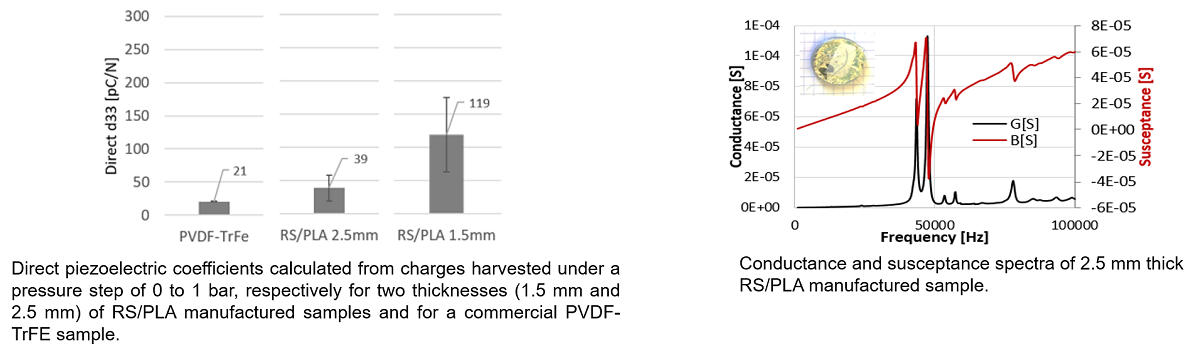

One century ago, ferroelectricity and then piezoelectricity were discovered using Rochelle salt crystals. Today, modern societies are invited to switch towards a resilient and circular economy model. In this context, this work proposes a method to manufacture piezoelectric devices made from agro-resources such as tartric acid and polylactide significantly reducing the energy budget without requiring any sophisticated equipement. These piezoelectric devices are manufactured by liquid phase epitaxy grown Rochelle salt (RS) crystals into a 3D printed poly(Lactic acid) (PLA) matrix being the artificial squared meshes which mimic the natural wood anatomy. This composite material can easily be produced in any fablab with renewable materials and at low processsing temperatures, reducing then the total energy consumed. Manufactured biodegradable samples are fully recyclable and have good piezoelectric properties without any pooling step. The measured piezoelectric coefficients of manufactured samples are higher than many piezoelectric polymers such as PVDF-TrFE.