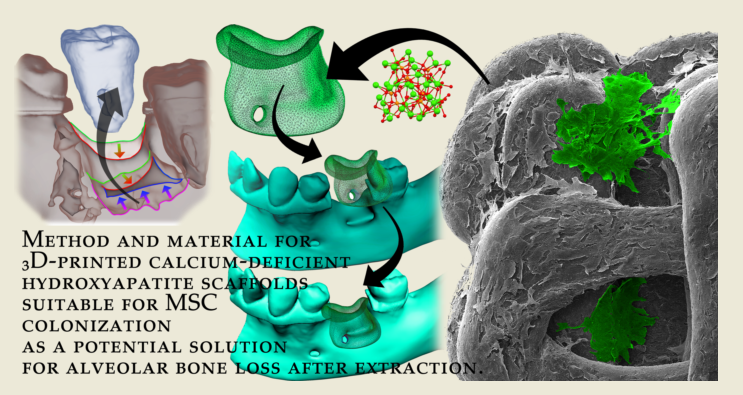

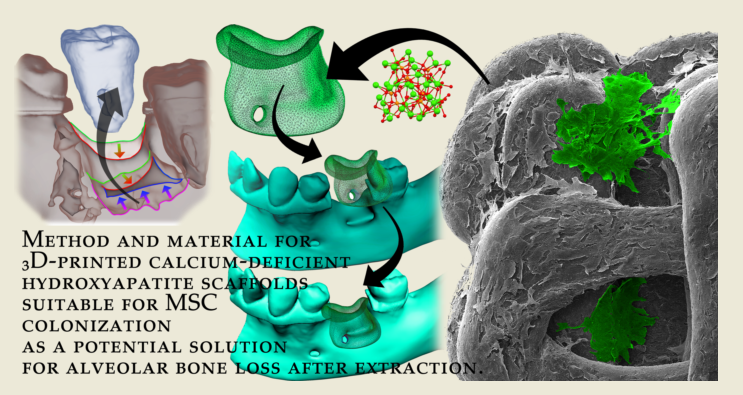

This paper presents a proof-of-concept study on the biocolonization of 3D-printed hydroxyapatite scaffolds with mesenchymal stem cells (MSCs). Three-dimensional (3D) printed biomimetic bone structure made of Calcium Deficient HydroxyApatite (CDHA) intended as future bone graft was made from newly developed composite material for FDM printing. The biopolymer polyvinyl alcohol serves in this material as a thermoplastic binder for 3D molding of the printed object with a passive function and is completely removed during sintering. The study presents the material, the process of fused deposition modeling (FDM) of CDHA scaffolds and its post-processing at three temperatures (1200, 1300, 1400 °C), as well it evaluates the cytotoxicity and biocompatibility of scaffolds with MTT and LDH release assays after 14 days. The study also includes a morphological evaluation of the cellular colonization with scanning electron microscopy (SEM) in two different filament orientations (rectilinear and gyroid). The results of the MTT assay showed that the tested material was not toxic, and cells were preserved in both orientations, with most cells present on the material fired at 1300°C. Results of the LDH release assay showed a slight increase in LDH leakage from all samples. Visual evaluation of SEM confirmed the ideal post-processing temperature of the 3D-printed FDM framework for samples fired at 1300°C and 1400°C, with a porosity of 0.3 mm between filaments. In conclusion, the presented fabrication and colonization of CDHA scaffolds have great potential to be used in the tissue engineering of bones.