1. Introduction

With the rapid growth of e-commerce and the widespread adoption of smart logistics systems, transportation logistics has become increasingly vital to national economic operations. As a key task in logistics management, material flow prediction significantly influences decisions such as warehouse scheduling, route optimization, and workforce deployment. However, affected by complex variables like urban traffic, weather changes, and holidays, logistics data exhibit strong temporal dynamics and nonlinearity, posing challenges for traditional prediction methods.

Conventional forecasting approaches, based on statistical or rule-based models, often struggle with multivariate and high-dimensional logistics data, lacking sufficient accuracy and adaptability. In contrast, deep learning has emerged as a powerful alternative, capable of autonomously learning patterns and dependencies from large-scale sequential data. Yet, effectively capturing both short-term trends and long-term dependencies remains difficult.

To address these challenges, this paper proposes a hybrid TCN-GRU (Temporal Convolutional Network–Gated Recurrent Unit) model. TCN efficiently captures local temporal features through convolutional operations and allows for parallel training, while GRU excels in modeling long-term dependencies and addressing gradient vanishing problems. The fusion of these architectures leverages their complementary strengths, enhancing both temporal feature extraction and model stability.

The model is trained and evaluated using the Amazon Delivery Dataset, which includes 43,632 records with rich details on orders, routes, traffic, and weather conditions. The case study focuses on Chennai, India. Experimental results—measured via Mean Absolute Error (MAE) and loss metrics—show that the TCN-GRU model outperforms traditional time-series forecasting methods in both accuracy and robustness. This study demonstrates the model's potential in improving predictive performance for real-world logistics applications and provides a scalable solution for smart logistics systems.

2. Literature Review

With the rapid development of intelligent logistics, urban delivery, and e-commerce supply chains, material flow forecasting plays a central role in logistics system management. High-precision flow prediction can not only effectively improve delivery efficiency and reduce transportation costs, but also provide scientific support for warehouse scheduling, route optimization, and resource allocation. Under the complex influence of changing traffic conditions, weather factors, and order fluctuations, material flow exhibits strong temporal characteristics and multivariate interaction patterns. Traditional forecasting methods are increasingly showing performance bottlenecks when dealing with such problems. In this section, we will review the latest technologies in the field of material flow forecasting.

Li H et al. developed a logistics network cargo volume prediction and adjustment strategy. They used LSTM neural networks to predict route cargo volumes and created models for adjusting the logistics network when a site is deactivated [

1]. Alqatawna A et al. combined time - series forecasting techniques with machine learning to predict logistics companies’ staffing needs and order volume. They used SARIMAX, ARIMA, AR, and LSTM models on a real dataset from an international shipping company, incorporating features like holidays and sales seasons. The SARIMAX model showed the best performance in predicting order trends for the UAE, KSA, and KWT, proving its effectiveness in logistics forecasting scenarios [

2].

Li A et al [

3]. reviewed the development of logistics technology and emphasized the role of smart logistics algorithms in improving efficiency. They proposed DRL4Route, a deep reinforcement learning framework for path optimization, addressing the inconsistency between training and testing objectives. These findings support the advancement of intelligent logistics.

Luo S et al [

4]. established an ARIMA-LSTM hybrid model to predict logistics cargo volumes, aiming to enhance the management efficiency of sorting centers. They used historical data to forecast daily and hourly cargo volumes for the next 30 days. The ARIMA model was applied for short-term forecasting, while the LSTM model handled complex nonlinear relationships and long-term dependencies. The model effectively predicted cargo volumes, providing reliable guidance for resource allocation and personnel deployment, and improving the overall management efficiency of sorting centers.

Talupula A et al [

5]. explored machine learning for outbound logistics demand forecasting. They experimented with CNN, ANN, and LSTM models on a dataset from a leading manufacturer. CNN outperformed LSTM and matched ANN in forecasting accuracy, demonstrating the efficacy of CNN in this domain. However, further testing is needed to compare different deep - learning architectures in outbound forecasting.

3. Data Introduction

3.1. Data Source

The dataset employed in this study is the Amazon Delivery Dataset, comprising 43,632 delivery records collected from multiple cities through Amazon’s logistics scheduling system. This dataset offers a detailed and realistic representation of last-mile logistics operations, making it highly suitable for material flow forecasting research. Each record includes key fields such as Order_ID, Order_Date, Traffic (categorized as “low,” “medium,” or “jam”), Weather, Delivery_Agent_ID, City, Expected_Delivery_Time, Actual_Delivery_Time, and Customer_Rating.

The dataset's strong temporal characteristics and multivariate structure enable the construction of predictive models that account for dynamic real-world delivery scenarios. Importantly, labeled outcomes such as delivery timeliness and duration serve as supervised targets, allowing models to learn the influence of factors like traffic and weather on delivery performance. This supports robust forecasting of material flow and operational efficiency in smart logistics environments.

Additionally, the dataset allows for comprehensive analysis of delivery behavior across varying environmental and urban contexts. Its diversity and granularity offer rich insights into system responsiveness and operational bottlenecks, making it an ideal benchmark for evaluating the performance of advanced deep learning models such as TCN-GRU in time-series forecasting tasks.

3.2. Descriptive Statistical Analysis

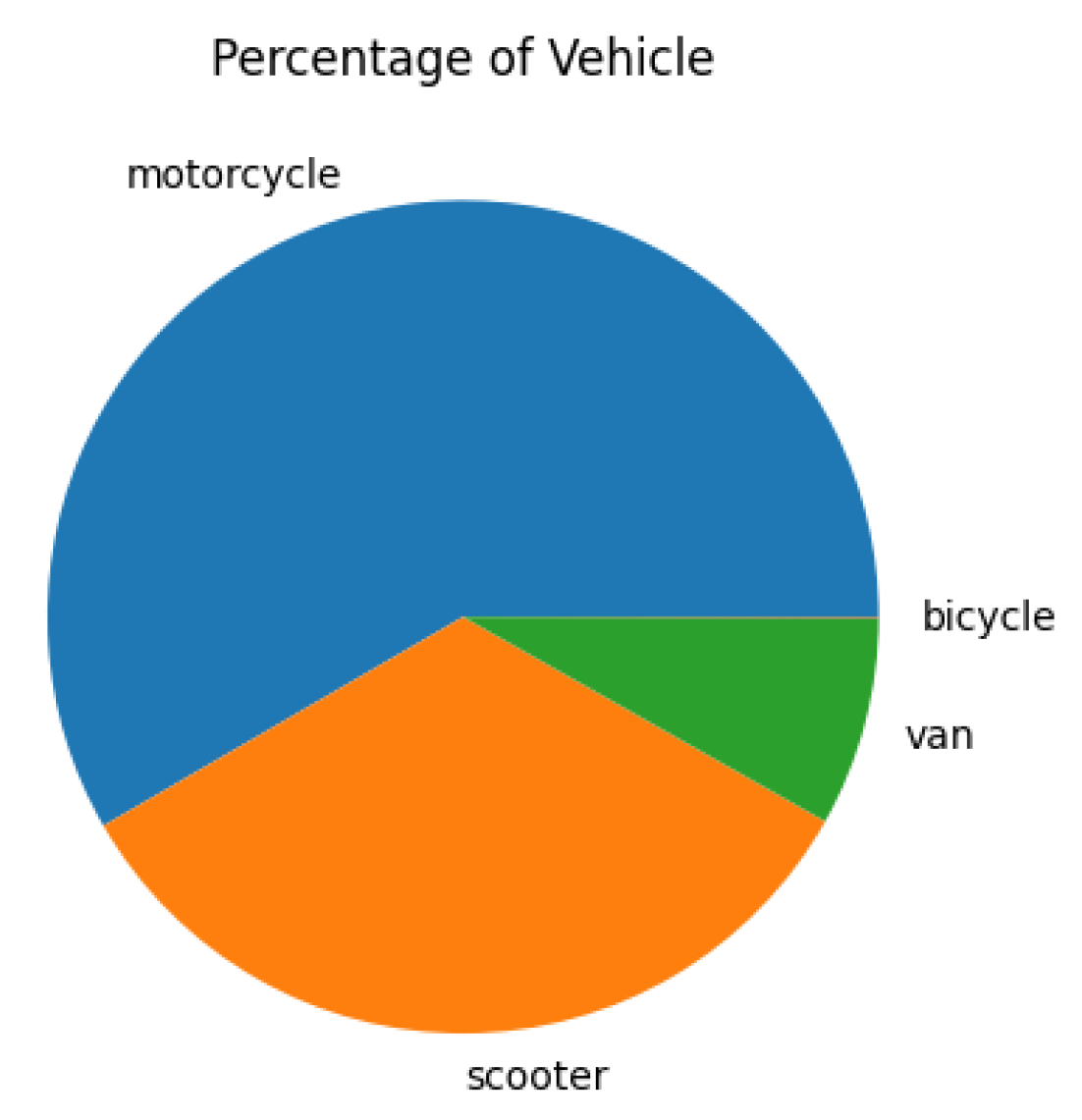

Figure 1 presents a statistical overview of the vehicles utilized in the delivery process within the data set. The table lists the vehicle types along with their respective counts: motorcycles (25,527), scooters (14,639), vans (3558), and bicycles (15). The pie chart visually illustrates the percentage distribution of each vehicle type, with motorcycles occupying the largest share, followed by scooters, vans, and bicycles. Motorcycles and scooters collectively dominate the distribution, reflecting their prevalent use in delivery operations likely due to their agility and cost - effectiveness in navigating urban environments. Vans are less common but still represent a significant portion, possibly for larger - capacity deliveries. Bicycles have minimal representation, which might be attributed to their limited load - carrying capacity and slower speeds, making them less suitable for most delivery tasks unless specific eco - friendly or short - distance delivery strategies are in place. This distribution underscores the preference for two - wheeled vehicles in the logistics sector for their adaptability and efficiency in urban delivery scenarios.

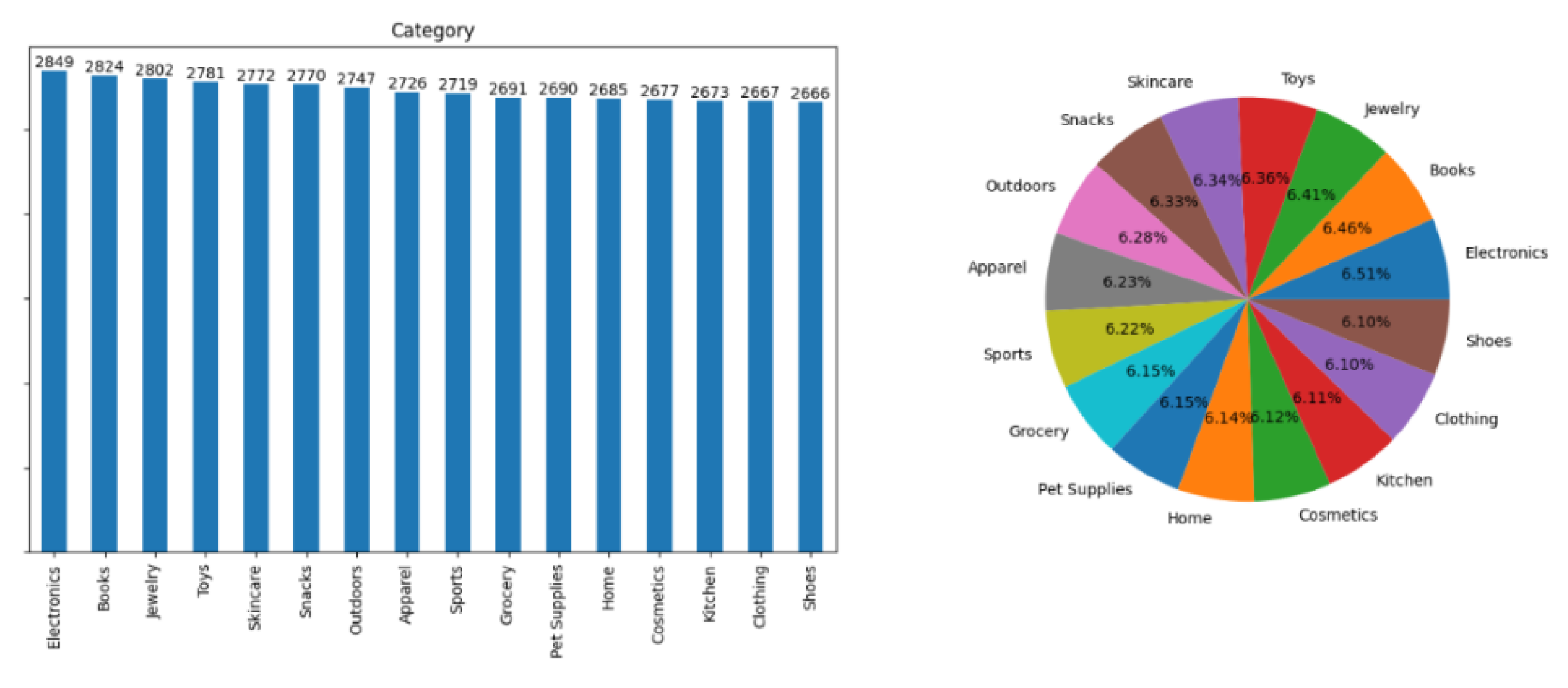

Figure 2 provides a visual representation of the distribution of delivery categories within the data set. The bar chart on the left details the number of deliveries for each category, showing that Electronics, Books, and Jewelry have the highest volumes, while the remaining categories exhibit relatively similar figures. The pie chart on the right offers a percentage breakdown of each category's contribution to the total deliveries. Categories like Toys, Skincare, and Snacks have slightly larger shares, while others such as Clothing, Shoes, and Kitchen items occupy smaller proportions. This distribution suggests that while certain categories dominate in terms of delivery volume, the overall diversity of goods being delivered is quite broad.

4. Model Introduction

In modern logistics systems, material flow exhibits strong temporal characteristics and complex multivariate coupling, especially in scenarios such as high-frequency urban deliveries, e-commerce promotional periods, and fluctuations in weather and traffic conditions. These dynamics make flow forecasting increasingly challenging. To more accurately capture the dynamic evolution of material flow and enhance the model's ability to perceive both short-term variations and long-term dependencies, this paper proposes a material flow prediction method based on a TCN-GRU deep fusion model.

The core design of the proposed model lies in integrating the structural advantages of the Temporal Convolutional Network (TCN) and the Gated Recurrent Unit (GRU), aiming to achieve efficient feature extraction and precise forecasting of complex logistics time-series data. The TCN component utilizes dilated convolutions to extract local features across different time scales in parallel, effectively modeling long-range dependencies with a larger receptive field and faster training efficiency. The GRU component, as a lightweight variant of recurrent neural networks, excels at capturing long-term temporal relationships while mitigating the problem of vanishing gradients, thereby improving training stability and prediction accuracy.

4.1. TCN

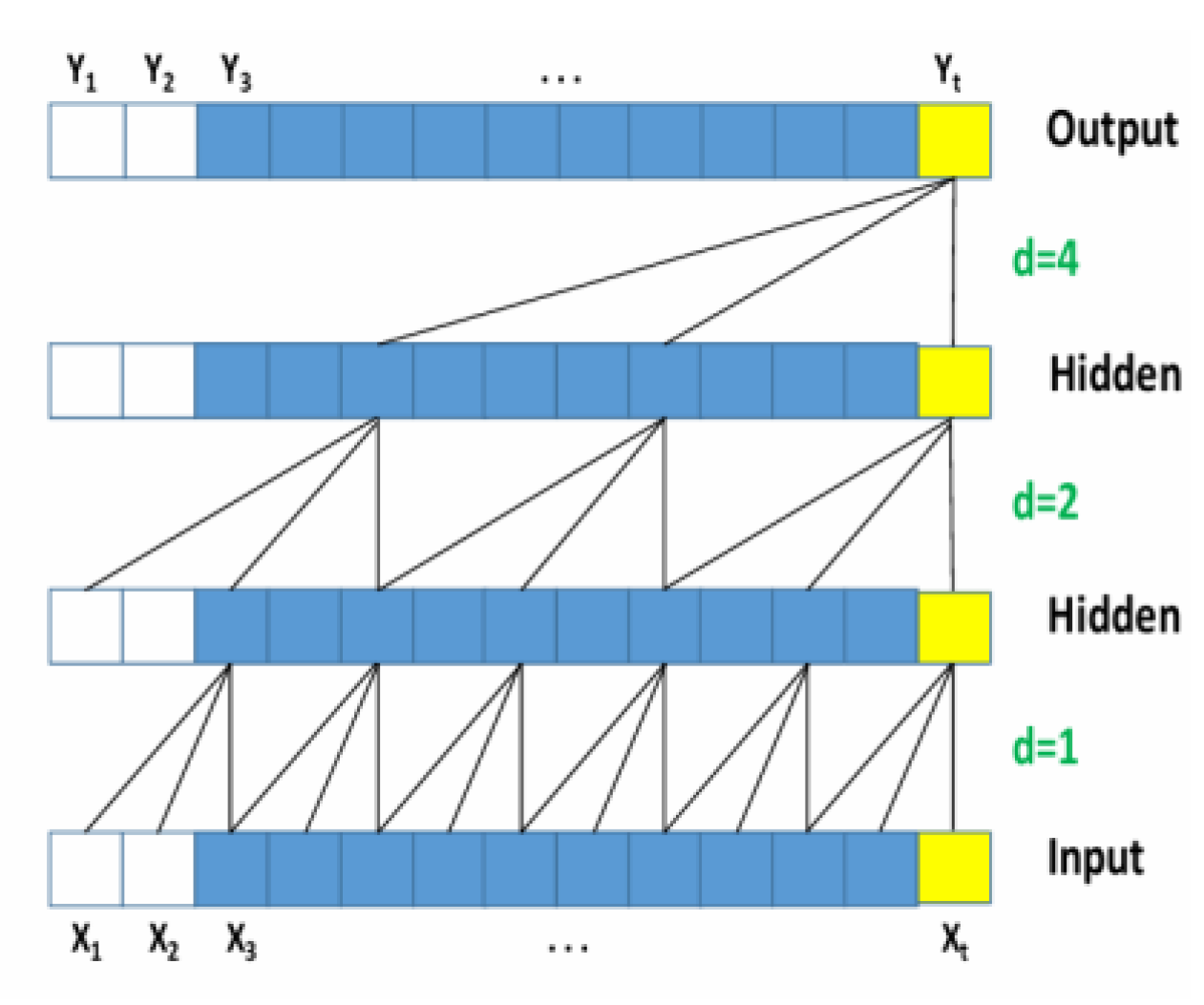

The Temporal Convolutional Network (TCN) is a feedforward neural architecture specifically designed for modeling time-series data in

Figure 3. Compared to traditional recurrent neural networks (RNNs), TCN offers superior parallel computing efficiency, more stable gradient propagation, and stronger capabilities in capturing local temporal dependencies. In the context of material flow prediction, where accurately modeling the temporal dynamics of orders, traffic, and weather conditions is critical, TCN is particularly well-suited and forms a foundational component of the proposed deep fusion framework.

The core structure of TCN consists of stacked one-dimensional convolutional layers that utilize causal convolutions to ensure that each output at a given time step is only influenced by current and past inputs, preserving the temporal causality essential to forecasting tasks. To expand the receptive field without significantly increasing model complexity, dilated convolutions are employed. By introducing gaps between convolution kernel elements, TCN is able to capture long-range temporal dependencies even in relatively shallow networks. This allows the model to learn both short- and medium-term temporal patterns such as sudden spikes in logistics flow or recurring delay cycles due to accumulated congestion.

In this study, the TCN model is applied to the multivariate sequential data derived from the Amazon Delivery Dataset, which includes over 43,000 delivery records featuring order density, delivery agent allocation, weather conditions, and traffic levels—factors that strongly influence material flow. During training, the TCN performs sliding convolutional operations over these temporal features, automatically extracting meaningful local structures such as "rain-induced order backlogs" or "delay propagation caused by peak-hour traffic." The resulting feature maps are passed through pooling layers to reduce dimensionality, retain critical information, and enhance computational efficiency.

To support deeper architectures and stabilize training, residual connections are introduced, effectively mitigating the vanishing gradient problem and improving model convergence. The temporal representations extracted by the TCN are then passed to the GRU module for modeling long-term dependencies and producing the final predictions. Experimental results demonstrate that the TCN component significantly improves the model’s ability to identify short-term logistics dynamics, providing a robust foundation for capturing complex patterns in material flow.

In summary, TCN serves as a key temporal feature extractor in this study, leveraging its architectural strengths to model short- and mid-term dependencies in multivariate logistics sequences. When combined with the GRU network, it enables the deep fusion model to jointly capture local fluctuations and global trends, thereby enhancing overall prediction accuracy and model robustness.

4.2. GRU

As a lightweight variant of recurrent neural networks, the Gated Recurrent Unit (GRU) is highly effective in modeling long-term dependencies in time-series data. By introducing gating mechanisms—specifically the update gate and reset gate—GRU balances modeling capability with computational efficiency, reducing the number of parameters and improving training speed while mitigating overfitting risks. In the context of material flow prediction, GRU is capable of capturing complex temporal dynamics over extended periods, providing a robust means to model the evolution of logistics systems under varying traffic and weather conditions [

7].

In this study, GRU is employed to further process the local temporal features extracted by the TCN component, enabling the modeling of long-range logistics trends. Specifically, the TCN module first captures short-term localized patterns in variables such as order density, courier dispatch status, and weather fluctuations. These are then passed into the GRU layer, which recursively learns temporal dependencies and contextual evolution. The GRU’s gated architecture allows it to retain critical historical information—for example, the cumulative effect of consecutive days of heavy rainfall on delivery delays, or the formation of demand peaks around holidays—thereby improving the accuracy of material flow forecasting.

For instance, when applied to delivery records in the Chennai region of the Amazon Delivery Dataset, the GRU model effectively identifies how weather and traffic variables influence delivery performance over time. Compared to traditional fully connected networks or shallow RNNs, GRU significantly enhances the model’s ability to capture long-term dependencies and contextual relationships in multivariate time-series data. It proves particularly advantageous in forecasting cyclical fluctuations and nonlinear disruptions, both of which are characteristic of real-world logistics systems.

Moreover, GRU supports end-to-end learning and requires no manual feature engineering of hidden states. Its compatibility with multivariate inputs and efficient parameterization make it highly scalable. Within the proposed TCN-GRU deep fusion framework, GRU works synergistically with TCN, with each component focusing on short-term and long-term temporal features respectively. This collaboration enhances the model’s generalization ability and forecasting accuracy in high-dimensional, dynamically changing logistics environments.

5. Model Results Analysis

5.1. Optimizer

As an optimization algorithm based on adaptive learning rates, Adam (Adaptive Moment Estimation) demonstrates outstanding performance in training neural networks with nonlinear and non-stationary data, and is particularly well-suited for large-scale, high-dimensional time-series forecasting tasks. The core strength of Adam lies in its combination of momentum-based methods and adaptive gradient descent. Specifically, it incorporates both the first-order moment (the exponentially weighted average of past gradients) and the second-order moment (the exponentially weighted average of past squared gradients) in each parameter update, allowing for dynamic adjustment of learning rates. This mechanism significantly accelerates convergence and enhances model stability [

8].

In the TCN-GRU deep fusion model proposed in this study, Adam is adopted as the primary optimizer to support efficient learning of complex temporal structures. When processing large-scale logistics datasets such as the Amazon Delivery Dataset, the model must dynamically adjust weights across multiple input features—including order volume, weather variations, traffic conditions, and courier activity. Adam’s ability to automatically control the step size of each parameter based on update frequency helps avoid excessive oscillations or premature convergence, making it particularly suitable for handling anomalies in logistics systems, such as sudden surges in demand or traffic congestion.

For example, in forecasting material flow in Chennai, India, where weather conditions change frequently and holidays are irregularly distributed, the input data exhibits strong temporal variability and noise. Under these conditions, Adam quickly adapts to volatile gradient behaviors during training, maintaining both the convergence speed and stability of parameter updates. This, in turn, improves the model’s generalization performance in handling abnormal delivery scenarios.

Moreover, Adam can quickly identify effective optimization paths during the early stages of training, reducing sensitivity to initial learning rate settings and enabling strong predictive performance within fewer training epochs. When combined with regularization techniques such as Dropout and Batch Normalization, Adam effectively mitigates overfitting risks and provides a stable and controlled learning environment for both the local feature extraction performed by TCN and the long-term dependency modeling carried out by GRU.

5.2. Ablation Experiment

This study conducted ablation experiments on the TCN-GRU framework and evaluated the accuracy of model predictions based on two indicators. The relevant data is shown in the table, and the specific analysis is as follows:

In

Table 1, the performance of different models in terms of MAE and RMSE is presented. The TCN-GRU model demonstrates the most outstanding performance, with the lowest MAE of 1.860 and RMSE of 5.813. This indicates that the TCN-GRU model can effectively utilize the features of the data to make more accurate predictions. In comparison, the TCN model has a higher MAE of 3.245 and RMSE of 9.425, while the GRU model shows a MAE of 2.986 and RMSE of 8.145. These results highlight that the TCN-GRU model possesses superior feature learning and pattern recognition capabilities when dealing with this kind of data. The integration of TCN and GRU in the TCN-GRU model likely contributes to its better performance, as it can capture both temporal dependencies and spatial features more effectively. This suggests that the TCN-GRU model is better suited for tasks requiring high predictive accuracy.

6. Conclusions

With the rapid development of e-commerce and smart logistics, the demand for accurate material flow prediction in logistics systems has become increasingly critical. Accurate forecasting not only enhances delivery efficiency and reduces operational costs, but also plays a crucial role in supporting key decisions such as warehouse scheduling, route optimization, and resource allocation. Particularly under complex and dynamic conditions involving weather and traffic fluctuations, material flow exhibits strong temporal characteristics and multivariate interactions, posing significant challenges for forecasting models in terms of modeling capability and generalization performance.

To address these challenges, this study proposes a material flow prediction method based on a TCN-GRU deep fusion model and conducts systematic experimental research using the Amazon Delivery Dataset. The dataset comprises 43,632 delivery records collected from multiple cities, covering essential variables such as order details, traffic conditions, weather changes, and delivery performance. It provides a solid foundation for analyzing the multivariate interactions affecting material flow. The city of Chennai, India, is selected as the primary experimental site to validate the model’s effectiveness and adaptability.

In terms of model architecture, the TCN-GRU model leverages the strengths of Temporal Convolutional Networks (TCN) in extracting local temporal features and supporting parallel computations, alongside the advantages of Gated Recurrent Units (GRU) in modeling long-term dependencies and improving training efficiency. This integrated structure enhances the model’s ability to capture both short-term fluctuations and long-term temporal patterns while mitigating common issues such as vanishing gradients in deep recurrent structures.

Experimental results demonstrate that the proposed model performs exceptionally well in the task of material flow prediction, achieving a Mean Absolute Error (MAE) of 1.860, significantly outperforming traditional time series forecasting methods. Whether using raw features or after feature selection, the model maintains high prediction stability and generalization capability, exhibiting strong capacity in time-series modeling and multivariate learning.

Despite the promising results, this study still has some limitations. First, the model is currently validated on data from a single city (Chennai), and its generalization ability in other cities or broader, more diverse logistics environments remains to be tested. Second, the model does not yet fully account for non-structured factors such as holiday surges, manual delays, and regional disparities, which may contribute to prediction errors in specific scenarios. Additionally, manual feature selection and handling of missing values during data preprocessing may influence the model’s final performance.

Future research could explore the following directions: (1) expanding the dataset to include multiple regions with varying climates and traffic densities to further validate the model’s robustness and scalability; (2) incorporating Graph Neural Networks (GNNs) or Attention Mechanisms to enhance the modeling of dynamic relationships between multivariate features; (3) developing lightweight versions of the model for deployment on edge devices in real-time logistics platforms; and (4) integrating reinforcement learning to establish a closed-loop system of prediction, optimization, and feedback, thereby enabling more intelligent logistics decision-making.

References

- Li, H.; Yu, Y.; Zhang, Z. Research on Cargo Volume Prediction and Adjustment Strategy of Logistics Network Based on Deep Learning and Optimisation Algorithm. Procedia Computer Science 2024, 243, 532–541. [Google Scholar] [CrossRef]

- Alqatawna, A.; Abu-Salih, B.; Obeid, N.; Almiani, M. Incorporating time-series forecasting techniques to predict logistics companies’ staffing needs and order volume. Computation 2023, 11, 141. [Google Scholar] [CrossRef]

- Li, A.; Zhuang, S.; Yang, T.; Lu, W.; Xu, J. Optimization of logistics cargo tracking and transportation efficiency based on data science deep learning models. Applied and Computational Engineering 2024, 69, 71–77. [Google Scholar] [CrossRef]

- Luo, S.; Jiao, T.; Zhang, X.; Liu, Y.; Li, R.; Guo, M. (2024, August). Logistics Cargo Volume Prediction Model Based on Combined ARIMA-LSTM Prediction Methods. In 2024 International Conference on Intelligent Algorithms for Computational Intelligence Systems (IACIS) (pp. 1-8). IEEE.

- Talupula, A. Demand forecasting of outbound logistics using machine learning. 2019.

- Hewage, P.; Behera, A.; Trovati, M.; Pereira, E.; Ghahremani, M.; Palmieri, F.; Liu, Y. Temporal convolutional neural (TCN) network for an effective weather forecasting using time-series data from the local weather station. Soft Computing 2020, 24, 16453–16482. [Google Scholar] [CrossRef]

- Dey, R.; Salem, F.M. (2017, August). Gate-variants of gated recurrent unit (GRU) neural networks. In 2017 IEEE 60th international midwest symposium on circuits and systems (MWSCAS) (pp. 1597-1600). IEEE.

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).