputs will be adopted. No inbuilt MATLAB® function will be employed; rather all programming will be done as a standalone code. However, use of its linking with inbuilt libraries in Simulink® will be employed to arrive at refined results. Use of third party software and plug – ins (e-g. Abaqus2Matlab (Papazafeiropoulos, Muñiz-Calvente, and Martínez-Pañeda 2017)) for integration with previous heat transfer model as and when needed will also be employed.

- Facilities: A dedicated IBM ThinkPad® P 51 machine with Intel Xeon E3-1505M v6 (Quad Core, 3.0 GHz on the base / up to 4.0 GHz with Intel Turbo, 8MB cache, 2400MHz speed), 32GB DDR4 Memory (upgraded to maximum 64 GB), 512 GB PCIe NVMe M.2 Solid State Drive (SSD), 15.6 Inch IPS FHD (1920x1080) Screen, Anti-glare, NVIDIA Quadro M2200 (4GB) graphics, 6 Cell Battery and Windows 10 Pro 64-bit is aimed to be employed. Average time taken to run one simulation is expected to be few minutes as the length of code is compensated for by its bifurcation in parts which ease out processing and decrease computational cost.

- Techniques of analysing data: Output results will be plotted in various forms using in built graphical functions of MATLAB as well as external software e-g Minitab®, Prism® which will be employed for performing various statistical analysis on generated data. These include, but not limited to ANOVA, standard deviation, standard error, 95% confidence and curve fitting.

- Expected results and impact: It is expected that with the use of this protocol, a modified solidification microstructure model accounting for numerical determination of solidification parameters will be obtained. This will give quantitative results rather than qualitative output. Its validity will be comprehensively tested for accuracy of simulation results by performing various simulations on different independent computing platforms and comparing results. It will also be tested for various alloys systems for a set of thermophysical properties which are expected to generate different but comparable results.

- Hypothesis: Null hypothesis is measurement of solid fraction of individual elements is ineffective means of arriving at physical microstructure which is true representation of actual solidification process in multicomponent bulk metallic glass matrix composites (BMGMC).

- Experimental procedure: Procedure adopted to achieve this objective will consist of use of cellular automaton theory to account for measurement of solid faction caused by individual elements rather than measurement of solid fraction of predetermined simulation-based phases from pseudo binary phase diagrams. Then solid fraction of individual elements will be grouped into different categories to give an estimate of evolved phases. The resulting microstructure will also depend on cellular automata transition rules. Various previously tested rules will be employed to arrive at highly optimised rule which gives physical picture resembling actual microstructure of alloy cross section under optical light microscopy. Again, temperature based thermophysical properties with well-established dimensionless numbers for mass transfer at microscale will be employed yielding best possible picture of physical processes happening at microscale for multicomponent alloys. MATLAB® programming will be assimilated with use of loops to account for iteration.

- Protocols: Step-by-step standard approach of the use of MATLAB® with user defined functions which lead to generation of vectors, loops and outputs will be adopted as was done for previous objective. Inbuilt MATLAB® functions which assign colour to evolving domain will be employed to represent microstructure consisting of different elements. Programming itself will be done as standalone code on a dedicated machine. Its linking with inbuilt libraries in Simulink® will also be employed. Use of third party softwares and plug – ins (e-g. Abaqus2Matlab (Papazafeiropoulos, Muñiz-Calvente, and Martínez-Pañeda 2017)) for integration with previous heat transfer model as and when needed will also be employed to explain real time additive manufacturing process.

- Facilities: A dedicated IBM ThinkPad® P 51 machine with Intel Xeon E3-1505M v6 (Quad Core, 3.0 GHz on the base / up to 4.0 GHz with Intel Turbo, 8MB cache, 2400MHz speed), 32GB DDR4 Memory (upgraded to maximum 64 GB), 512 GB PCIe NVMe M.2 Solid State Drive (SSD), 15.6 Inch IPS FHD (1920x1080) Screen, Anti-glare, NVIDIA Quadro M2200 (4GB) graphics, 6 Cell Battery and Windows 10 Pro 64-bit is aimed to be employed.. Average time taken to run one simulation was observed to be few minutes as the length of code is compensated for by its divisions in parts which make it computationally inexpensive.

- Techniques of analysing data: Output results will be plotted in the form of evolving dendrite using inbuilt plot and surf functions of MATLAB®. Their input will be based on matrix values.

- Expected results and impact: It is expected that with the use of this protocol a detailed 2D physical solidification microstructure of bulk metallic glass matrix composites will be obtained. It will be tested by varying (a) composition, (b) thermophysical properties and (c) iteration cycles. It is expected that variation in these values will result in varied microstructures which will yield a detailed and in depth understanding of solidification phenomena of BMGMC.

4. Research Approach and Methods

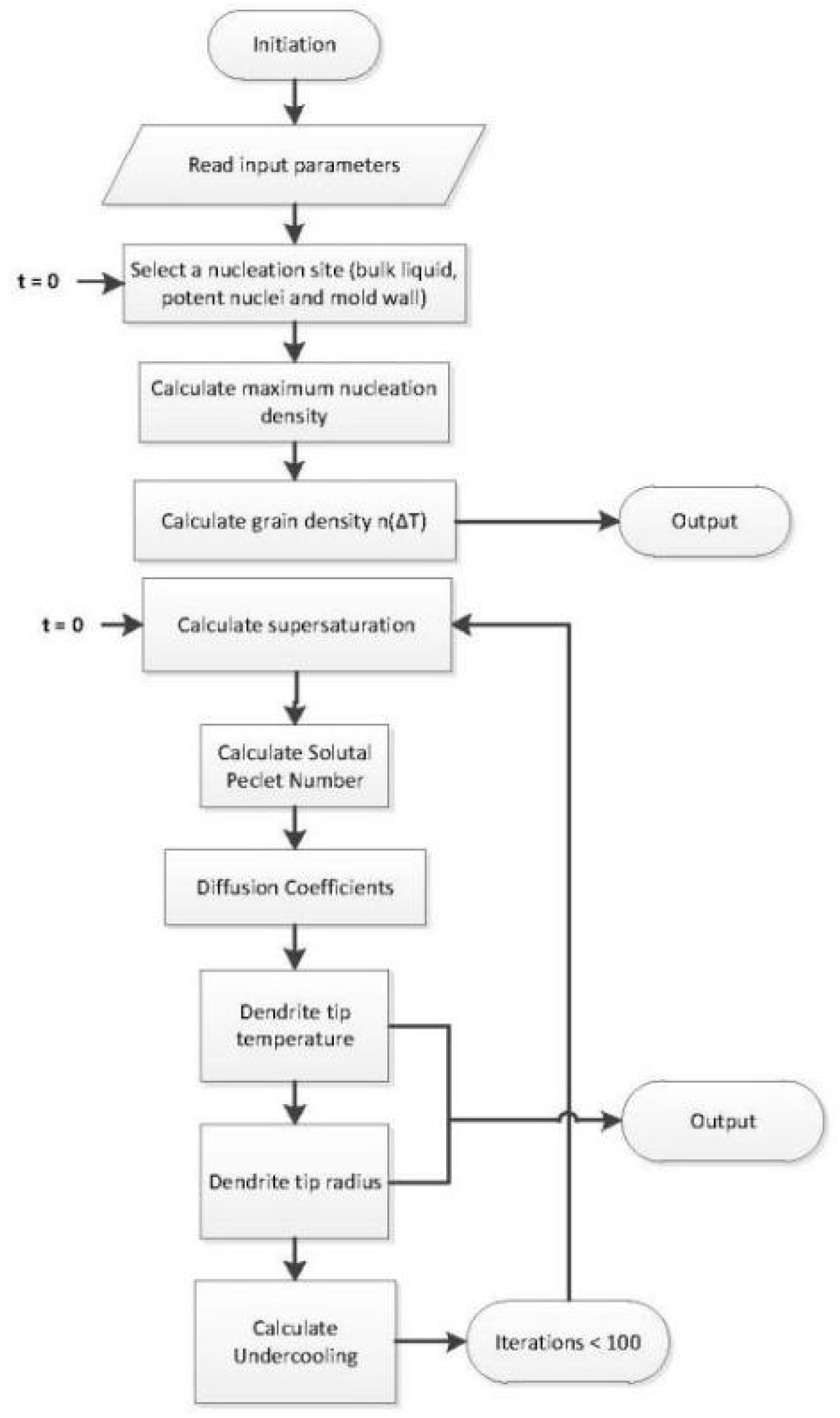

- Quantitative / Deterministic part: Model is significant modification of existing KGT theory of alloy solidification. It consists of nucleation and growth of ductile phase dendrites.

- a.

- Supersaturation of individual elements is aimed to be measured to account for overall behavior of multicomponent system – an approach missing previously.

- b.

- It comprises of effort to remove / reduce error by use of iteration-based approach for model refinement.

- c.

- Programming of model will be done in MATLAB® – not done elsewhere previously.

- d.

- Temperature dependent properties (transient heat and mass transfer conditions) will be used.

- e.

- A unique approach based on segregation coefficient (k) as a function of temperature was adopted (Previously (Kurz, Giovanola, and Trivedi 1986), it was only velocity dependent).

- f.

- Slope of liquids (m) is taken to be concentration (C*) dependent.

- g.

-

Peclet number (Pe) & ξ are not taken as constant like previous studies [Bobadilla, M., J. Lacaze, and G. Lesoult, Journal of Crystal Growth, 1988. 89(4): p. 531-544] in which it is assumed;

- i.

- ξ = 1 (low growth rate) (low Pe)

- ii.

- ξ = 0 (very fast cooling rate – typical Additive Manufacturing conditions)

- iii.

- 2Γ / R = 1 (high velocity AM conditions).

- h.

- New relation for dendrite tip temperature was developed.

- 2.

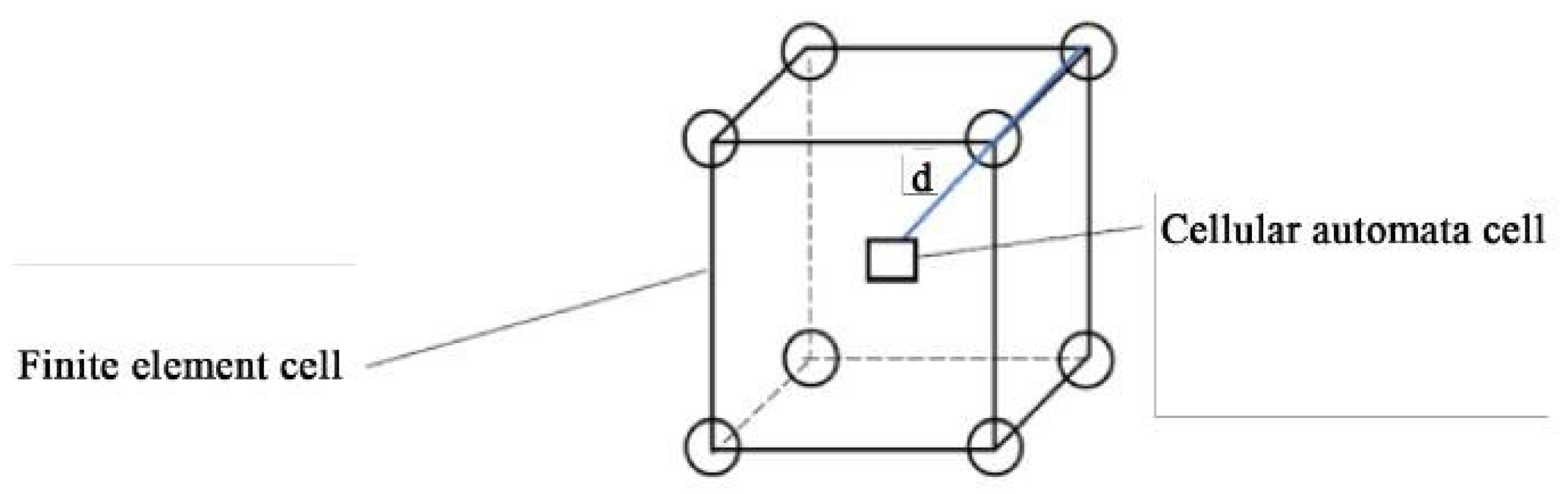

- Probabilistic Part: It consists of making a detailed probabilistic model explaining two dimensional (2D) evolution of dendritic microstructure (e-g. B2 in CuZrAlCo and β-Zr in CuZrAlNi alloys) in a carefully selected simulation domain based on cellular automaton (CA) method (Wei et al. 2007; Gu et al. 2017; Dezfoli et al. 2017).

- a.

-

It accounts for transient thermal parameters (temperature, density, specific heat capacity (Cp), thermal conductivity (k)) from detailed heat transfer model in ABAQUS® (Zhou et al. 2016; Hussein et al. 2013; Dong et al. 2009). CA process adopted is;

- i.

- Determine phases to be evolved in a typical selected alloy system (based on literature).

- ii.

- Determine their volume fraction (Vf) (based on literature).

- iii.

- Select Representative Volume Element (RVE) in a test piece / coupon (in mm).

- iv.

- Select simulation domain (cartesian or point based grid) (e-g. 300 x 300). This will be done in MATLAB®.

- v.

- Select cell shape (square, hexagon, rectangle (based on literature)). This will be done in MATLAB®.

- vi.

-

Select parameters to account for mesh anisotropy. This can be done by any of following;

- 1.

- Selection of modified square cell (decentred square algorithm (DCSA) (Zhang et al. 2013; Chen, Xu, and Liu 2014; Tan and Shin 2015)) (most popular approach).

- 2.

- Refining of square cells e.g. limited angle method (Chen, Xu, and Liu 2015).

- 3.

- Refining of mesh (by decreasing it physical size from micron to nm) (computationally inefficient).

- vii.

- Select neighborhood transition rules based on well-established CA pattern selected in step v above (These rules are well defined in literature e.g. Von Numen rules, Moore rules (popular, accurate but computationally expensive) (Wei et al. 2011), Solid / Liquid Interface generation and energy at tip (Sharifi and Larouche 2014; Hamid and Daniel 2015)).

- viii.

- Scan whole simulation domain for n number of cells and assign a random number r (0 < r < 1) to each cell.

- ix.

- Select physical appearance of next cells based on neighborhood transition rules of step vii above.

5. Research Significance

6. Enhancement of Career Development

7. Relationship to The Ohio State University

8. Broader Impact of Proposed Activities

References

- Arul Kumar, M.; Kanjarla, A.K.; Niezgoda, S.R.; Lebensohn, R.A.; Tomé, C.N.. Numerical study of the stress state of a deformation twin in magnesium. Acta Materialia 2015, 84, 349–358. [CrossRef]

- Baumgartner, Jens, Archan Dey, Paul H. H. Bomans, Cécile Le Coadou, Peter Fratzl, Nico A. J. M. Sommerdijk, and Damien Faivre. Nucleation and growth of magnetite from solution. Nat Mater 2013, 12, 310–314. [CrossRef]

- Beeley, P. 2001. Foundry Technology (Elsevier Science).

- Browne, David J., Zsolt Kovacs, and Wajira U. Mirihanage. Comparison of nucleation and growth mechanisms in alloy solidification to those in metallic glass crystallisation — relevance to modeling. Transactions of the Indian Institute of Metals 2009, 62, 409–412. [CrossRef]

- Buchbinder, Damien, Wilhelm Meiners, Norbert Pirch, Konrad Wissenbach, and Johannes Schrage. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. Journal of Laser Applications 2014, 26, 012004. [CrossRef]

- Campbell, J. 2003. Castings (Elsevier Science).

- 2004. Castings Practice: The Ten Rules of Castings (Elsevier Science).

- Chalmers, B. 1964. Principles of solidification (Wiley).

- Charbon, C., and M. Rappaz. 3D probabilistic modelling of equiaxed eutectic solidification. Modelling and Simulation in Materials Science and Engineering 1993, 1, 455. [CrossRef]

- Chen, Qiang, Gildas Guillemot, Charles-André Gandin, and Michel Bellet. 2016. "Finite element modeling of deposition of ceramic material during SLM additive manufacturing." In MATEC Web of Conferences, 08001. EDP Sciences.

- Chen, Rui, Qingyan Xu, and Baicheng Liu. A Modified Cellular Automaton Model for the Quantitative Prediction of Equiaxed and Columnar Dendritic Growth. Journal of Materials Science & Technology 2014, 30, 1311–1320.

- Cellular automaton simulation of three-dimensional dendrite growth in Al–7Si–Mg ternary aluminum alloys. Computational Materials Science 2015, 105, 90–100. [CrossRef]

- Cheng, Jia-Lin, Guang Chen, Chain-Tsuan Liu, and Yi Li. Innovative approach to the design of low-cost Zr-based BMG composites with good glass formation. Scientific Reports 2013, 3, 2097. [CrossRef]

- Conner, R. D., R. B. Dandliker, and W. L. Johnson. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Materialia 1998, 46, 6089–6102. [CrossRef]

- Coquerel, Gerard. Crystallization of molecular systems from solution: phase diagrams, supersaturation and other basic concepts. Chemical Society Reviews 2014, 43, 2286–2300.

- Cordero, Zachary C., Ralph B. Dinwiddie, David Immel, and Ryan R. Dehoff. Nucleation and growth of chimney pores during electron-beam additive manufacturing. Journal of Materials Science 2017, 52, 3429–3435. [CrossRef]

- Cunningham, Ross, Andrea Nicolas, John Madsen, Eric Fodran, Elias Anagnostou, Michael D. Sangid, and Anthony D. Rollett. Analyzing the effects of powder and post-processing on porosity and properties of electron beam melted Ti-6Al-4V. Materials Research Letters 2017, 1-10.

- Dantzig, J.A., and M. Rappaz. 2016. Solidification: 2nd Edition - Revised & Expanded (Taylor & Francis Group).

- Dezfoli, Amir Reza Ansari, Weng-Sing Hwang, Wei-Chin Huang, and Tsung-Wen Tsai. Determination and controlling of grain structure of metals after laser incidence: Theoretical approach. 2017, 7, 41527.

- Dmowski, W., Y. Yokoyama, A. Chuang, Y. Ren, M. Umemoto, K. Tsuchiya, A. Inoue, and T. Egami. Structural rejuvenation in a bulk metallic glass induced by severe plastic deformation. Acta Materialia 2010, 58, 429–438. [CrossRef]

- Dong, L., A. Makradi, S. Ahzi, and Y. Remond. Three-dimensional transient finite element analysis of the selective laser sintering process. Journal of Materials Processing Technology 2009, 209, 700–706. [CrossRef]

- Dunbar, Alexander Jay. 2016. Analysis of the laser powder bed fusion additive manufacturing process through experimental measurement and finite element modeling (The Pennsylvania State University).

- Erdemir, Deniz, Alfred Y. Lee, and Allan S. Myerson. Nucleation of Crystals from Solution: Classical and Two-Step Models. Accounts of Chemical Research 2009, 42, 621–629. [CrossRef]

- Ferry, M., K. J. Laws, C. White, D. M. Miskovic, K. F. Shamlaye, W. Xu, and O. Biletska. Recent developments in ductile bulk metallic glass composites. MRS Communications 2013, 3, 1–12. [CrossRef]

- Flemings, M.C. 1974. Solidification Processing (McGraw-Hill).

- Francois, M. M., A. Sun, W. E. King, N. J. Henson, D. Tourret, C. A. Bronkhorst, N. N. Carlson, C. K. Newman, T. Haut, J. Bakosi, J. W. Gibbs, V. Livescu, S. A. Vander Wiel, A. J. Clarke, M. W. Schraad, T. Blacker, H. Lim, T. Rodgers, S. Owen, F. Abdeljawad, J. Madison, A. T. Anderson, J. L. Fattebert, R. M. Ferencz, N. E. Hodge, S. A. Khairallah, and O. Walton. Modeling of additive manufacturing processes for metals: Challenges and opportunities. Current Opinion in Solid State and Materials Science 2017.

- Frank, Xavier, Nicolas Dietrich, Jing Wu, Renaud Barraud, and Huai Z. Li. Bubble nucleation and growth in fluids. Chemical Engineering Science 2007, 62, 7090–7097. [CrossRef]

- 'Front Matter A2 - CHRISTIAN, J.W.' in. 2002. The Theory of Transformations in Metals and Alloys (Pergamon: Oxford).

- Fullwood, D. T., S. R. Kalidindi, S. R. Niezgoda, A. Fast, and N. Hampson. Gradient-based microstructure reconstructions from distributions using fast Fourier transforms. Materials Science and Engineering A 2008, 494, 68–72. [CrossRef]

- Fullwood, David T., Stephen R. Niezgoda, Brent L. Adams, and Surya R. Kalidindi. Microstructure sensitive design for performance optimization. Progress in Materials Science 2010, 55, 477–562. [CrossRef]

- Fullwood, David T., Stephen R. Niezgoda, and Surya R. Kalidindi. Microstructure reconstructions from 2-point statistics using phase-recovery algorithms. Acta Materialia 2008, 56, 942–948. [CrossRef]

- Ganeriwala, Rishi, and Tarek I. Zohdi. Multiphysics Modeling and Simulation of Selective Laser Sintering Manufacturing Processes. Procedia CIRP 2014, 14, 299–304. [CrossRef]

- Gránásy, L., T. Pusztai, T. Börzsönyi, G. Tóth, G. Tegze, J. A. Warren, and J. F. Douglas. Phase field theory of crystal nucleation and polycrystalline growth: A review. Journal of Materials Research 2006, 21, 309–319. [CrossRef]

- Gránásy, László, László Rátkai, Attila Szállás, Bálint Korbuly, Gyula I. Tóth, László Környei, and Tamás Pusztai. Phase-Field Modeling of Polycrystalline Solidification: From Needle Crystals to Spherulites—A Review. Metallurgical and Materials Transactions A 2014, 45, 1694–1719. [CrossRef]

- Greer, A. L., Y. Q. Cheng, and E. Ma. Shear bands in metallic glasses. Materials Science and Engineering: R: Reports 2013, 74, 71–132. [CrossRef]

- Gu, C., Y. Wei, X. Zhan, and Y. Li. A three-dimensional cellular automaton model of dendrite growth with stochastic orientation during the solidification in the molten pool of binary alloy. Science and Technology of Welding and Joining 2017, 22, 47–58. [CrossRef]

- Gusarov, A. V., and J. P. Kruth. Modelling of radiation transfer in metallic powders at laser treatment. International Journal of Heat and Mass Transfer 2005, 48, 3423–3434. [CrossRef]

- Hamid, Sharifi, and Larouche Daniel. An automatic granular structure generation and finite element analysis of heterogeneous semi-solid materials. Modelling and Simulation in Materials Science and Engineering 2015, 23, 065013. [CrossRef]

- Hammond, Vincent H., Marlene D. Houtz, and James M. O’Reilly. Structural relaxation in a bulk metallic glass. Journal of Non-Crystalline Solids 2003, 325, 179–186. [CrossRef]

- Hays, C. C., C. P. Kim, and W. L. Johnson. Microstructure Controlled Shear Band Pattern Formation and Enhanced Plasticity of Bulk Metallic Glasses Containing in situ Formed Ductile Phase Dendrite Dispersions. Physical Review Letters 2000, 84, 2901–2904. [CrossRef]

- Ho, C. Y., and H. H. Li. Computerized comprehensive numerical data system on the thermophysical and other properties of materials established at CINDAS/Purdue University. International Journal of Thermophysics 1986, 7, 949–962. [CrossRef]

- Ho, CY, and HH Li. Numerical databases on materials property data at CINDAS/Purdue University. Journal of chemical information and computer sciences 1993, 33, 36–45. [CrossRef]

- Hofmann, Douglas C. Bulk Metallic Glasses and Their Composites: A Brief History of Diverging Fields. Journal of Materials 2013, 2013, 8.

- Hofmann, Douglas C., Jin-Yoo Suh, Aaron Wiest, Gang Duan, Mary-Laura Lind, Marios D. Demetriou, and William L. Johnson. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [CrossRef]

- Hofmann, Douglas C., Jin-Yoo Suh, Aaron Wiest, Mary-Laura Lind, Marios D. Demetriou, and William L. Johnson. Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility. Proceedings of the National Academy of Sciences 2008, 105, 20136–20140. [CrossRef]

- Hussein, Ahmed, Liang Hao, Chunze Yan, and Richard Everson. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Materials & Design (1980-2015) 2013, 52, 638–647.

- Jabbareh, Mohammad Amin, and Hamid Assadi. Modeling of Grain Structure and Heat-Affected Zone in Laser Surface Melting Process. Metallurgical and Materials Transactions B 2013, 44, 1041–1048. [CrossRef]

- Jiang, Yunpeng, Longgang Sun, Qingqing Wu, and Kun Qiu. Enhanced tensile ductility of metallic glass matrix composites with novel microstructure. Journal of Non-Crystalline Solids 2017, 459, 26–31. [CrossRef]

- Jones, S. F., G. M. Evans, and K. P. Galvin. Bubble nucleation from gas cavities — a review. Advances in Colloid and Interface Science 1999, 80, 27–50. [CrossRef]

- Kalikmanov, V. 2012. Nucleation Theory (Springer Netherlands).

- Karthika, S., T. K. Radhakrishnan, and P. Kalaichelvi. A Review of Classical and Nonclassical Nucleation Theories. Crystal Growth & Design 2016, 16, 6663–6681.

- Katz, J. L. 1992. "Homogeneous nucleation theory and experiment: A survey." In Pure and Applied Chemistry, 1661.

- Ketov, S. V., Y. H. Sun, S. Nachum, Z. Lu, A. Checchi, A. R. Beraldin, H. Y. Bai, W. H. Wang, D. V. Louzguine-Luzgin, M. A. Carpenter, and A. L. Greer. Rejuvenation of metallic glasses by non-affine thermal strain. Nature 2015, 524, 200–203. [CrossRef]

- Khairallah, Saad A., Andrew T. Anderson, Alexander Rubenchik, and Wayne E. King. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Materialia 2016, 108, 36–45. [CrossRef]

- Khairallah, Saad A., and Andy Anderson. Mesoscopic simulation model of selective laser melting of stainless steel powder. Journal of Materials Processing Technology 2014, 214, 2627–2636. [CrossRef]

- Kim, Yu Chan, Do Hyang Kim, and Jae-Chul Lee. Formation of Ductile Cu-Based Bulk Metallic Glass Matrix Composite by Ta Addition. MATERIALS TRANSACTIONS 2003, 44, 2224–2227. [CrossRef]

- King, W., A. T. Anderson, R. M. Ferencz, N. E. Hodge, C. Kamath, and S. A. Khairallah. Overview of modelling and simulation of metal powder bed fusion process at Lawrence Livermore National Laboratory. Materials Science and Technology 2015, 31, 957–968. [CrossRef]

- King, W. E., A. T. Anderson, R. M. Ferencz, N. E. Hodge, C. Kamath, S. A. Khairallah, and A. M. Rubenchik. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Applied Physics Reviews 2015, 2, 041304. [CrossRef]

- King, Wayne E., Holly D. Barth, Victor M. Castillo, Gilbert F. Gallegos, John W. Gibbs, Douglas E. Hahn, Chandrika Kamath, and Alexander M. Rubenchik. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. Journal of Materials Processing Technology 2014, 214, 2915–2925. [CrossRef]

- Kurz, W., and D.J. Fisher. 1986. Fundamentals of solidification (Trans Tech Publications).

- Kurz, W., B. Giovanola, and R. Trivedi. Theory of microstructural development during rapid solidification. Acta Metallurgica 1986, 34, 823–830. [CrossRef]

- Launey, Maximilien E., Douglas C. Hofmann, William L. Johnson, and Robert O. Ritchie. Solution to the problem of the poor cyclic fatigue resistance of bulk metallic glasses. Proceedings of the National Academy of Sciences 2009, 106, 4986–4991. [CrossRef]

- Laurentiu, Nastac, and M. Stefanescu Doru. Stochastic modelling of microstructure formation in solidification processes. Modelling and Simulation in Materials Science and Engineering 1997, 5, 391. [CrossRef]

- Lavery, Nicholas P, Stephen GR Brown, Johann Sienz, John Cherry, and Fawzi Belblidia. A review of Computational Modelling of Additive Layer Manufacturing–multi-scale and multi-physics. Sustainable Design and Manufacturing 2014, 651–673.

- Lee, Kyong-Yee, and Chun P Hong. Stochastic modeling of solidification grain structures of Al-Cu crystalline ribbons in planar flow casting. ISIJ international 1997, 37, 38–46.

- 66. Lee, YS, and W Zhang. 2015. "Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive manufacturing." In International Solid Free Form Fabrication Symposium, Austin, 1154–1165.

- Li, Gong, Liling Sun, Jun Zhang, Riping Liu, Qin Jing, Wenkui Wang, Yunpeng Gao, and Dan Chen. Structural relaxation of Zr41Ti14Cu12.5Ni10Be22.5 bulk metallic glass under high pressure. Science in China Series G: Physics, Mechanics and Astronomy 2003, 46, 468–473. [CrossRef]

- Li, X. P., M. P. Roberts, S. O'Keeffe, and T. B. Sercombe. Selective laser melting of Zr-based bulk metallic glasses: Processing, microstructure and mechanical properties. Materials & Design 2016, 112, 217–226.

- Liou, Frank, Joseph Newkirk, Zhiqiang Fan, Todd Sparks, Xueyang Chen, Kenneth Fletcher, Jingwei Zhang, Yunlu Zhang, Kannan Suresh Kumar, and Sreekar Karnati. 2015. 'Multiscale and Multiphysics Modeling of Additive Manufacturing of Advanced Materials'.

- Lipton, J, ME Glicksman, and W Kurz. Dendritic growth into undercooled alloy metals. Materials Science and Engineering 1984, 65, 57–63. [CrossRef]

- Liu, Shibo, Afia Kouadri-Henni, and Adinel Gavrus. 2016. "Modeling grain orientation of DP600 steel by Nd: YAG laser." In MATEC Web of Conferences, 02010. EDP Sciences.

- Manvatkar, V., A. De, and T. DebRoy. Heat transfer and material flow during laser assisted multi-layer additive manufacturing. Journal of Applied Physics 2014, 116, 124905. [CrossRef]

- Markl, Matthias, and Carolin Körner. Multiscale Modeling of Powder Bed–Based Additive Manufacturing. Annual Review of Materials Research 2016, 46, 93–123. [CrossRef]

- Martin, Scot T. Phase Transitions of Aqueous Atmospheric Particles. Chemical Reviews 2000, 100, 3403–3454. [CrossRef]

- Musaddique Ali Rafique, Muhammad. 2018. Simulation of Solidification Parameters during Zr Based Bulk Metallic Glass Matrix Composite’s (BMGMCs) Additive Manufacturing.

- Nastac, L. Numerical modeling of solidification morphologies and segregation patterns in cast dendritic alloys. Acta Materialia 1999, 47, 4253–4262. [CrossRef]

- Neilson, G. F., and M. C. Weinberg. A test of classical nucleation theory: crystal nucleation of lithium disilicate glass. Journal of Non-Crystalline Solids 1979, 34, 137–147. [CrossRef]

- Niezgoda, Stephen R., Anand K. Kanjarla, Irene J. Beyerlein, and Carlos N. Tomé. Stochastic modeling of twin nucleation in polycrystals: An application in hexagonal close-packed metals. International Journal of Plasticity 2014, 56, 119–138. [CrossRef]

- Niezgoda, Stephen R., David M. Turner, David T. Fullwood, and Surya R. Kalidindi. Optimized structure based representative volume element sets reflecting the ensemble-averaged 2-point statistics. Acta Materialia 2010, 58, 4432–4445. [CrossRef]

- Niezgoda, Stephen R., Yuksel C. Yabansu, and Surya R. Kalidindi. Understanding and visualizing microstructure and microstructure variance as a stochastic process. Acta Materialia 2011, 59, 6387–6400. [CrossRef]

- Palma, J.M.L.M., P. Amestoy, M. Daydé, M. Mattoso, and J.C. Lopes. 2008. High Performance Computing for Computational Science - VECPAR 2008: 8th International Conference, Toulouse, France, June 24-27, 2008. Revised Selected Papers (Springer).

- Panwisawas, C., C. L. Qiu, Y. Sovani, J. W. Brooks, M. M. Attallah, and H. C. Basoalto. On the role of thermal fluid dynamics into the evolution of porosity during selective laser melting. Scripta Materialia 2015, 105, 14–17. [CrossRef]

- Papazafeiropoulos, George, Miguel Muñiz-Calvente, and Emilio Martínez-Pañeda. Abaqus2Matlab: suitable tool for finite element post-processing. Advances in Engineering Software 2017, 105, 9–16. Pehlke, Robert Donald, A Jeyarajan, and H Wada. 1982. 'Summary of thermal properties for casting alloys and mold materials', NASA STI/Recon Technical Report N, 83. [CrossRef]

- Pengpeng, Yuan, and Gu Dongdong. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: simulation and experiments. Journal of Physics D: Applied Physics 2015, 48, 035303. [CrossRef]

- Pfeif, E. A., and K. Kroenlein. Perspective: Data infrastructure for high throughput materials discovery. APL Materials 2016, 4, 053203. [CrossRef]

- Pruppacher, Hans R., James D. Klett, and Pao K. Wang. Microphysics of Clouds and Precipitation. Aerosol Science and Technology 1998, 28, 381–382. [CrossRef]

- Qiu, Chunlei, Chinnapat Panwisawas, Mark Ward, Hector C. Basoalto, Jeffery W. Brooks, and Moataz M. Attallah. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Materialia 2015, 96, 72–79. [CrossRef]

- Rafique, M. M. A., and J. Iqbal. Modeling and simulation of heat transfer phenomena during investment casting. International Journal of Heat and Mass Transfer 2009, 52, 2132–2139. [CrossRef]

- Rafique, Muhammad Musaddique Ali. 2015. 'Modeling and Simulation of Heat Transfer Phenomena'.

- ———. 2018a. 'Effect of Inoculation on Phase Formation and Indentation Hardness Behaviour of Zr<SUB>47.5</SUB>Cu<SUB>45.5</SUB>Al<SUB>5</SUB>Co<SUB>2</SUB> and Zr<SUB>65</SUB>Cu<SUB>15</SUB>Al<SUB>10</SUB>Ni<S UB>10</SUB> Bulk Metallic Glass Matrix Composites', Engineering, Vol.10No.08: 30.

- ———. 2018b. 'Modelling and Simulation of Solidification Phenomena during Additive Manufacturing of Bulk Metallic Glass Matrix Composites (BMGMC)¡ªA Brief Review and Introduction of Technique', Journal of Encapsulation and Adsorption Sciences, Vol.08No.02: 50.

- ———. 2018c. "Probabilistic Modeling and Simulation of Microstructural Evolution in Zr Based Bulk Metallic Glass Matrix Composites During Solidification." In, 305–309. Cham: Springer International Publishing.

- ———. 2018d. 'Probabilistic Modelling of Microstructural Evolution in Zr Based Bulk Metallic Glass Matrix Composites during Solidification in Additive Manufacturing', Engineering, Vol.10No.04: 12.

- Rafique, Muhammad Musaddique Ali, Dong Qiu, and Mark Easton. Modeling and simulation of microstructural evolution in Zr based Bulk Metallic Glass Matrix Composites during solidification. MRS Advances 2017, 2, 3591–3606. [CrossRef]

- and simulation of microstructural evolution in Zr based Bulk Metallic Glass Matrix Composites during solidification. MRS Advances 2017, 1-16.

- Rappaz, M., and Ch A. Gandin. Probabilistic modelling of microstructure formation in solidification processes. Acta Metallurgica et Materialia 1993, 41, 345–360. [CrossRef]

- Reuther, K., and M. Rettenmayr. Perspectives for cellular automata for the simulation of dendritic solidification – A review. Computational Materials Science 2014, 95, 213–220. [CrossRef]

- Roehling, Tien T., Sheldon S. Q. Wu, Saad A. Khairallah, John D. Roehling, S. Stefan Soezeri, Michael F. Crumb, and Manyalibo J. Matthews. Modulating laser intensity profile ellipticity for microstructural control during metal additive manufacturing. Acta Materialia 2017, 128, 197–206. [CrossRef]

- Sagui, Celeste, and Martin Grant. Theory of nucleation and growth during phase separation. Physical Review E 1999, 59, 4175. [CrossRef]

- Sarac, B. 2015. Microstructure-Property Optimization in Metallic Glasses (Springer International Publishing).

- Schoinochoritis, Babis, Dimitrios Chantzis, and Konstantinos Salonitis. Simulation of metallic powder bed additive manufacturing processes with the finite element method: A critical review. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 2017, 231, 96–117. [CrossRef]

- Sharifi, Hamid, and Daniel Larouche. A Numerical Method for Microstructure Generation of a Binary Aluminum Alloy and Study of Its Mechanical Properties Using the Finite Element Method. Metallurgical and Materials Transactions A 2014, 45, 5866–5875. [CrossRef]

- Shiffman, D. 2012. The Nature of Code (D. Shiffman).

- Siegrist, Marco E. 2007. 'Bulk metallic glass composites'.

- Siegrist, Marco E., Esther D. Amstad, and Jörg F. Löffler. Tribological properties of graphite- and ZrC-reinforced bulk metallic glass composites. Intermetallics 2007, 15, 1228–1236. [CrossRef]

- Siegrist, Marco E., and Jörg F. Löffler. Bulk metallic glass–graphite composites. Scripta Materialia 2007, 56, 1079–1082. [CrossRef]

- Siegrist, Marco E., David P. Steinlin, and Jörg F. Löffler. Processing of diamond-reinforced bulk metallic glass composites. Materials Science and Engineering: A 2007, 447, 298–302. [CrossRef]

- Smith, Jacob, Wei Xiong, Wentao Yan, Stephen Lin, Puikei Cheng, Orion L. Kafka, Gregory J. Wagner, Jian Cao, and Wing Kam Liu. Linking process, structure, property, and performance for metal-based additive manufacturing: computational approaches with experimental support. Computational Mechanics 2016, 57, 583–610. [CrossRef]

- Sun, Hongqing, and Katharine M. Flores. Spherulitic crystallization behavior of a metallic glass at high heating rates. Intermetallics 2011, 19, 1538–1545. [CrossRef]

- Spherulitic crystallization mechanism of a Zr-based bulk metallic glass during laser processing. Intermetallics 2013, 43, 53–59. [CrossRef]

- Tan, Wenda, and Yung C. Shin. Multi-scale modeling of solidification and microstructure development in laser keyhole welding process for austenitic stainless steel. Computational Materials Science 2015, 98, 446–458. [CrossRef]

- Thanh, Nguyen T. K., N. Maclean, and S. Mahiddine. Mechanisms of Nucleation and Growth of Nanoparticles in Solution. Chemical Reviews 2014, 114, 7610–7630. [CrossRef]

- Thijs, Lore, Frederik Verhaeghe, Tom Craeghs, Jan Van Humbeeck, and Jean-Pierre Kruth. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Materialia 2010, 58, 3303–3312. [CrossRef]

- Valencia, Juan J, and PN Quested. 2001. 'Thermophysical properties', Modeling for Casting and Solidification Processing: 189.

- Vehkamäki, H. 2006. Classical Nucleation Theory in Multicomponent Systems (Springer Berlin Heidelberg). Venables, J. A., G. D. T. Spiller, and M. Hanbucken. Nucleation and growth of thin films. Reports on Progress in Physics 1984, 47, 399.

- Wei, Lei, Xin Lin, Meng Wang, and Weidong Huang. A cellular automaton model for the solidification of a pure substance. Applied Physics A 2011, 103, 123–133. [CrossRef]

- Wei, Y. H., X. H. Zhan, Z. B. Dong, and L. Yu. Numerical simulation of columnar dendritic grain growth during weld solidification process. Science and Technology of Welding and Joining 2007, 12, 138–146. [CrossRef]

- Weissmayer, Lisa, Tim Schubert, Timo Bernthaler, and Gerhard Schneider. Applications of Microscopy in Additive Manufacturing. Optik & Photonik 2015, 10, 44–46.

- Wilthan, Boris, Erik A. Pfeif, Vladimir V. Diky, Robert D. Chirico, Ursula R. Kattner, and Kenneth Kroenlein. Data resources for thermophysical properties of metals and alloys, Part 1: Structured data capture from the archival literature. Calphad 2017, 56, 126–138. [CrossRef]

- Wu, Y., H. Wang, X. J. Liu, X. H. Chen, X. D. Hui, Y. Zhang, and Z. P. Lu. Designing Bulk Metallic Glass Composites with Enhanced Formability and Plasticity. Journal of Materials Science & Technology 2014, 30, 566–575.

- Wu, Y., H. Wang, H. H. Wu, Z. Y. Zhang, X. D. Hui, G. L. Chen, D. Ma, X. L. Wang, and Z. P. Lu. Formation of Cu–Zr–Al bulk metallic glass composites with improved tensile properties. Acta Materialia 2011, 59, 2928–2936. [CrossRef]

- Yap, C. Y., C. K. Chua, Z. L. Dong, Z. H. Liu, D. Q. Zhang, L. E. Loh, and S. L. Sing. Review of selective laser melting: Materials and applications. Applied Physics Reviews 2015, 2, 041101. [CrossRef]

- Yuan, Mengqi. 2013. 'Additive manufacturing of laser sintered polyamide optically translucent parts'.

- Zhang, Jingwei, Frank Liou, William Seufzer, Joseph Newkirk, Zhiqiang Fan, Heng Liu, and Todd E Sparks. . "Probabilistic simulation of solidification microstructure evolution during laser-based metal deposition." In Proc. Int. Solid Freeform Fabr. Symp. 2013, 24, 739–748.

- Zhang, M., Y. M. Wang, F. X. Li, S. Q. Jiang, M. Z. Li, and L. Liu. Mechanical Relaxation-to-Rejuvenation Transition in a Zr-based Bulk Metallic Glass. Scientific Reports 2017, 7, 625. [CrossRef]

- Zhou, Xiangman, Haiou Zhang, Guilan Wang, Xingwang Bai, Youheng Fu, and Jingyi Zhao. Simulation of microstructure evolution during hybrid deposition and micro-rolling process. Journal of Materials Science 2016, 51, 6735–6749. [CrossRef]

- Zohdi, T. I. Additive particle deposition and selective laser processing-a computational manufacturing framework. Computational Mechanics 2014, 54, 171–191. [CrossRef]

- Zong, Hongxiang, Turab Lookman, Xiangdong Ding, Cristiano Nisoli, Don Brown, Stephen R. Niezgoda, and Sun Jun. The kinetics of the ω to α phase transformation in Zr, Ti: Analysis of data from shock-recovered samples and atomistic simulations. Acta Materialia 2014, 77, 191–199. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).